Sliding platform and construction method for separately mounting grid structures on high altitudes

A sliding platform and high-altitude bulk technology, which is applied in the direction of scaffolding supported by house structure, house structure support, house structure support, etc., can solve the problems of complex structure, cumbersome construction, and insufficient stability of sliding scaffolding, so as to facilitate construction organization, Good safety and reduced labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

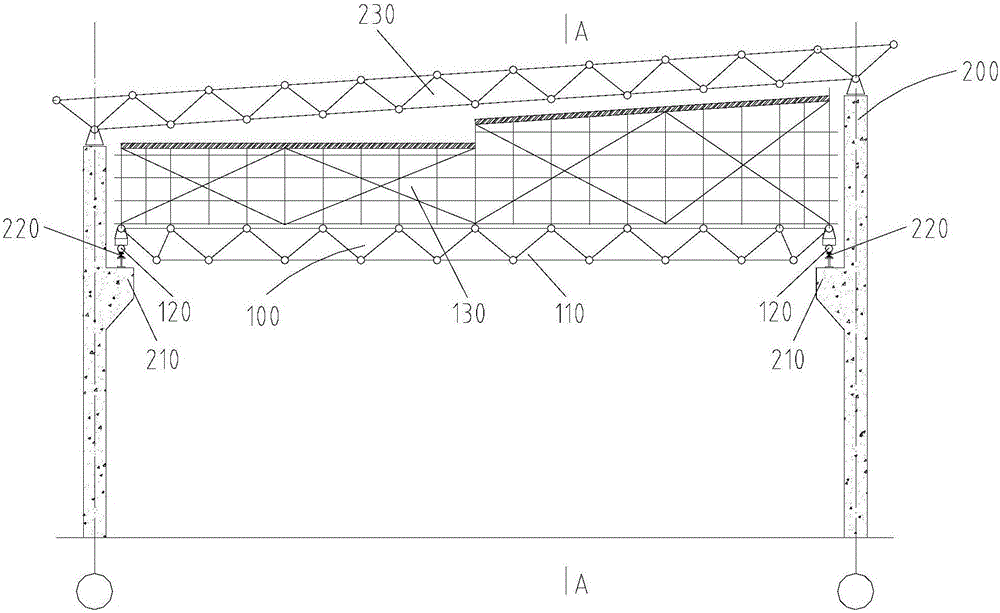

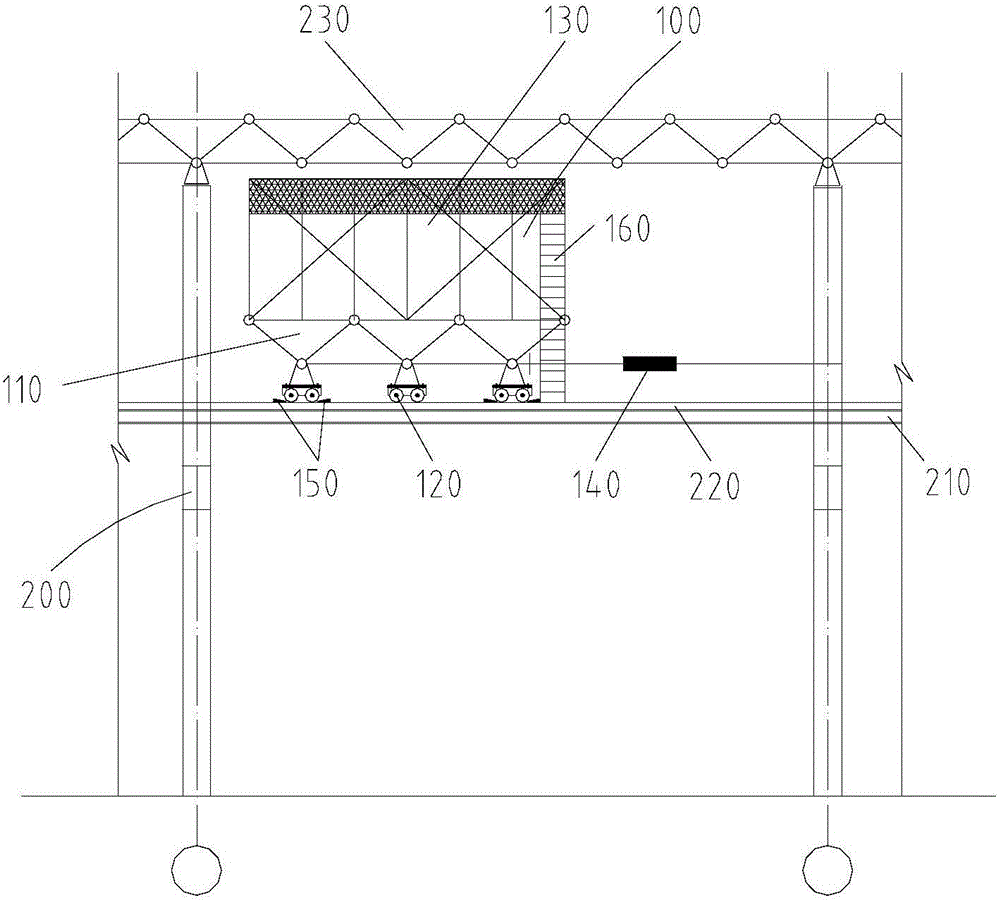

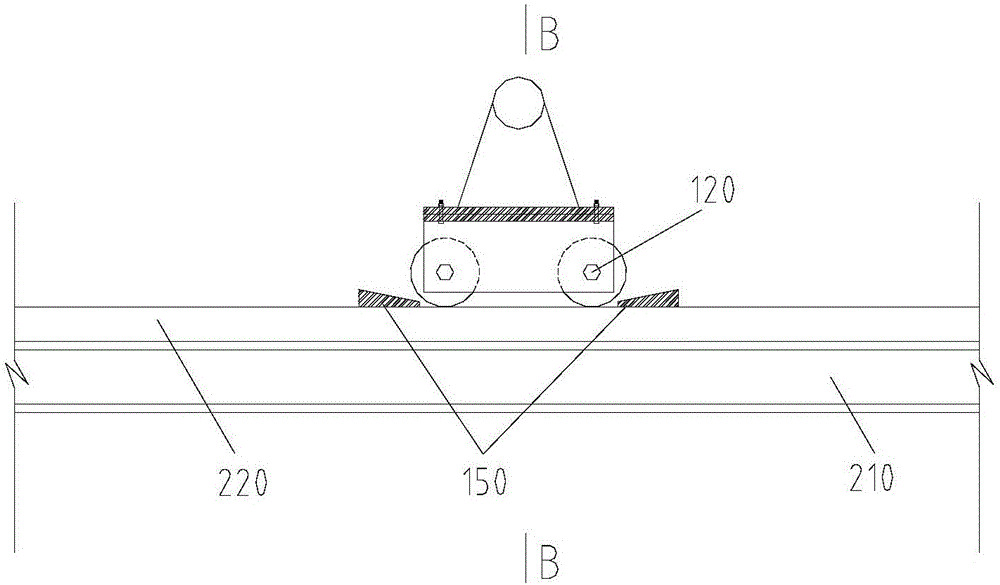

[0063] like figure 1 and figure 2 As shown, the grid high-altitude bulk skid platform 100 of the present invention is arranged in the industrial plant 200, the industrial plant 200 has a crane beam 210, and the crane beam 210 has a crane track 220, and the grid high-altitude bulk skid platform 100 of the present invention It is arranged on the crown train track 220 and is used for construction of the steel grid structure 230 to be built in the industrial plant 200 .

[0064] Specifically, the grid high-altitude bulk skid platform 100 includes a grid-type skid platform 110 , skid rollers 120 , a scaffolding operation platform 130 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com