Inclined wedge mechanism with lateral material pressing function

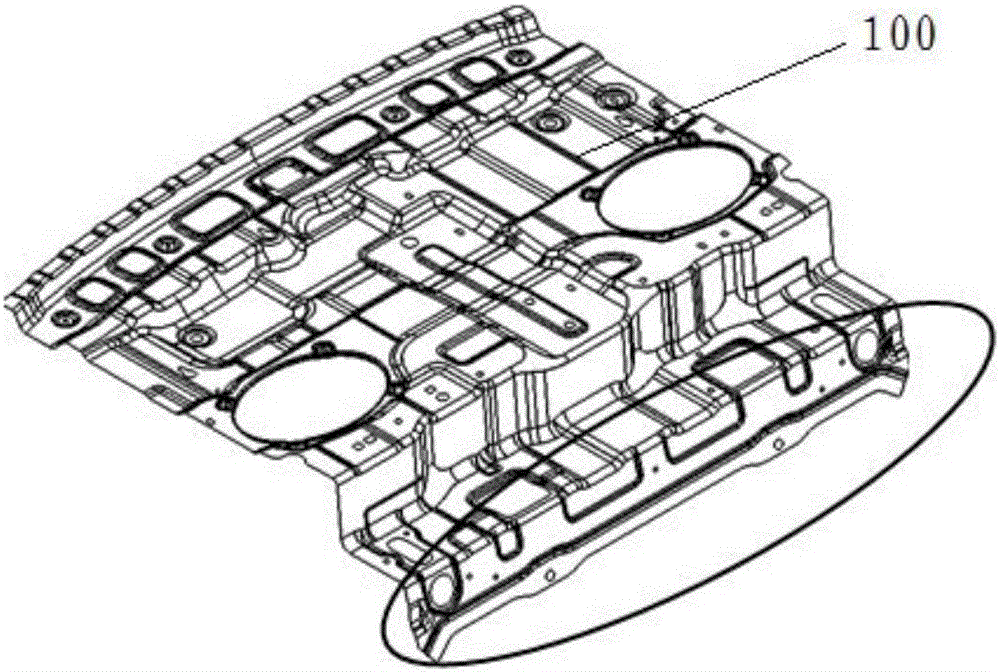

A technology of oblique wedge and function, applied in the field of oblique wedge mechanism with side pressing function, can solve problems such as inability to achieve the effects of ensuring lap joint quality, improving edge trimming and punching quality, and preventing profile changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

