Ventilation and dustproof method used for tunnel construction

A technology for tunnel construction and air ducts, which is applied to mine/tunnel ventilation, dust prevention, and earth-moving drilling and mining, etc., can solve the problems of complex ventilation systems and difficult management, achieve good economic benefits, reduce noise pollution, and strengthen The effect of ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

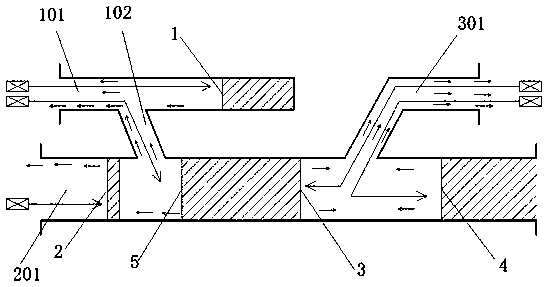

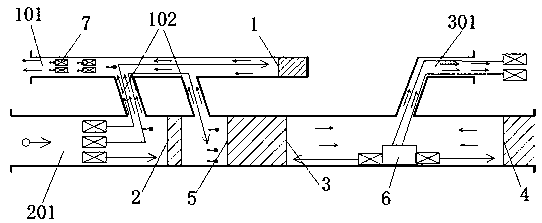

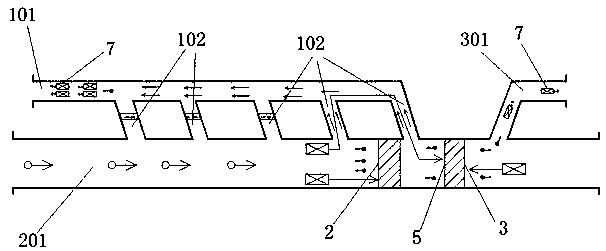

[0052] Please refer to Figure 1-5 As shown, a ventilation and dust prevention method for tunnel construction includes the following steps: Step 1: the first working face 1 excavated in the horizontal guide 101, the second working face 2 excavated in the main tunnel 201, and the inclined shaft 301 Air ducts are installed in front of the excavated third working face 3, and fans and air ducts are installed outside the horizontal guideway 101, the main tunnel 201 and the inclined shaft 301. The hole 201 is connected, and during the excavation process, the air duct moves forward with each working face; Step 2: After the main hole 201 is connected with the first cross passage 102, the fan is arranged at the intersection of the main hole 201 and the first cross passage 102 , the air ducts are respectively arranged to the second working face 2 excavated in the main hole 201 and the first working face 1 of the flat guide 101, and the jet fan 7 is set in the flat guide 101 hole to guid...

Embodiment 2

[0059] Please refer to Figure 1-5 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment designs step 1 in detail, so that the ventilation method of step 1 in Embodiment 1 can be better realized.

[0060] In an embodiment, Step 1 includes the following steps:

[0061] Step 1.1: Install fans on the horizontal guide 101, one end of the main tunnel 201 and outside the inclined shaft 301, and connect the air ducts to the first working surface 1, the second working surface 2 and the third working surface 3 that need to be excavated;

[0062] Step 1.2: Excavate the flat guide 101 forward, and excavate the first cross channel 102 to the main hole 201 until it communicates with the main hole 201, and set two air ducts on the flat guide 101 to lead to the inside of the flat guide 101 and the first channel respectively. The intersection of the cross passage 102 and the main tunnel 201 is excavated to the other end of the main tunnel 201, and the air ...

Embodiment 3

[0072] Please refer to Figure 1-5 As shown, the difference between this embodiment and Embodiment 2 is that this embodiment has carried out a detailed optimization design on how to install the fan in the main hole 201, so as to achieve a better ventilation effect.

[0073] In this embodiment, step 2 includes the following steps:

[0074] Step 2.1: After the main hole 201 is connected with the first cross passage 102, the fan moves to the vicinity of the intersection of the main hole 201 and the first cross passage 102, and moves to the first working surface 1 and the main hole 201 respectively advancing to the flat guide 101. Air ducts are arranged on the second working surface 2 and the second cross passage 102 and the fifth working surface 5;

[0075] Step 2.2: Excavate the horizontal guide 101 to the main hole 201 to form the second cross passage 102. After the second cross passage 102 connects with the main hole 201, turn to the other end of the main hole 201 for excavat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com