Preparation method of rare earth modified cobalt-based WC ceramic coating

A ceramic coating and rare earth modification technology, which is applied in the coating, metal material coating process, etc., can solve the problems of the corrosion resistance of cobalt-based ceramic composite coatings and other problems, achieve significant improvement effects, improve corrosion resistance, The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0015] In this embodiment, by weight percent, the chemical composition of the pusher plate follows: C0.41, Si0.22, Mn0.73, P0.015, S0.01, Cr1.10, Ni0.24, Mo0.21, N0.13, Fe remainder.

[0016] The surface strengthening method comprising the steps of:

[0017] (1) The scale and oil removal 42CrMo alloy surface;

[0018] (2) the deployment of Stellite 6, WC, CeO 2 Reasonable proportion;

[0019] (3) drying and homogenizing the mixed powder;

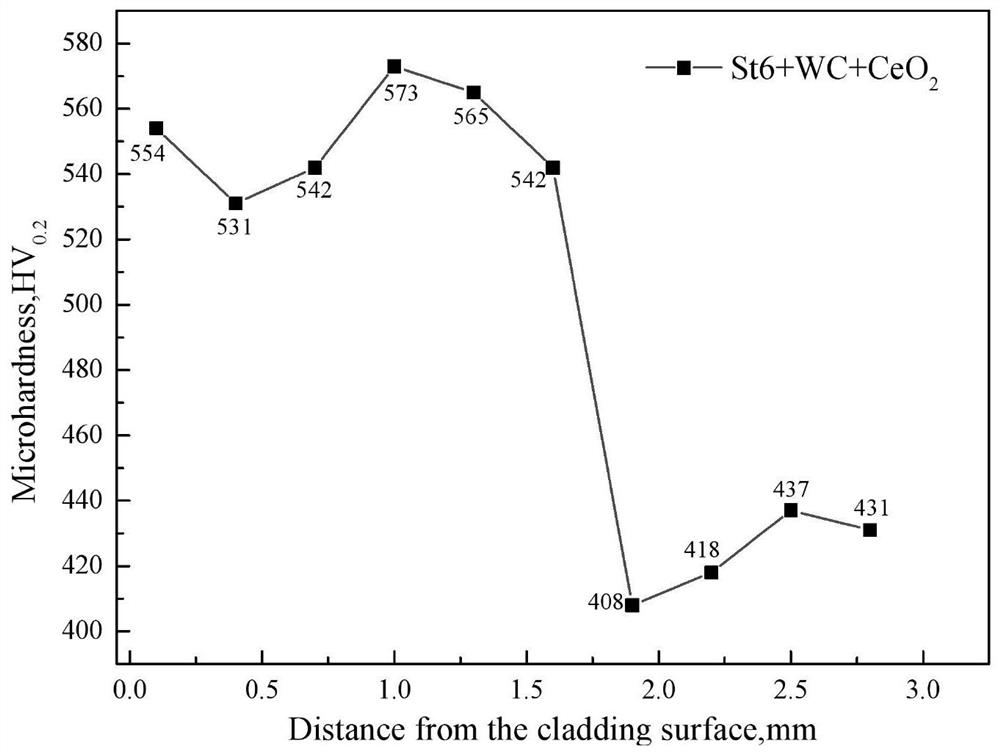

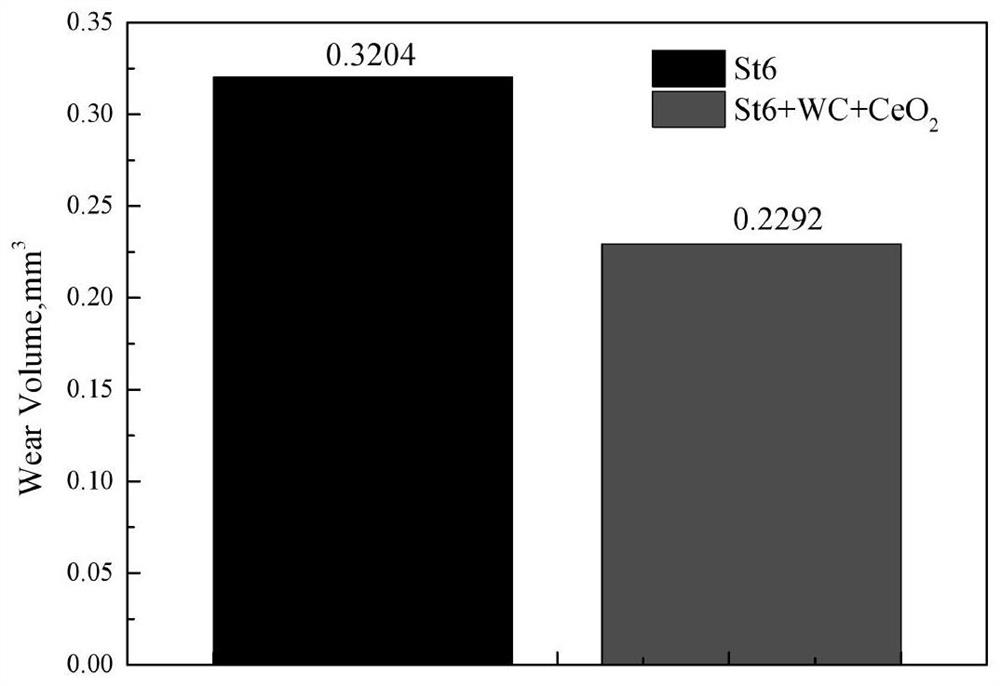

[0020] (4) optimize the laser process parameters, 42CrMo alloy stripper laser cladding surface, by coating the surface hardness test and PT NDT than the highest hardness and crack-free coating;

[0021] (5) finishing.

[0022] Step (1), the clamping 42CrMo steel plate on the ejector milling machine, using the dry cleaning agent, the surface of the steel substrate 42CrMo milling off the scale, the exposed metal surface clean bright.

[0023] Step (2), the electronic balance weighed amount of composite powder, by weight percent, Stellite 6 to 68%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com