Electromagnetic wire for high-power wind driven generator

A technology of wind power generators and electromagnetic wires, applied to circuits, insulated cables, electrical components, etc., can solve problems such as low motor slot fullness, copper wires are easily deformed, and insulation damage, etc., to achieve reduced overall strength and hardness, and regular and beautiful shapes , easy processing and forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

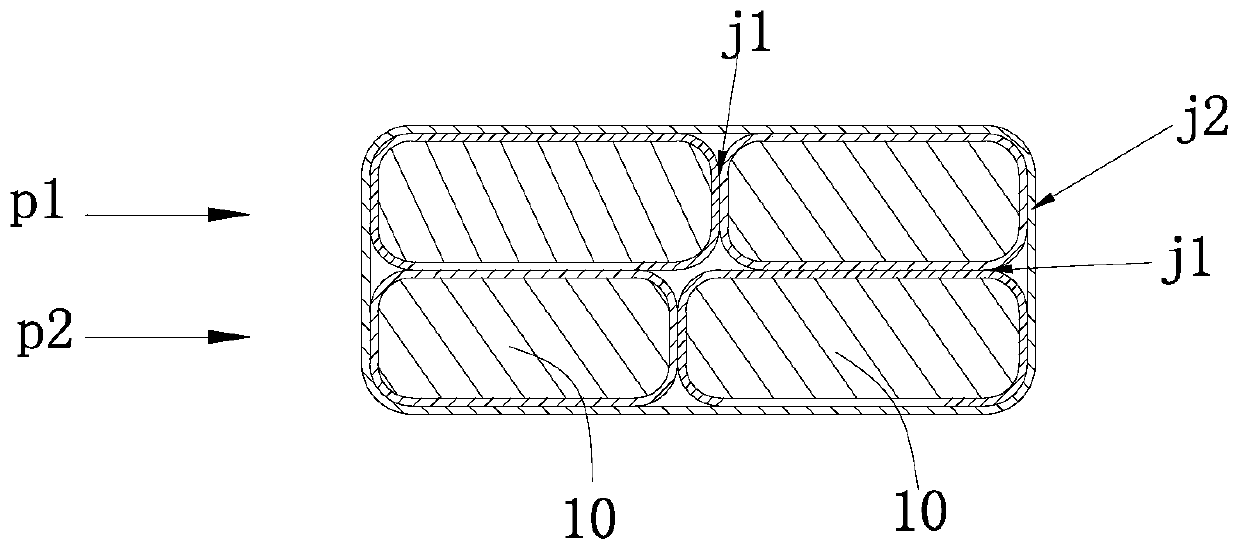

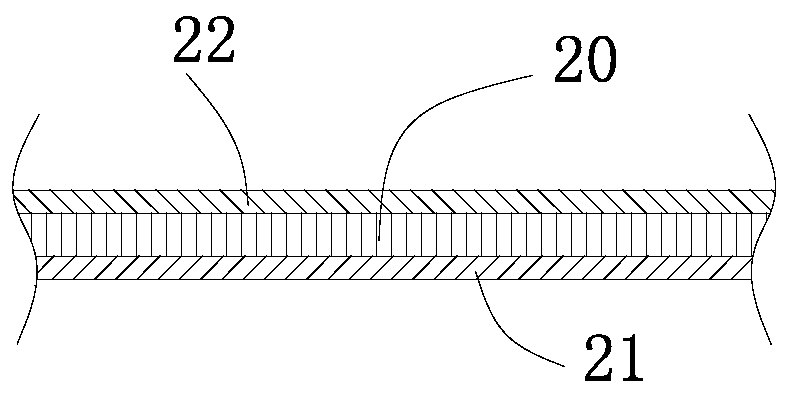

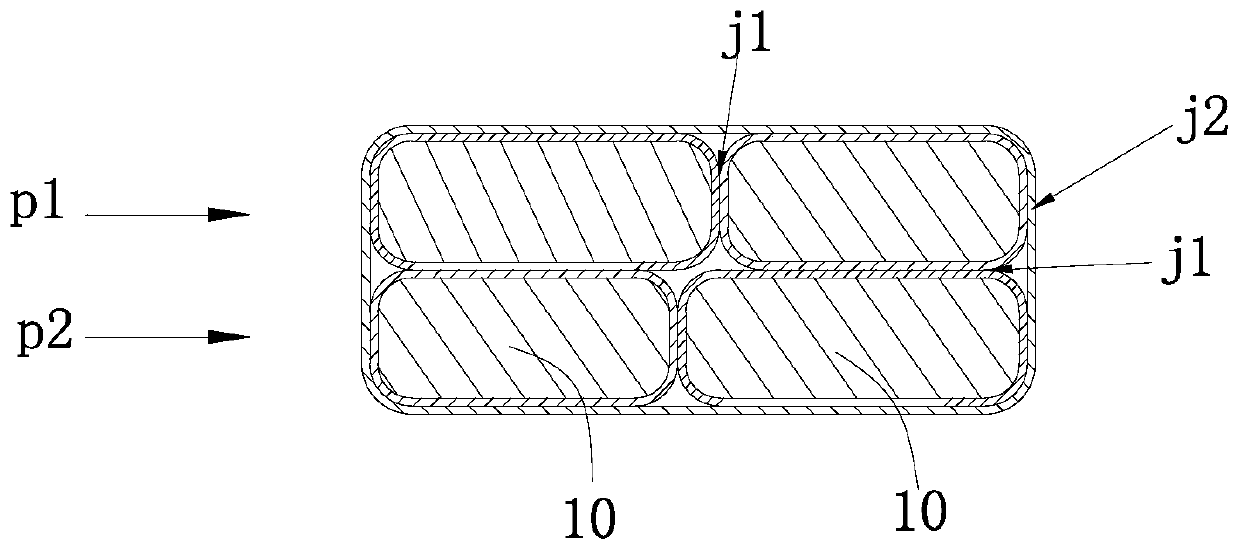

[0021] Such as figure 1 , figure 2 As shown, a magnet wire for a high-power wind power generator includes a conductor 10 and an insulating layer attached to the outside of the conductor 10. There are four conductors 10, and the four conductors 10 are arranged and arranged close together. The four conductors 10 are arranged and formed There are the first row p1 and the second row p2, the cross-sectional shape of the four conductors 10 arranged close together is rectangular, the widths of the two conductors 10 in the first row p1 are not equal, and the widths of the two conductors 10 in the second row p2 The width values of the conductors 10 are not equal, and the total width value of the two conductors 10 in the first row p1 is equal to the total width value of the two conductors 10 in the second row p2. The width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com