Method for preventing and controlling water damage reinforcement of coal seam floor fault

A technology of coal seam floor and fault is applied in the field of water damage reinforcement prevention and control of coal seam floor and fault, which can solve the problems of good replenishment, easy shrinkage, fault effect of strengthening strength and poor waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

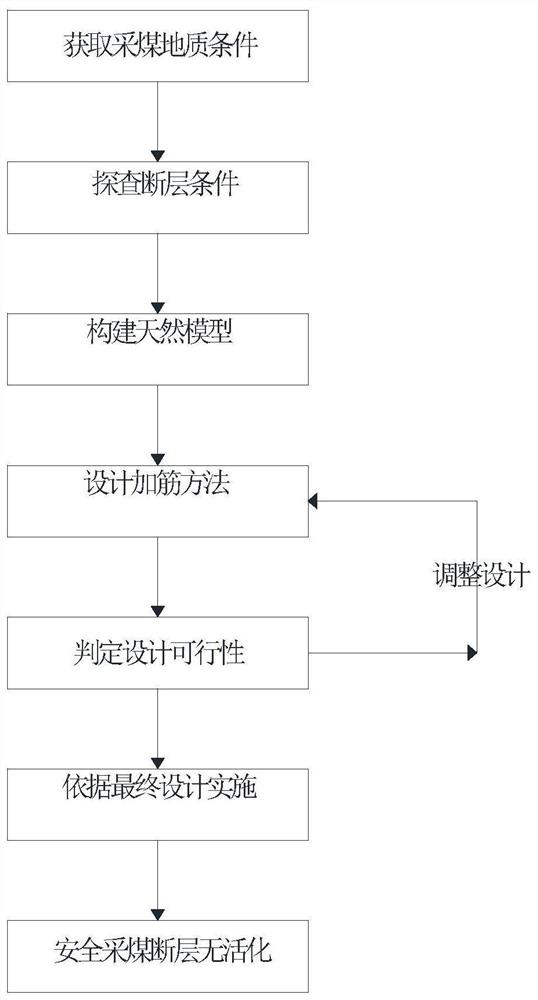

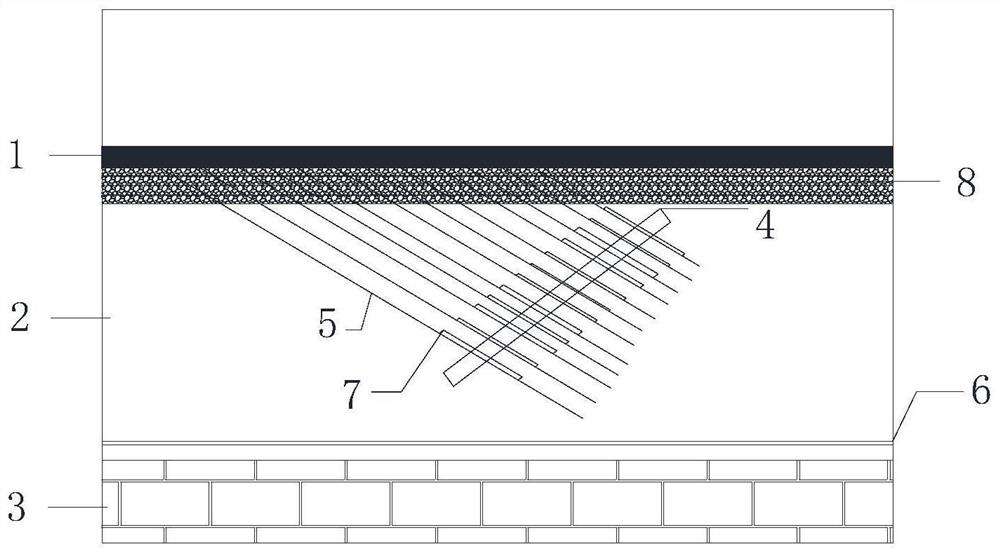

[0044] When coal seam 1 was mined in a coal mine in Guizhou, my country, it was threatened by the underlying Maokou limestone water, especially under the influence of fault 4, floor water inrush occurred many times, and conventional cement grouting had no effect. The process of prevention and control of floor water damage through fault reinforcement is as follows:

[0045] Step 1: Obtain coal mining geological conditions: Obtain the direction and thickness of the middle rock layer 2 under the floor of the coal seam 1 through the geological histogram, and obtain the location of the water damage source layer 3.

[0046] Step 2: Investigate fault conditions: Determine the thickness and extension of the fractured zone of fault 4 through geophysical prospecting and drilling.

[0047]Step 3: Build a natural model. According to the coal mining geological conditions obtained in the first step and the geological and fault conditions determined in the second step, a natural numerical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com