Sheet structure and method of manufacturing the same

A technology of electronic equipment and manufacturing method, which is applied in the direction of lighting and heating equipment, heat exchange equipment, circuits, etc., can solve the problems that carbon nanotubes cannot be fully utilized, high thermal conductivity, etc., to prevent shape changes, increase surface density, and improve Effects of Thermal and Electrical Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

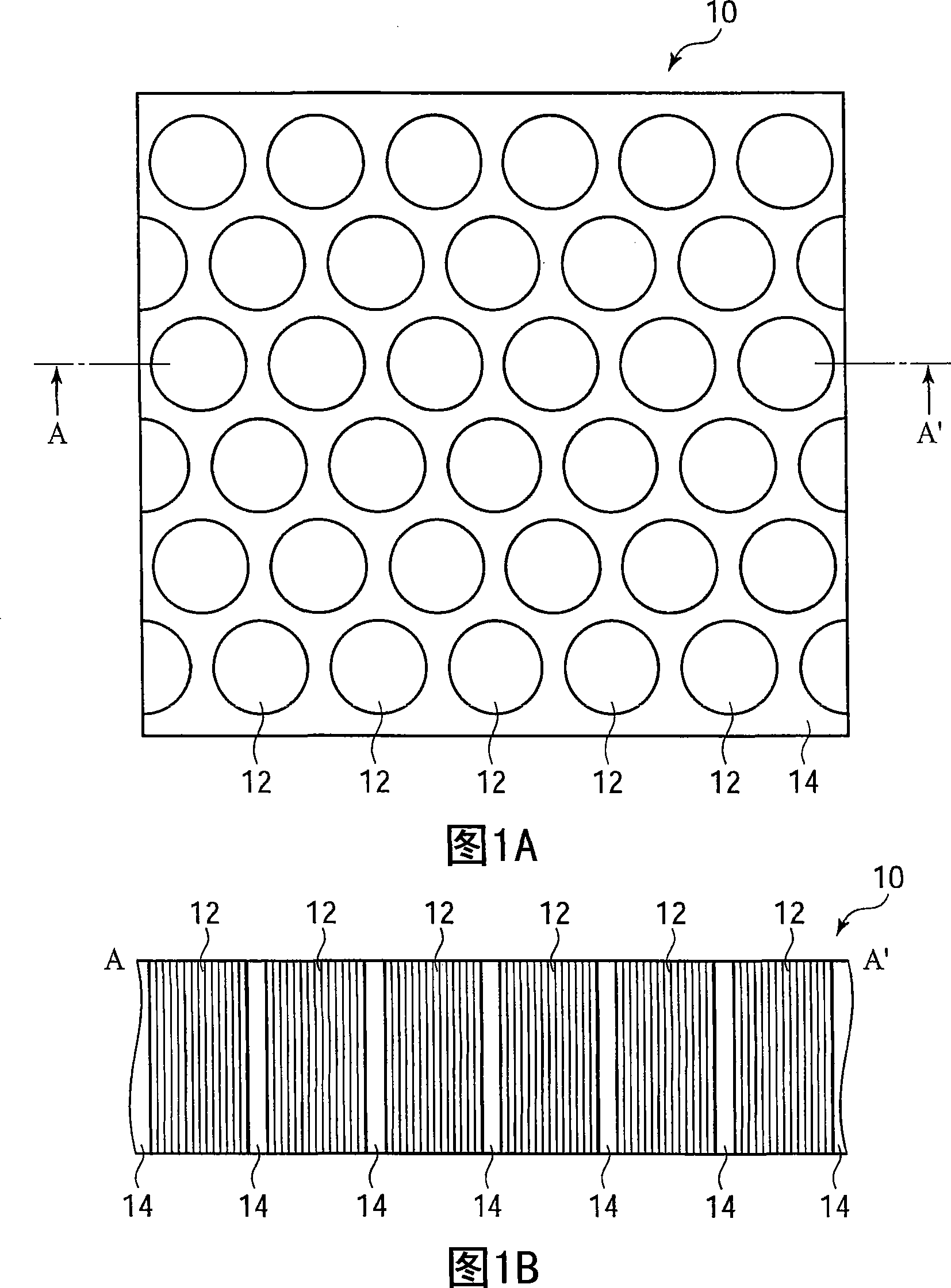

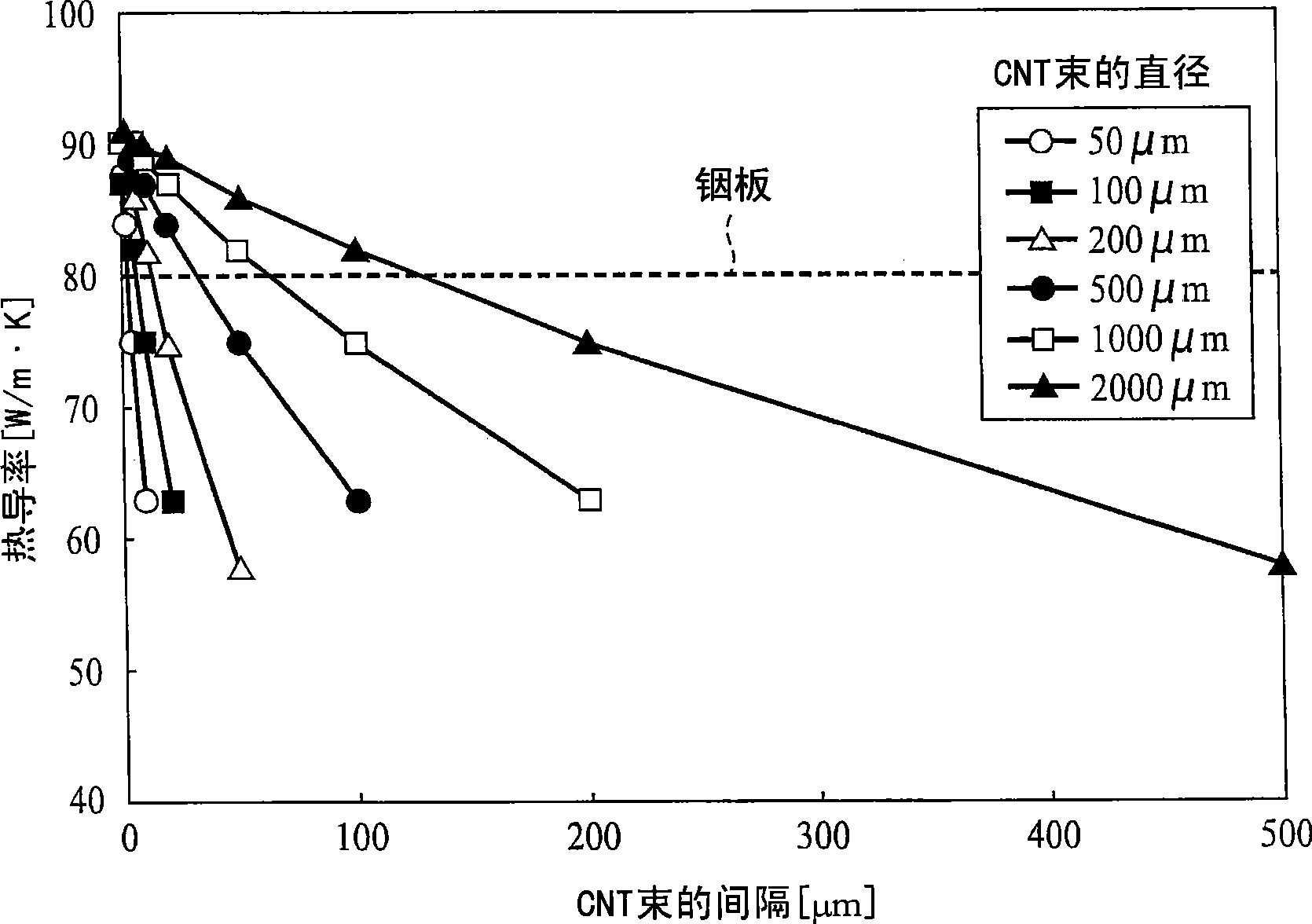

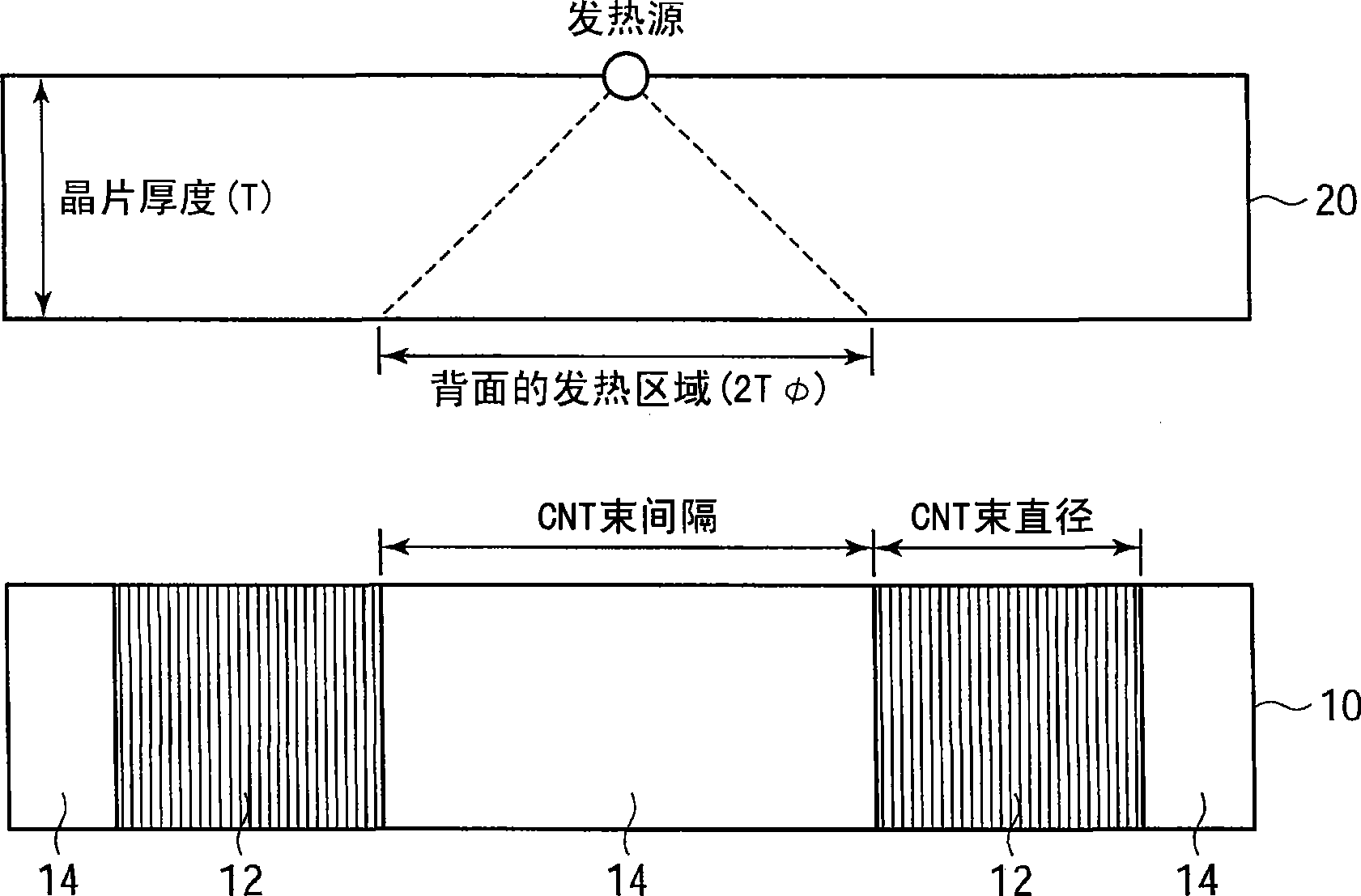

[0051] Referring to Figure 1A to Figure 7D The carbon nanotube sheet and its manufacturing method of the first embodiment will be described.

[0052] 1A and 1B are a plan view and a schematic cross-sectional view showing the structure of a carbon nanotube sheet according to the present embodiment. figure 2 It is a graph showing the relationship between the thermal conductivity of the carbon nanotube sheet and the distance between the carbon nanotube bundles of the present embodiment. image 3 It is a figure explaining the suitable spacing of the carbon nanotube bundles of the carbon nanotube