Novel water control method suitable for mine shafts

A technology for preventing and controlling water and shafts, applied in shaft equipment, drainage, mining equipment, etc., can solve problems such as shortening the service life of mines, affecting the safety of shafts, and increasing the difficulty of drainage, so as to solve water damage problems, improve construction quality, and protect mines safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

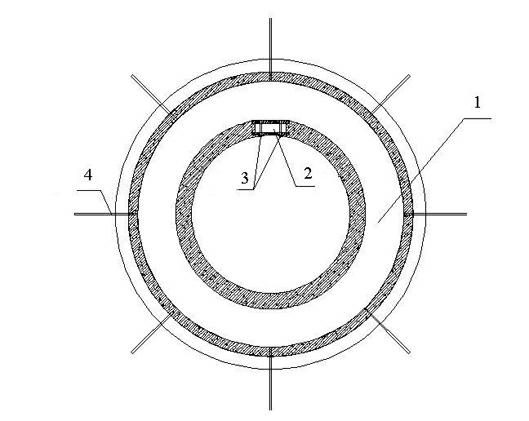

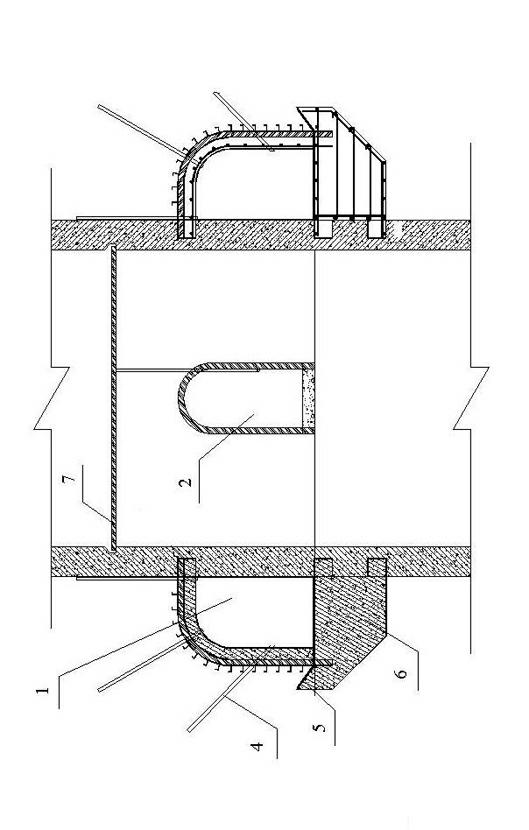

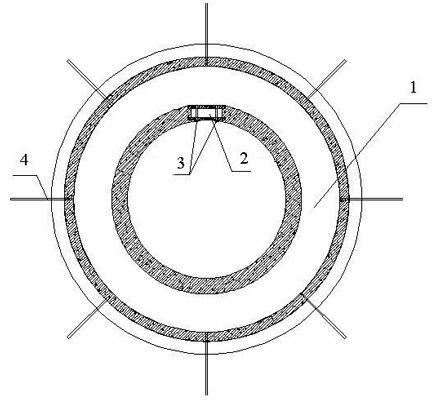

[0021] Example 1, reference figure 1 , 2, a new water prevention method suitable for mine shafts,

[0022] (1) First, use grouting to plug water in the upper aquifer of the wellbore;

[0023] (2) A wall base 6 is provided at the junction of the aquifer and the water-resistant layer. The wall base 6 is provided with a bypass 1 for water interception. The bypass 1, the wall base 6 and the wellbore are constructed as a whole; a water discharge hole is set in the bypass 1. There is a water pipe 4 in the hole; the wall base 6 is wider than the bypass 1, and the wide part is tilted to form a water retaining 5; the bottom of the bypass 1 has a slope of 1 to 3%, and the lowest point is set at the connecting channel in the wellbore, and inorganic waterproofing Paint waterproof;

[0024] (3) A catchment circle 7 is set in the upper wellbore of the connecting road 2, and the water collected by the catchment circle 7 is discharged into the bypass 1 behind the wall;

[0025] (4) The bottom plate ...

Embodiment 2

[0026] In Example 2, the step (1) of the new water prevention method suitable for mine shafts described in Example 1 is: during the construction of the shaft, the aquifer is grouted and water shut off according to the conditions of the rock strata that the shaft passes through; When watering, first use cement slurry, or cement and sodium silicate double liquid slurry, or cement, sodium silicate and clay materials to fill the cracks in the surrounding rock, block the water outlet and isolate the water source; at the same time, cement and strengthen the mine surrounding rock to increase the stability of the shaft .

Embodiment 3

[0027] In embodiment 3, in step (2) of the new water prevention method suitable for mine shafts described in embodiment 1, the foundation of the wall base 6 is placed on a stable water-resistant layer, and the depth of the embedded water-resistant layer is controlled, Make it not penetrate the water barrier; reserve a connecting channel 2 on the shaft wall to connect the bypass 1 with the wellbore; the wall seat 6, the shaft wall and the bypass 1 support form a whole, the wall seat 6 serves as the bottom plate of the bypass 1, and the shaft wall As the inner wall of the bypass 1; the width of the wall seat 6 is 400-600mm wider than that of the bypass 1, and it is tilted on the outside to form a water retaining 5 so that the water seepage from the outer wall of the bypass 1 penetrates into the bypass 1 through the construction joint of the outer wall of the bypass 1;

[0028] The bypass 1 is supported by a steel support and reinforced concrete. A steel arch is provided every 0.4-0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com