Patents

Literature

73 results about "Grout curtain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grout curtain is a barrier that protects the foundation of a dam from seepage and can be made during initial construction or during repair. Additionally, they can be used to strengthen foundations and contain spills.

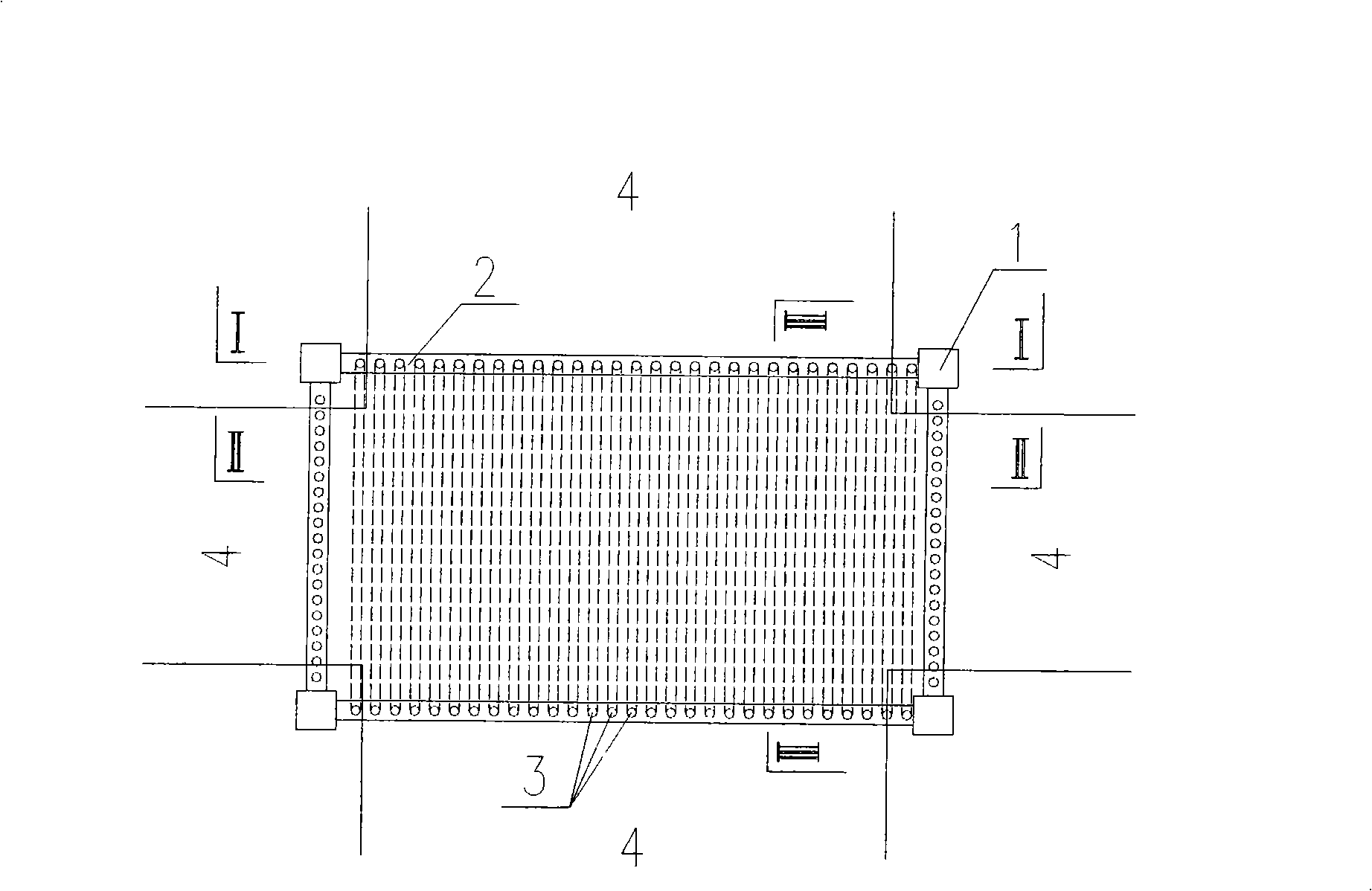

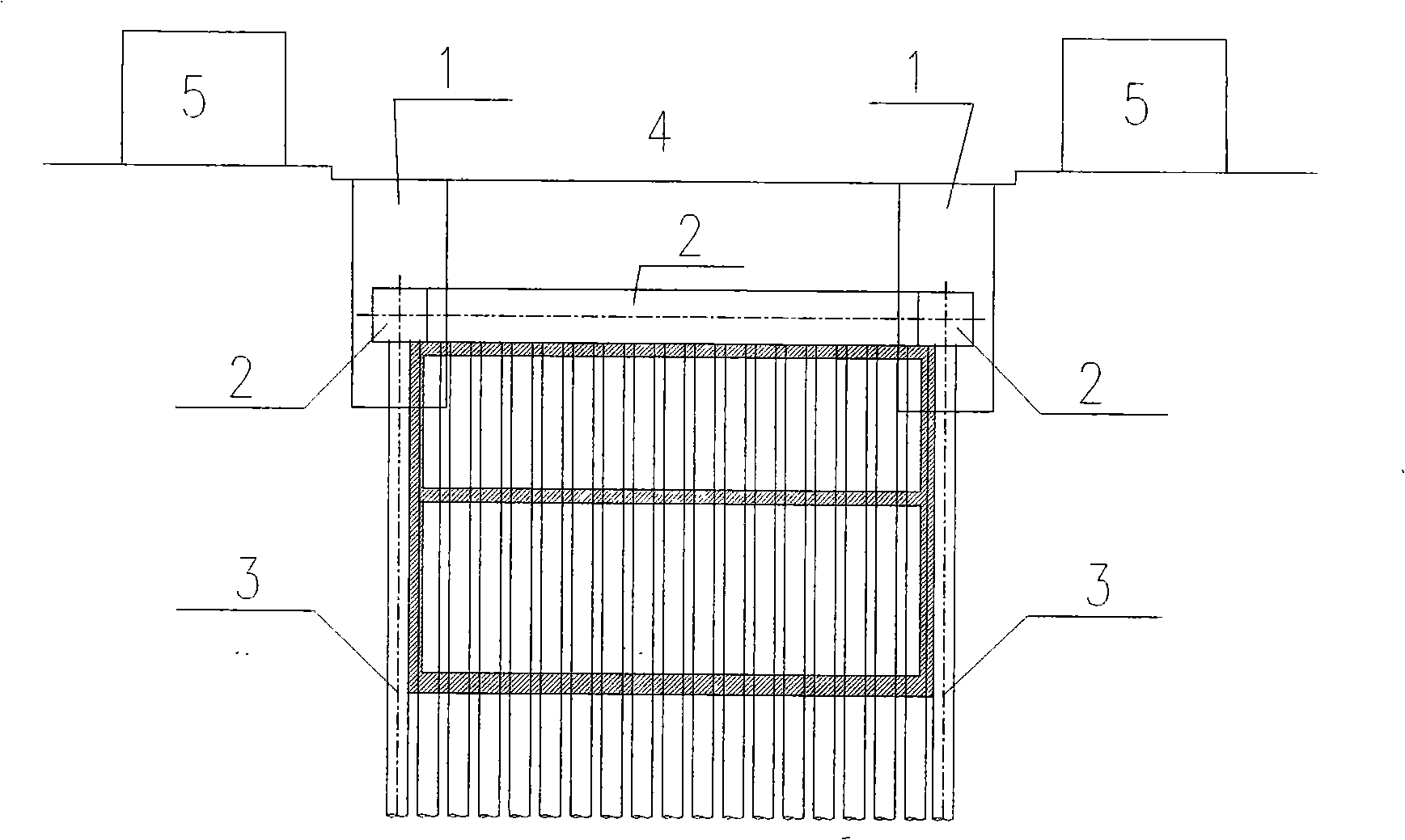

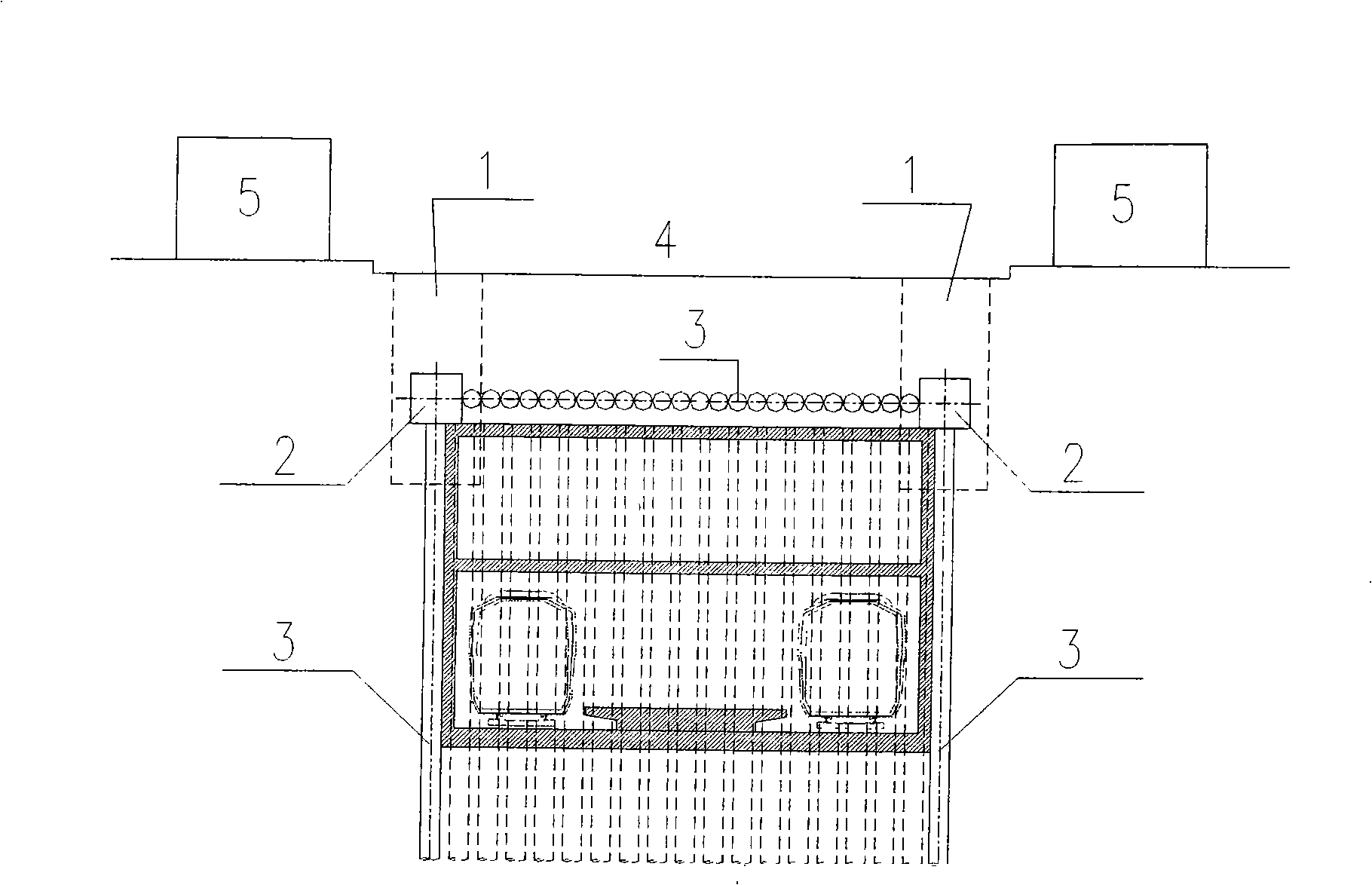

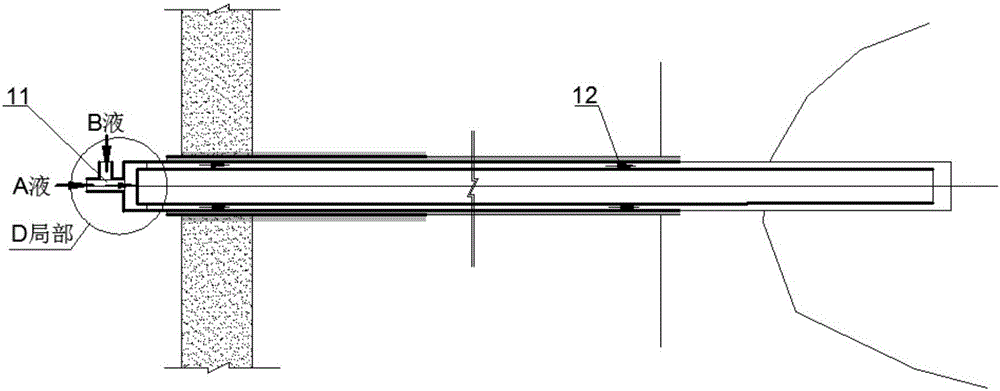

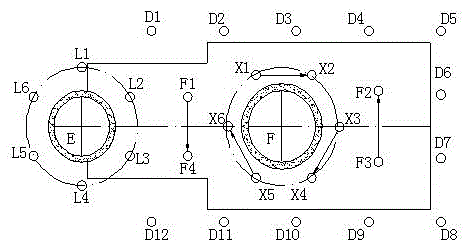

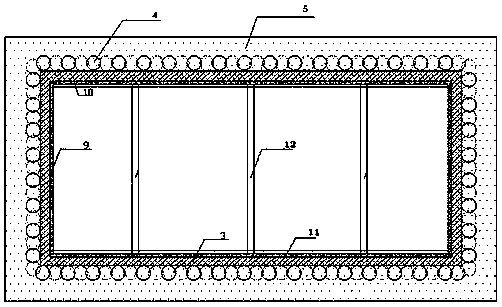

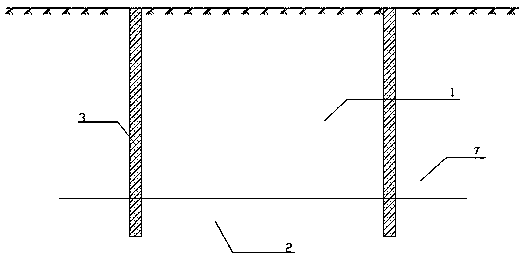

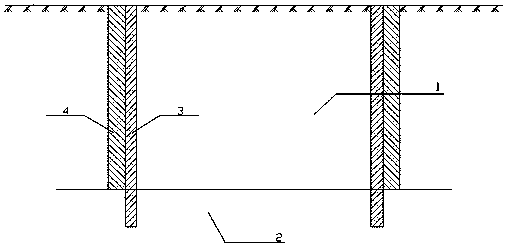

Undermining method for three-dimensional pipe-roof

ActiveCN101285385ASolve underground excavation constructionBroad engineering application prospectsUnderground chambersTunnel liningParking areaSubway station

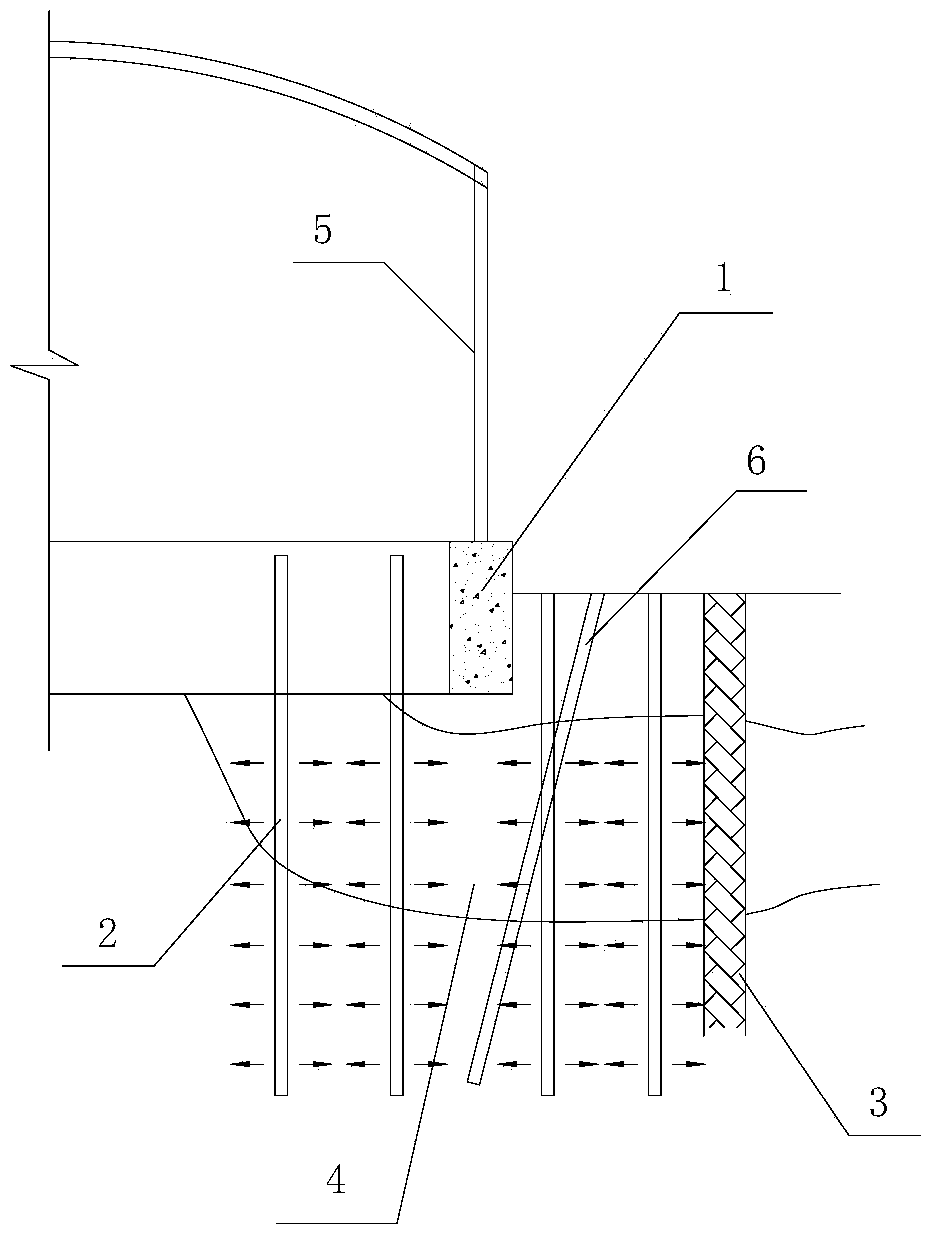

The invention discloses a three-dimensional pipe-curtain subsurface excavation method. The steps of the method are as follows: A. a vertical working well is formed at the circumference of an underground structure; B. a horizontal working channel is formed on the outer surface of the underground structure; C. a pipe roofing support is formed at the outer surface and a pipe roofing curtain is constructed inside the horizontal working channel; D. grouting and reinforcement are carried out by using pipe roofing steel pipes, and the grouting is carried out by pipe roofing to form a curtain after the pipe roofing construction inside the horizontal working channel is finished; E. digging is started; when the pipe roofing grouting curtain reaches the strength, the digging construction of soil mass inside the three-dimensional curtain is carried out; afterwards, the construction of the underground structure is carried out. The method is simple and convenient, and safe and convenient in construction. Particularly, for a large span underground structure under a crossroad, the method only digs half of one side of a certain road, thus the method can ensure that the road is unblocked in the construction process. Accordingly, the method can be widely applied to projects with roads and other buildings, etc., such as subway stations of a city, road tunnels with large span, underground parking areas with large span and down-traversing tunnels under main roads of the city.