sheet of this embodiment. Figure 4A ~ Figure 4E It is a plan view showing the shape of the carbon nanotube bundles of the carbon nanotube sheet of the present embodiment. Figure 5A ~ Figure 5D It is a schematic cross-sectional view showing the structure of the carbon nanotube sheet of the present embodiment. Figure 6A ~ Figure 6D and Figure 7A ~ Figure 7D It is a process sectional...

no. 2 approach

[0110] refer to Figure 8A to Figure 11B The carbon nanotube sheet and its manufacturing method of the second embodiment will be described. Additionally, for and Figures 1A to Figure 7D The same structural elements of the carbon nanotube sheet and its manufacturing method of the first embodiment shown are assigned the same reference numerals and descriptions are omitted or simplified.

[0111] Figure 8A , Figure 8B It is a perspective view and a schematic cross-sectional view showing the structure of the carbon nanotube sheet of the present embodiment. Figure 9A to Figure 11B It is a process sectional view showing the manufacturing method of the carbon nanotube sheet of this embodiment.

[0112] First, refer to Figure 8A , Figure 8B The structure of the carbon nanotube sheet of this embodiment will be described. Figure 8A and Figure 8B These are a perspective view and a cross-sectional view showing the structure of the carbon nanotube sheet of the present embod...

no. 3 approach

[0134] refer to Figures 12A to 14C The carbon nanotube sheet and its manufacturing method of the third embodiment will be described. Additionally, for and Figures 1A to Figure 11B The same structural elements of the carbon nanotube sheets and their manufacturing methods of the first and second embodiments shown are assigned the same reference numerals, and explanations are omitted or simplified.

[0135] Figure 12A , Figure 12B It is a perspective view and a schematic cross-sectional view showing the structure of the carbon nanotube sheet of the present embodiment. Figure 13A ~ Figure 13C and Figure 14A ~ Figure 14C It is a process sectional view showing the manufacturing method of the carbon nanotube sheet of this embodiment.

[0136] First, referring to Figure 12, Figure 12B The structure of the carbon nanotube sheet of this embodiment will be described. Figure 12A and Figure 12B These are a perspective view and a cross-sectional view showing the structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com