Organic bentonite composition modified emulsified asphalt and its preparing method

A technology for emulsified asphalt and bentonite, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of high cost, complex production, and poor comprehensive performance of emulsified asphalt modifiers, and achieves extended service life, The effect of saving energy and shortening the time of closing traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

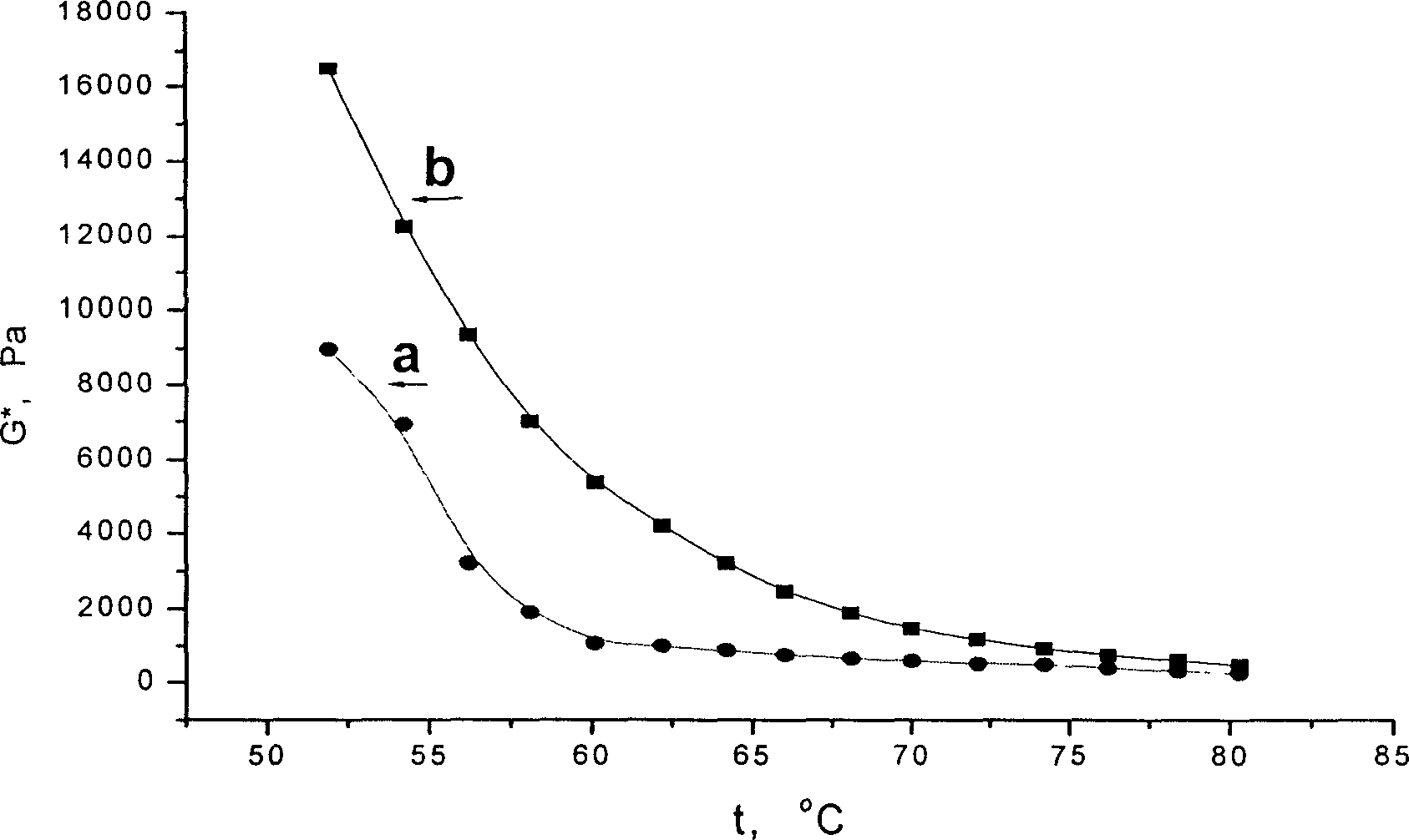

Method used

Image

Examples

Embodiment 1

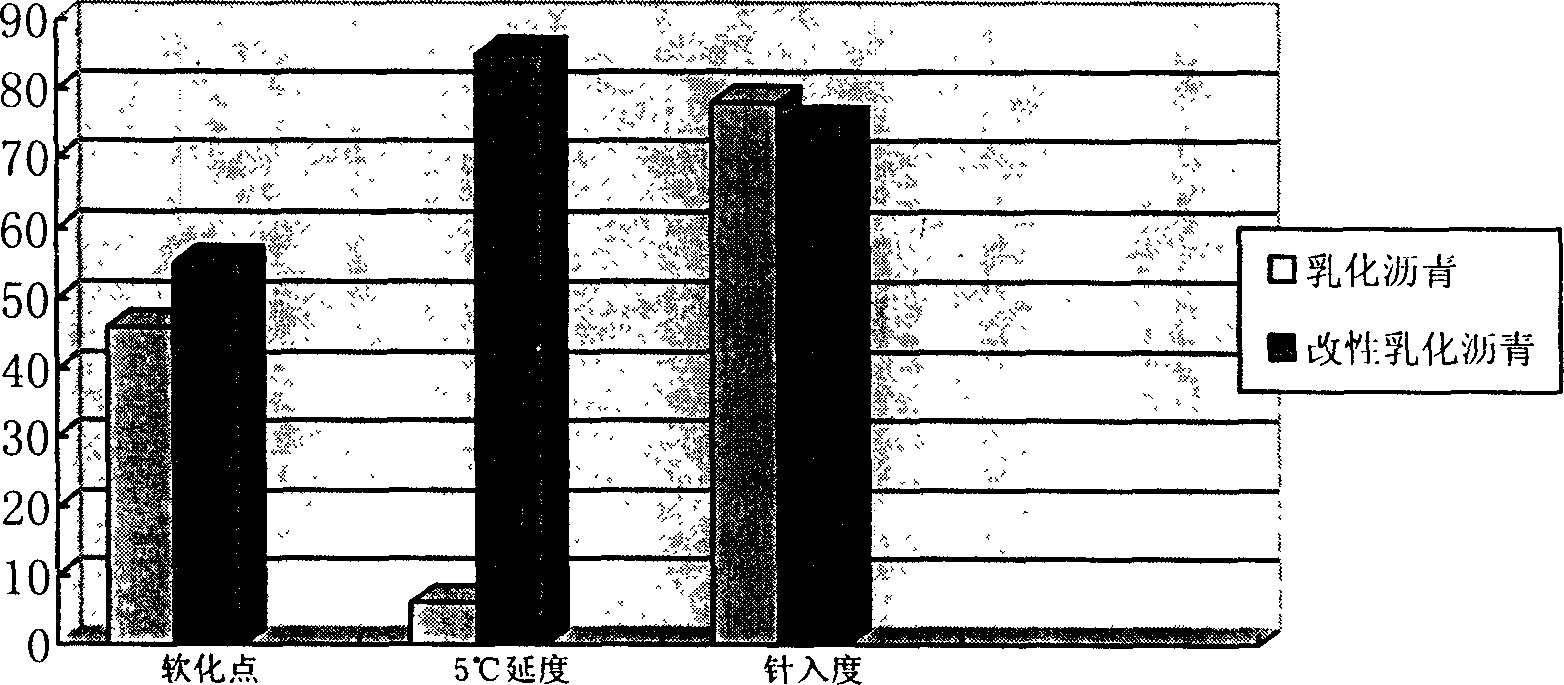

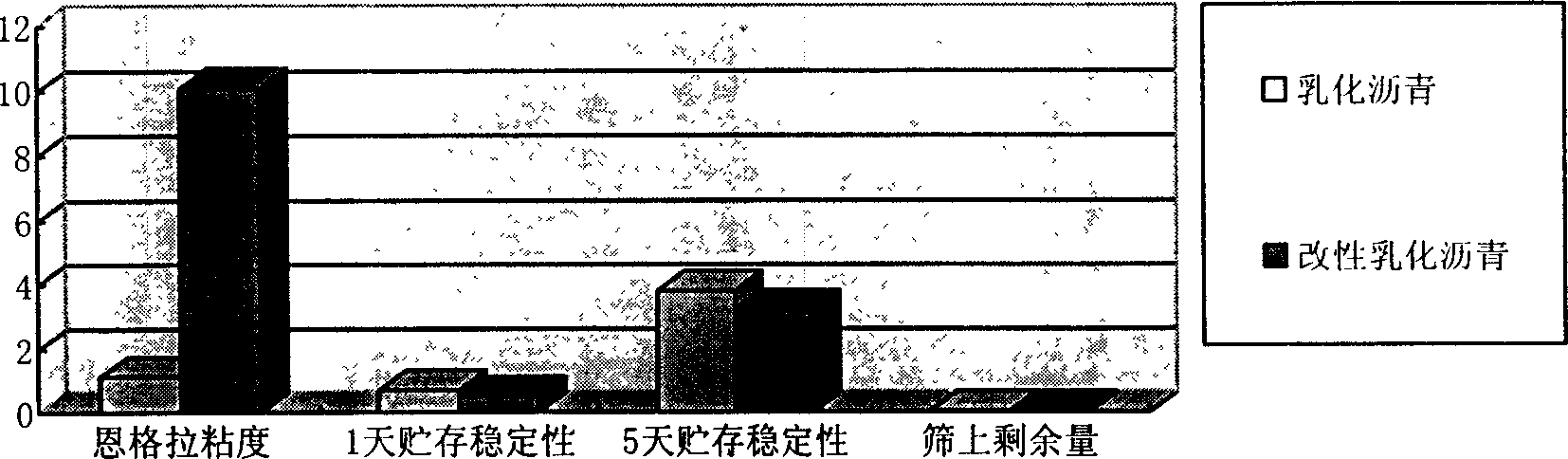

[0024] Add 1 part of organic bentonite with a particle size of 19 microns to a solution of 0.1 part of thickener and 5 parts of water, stir evenly, add hydrochloric acid to acidify to pH 4, leave it for 20 hours, and set aside; add 0.6 parts of cationic emulsifier, 3 parts of styrene-butadiene latex and 30 parts of water are stirred and mixed evenly, and hydrochloric acid is added to adjust the pH value to 5, then heated to 55°C, and mixed and emulsified with 60 parts of base asphalt heated to 120°C through an emulsifier, and the above-mentioned The prefabricated organic bentonite and thickener mixture are