Owner:WUHAN ZHONGJIAO TRAFFIC ENG CO LTD

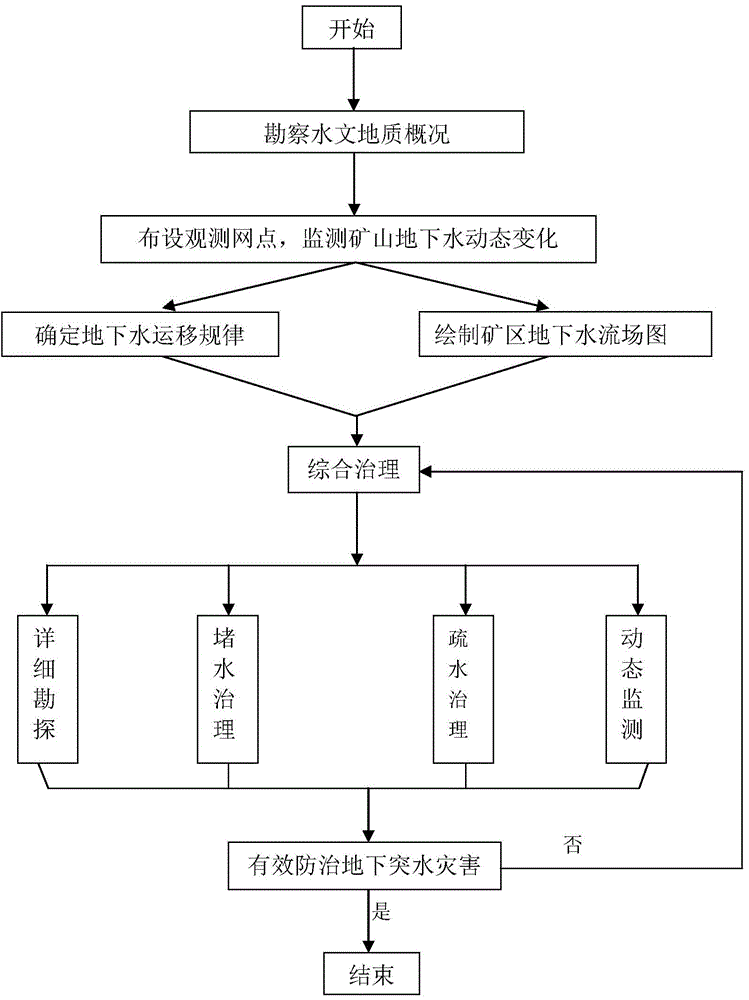

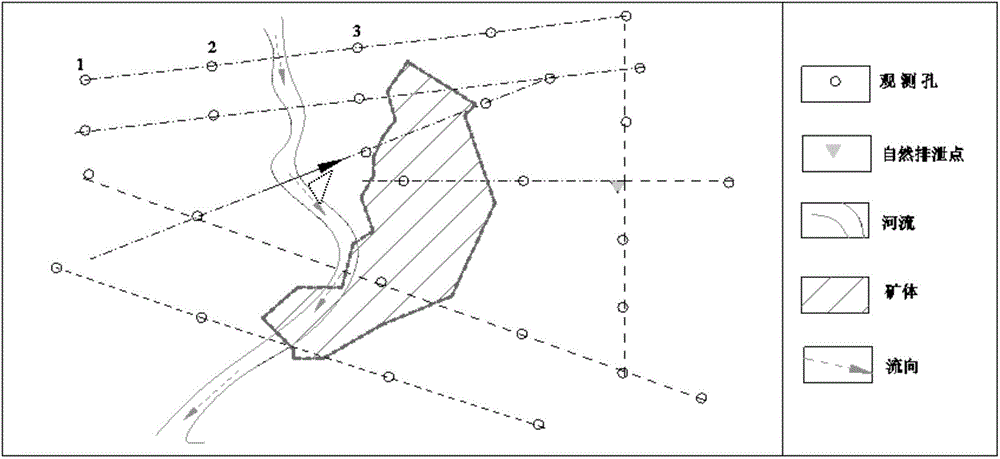

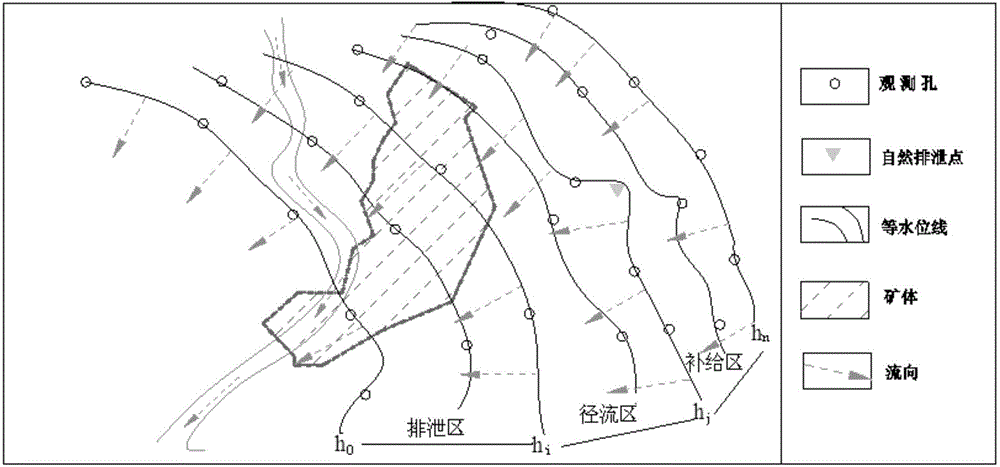

Comprehensive treatment method of mine water inrush

The invention relates to the field of controlling underground water inrush disaster for mining projects and relates to a comprehensive treatment method of mine water inrush. The method includes the steps of setting a mine hydrogeology observation network; measuring a mine underwater supply area, a mine drainage area and a mine runoff area; exploring and measuring a water guide passage and fissures of the mine underwater supply area; determining and implementing a grouting curtain blocking scheme of the mine underwater supply area; designing and implementing a drainage treatment scheme of the mine drainage area, and after implementing the grouting curtain blocking scheme, performing underwater drainage treatment in the mine drainage area; implementing a scheme for dynamic monitoring of mine underwater level and information-based dredging and blocking treatment, during underwater drainage treatment in the mine drainage area, and dynamically monitoring the underwater level in the mine runoff area to finish the scheme.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

