Combined construction method of forward and reverse in special-shaped plane deep foundation pit

A construction method and technology of deep foundation pits, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as high cost and difficulty of support engineering, achieve significant energy-saving and environmental protection benefits, avoid impacts, and ensure engineering quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order for examiners to better understand the technical features, technical contents and technical effects of the present invention, the accompanying drawings of the present invention will now be described in more detail in conjunction with the embodiments. However, the drawings shown are only for better illustration of the technical solutions of the present invention, not the true scale and optimal configuration of the present invention, so the examiner is requested not to limit the scope of the present invention with respect to the ratio and configuration of the drawings Scope of claims.

[0031] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

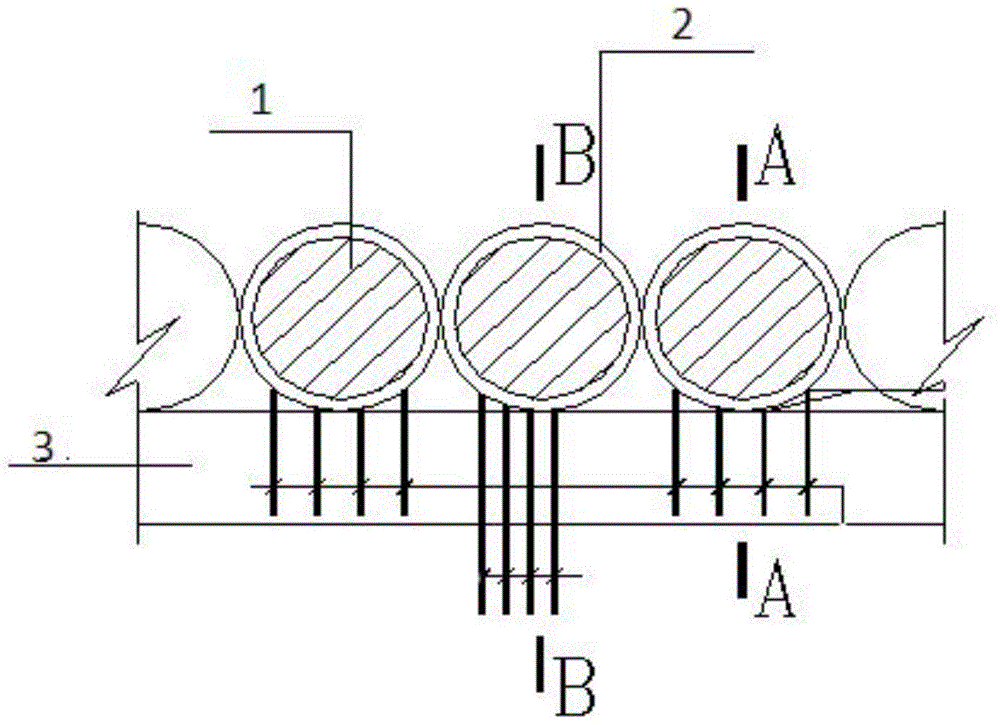

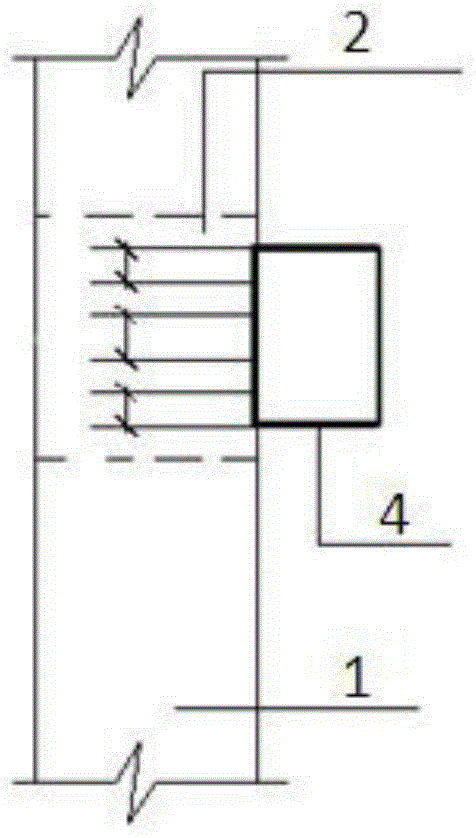

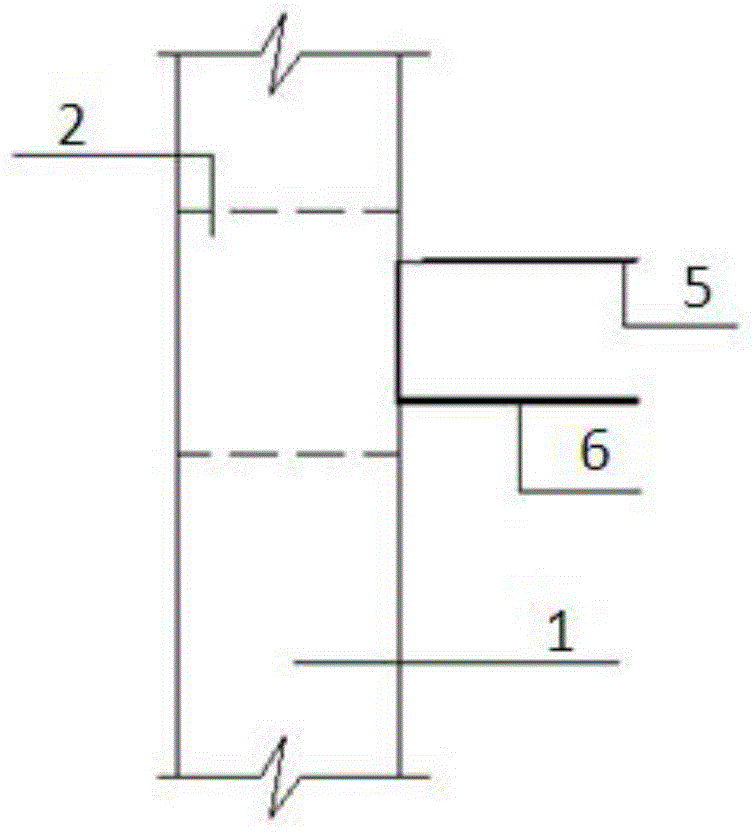

[0032] Such as Figure 1-3 As shown, the present invention provides a special-shaped plane deep foundation pit combined forward and reverse construction method, which is characterized in that it includes the following steps:

[0033] Step 1 Constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com