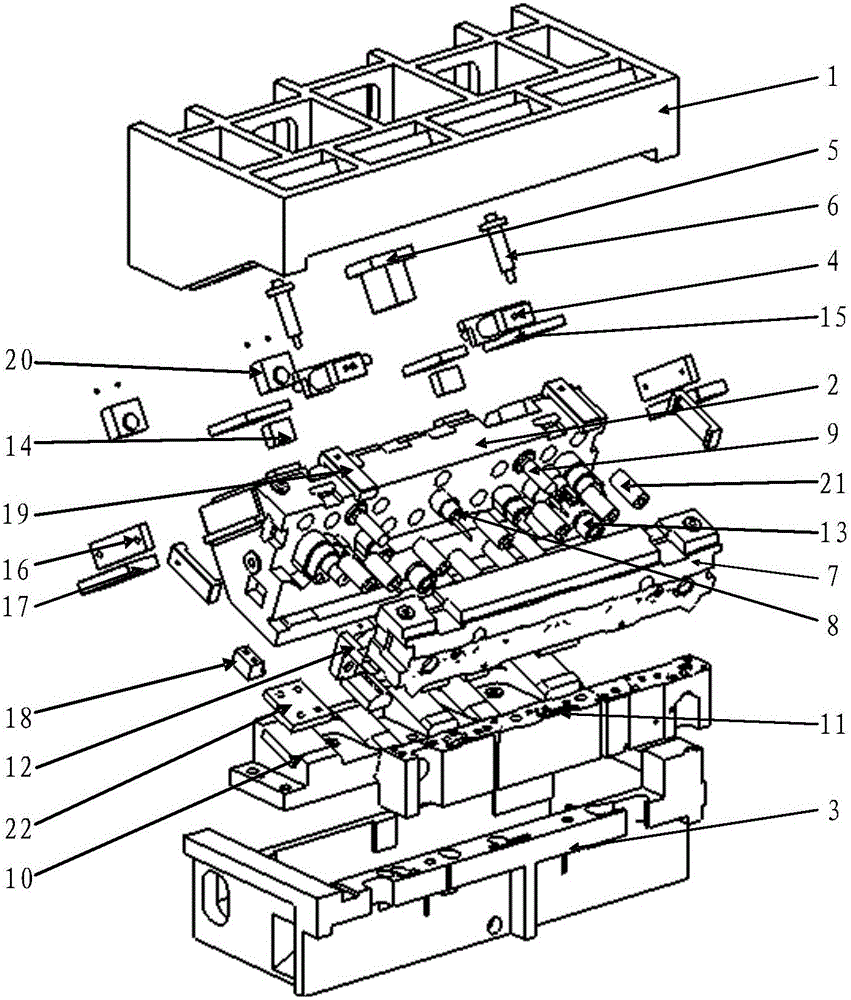

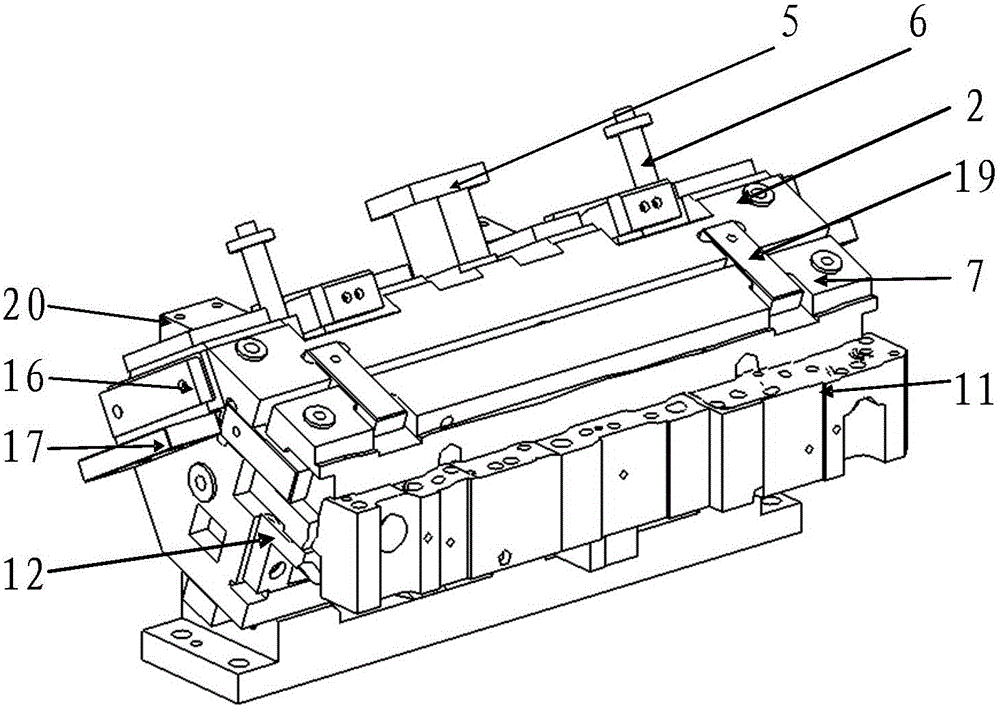

[0029] Embodiment 1 of the present invention: as Figure 2-Figure 8 As shown, a wedge mechanism with a side pressing function includes an upper mold base 1, a wedge body 2 and a lower mold base 3, a nitrogen spring 4 is installed on the bottom of the upper mold base 1, and the nitrogen spring 4 Interact with the top surface of the wedge body 2 to realize the return of the wedge body 2, the safety hook 5 and the safety bolt 6 pass through the through hole on the upper die base 1 and connect with the wedge body 2 through the screw. The wedge body 2 is fixedly connected, and the wedge body 2 is provided with a pressing core 7, a punch upper die 8 and a trimming knife block 12, and the pressing core 7 is provided with a guide sleeve 13, and the guide sleeve 13 It is fixedly installed on the pressing core 7 through interference fit, and a guide post 9 is arranged on the wedge body 2, and the guide post 9 is fixedly installed on the wedge body 2 through interference fit. The guide ...

Embodiment 2

[0031] Embodiment 2 of the present invention: as Figure 2-Figure 8 As shown, a wedge mechanism with side pressing function includes an upper mold base 1, a wedge body 2 and a lower mold base 3, and the bottom of the upper mold base 1 is fixed with a nitrogen spring 4 by screws and pins. The top surface of the wedge body 2 is fixed with a nitrogen spring support block 14 by screws, and the nitrogen spring support block 14 is in contact with the nitrogen spring 4, and the nitrogen spring 4 is responsible for the return of the wedge body 2. position, the nitrogen spring support block 14 is used to protect the top of the wedge body 2 and prevent the top of the wedge body 2 from being deformed under pressure; those skilled in the art can understand that the wedge body 2 is in the Under the action of the nitrogen spring 4, the return is performed at a faster speed and with a greater impact force. In order to prevent the wedge body 2 from colliding with the upper mold base 1 and bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com