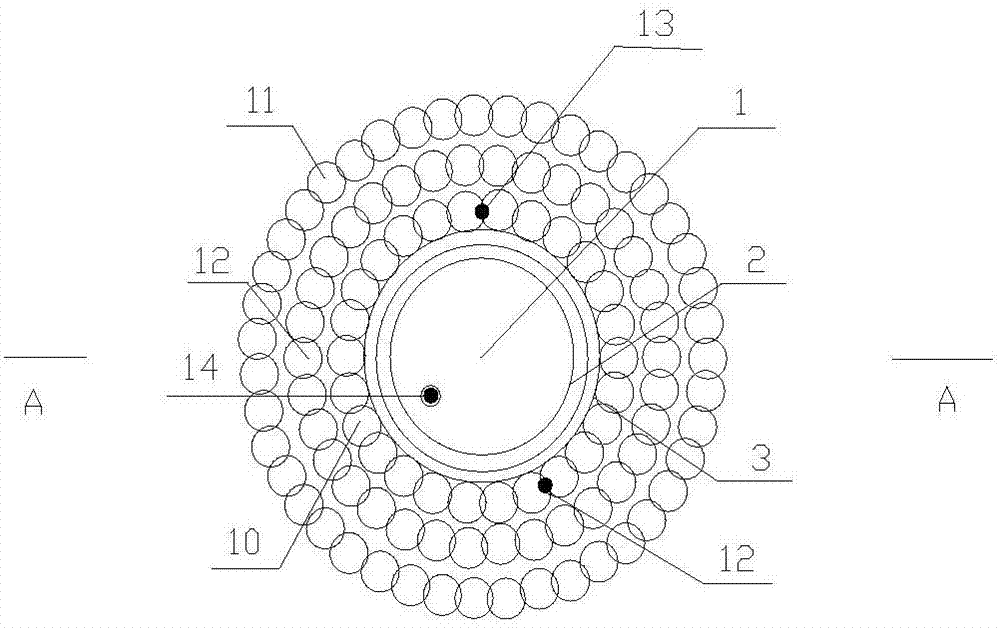

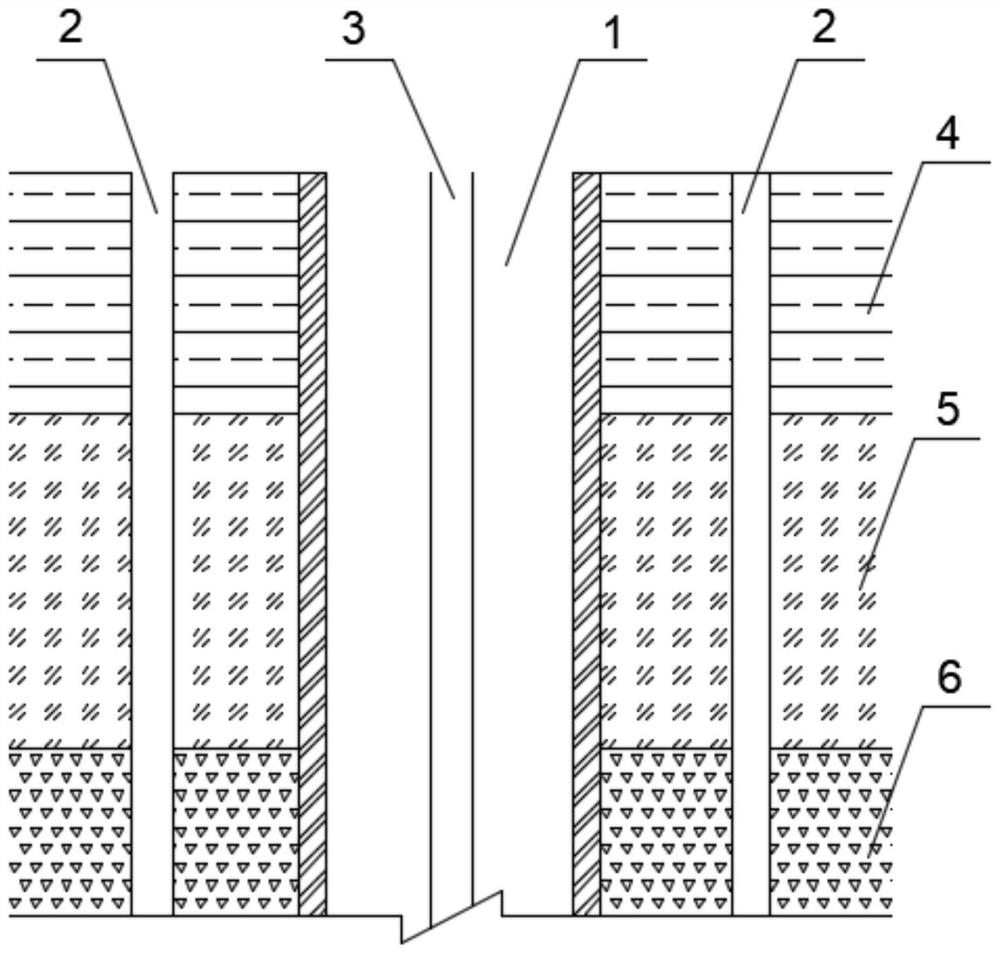

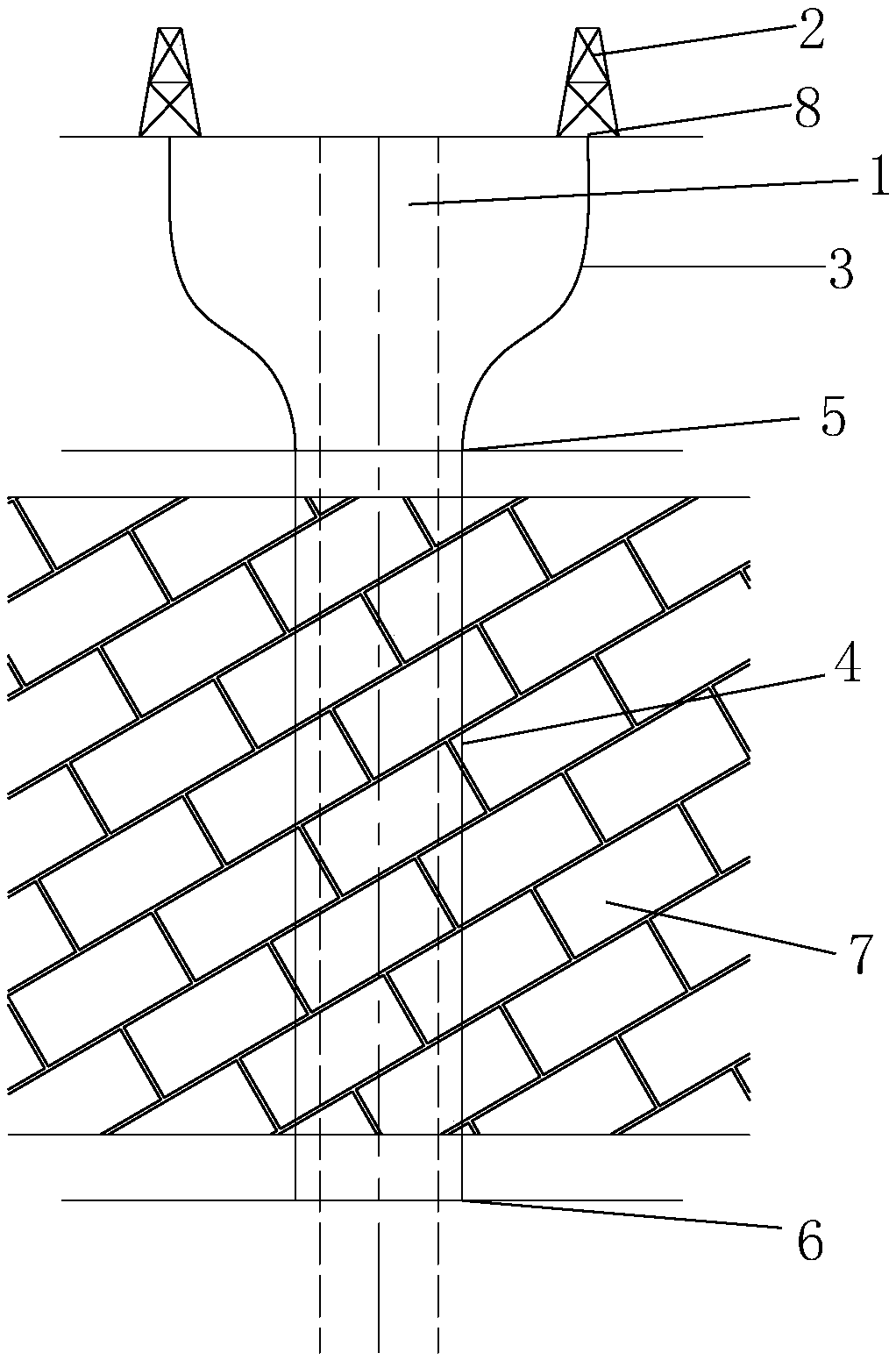

Vertical shaft wall structure in bad stratum and construction device and method

ActiveCN107246267AQuick diggingNovel ideaDirectional drillingHydro energy generationGrout curtainMechanical engineering

The invention relates to a vertical shaft wall structure in a bad stratum and belongs to mine vertical shaft construction. The vertical shaft wall structure comprises a shaft arranged in the bad stratum and is characterized in that the upper shaft collar section of a vertical shaft is provided with a high-pressure-jet-grouting curtain pile shaft wall structure, a bedrock section is provided with a positioning targeting grouting section shaft wall structure and a shaft wall, and the upper and lower shaft wall structures are concentric, identical in diameter and tightly integrally connected to protect the shaft wall; the high-pressure-jet-grouting curtain pile shaft wall structure is provided with at least three circles of annular high-pressure-jet-grouting curtain walls with sealed heads and tails on the periphery, 0.6m away from a shaft outer diameter line, of the shaft outer diameter line by using the center of the shaft as the circle center, the positioning targeting grouting section shaft wall structure is provided with at least 8 positioning targeting grouting sections, vertical to the ground, on the periphery, 2m away from the shaft outer diameter line, of the shaft outer diameter line, and the two wall structures protect the shaft wall. The vertical shaft wall structure has the advantages that the vertical shaft wall structure is novel in concept, simple, stable and reliable; the high-pressure-jet-grouting curtain walls and the positioning targeting grouting sections protect the shaft wall, bearing capacity and deformation resistance are enhanced, and a good water blocking effect is achieved; the vertical shaft wall structure is fast and convenient in construction, fast shaft construction can be achieved, cost can be saved, and mine production can be performed safely and smoothly.

