Connecting method of prefabricated composite multi-ribbed floor slabs and steel beams of assembly type steel structure house

A connection method and steel structure technology, which is applied to floors, building components, building structures, etc., can solve the problems of time-consuming and labor-intensive threading of steel bars, slow construction speed, etc., and achieve the effects of reducing wet work, saving resources, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

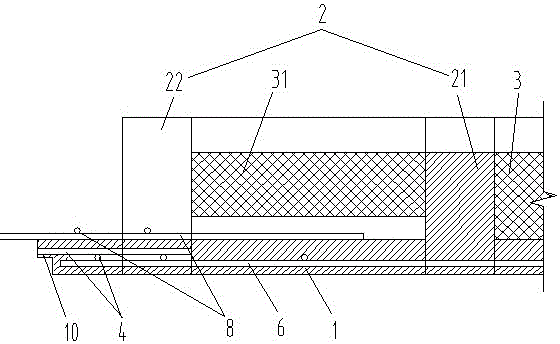

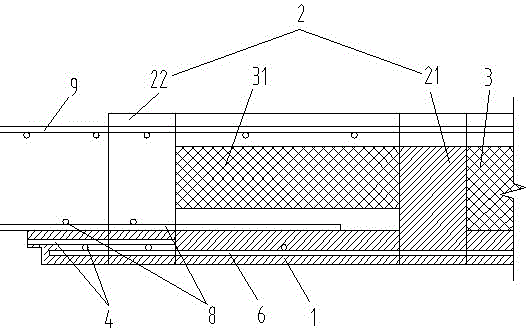

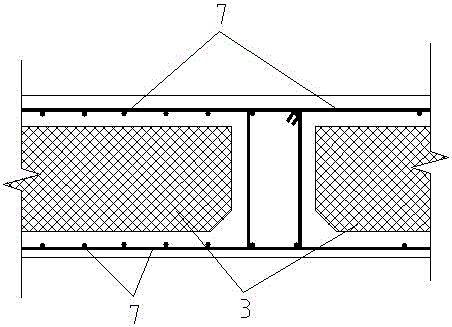

[0036] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0037] attached Figure 1-8 It can be seen that a method for connecting prefabricated laminated densely ribbed floor slabs and steel girders and a connecting method for steel girders in prefabricated steel structure houses comprises the following steps:

[0038] The steel columns and steel beams are hoisted in place, and the support points of the prefabricated laminated ribbed floors are ejected according to the axes of the steel columns and steel beams;

[0039] Install support frames and wooden beams according to the support plan of laminated slabs;

[0040] According to the installation sequence of the prefabricated laminated ribbed slab, hoist the prefabricated laminated densely ribbed floor;

[0041] The connecting reinforcement set on the top edge of the prefabricated laminated floor slab runs through the web 43;

[0042] Binding the cast-in-place reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com