A molding binding device of firecrackers tube cake

A firecracker tube and equipment technology, which is applied in the field of firecracker tube cake forming and binding equipment, can solve the problems that it is difficult to meet the actual needs of fully automated production, the forming process cannot be separated from manual assistance, and the binding cannot be completed automatically, so as to solve the shortage of labor force , fast maintenance, and tight knotting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

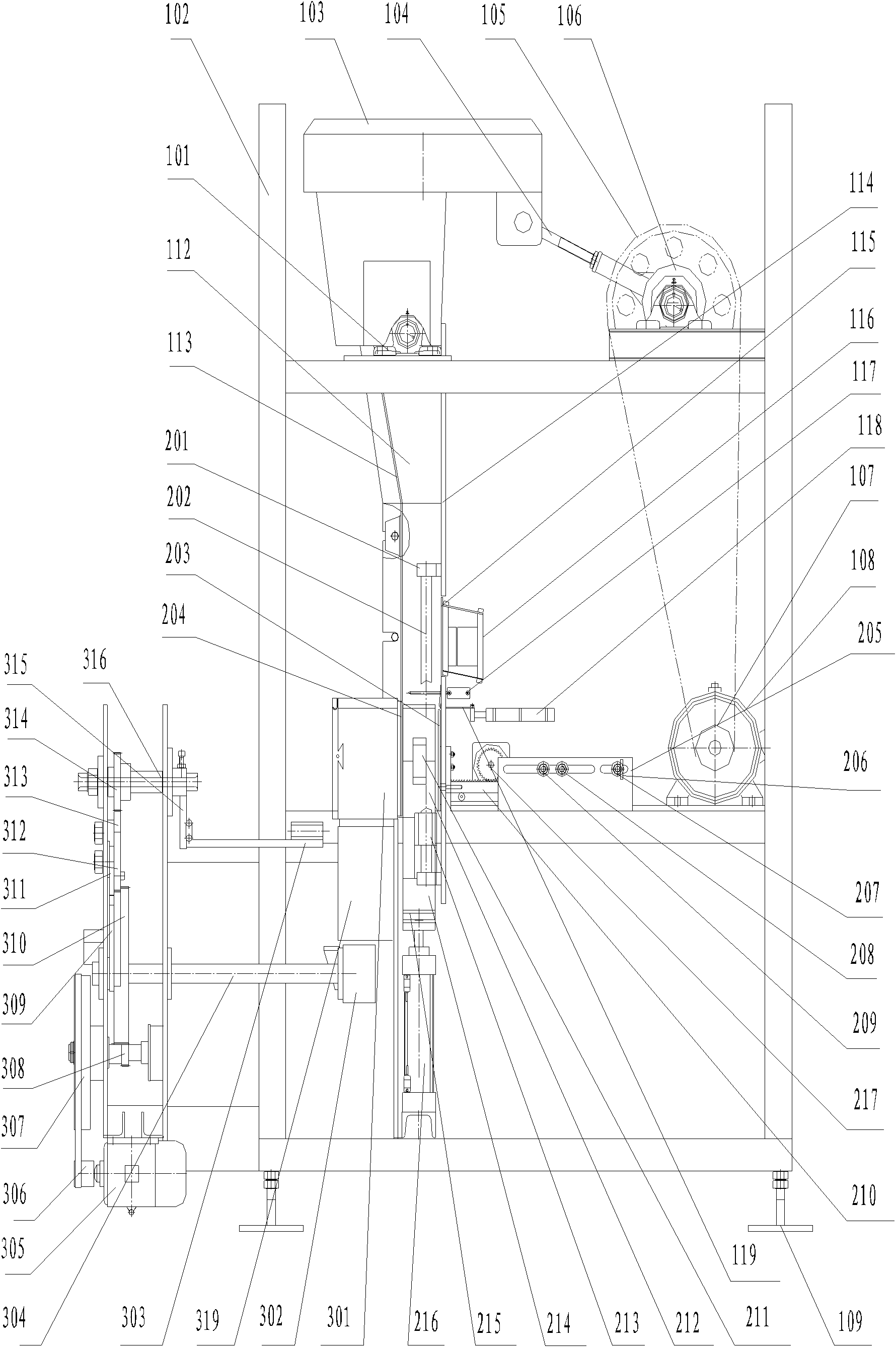