Owner:MAGANG (GROUP) HOLDING CO LTD

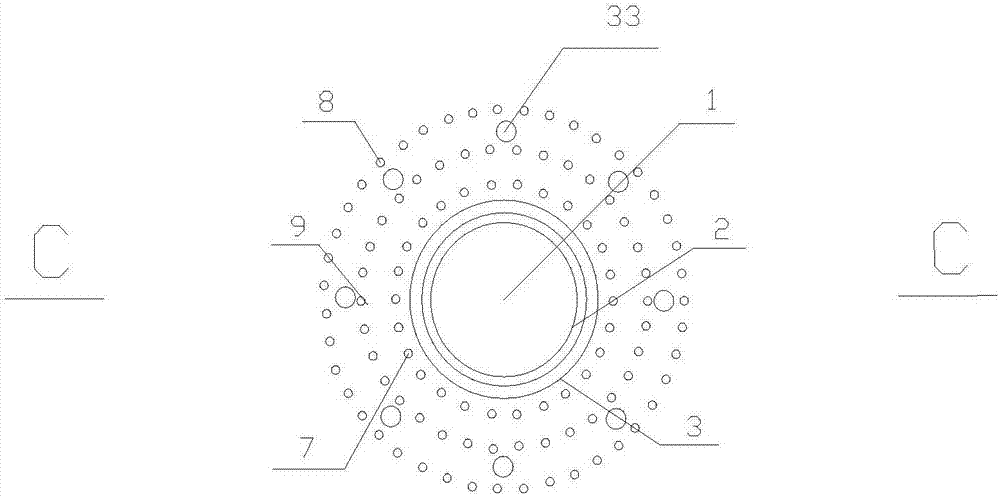

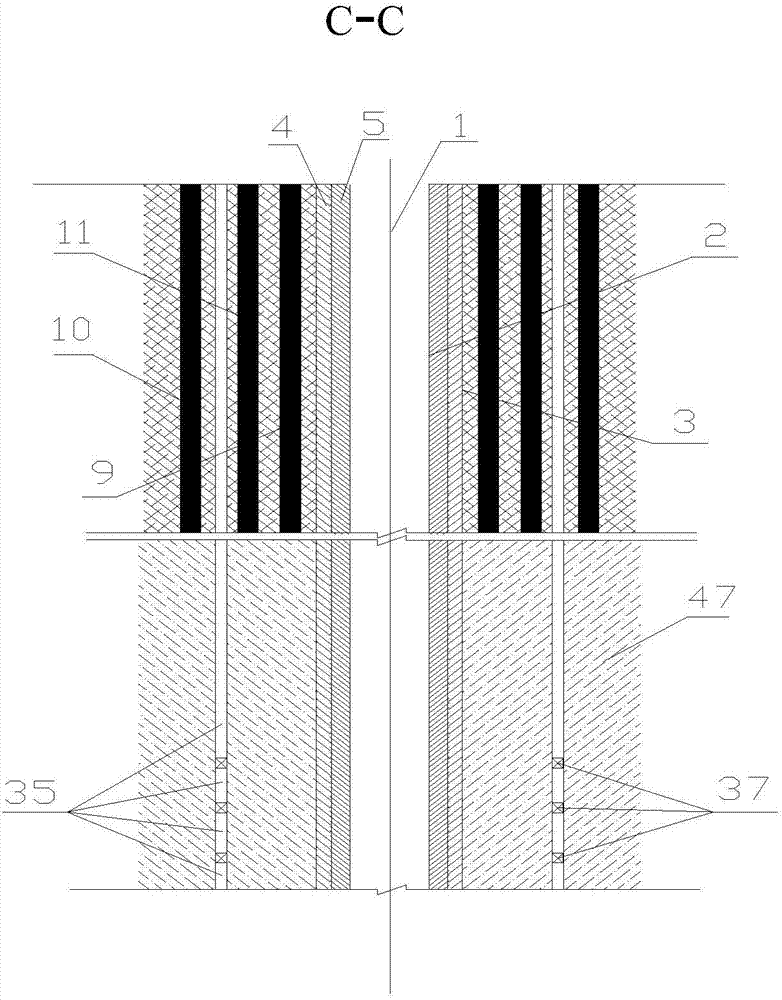

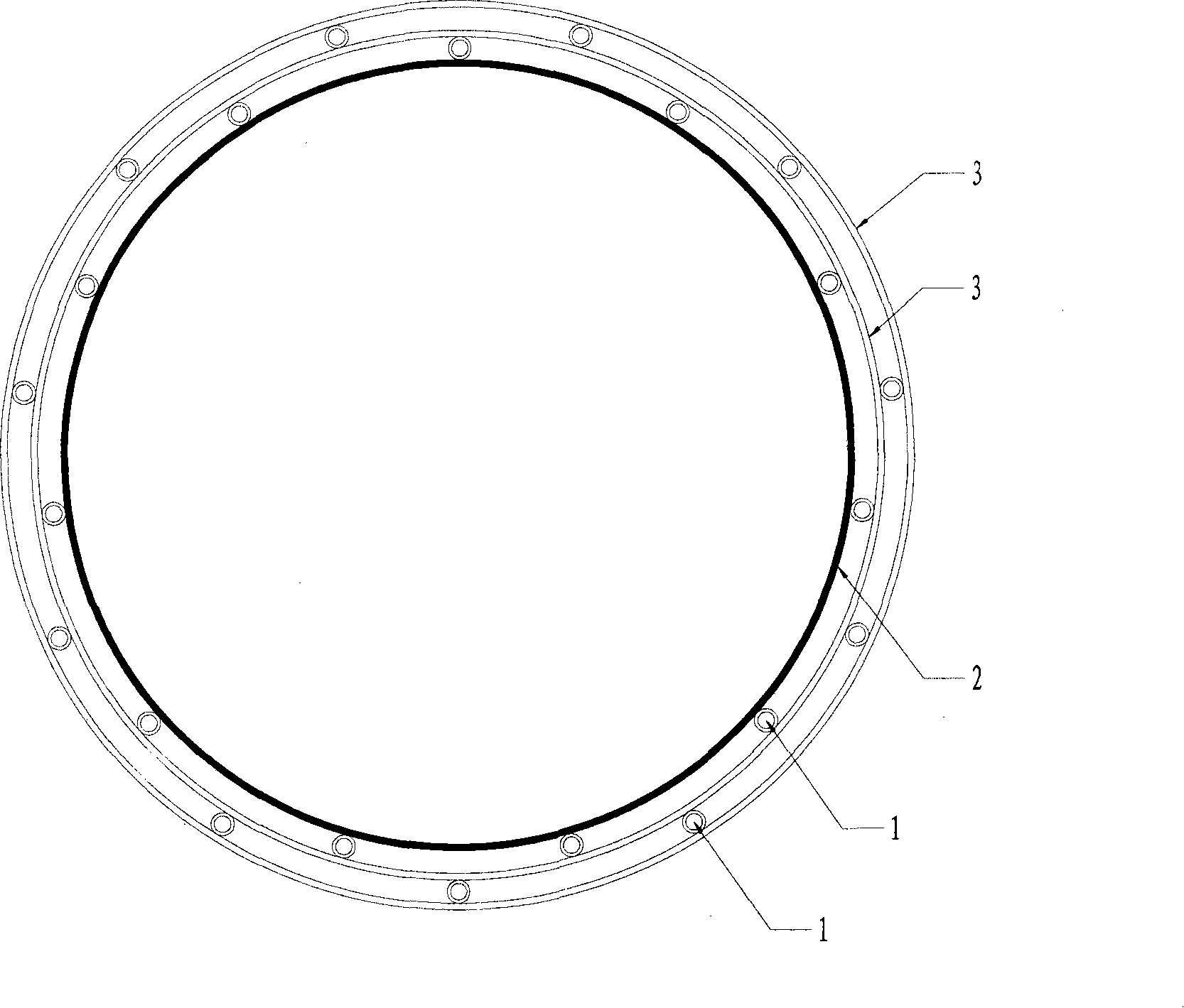

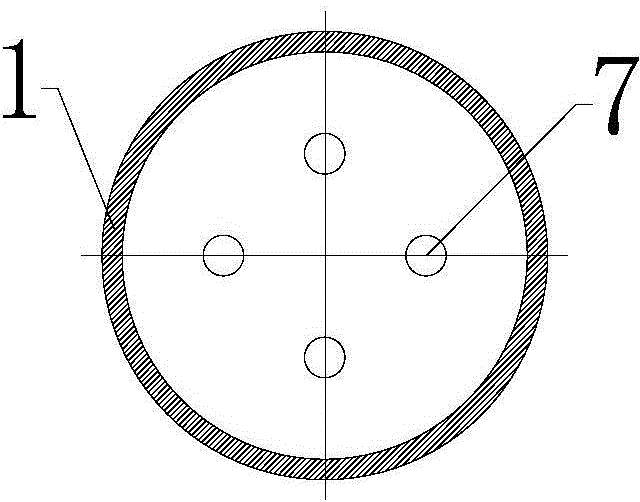

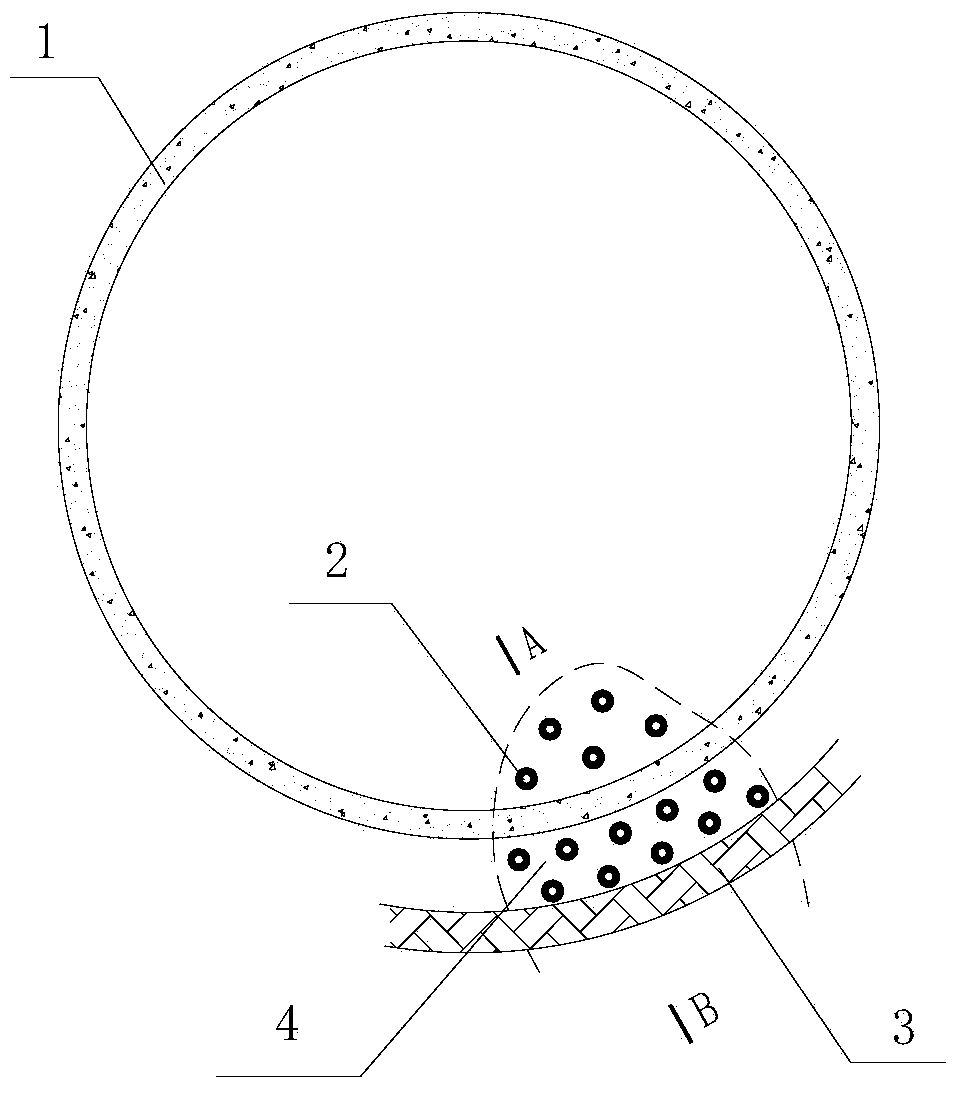

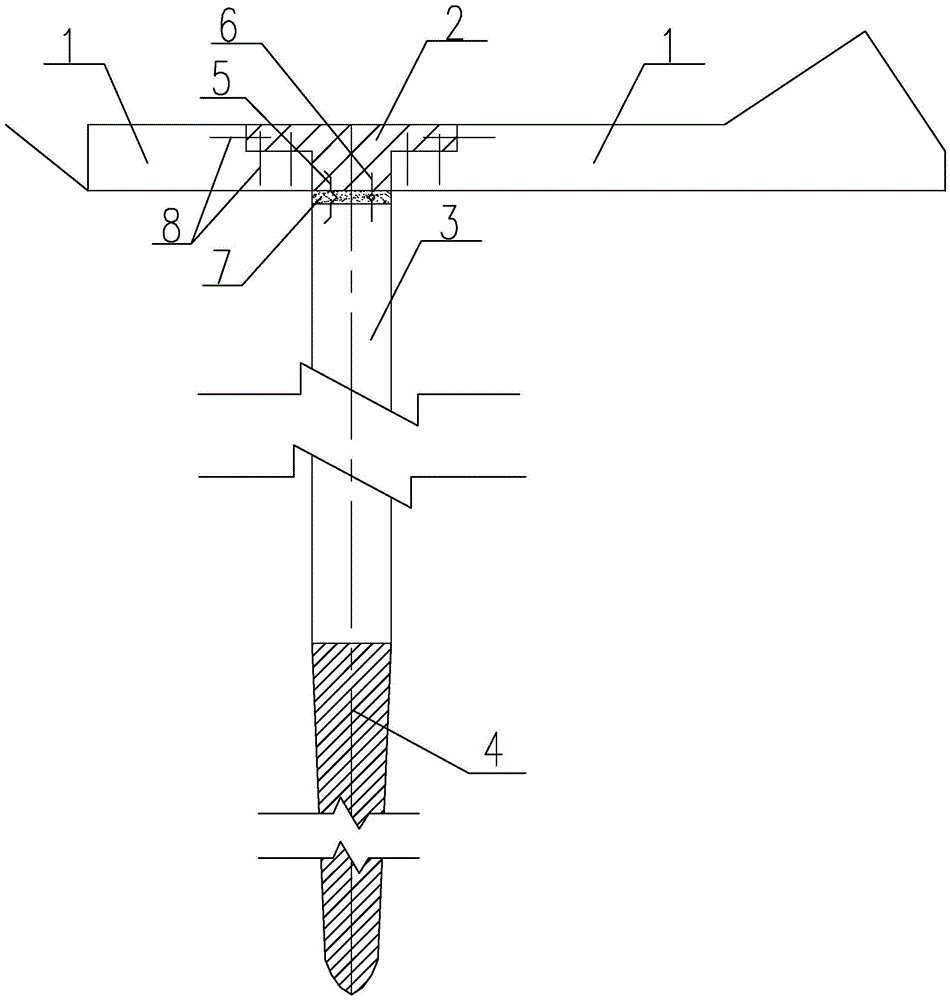

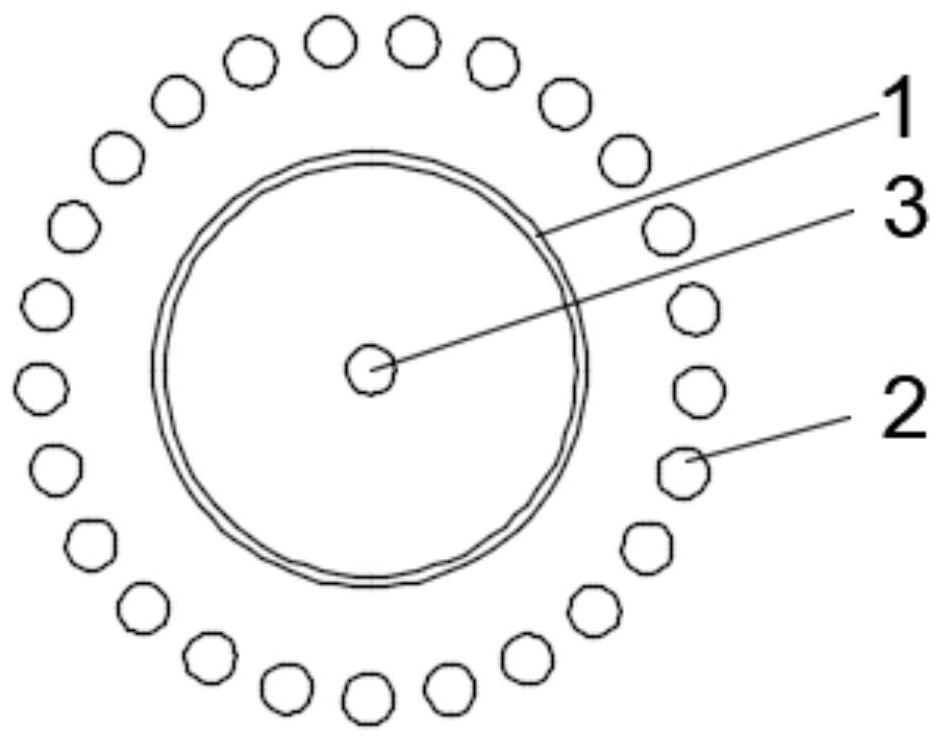

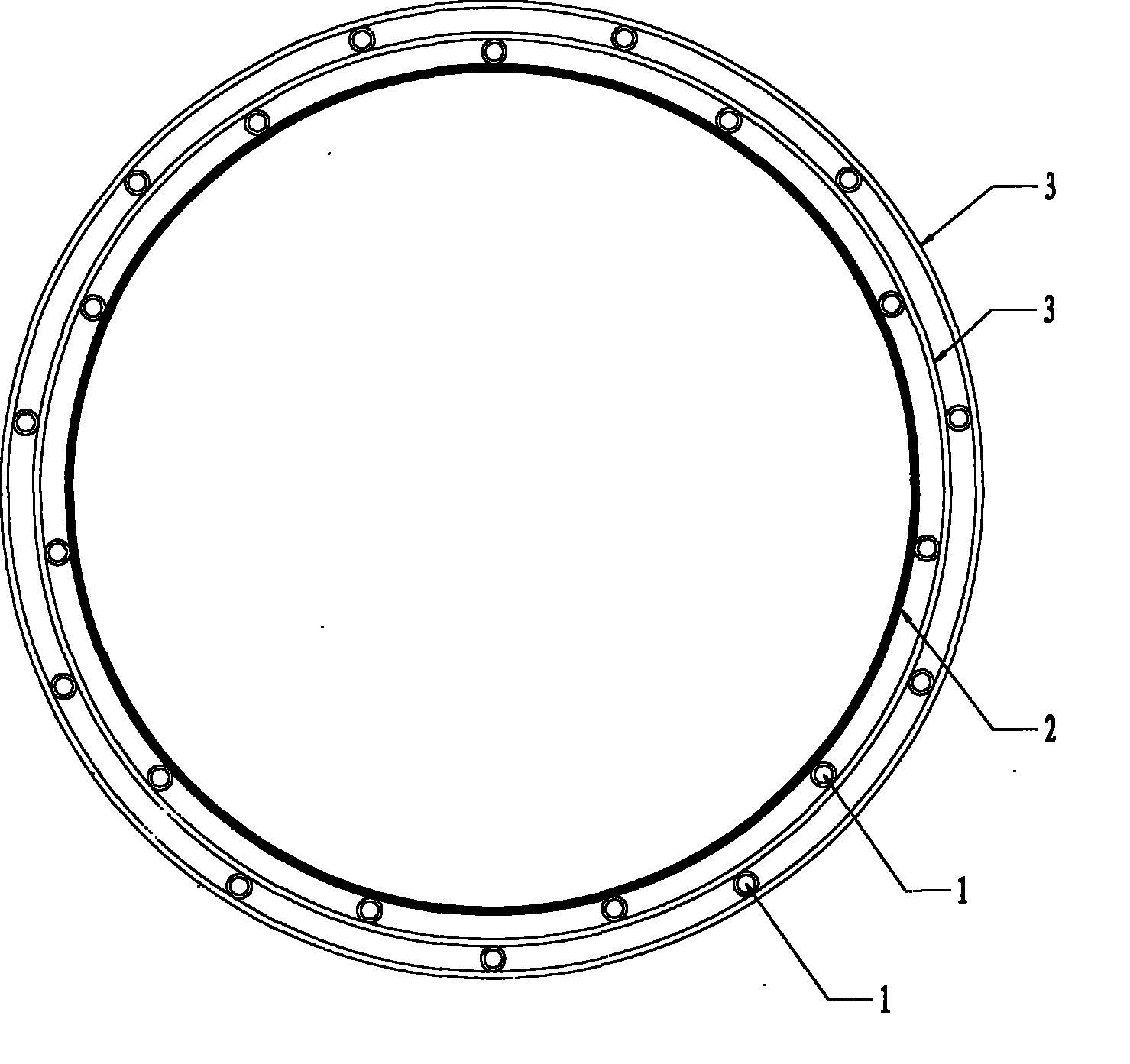

Method for preventing slurry leakage and hole collapse of large-diameter deep-borehole cast-in-situ bored pile by casting curtain method

The invention discloses a method of grout curtain to prevent mud leakage and hole collapse of the large diameter deep hole bored cast-in-place pile. A grouting locating ring is arranged on the outside of the steel casing of the bored pile. A plurality of holes are drilled along the circumference at intervals between the steel casing grouting locating ring and the grouting holes are injected with cement slurry. The slurry completely spreads and fills gaps and is fixedly connected with a loose permeable layer, which can form a high strength waterproof curtain. The method can solve the problems of the mud leakage and hole collapse of the large diameter deep hole bored cast-in-place pile. The cement slurry is injected into the loose permeable layer and is fixedly mixed with the loose permeable layer to fill gaps and form a ring of high strength stop water curtain. The invention has the advantages that plugging results are good, problems are solved completely, the problems of mud leakage and hole collapse will not happen again in subsequent construction, the construction speed is rapid, input is low, incident handling costs can be greatly reduced. Meanwhile, the method can be applied to prevent the incidents of mud leakage and hole collapse while loose permeable layers of silty sand, drift sand, pebble soil and other soil are drilled.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Guiding horizontal jet grouting pile pre-support construction method for scattered particle rock surrounding tunnel

ActiveCN102251781AEasy constructionReasonable structureUnderground chambersTunnel liningSlurryCement paste

