Annular cutting pipe pulling construction process and annular cutting pipe pulling drilling machine

A construction process and a technology for circumcising drill bits, which are applied in the directions of pipes/pipe joints/pipes, machinery and equipment, earth-moving drilling, etc. Stability, novel design, improved power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

[0031] The present embodiment provides a construction technique of circumcision and extubation, which is characterized in that it comprises the following steps:

[0032] Step 1, digging and setting operation pits at both ends of the old pipeline to be replaced;

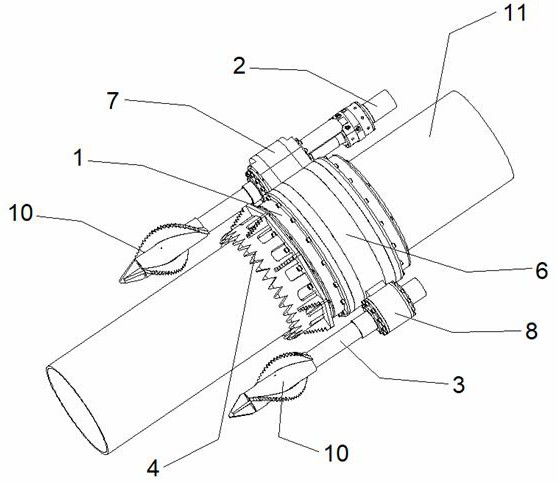

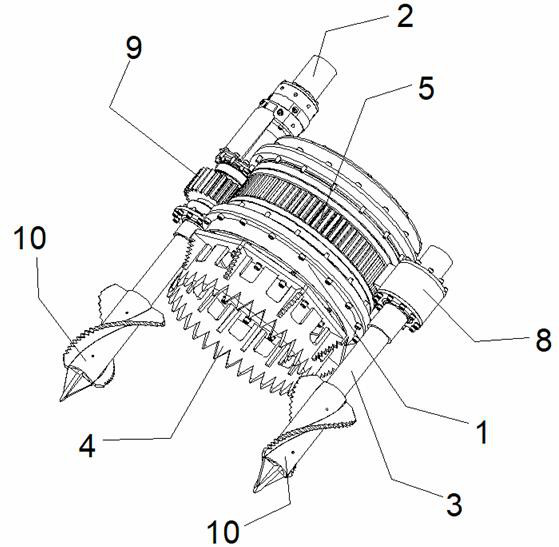

[0033] Step 2, arranging a circumcision and extubation drilling rig in the operation well pit at one end of the old pipeline to be replaced, and selecting a circumcision drill bit matching the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com