A metal paper basket side wall forming machine

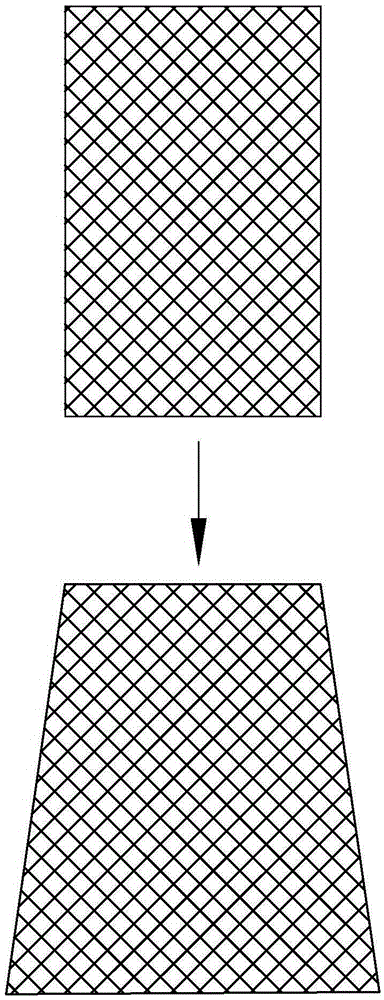

A side wall surface and forming machine technology, applied to wire mesh, other household appliances, household appliances, etc., can solve the problems of not being able to win the favor of consumers, poor appearance coordination, and different sizes of wire mesh meshes, etc., to achieve simplified components, The effect of regular shape and uniform transition of mesh size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

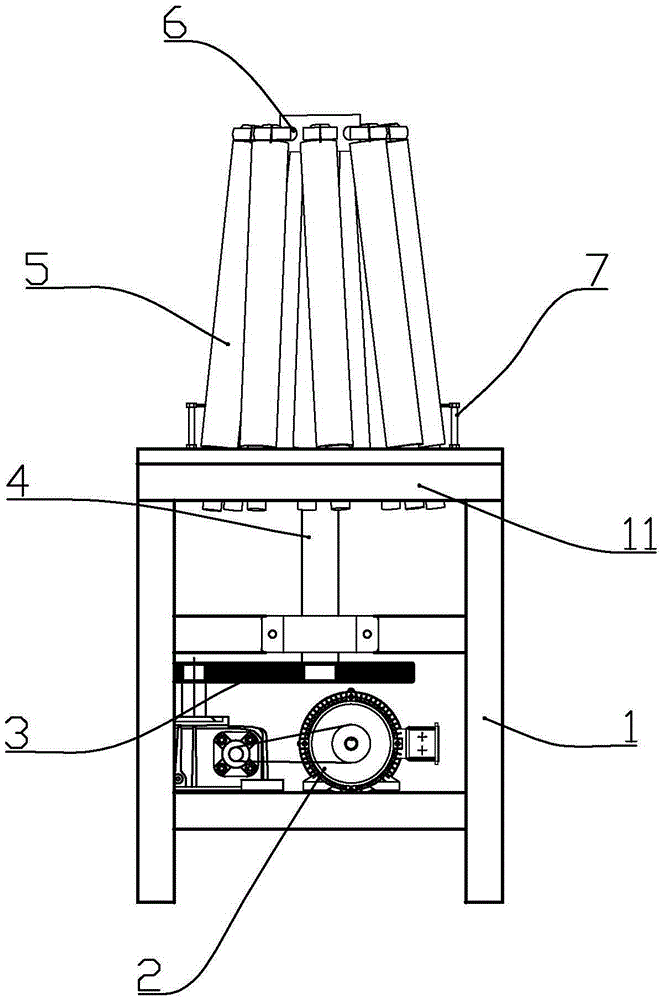

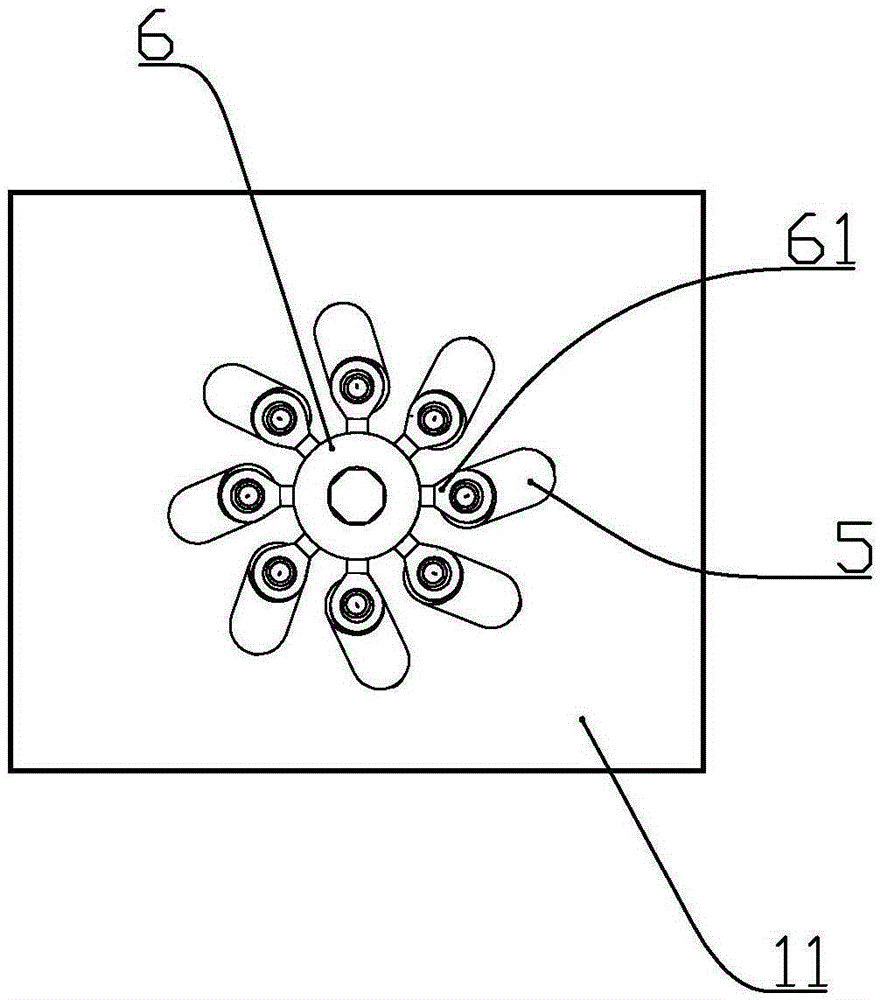

[0011] according to Figure 1 to Figure 3 As shown, a metal paper basket side wall forming machine described in this embodiment includes a frame 1, a horizontal worktable 11 is welded above the frame, and 8 or 10 worktables are connected by bearings on the worktable. Eccentric rollers 5, the upper end of each eccentric roller is connected to a transmission frame 6 through bearings, and a transmission shaft 4 is connected to the middle of the worktable through bearings, the upper end of the transmission shaft extends to the position of the transmission frame, and the distance between the transmission shaft and the upper ends of each eccentric roller The upper ends of the eccentric rollers are connected by transmission chains or transmission gear sets; the upper ends of the eccentric rollers are close to each other with the transmission sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com