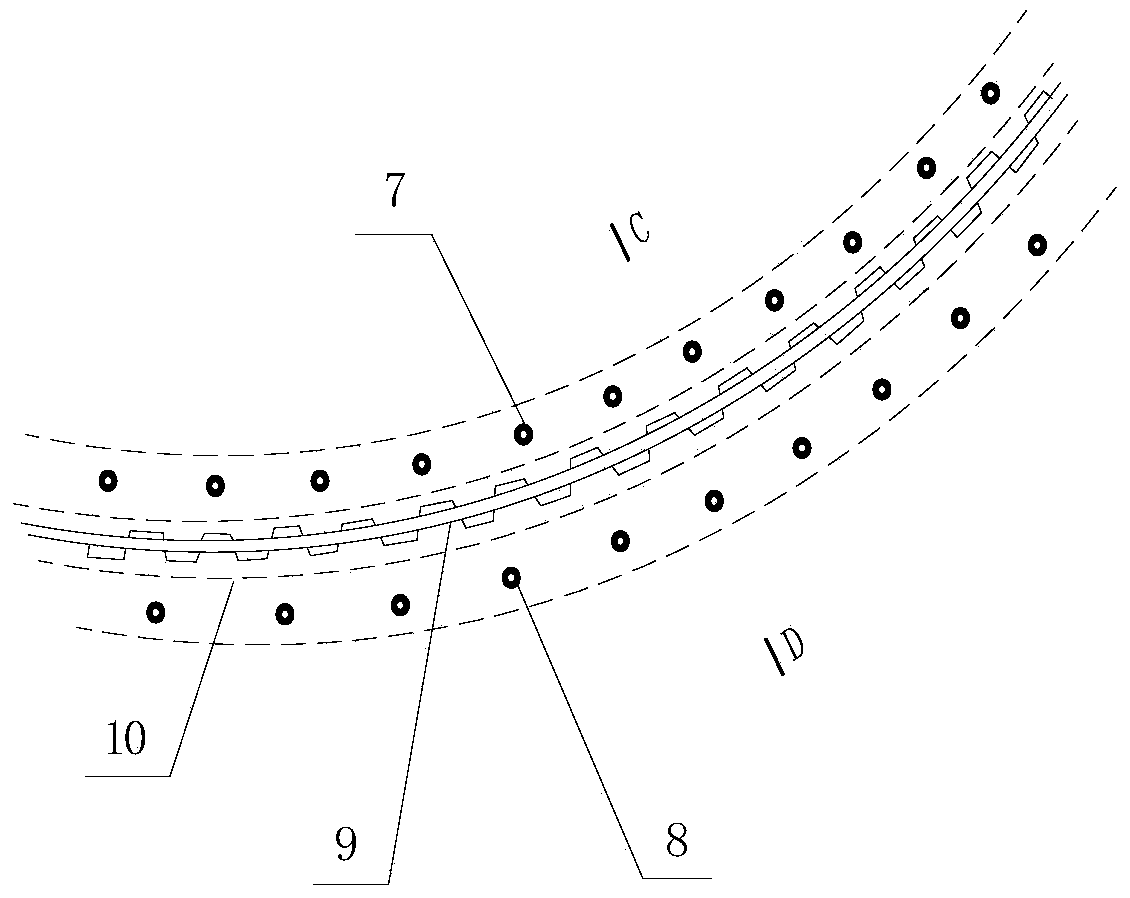

The invention discloses a guiding horizontal jet grouting pile pre-support construction method for a scattered particle rock surrounding tunnel. The method comprises the following steps of: drilling a guide hole with precision of more than 0.5 percent by adopting a horizontal directional drilling machine, retracting a drill rod by rotating after the guide hole is drilled to the design length, andspraying the prepared cement paste to the soil through the drill rod under the pressure of 35 to 40MPa while retracting the drill rod. Jet stream cuts the soil with huge impact force, soil particles are forcibly stirred and mixed with the cement paste, and a horizontal cylindrical cement soil solidified body, namely a horizontal jet grouting pile, is formed after cementing and hardening. After the jet grouting piles are mutually engaged, a closed horizontal jet grouting curtain body for forming an ultra pre-support is formed at the outer side of an arch of the tunnel in a concentric circle form, so that collapse caused by sand leakage is effectively prevented; and the cost is low, and the construction speed is greatly quickened when the safety is ensured.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

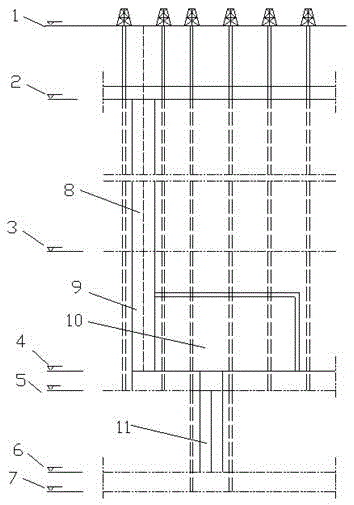

Curtain grouting process suitable for water-rich mine underground mining water plugging

ActiveCN103967507AStrong targetingLess ineffective drillingUnderground chambersTunnel liningKarstHigh pressure

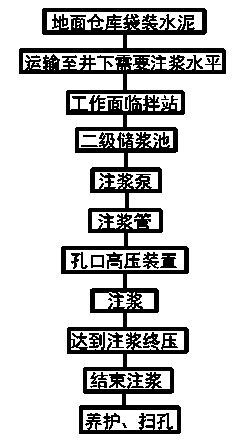

The invention discloses a curtain grouting process suitable for water-rich mine underground mining water plugging. According to the arrangement method of grouting holes, six grouting holes facing upwards by 5 degrees, six grouting holes facing upwards by 15 degrees and six grouting holes facing upwards by 25 degrees are formed in each chamber, the grouting holes facing upwards by 5 degrees, the six grouting holes facing upwards by 15 degrees and the six grouting holes facing upwards by 25 degrees are evenly distributed in the plane in a 60-degree staggered mode, and grouting holes facing downwards by -5 degrees, grouting holes facing downward by -30 degrees and grouting holes facing downwards by -60 degrees are formed outward in the chambers at the ends. According to the grouting process, bagged cement in a ground warehouse is transported to underground positions where grouting and leveling are needed, grouting is conducted through a working face temporary stirring station, a two-level pulp storage pond, a grouting pump, a grouting pipe and a hole opening high pressure device, grouting is completed after the designed final grouting pressure is reached, and the whole curtain grouting work is completed after further maintenance and hole cleaning. A grouting curtain with a high water plugging rate is set up underground for roof karst cracks, the water isolation function and the reinforcing function can be achieved, an ore body is safely and efficiently freed under protection of the grouting curtain, technical guarantees are provided for safe and efficient mining of the mine, project input is small, and the construction period is short.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

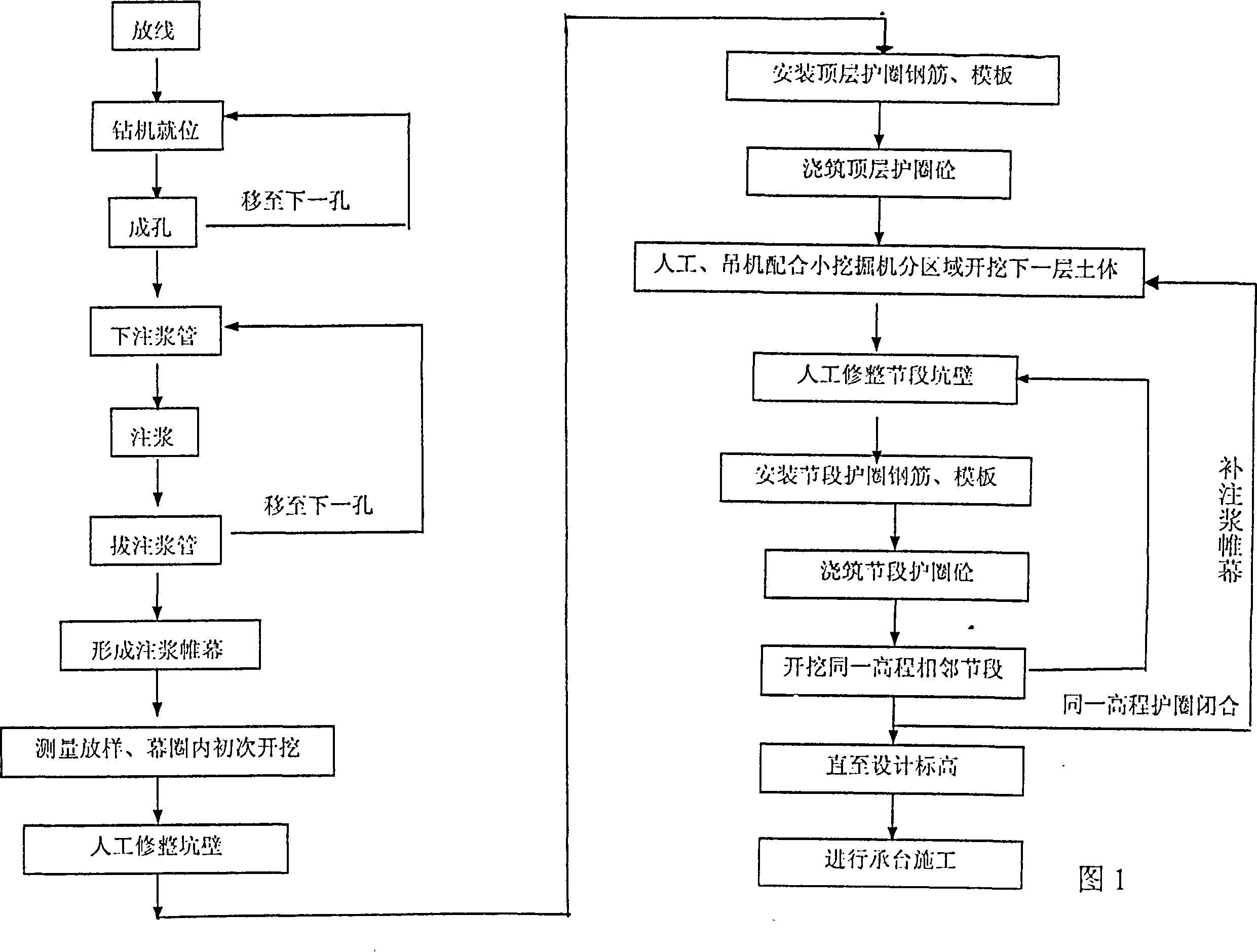

Construction method for grouting curtain combined with steel reinforced concrete guard ring

InactiveCN101200897AReduce thicknessImprove anti-seepage effectSoil preservationReinforced concreteCofferdam

The present invention relates to a construction method by which grout curtains are combined with reinforced concrete cages. The construction of a grout curtain is carried out by an engineering driller and a grouter as the construction of drilled piles is carried out, a foundation ditch is dug layer by layer while the reinforced concrete cages are constructed, the soil body on the periphery of a cofferdam is concreted, stepped excavation and stepped shoring are carried out till the bottom of the foundation ditch, and after the construction of the drilled piles is finished, the construction of a bearing platform is carried out. The curtain formed by grouting is waterproof, the reinforced concrete cages are constructed while the bearing platform foundation ditch is dug, so the soil pressure, water pressure and unbalanced construction load generated by the excavation of the foundation ditch are resisted. The construction of the grout curtain can be carried out as the construction of drilled piles is carried out, the foundation ditch is dug layer by layer while the reinforced concrete cages are constructed, consequently, the construction period is effectively shortened and the construction equipment which is put into use is reduced. The construction by reinforced concrete caissons, steel cofferdams and steel plate piles is difficult, the present invention can easily resolve the problem, and meanwhile, according to the geological conditions, the construction of the bearing platform can apply non-bottom sealing construction, thus saving the cost.

