Medical cutting tool manufacturing apparatus and method

A technology for manufacturing devices and manufacturing methods, applied in the field of manufacturing devices for medical cutting tools, capable of solving problems such as shaking, increasing the clearance of sliding parts, and spherical deformation, and achieving the effects of cost reduction, shape change prevention, and structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

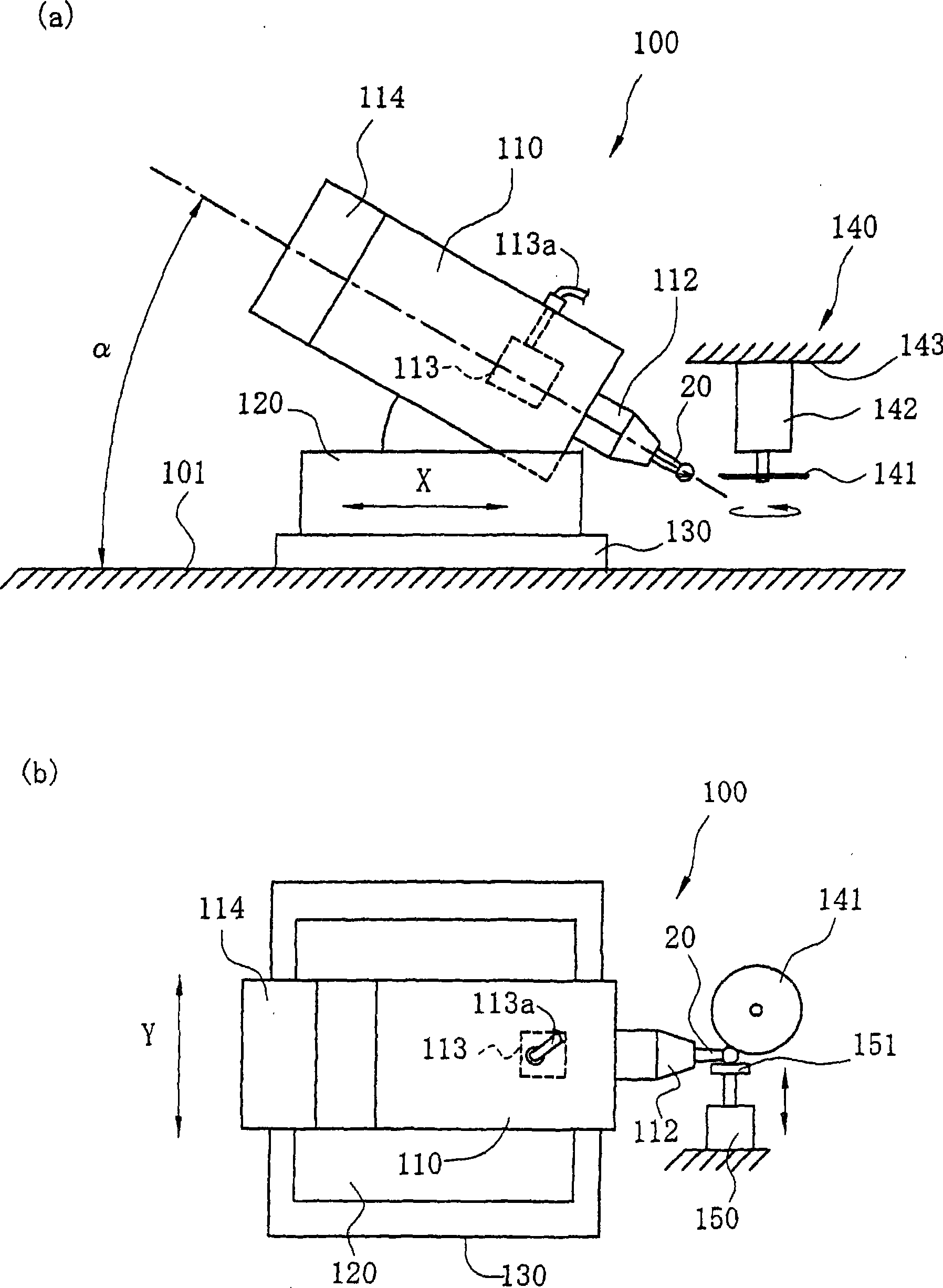

