Ash-free smoke sampling device

A sampling device and flue gas technology, applied in the direction of sampling devices, etc., can solve the problems of inaccurate measurement of the concentration and form of flue gas components, non-continuous sampling, etc., to prevent oxidation or form changes, reduce costs, and simplify the device system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

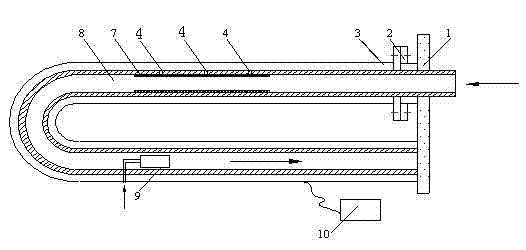

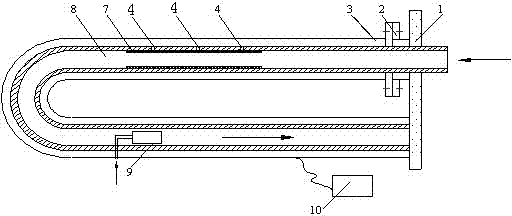

[0016] like figure 1 As shown, the flue gas ashless sampling device provided by the present invention includes a U-shaped sampling gun 8, a flange 2, an electric heating element 3 and a temperature controller 10, a porous ceramic tube liner 7, a jet mechanism 9, and the like.

[0017] The flue gas ashless sampling device is fixed on the flue wall 1 through the flange 2 . The middle section of the U-shaped sampling gun 8 is provided with a porous ceramic bushing 7, and three sampling holes 4 are opened on the porous ceramic bushing 7, and a jet mechanism 9 is housed in the end section of the U-shaped sampling gun 8, and a built-in electric circuit is installed outside the U-shaped sampling gun 8. Heating element 3 and thermostat 10.

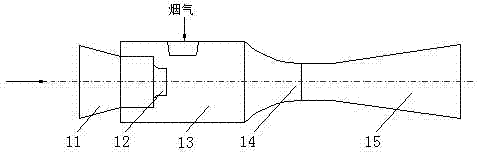

[0018] The jet mechanism 9 includes an air inlet 11, a nozzle 12, a mixing chamber 13, a transition section 14, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com