Freezing method of frozen wall of inclined shaft

A freezing method and freezing wall technology, which are applied in well sinking, earthwork drilling, shaft equipment, etc., can solve the problems of slow construction speed and difficult excavation, and achieve the effects of easy excavation, guaranteed maintenance quality, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Utilize the freezing method of inclined shaft frozen wall of the present invention, form frozen wall at the periphery of coal mine inclined shaft and comprise the following steps:

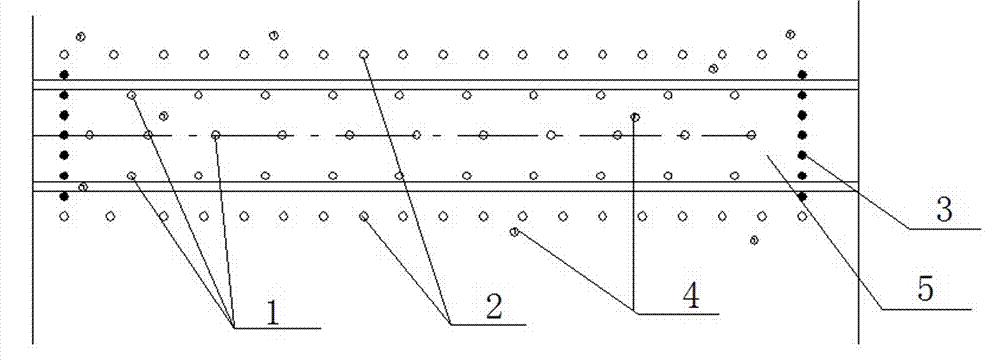

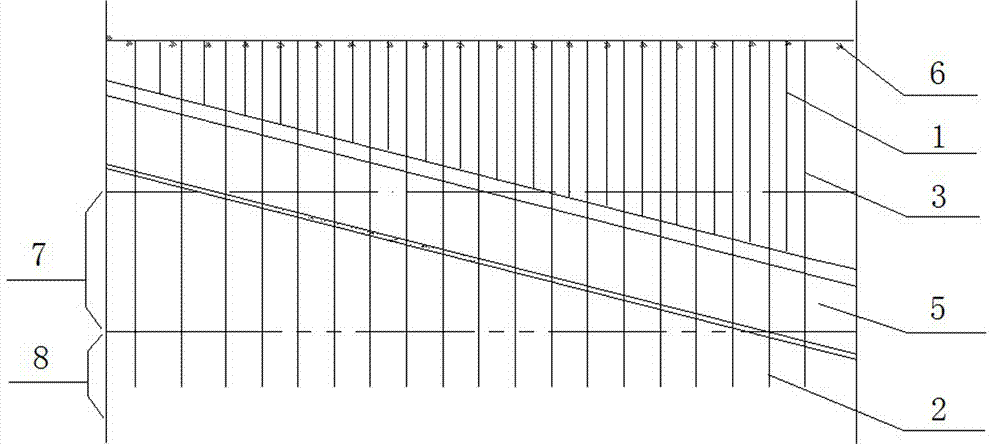

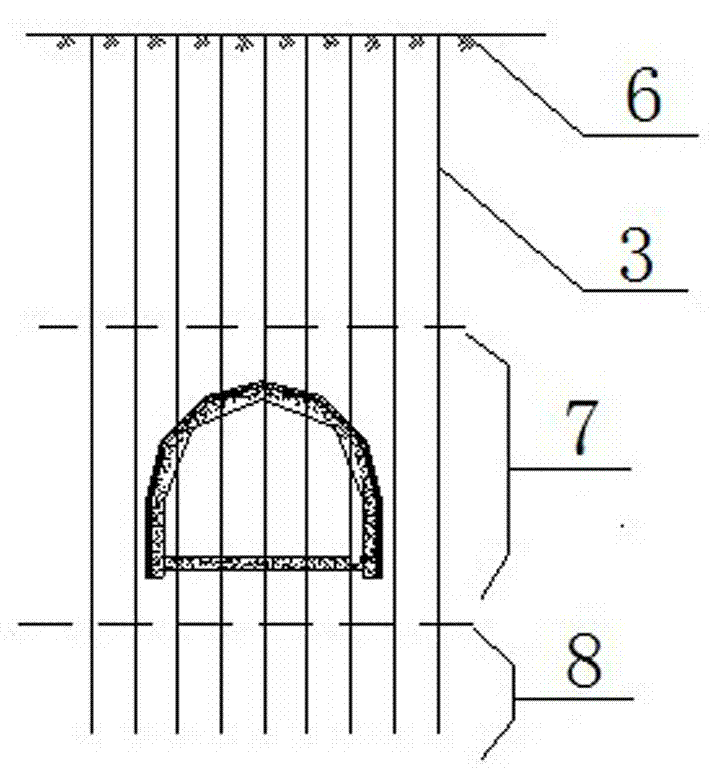

[0023] a. From the surface 6 along the axial freezing range of the inclined wellbore 5, drill several rows of parallel and vertically arranged freezing holes. Numerical calculations determine, such as Figure 1 ~ Figure 4 As shown, the depths of the side freezing holes 2 on both sides of the inclined shaft 5 and the end freezing holes 3 at both ends go deep into the aquifer 8 below the lowest end of the freezing section of the inclined shaft 5, and the aquifer 8 is used to isolate the lower aquifer. 7, the depth of the top freezing hole 1 above the inclined shaft 5 reaches the top of the inclined shaft 5;

[0024] b. A freezing pipe and a liquid supply pipe with a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com