Curtain grouting process suitable for water-rich mine underground mining water plugging

A curtain grouting and mining technology, which is applied in wellbore lining, underground chambers, mining equipment, etc., can solve problems such as difficulty in adaptation, and achieve the effects of saving drainage costs, significant economic benefits, and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

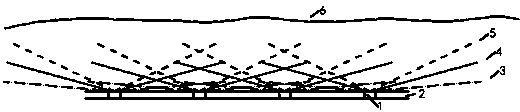

[0046] by figure 1 Shown is a vertical projection diagram of a curtain grouting process suitable for water shutoff in underground mining in rich water mines and combined with figure 2 It can be seen that the lane 2 is located below the water level 6, and each chamber 1 is arranged laterally along the lane 2.

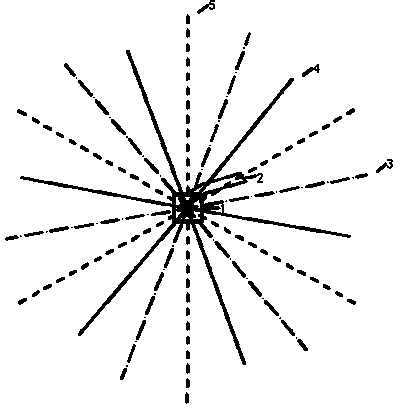

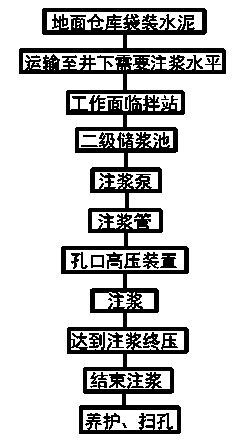

[0047] 1) Arrangement of upward water exploration and grouting holes: In each chamber 1, 6 water exploration and grouting holes are arranged 5°, 15° and 25° respectively, forming a borehole control network within 8m×8m. The design of exploration and injection drilling is based on the center of the chamber, 6 5° water exploration grouting holes 3, 6 15° water exploration grouting holes 4, and 6 25° water exploration grouting holes 5 are mutually staggered on the plane. It is evenly arranged at 60° and the hole depth is 50m. The 5°, 15° and 25° water prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com