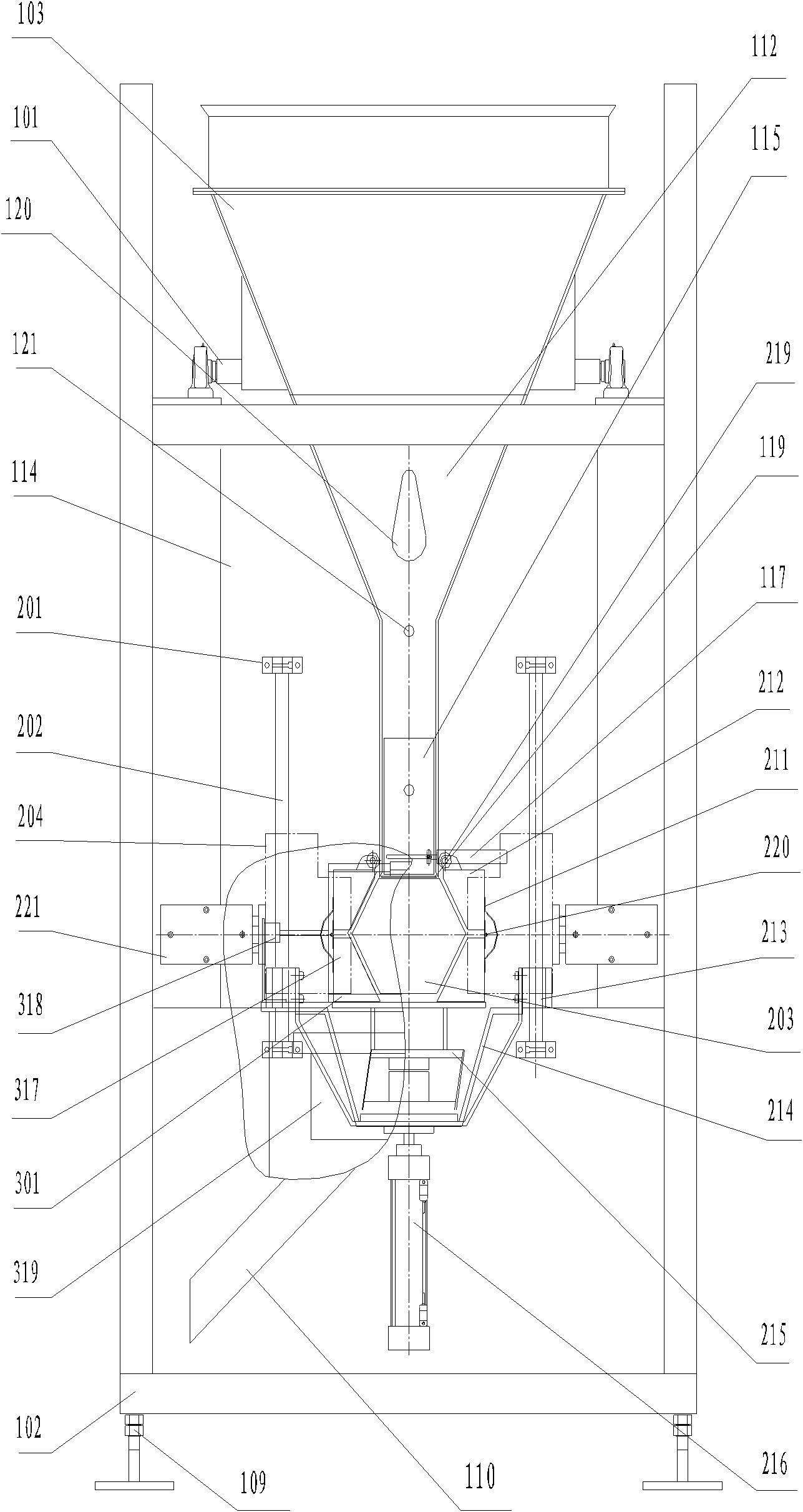

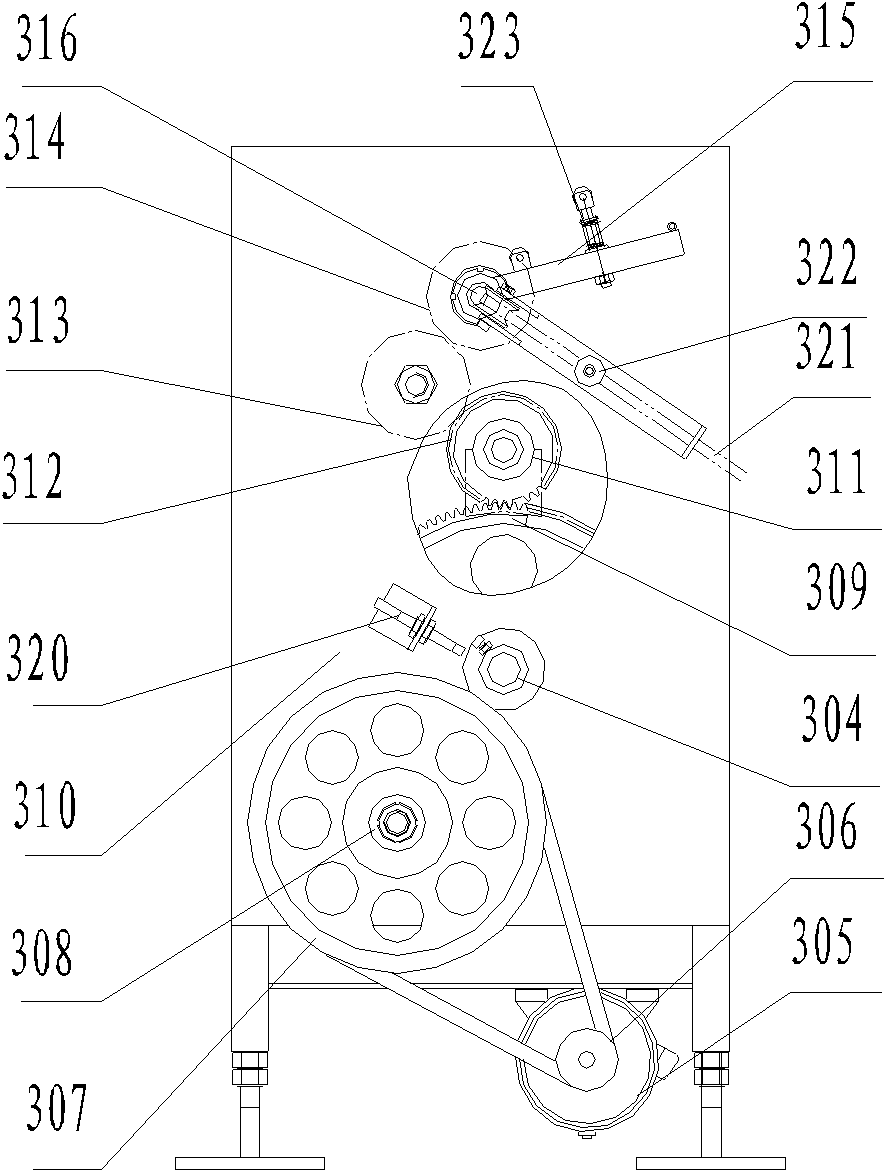

[0038] Referring to the accompanying drawings, reflecting a specific structure of the present invention, the firecracker tube cake forming and bundling equipment includes a vertical blanking system, a splicing and forming system, a bundling system and a control system. Its specific structure and workflow are as follows:

[0039] The feeding hopper 103 is supported on the upper layer of the frame 102 by two sets of bearing seat groups 101, and the frame 102 is adjusted by six adjustable shock-proof large plate feet 109 to ensure stable operation of the equipment and effectively reduce the requirements on the site. The feeding hopper 103 forms a vibration frequency of 420-450 / min through the connecting rod 104, the eccentric wheel 106, the balance block 111, the large pulley 105, the small pulley 107, and the main motor 108 to meet the needs of feeding and forming. The main motor 108 is mounted on the middle fixing plate of the frame.

[0040] The side plate 122 , the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com