Main bridge steel structure construction method

A steel structure construction and steel structure technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of long time consumption, and achieve the effect of simple construction, low cost and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

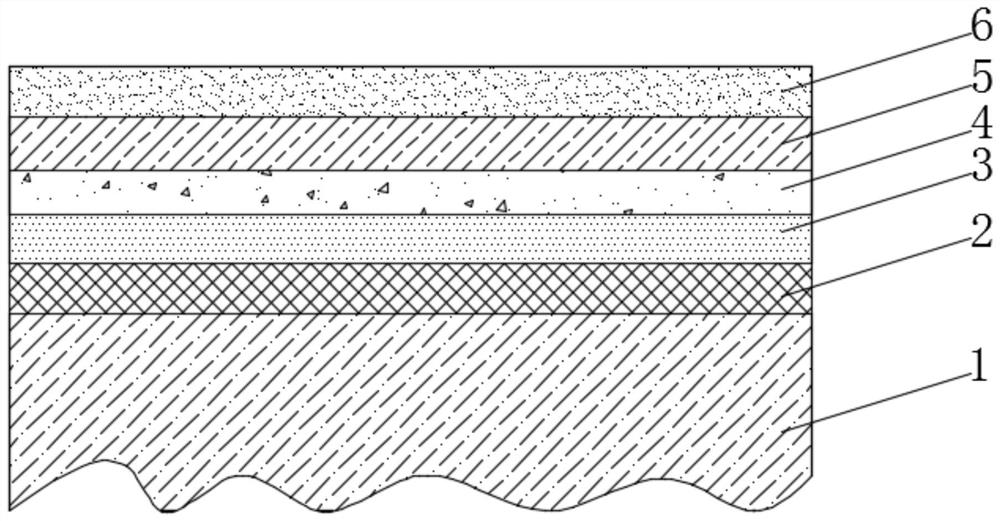

[0057] see Figure 1~5 As shown, the construction method of the steel structure of the main bridge in this embodiment includes the steel structure bridge 1, the epoxy asphalt carbon fiber protective layer 2, the epoxy asphalt macadam shear layer 3, the epoxy asphalt Concrete layer 4, modified epoxy waterproof reinforcement layer 5 and modified epoxy gravel micro-surface treatment layer 6;

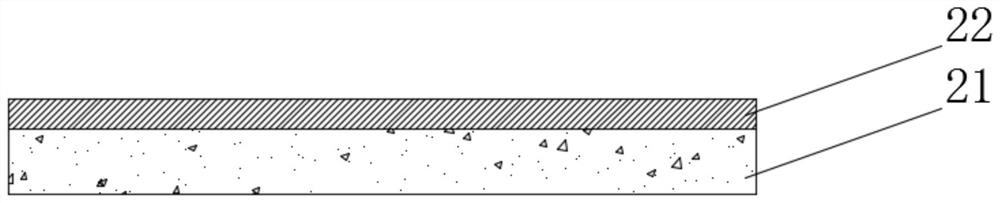

[0058] The epoxy asphalt carbon fiber protective layer 2 is composed of a first epoxy asphalt resin layer 21 arranged on the bridge surface of the steel structure bridge 1 and a carbon fiber cloth layer 22 bonded to the first epoxy asphalt resin layer 21;

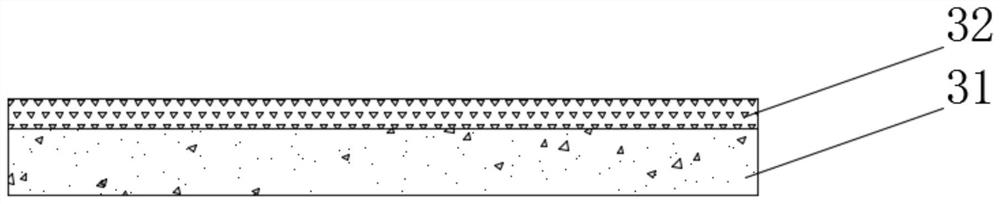

[0059] The epoxy asphalt macadam shear layer 3 is composed of a second epoxy asphalt resin layer 31 arranged on the carbon fiber cloth layer 22 and a macadam shear layer 32 laid on the second epoxy asphalt resin layer 31;

[0060] The epoxy asphalt concrete layer 4 is formed by solidifying the mixture composed of epoxy asphalt resin, co...

Embodiment 2

[0073] see Figure 6-15 As shown, the bridge deck construction equipment in Embodiment 1 includes an asphalt laying mechanism 100 and an asphalt flat pressing mechanism 200, and the bottom of the asphalt laying mechanism 100 is equipped with an asphalt flat pressing mechanism 200;

[0074] Wherein, the asphalt paving mechanism 100 includes a mounting frame 101, a feeding pipe 102, an outer casing 103, a hopper 105, a support frame 107, a rotating cylinder 109, a driving motor 112, a track 113, a spindle-shaped tank body 118, and conveying and shearing leaves. 120. Auxiliary roller 123, rotating wheels 108 are installed on both sides of the bottom of the mounting frame 101 through the rotating shaft, two supporting frames 107 are installed on the top of the mounting frame 101, and a rotating cylinder is installed on the top of the two supporting frames 107 109, an outer casing 103 is arranged directly above the rotating cylinder 109, a shield cover 104 is installed at one end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com