A channel connecting the core tube and the peripheral steel structure and its construction method

A technology of steel structure construction and construction method, applied in building structure, processing of building materials, construction, etc., can solve the problems of vertical transportation of small tools and difficult vertical transportation of small steel structure tools, so as to reduce the difficulty of construction and simplify the structure , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

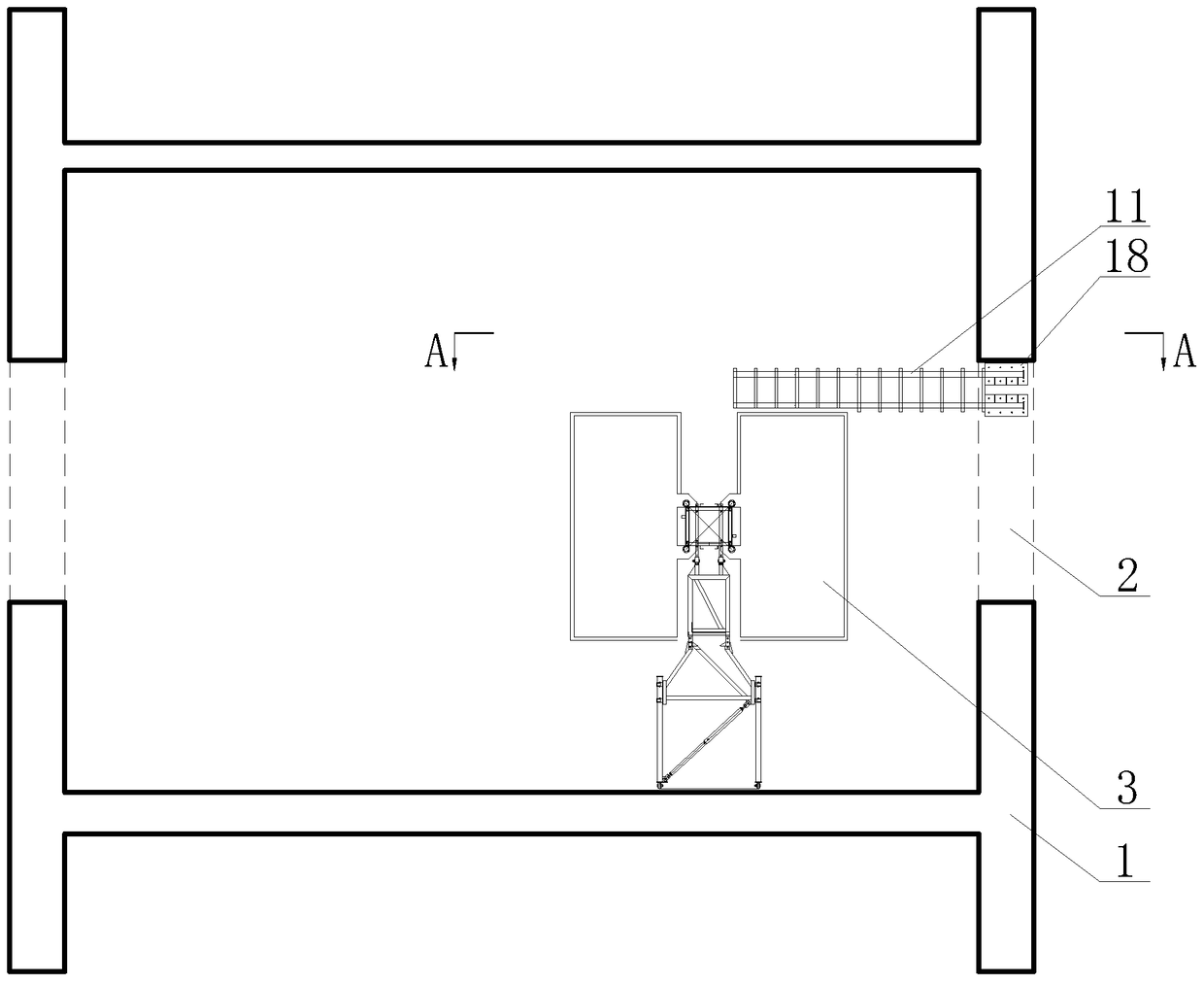

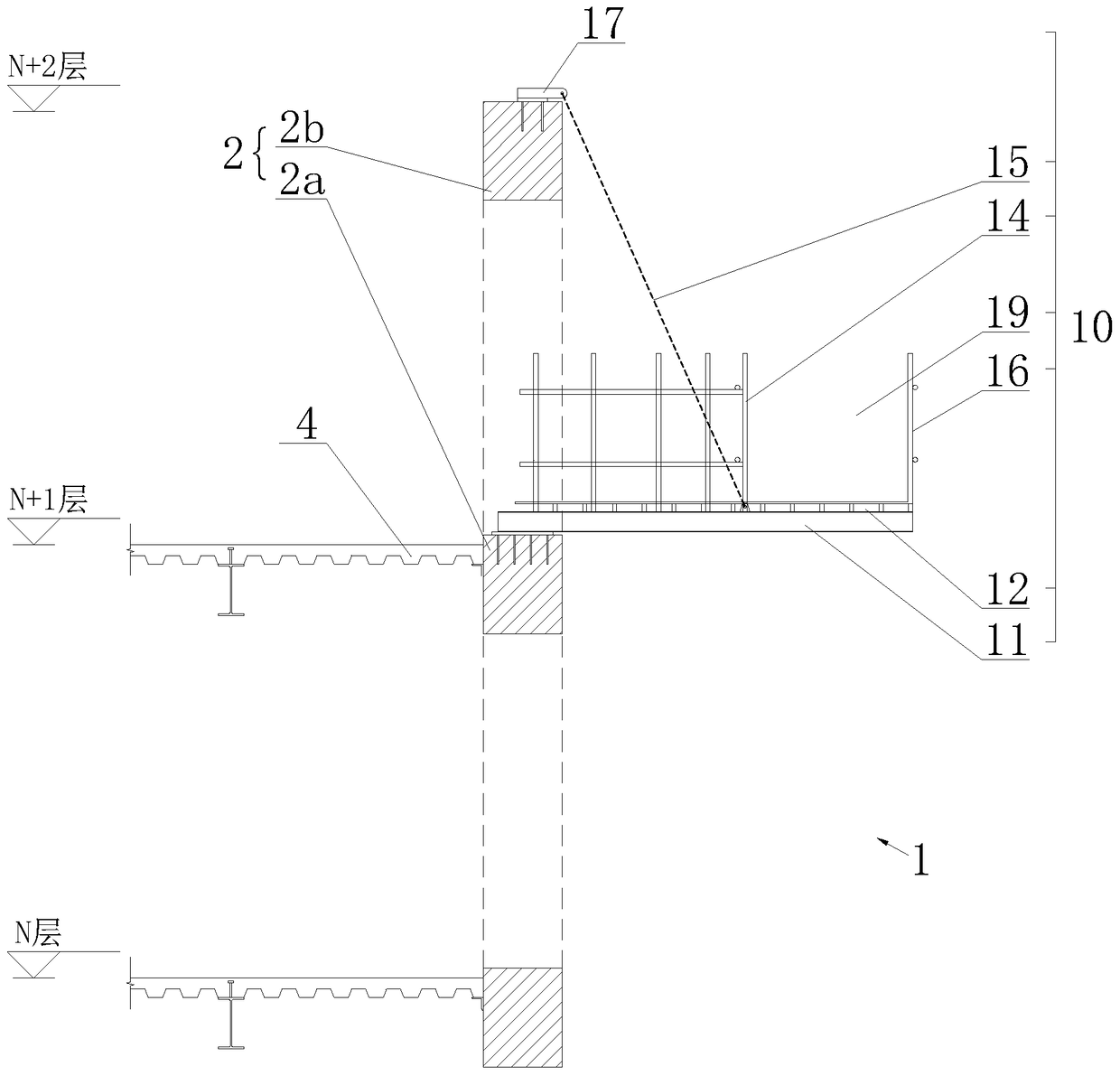

[0022] Example 1: Combining figure 1 and figure 2 Illustrate the channel 10 connecting the core tube and the peripheral steel structure of the present invention, which includes a walkway plate 11 made of section steel and horizontally arranged in the core tube 1; the edge of the walkway plate 11 is provided with a guardrail 14; one end of the walkway plate 11 It is fixed on the concrete connecting beam 2a of the core tube 1, and the other end is fixed on the concrete connecting beam 2b above the fixed end of the walkway slab 11 through at least two cable wind ropes 15; and one end of the channel 10 is provided with a hole 19 It communicates with the construction elevator 3 in the core tube 1, and the other end of the channel 10 is provided with a hole 2 (not shown in the figure) to communicate with the floor 4 of the peripheral steel structure.

[0023] The channel 10 connecting the core tube and the peripheral steel structure of the present invention has one end fixed on th...

Embodiment 2

[0029] Embodiment 2: Combination figure 1 and figure 2 Illustrate the construction method of the channel connecting the core tube and the peripheral steel structure of the present invention, the specific steps are as follows:

[0030] 1. Hoist the channel 10 in the core tube 1, fix one end of the channel 10 on the concrete connecting beam 2a of the core tube 1, and fix the other end of the channel 10 on the concrete connecting beam 2b above the channel 10 through the cable wind rope 15 , so that the opening 19 at one end of the passage 10 can communicate with the construction elevator 3 in the core tube 1, and the opening 2 at the other end of the passage 10 can communicate with the floor 4 of the peripheral steel structure;

[0031] 2. After the construction of the peripheral steel structure at the current height is completed, the channel 10 is removed and hoisted to the upper peripheral steel structure area to be constructed. Repeat step 1, and the channel 10 is cantilever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com