mixed evenly and left to stand for automatic defoaming to make products. The measured 25-degree Engela viscosity is 10.1, the remaining amount (%) on the sieve is 0.08, the 1-day storage stability (%) is 0.5, the 5-day storage stability (%) is 3.2, and the residue 5-degree ductility (5 cm / min, 5°C, cm) is 85, 25 degree penetration (25°C, 100 g, 5 seconds, 0.1 mm) is 75, soft...

Embodiment 2

[0026] Add 2 parts of organic bentonite with a particle size of 74 microns to a solution of 0.1 part of thickener and 6 parts of water, stir evenly, add hydrochloric acid to acidify to a pH value of 5, leave it for 30 hours, and set aside; add 0.7 parts of cationic emulsifier, 2 parts of styrene-butadiene latex and 36.4 parts of water are stirred and mixed evenly, and hydrochloric acid is added to adjust the pH value to 6, and then heated to 65°C, and then mixed and emulsified with 62 parts of base asphalt heated to 130°C through an emulsifier, and the above-mentioned The prefabricated organic bentonite and thickener mixture are mixed evenly and left to stand for automatic defoaming to make products. The measured 25-degree Engela viscosity is 10.4, the remaining amount (%) on the sieve is 0.03, the 1-day storage stability (%) is 0.5, the 5-day storage stability (%) is 0.8, and the residue 5-degree ductility (5 cm / min, 5°C, cm) is 44.6, 25 degree penetration (25°C, 100 g, 5 sec...

Embodiment 3

[0028] Add 3 parts of organic bentonite with a particle size of 35 microns to a solution of 0.2 parts of thickener and 7 parts of water, stir evenly, add hydrochloric acid to acidify to pH 4, leave it for 24 hours, and set aside; add 0.8 parts of cationic emulsifier, 4 parts of styrene-butadiene latex and 32 parts of water are stirred and mixed evenly, and hydrochloric acid is added to adjust the pH value to 6, and then heated to 58°C, and then mixed and emulsified with 61 parts of base asphalt heated to 124°C through an emulsifier, and the above-mentioned The prefabricated organic bentonite and thickener mixture are mixed evenly and left to stand for automatic defoaming to make products. The determined 25-degree Engela viscosity is 9.4, the remaining amount (%) on the sieve is 0.02, the 1-day storage stability (%) is 0.7, the 5-day storage stability (%) is 3.0, and the residue 5-degree ductility (5 cm / min, 5°C, cm) is 58.5, 25 degree penetration (25°C, 100 g, 5 seconds, 0.1 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com