Downhole high pressure and large flow uncontrolled hydrological drilling plugging system and method

A high-flow, high-pressure technology, used in drilling compositions, chemical instruments and methods, and earth-moving drilling, etc., can solve the problems of long processing time, poor cartilage effect, long time, etc., to reduce surges. The effect of water volume, reduction of ineffective drainage costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but are not intended to limit the protection scope of the present invention.

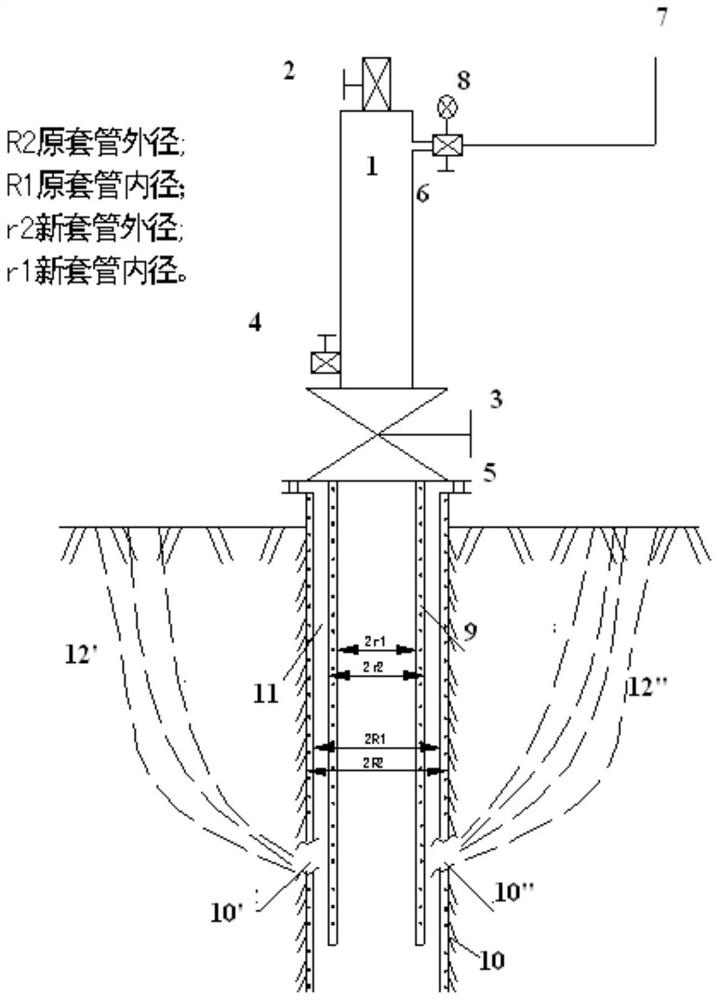

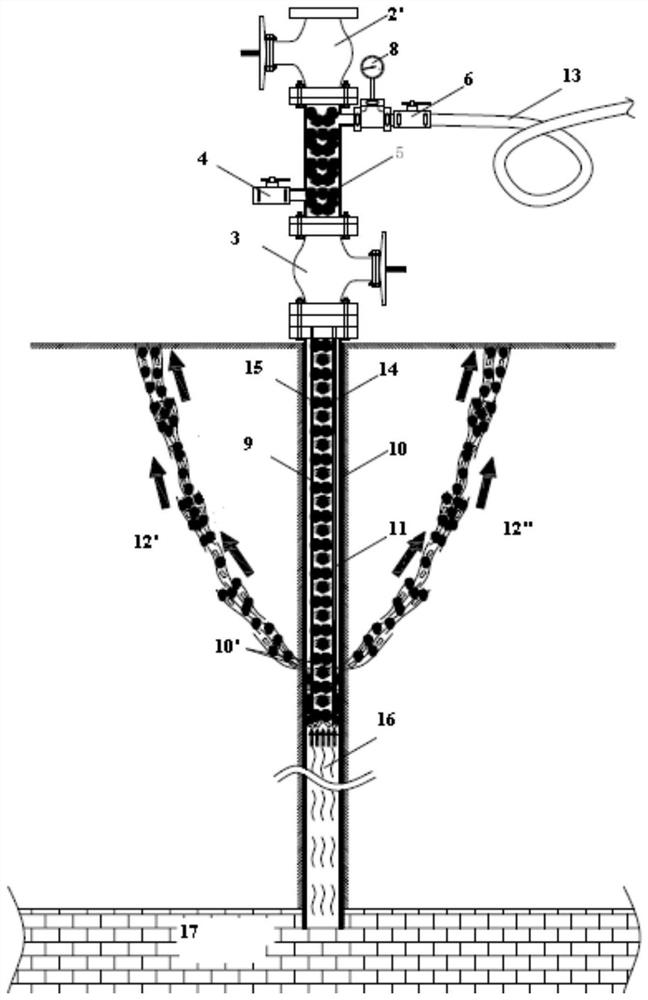

[0031] Such as figure 1 As shown, the downhole high-pressure large-flow out-of-control hydrological drilling plugging system in this embodiment includes: packing cylinder 1, packing port 2, valve 3, pressure relief gate valve 4, flange plate 5, grouting gate valve 6, new lower The casing 9 and the original casing 10, the stuffing port 2 is set above the stuffing tube 1, the valve 3 is installed at the bottom of the stuffing tube 1, the pressure relief gate valve 4 is installed on the side wall below the stuffing tube 1, and the valve 3 passes through the flange 5 Connect the new casing 9, the grouting gate valve 6 is installed on the side opposite to the pressure relief gate valve 4 above the stuffing tube 1, there is a casing gap 11 between the new casing 9 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com