Gear broaching process for thin-wall internal spline shaft

A technology of internal spline and process, which is applied in the field of tooth drawing process of thin-walled internal spline shaft, can solve the problems of poor accuracy and quality of internal spline shaft, low production efficiency of gear shaping process, poor product quality stability, etc. Accuracy, reduced product damage rate, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

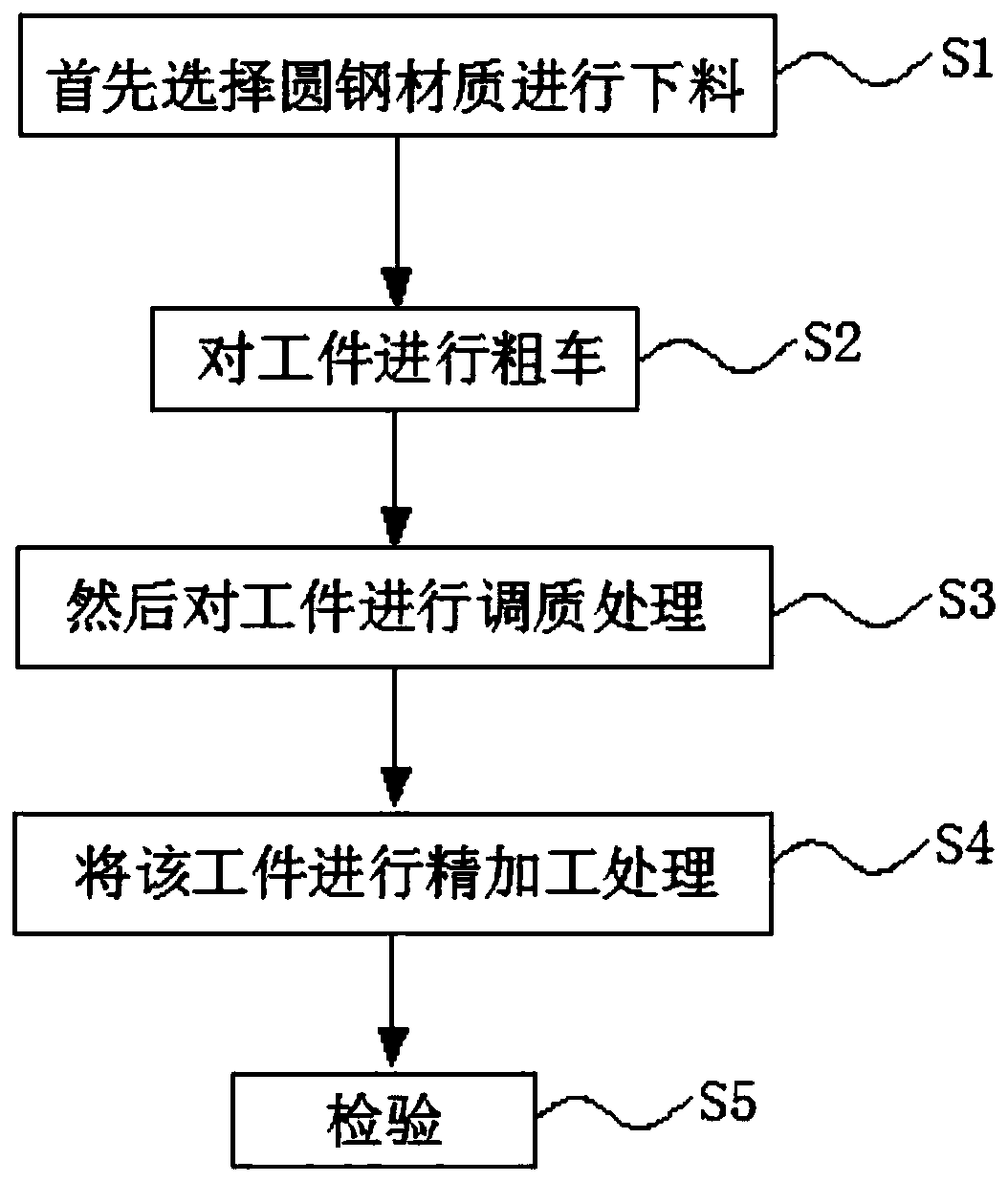

[0027] A thin-walled internal spline shaft broaching process, specifically comprising the following steps:

[0028] S1. First, select the round steel material for blanking. According to the required workpiece size, cut the round steel material into the size required by the inner spline shaft through the cutting equipment to form a blank;

[0029] S2. Carry out rough turning on the workpiece, and grind the cut blank through the grinding equipment. After the grinding is completed, the workpiece is clamped by the fixture, and then the inner hole, outer circle and length of the workpiece are roughed by a horizontal lathe. Processing, so that the workpiece is close to the final shape and size, leaving a machining allowance of 0.7mm for the inner hole, outer circle and length of the workpiece after rough turning;

[0030] S3, then carry out quenching and tempering treatment on the workpiece, the workpiece passes through the process of quenching and high temperature tempering, so tha...

Embodiment 2

[0040] A thin-walled internal spline shaft broaching process, specifically comprising the following steps:

[0041] S1. First, select the round steel material for blanking. According to the required workpiece size, cut the round steel material into the size required by the inner spline shaft through the cutting equipment to form a blank;

[0042] S2. Carry out rough turning on the workpiece, and grind the cut blank through the grinding equipment. After the grinding is completed, the workpiece is clamped by the fixture, and then the inner hole, outer circle and length of the workpiece are roughed by a horizontal lathe. Processing, so that the workpiece is close to the final shape and size, leaving a machining allowance of 0.4mm for the inner hole, outer circle and length of the workpiece after rough turning;

[0043] S3, then carry out quenching and tempering treatment on the workpiece, the workpiece passes through the process of quenching and high temperature tempering, so tha...

Embodiment 3

[0053] A thin-walled internal spline shaft broaching process, specifically comprising the following steps:

[0054] S1. First, select the round steel material for blanking. According to the required workpiece size, cut the round steel material into the size required by the inner spline shaft through the cutting equipment to form a blank;

[0055] S2. Carry out rough turning on the workpiece, and grind the cut blank through the grinding equipment. After the grinding is completed, the workpiece is clamped by the fixture, and then the inner hole, outer circle and length of the workpiece are roughed by a horizontal lathe. Processing, so that the workpiece is close to the final shape and size, leaving a machining allowance of 1 mm for the inner hole, outer circle and length of the workpiece after rough turning;

[0056] S3, then carry out quenching and tempering treatment on the workpiece, the workpiece passes through the process of quenching and high temperature tempering, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com