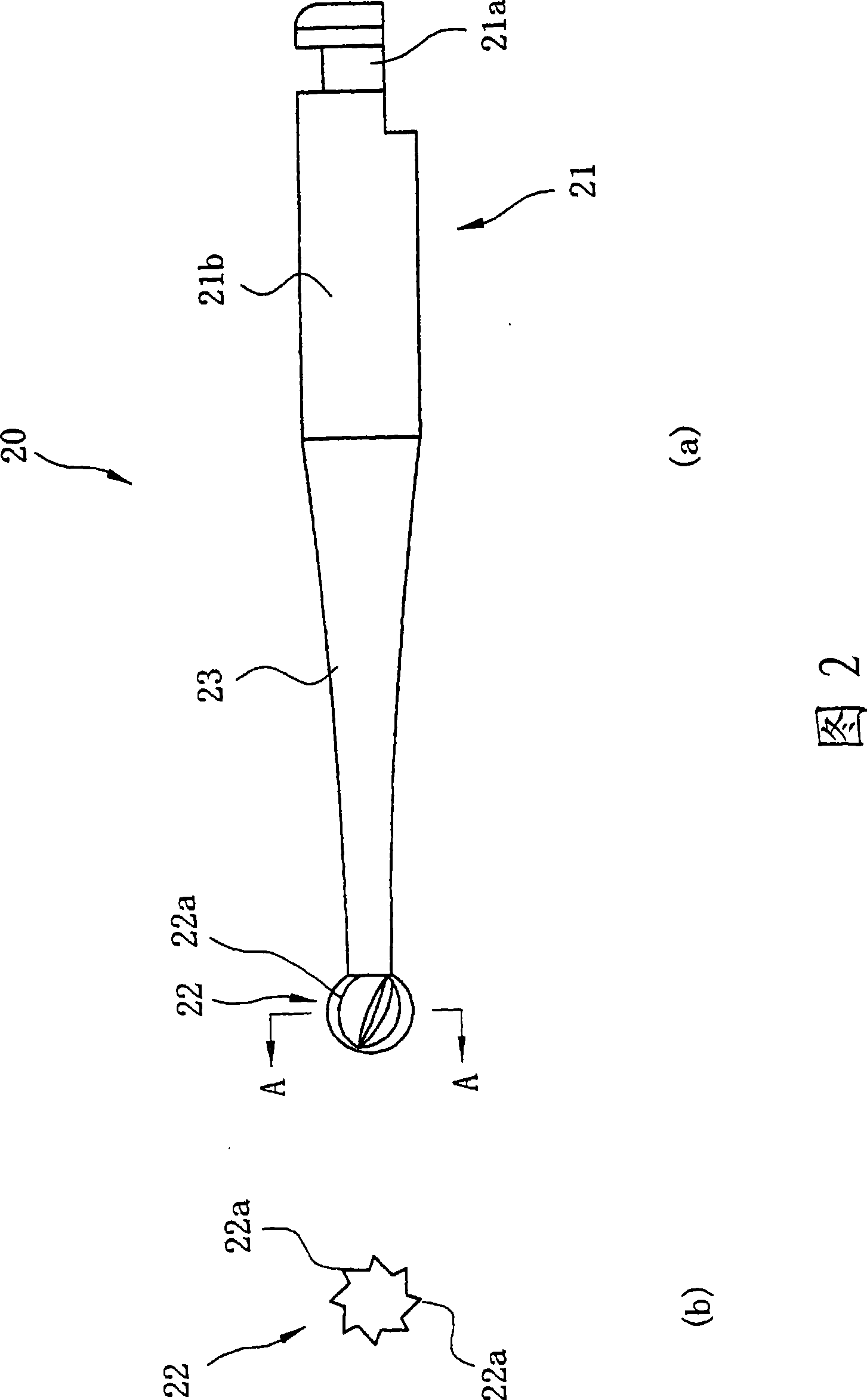

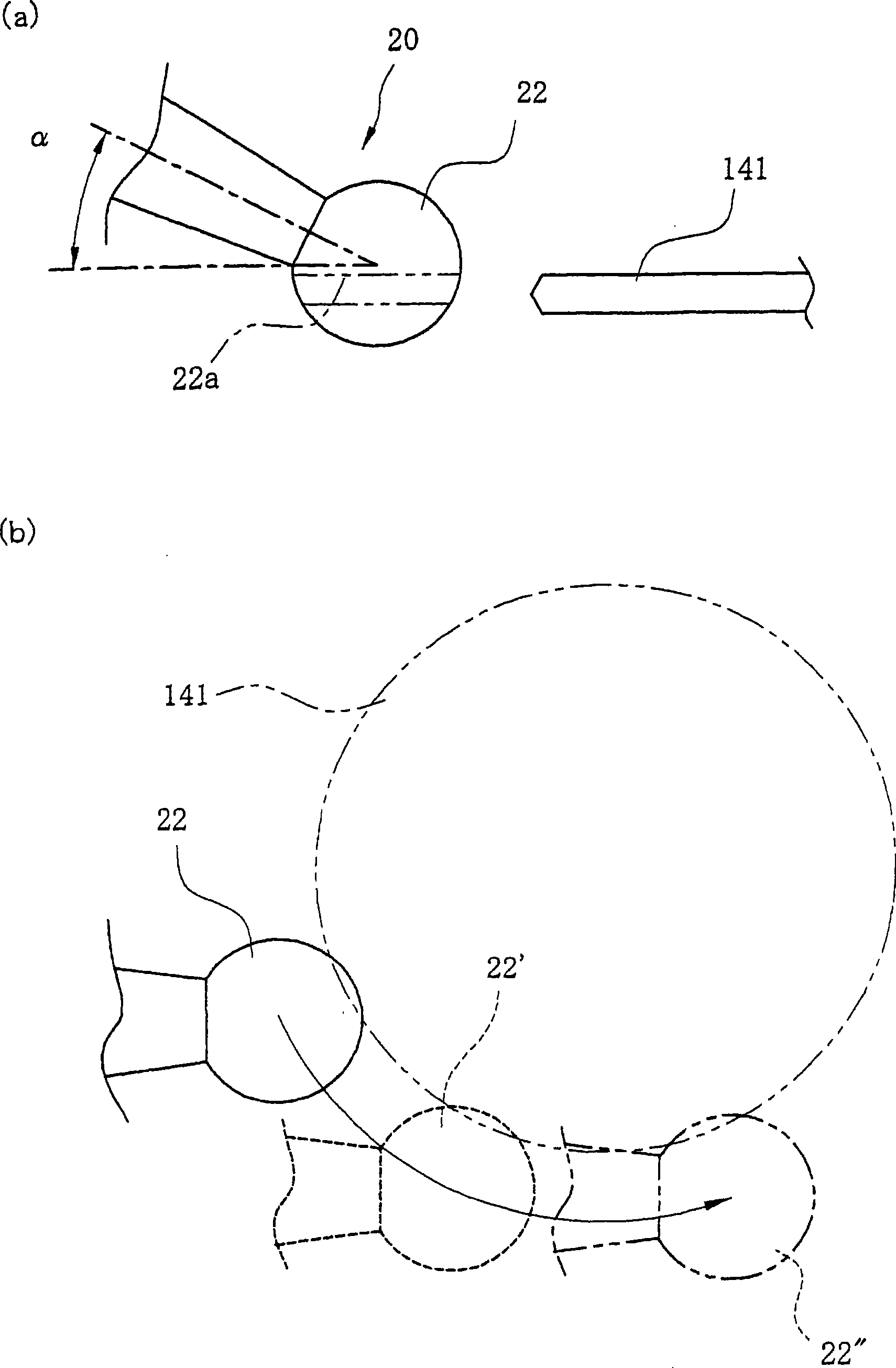

[0023] figure 1 It is a schematic diagram which shows the main part structure of the manufacturing apparatus of the medical cutting tool of this invention, (a) is a front view, (b) is a top view. Hereinafter, a medical cutting tool will be described using a steel bur as an example. As shown in the figure, the medical cutting tool manufacturing apparatus 100 of the present invention includes a main shaft part 110, a main shaft support part 120 supporting the main shaft part 110, an XY table 130 for moving the main shaft support part 120 in the X and Y directions, and a rotary The grindstone unit 140 is constituted.

[0024] The main shaft part 110 has a chuck 112, and the clamping device 113 formed inside the main shaft part 110 is driven by the high-pressure fluid supplied from the pipe body 113a, and can attach and detach the steel drill bit 20 as a workpiece.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com