Water Hazard Prevention and Control Method for Roadway under Strongly Rich Water and Weakly Consolidated Aquifer

A weak cementation and roadway technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve problems such as water damage and roof accidents that cannot be effectively solved, and achieve the effect of avoiding water damage and roof accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

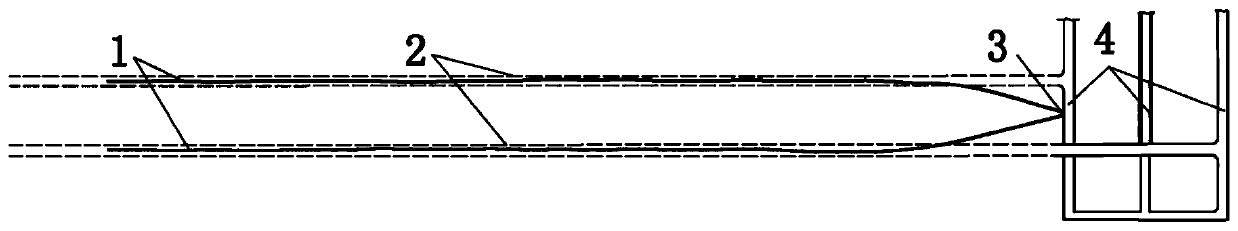

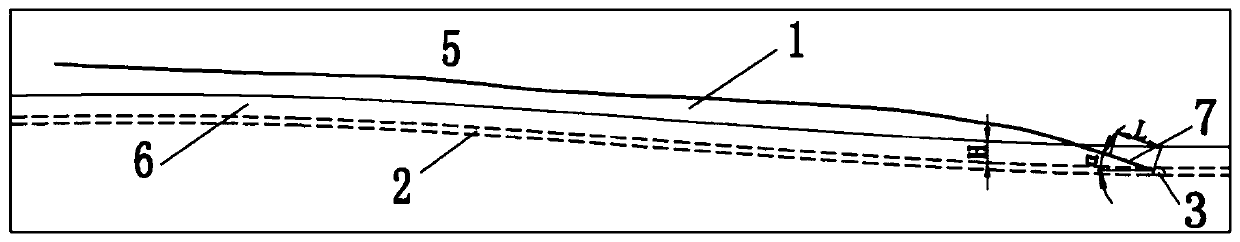

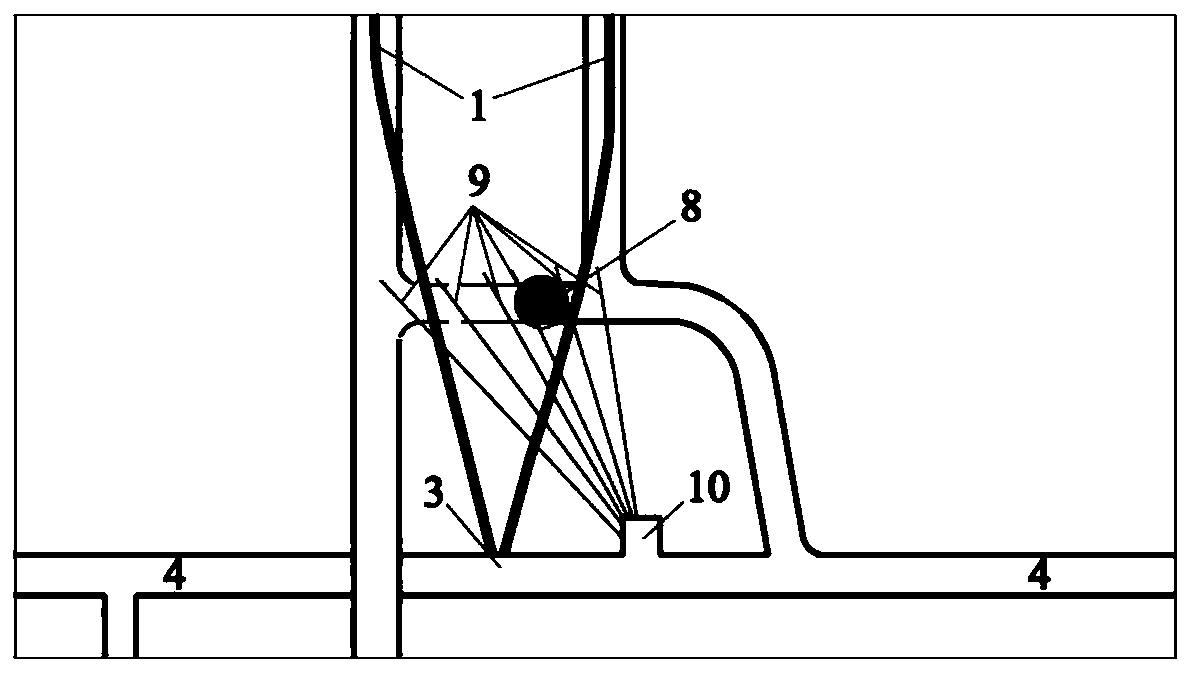

[0030] see Figure 1A to Figure 4 , showing the method for preventing and controlling water damage in roadways under strong water-rich and weakly cemented aquifers of the present invention.

[0031] The method for preventing and controlling water hazards in roadways under strong water-rich and weakly cemented aquifers is comprehensively prevented and controlled according to the characteristics of water hazards and roof accidents such as the thickness of the roadway roof aquifer, water-richness, cementability, and water-resisting layer thickness, which includes the following specific steps:

[0032] Step 1: see Figure 1A and Figure 1B , constructing long-distance directional drilling at the bottom of the aquifer on the roof of the roadway: according to the actual conditions in the well, select a suitable location for the excavated roadway 4 as the drilling site 3, and construct the long-distance directional drilling 1, and the long-distance directional drilling 1 is on the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com