Owner:THE 2ND ENG CO LTD MBEC

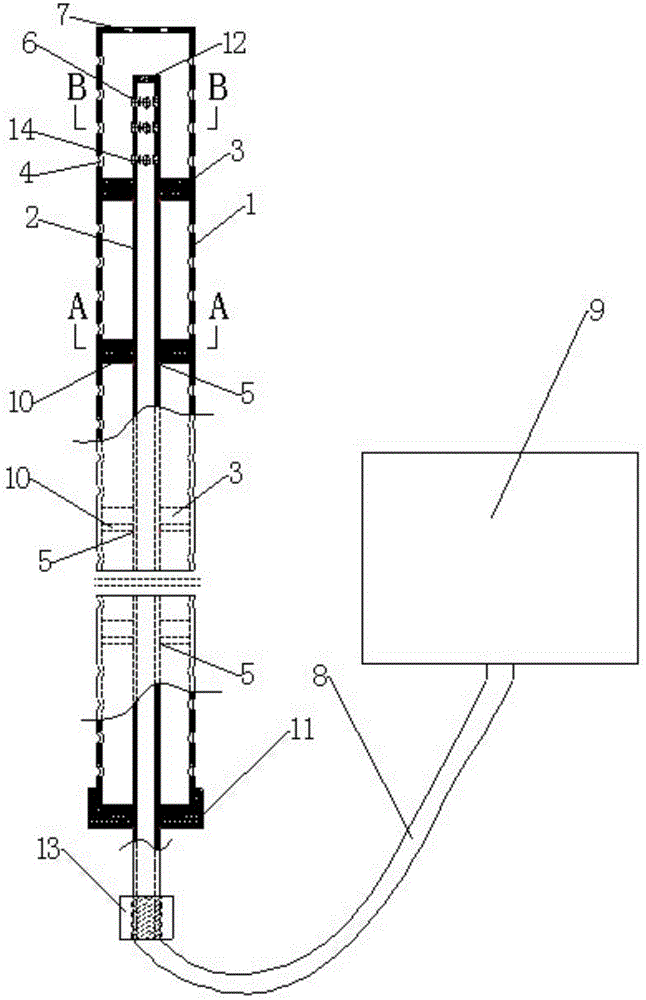

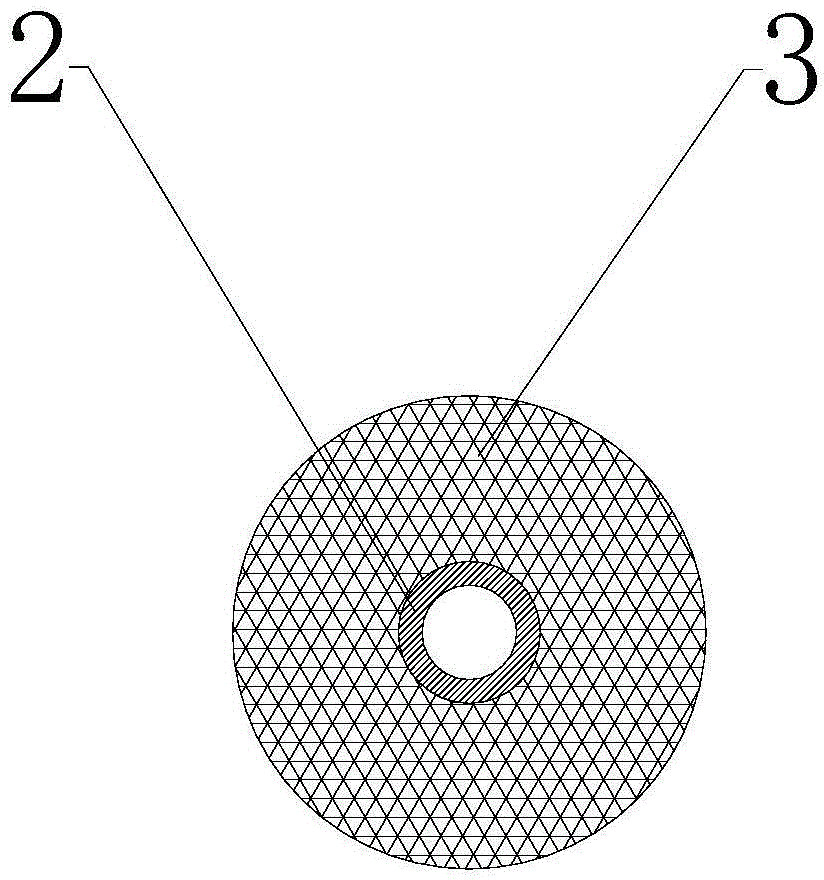

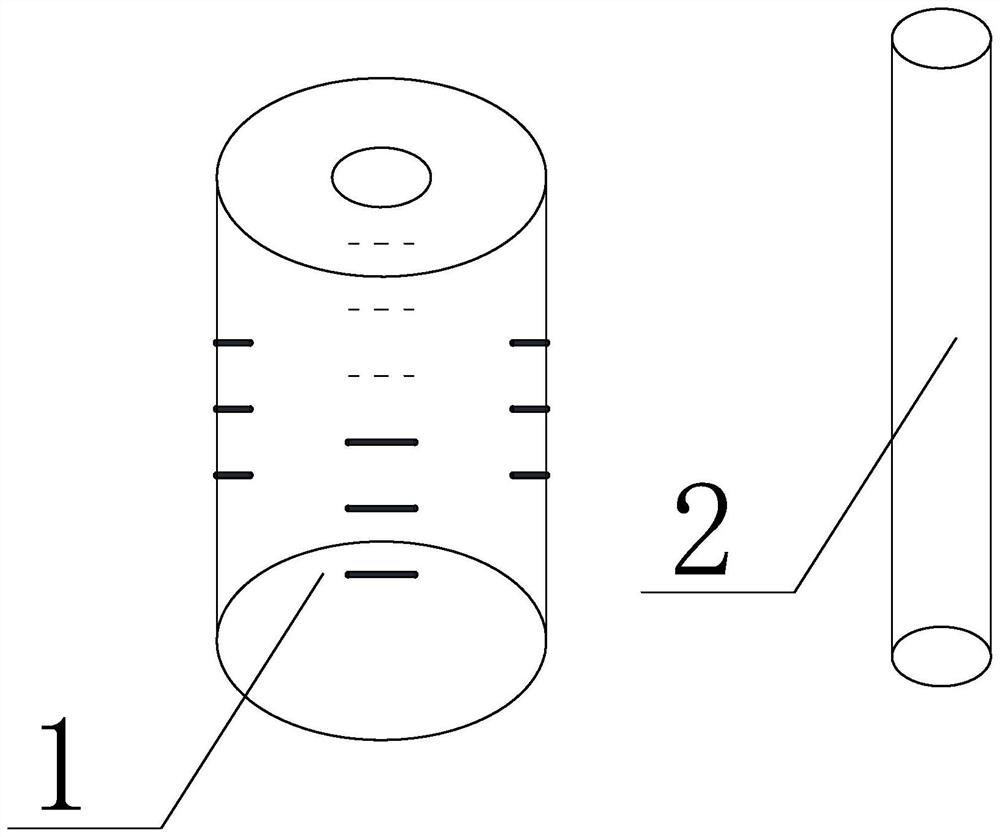

Grouting pipe for miscellaneous fill stratum and construction method

InactiveCN104975594AEffective reinforcementEasy to processSoil preservationArchitectural engineeringSlurry

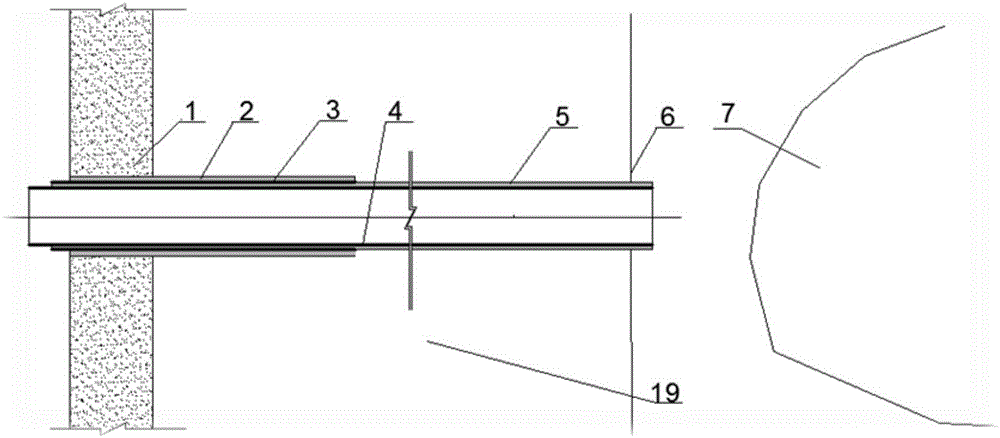

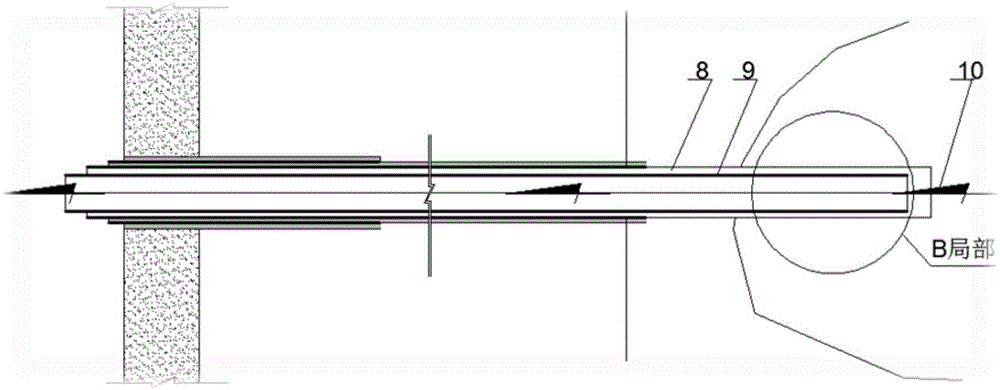

Disclosed are a grouting pipe for a miscellaneous fill stratum and a construction method. The grouting pipe is mainly composed of an external grouting pipe body, an internal grouting pipe body, a slurry stop plug, a segment spacer ring and a sealing plug, wherein one end of the external grouting pipe body and the surface of the pipe body are provided with grouting holes; the internal grouting pipe body is fixed to the segment spacer ring through the slurry stop plug; a grouting hole is formed in the top end of the internal grouting pipe body, and grouting holes are evenly distributed around one end of the pipe body; the bottom end of the internal grouting pipe body is connected with a grouting machine through a mortar conveying pipe; the segment spacer ring is fixed to the inner wall of the external grouting pipe body. The grouting pipe has the characteristics of low pressure, high frequency, segmentation and quick grouting, thereby accurately controlling the grouting pressure and grouting parameters for the complex situations of miscellaneous fill stratums containing large gravel or building rubbish; a grouting curtain within a certain range is formed in the stratum, greening vegetation over the stratum is not affected, and the purpose of effectively reinforcing the miscellaneous fill stratum is achieved. The grouting pipe is convenient to use, conducts grouting quickly and can be widely applied to miscellaneous fill stratums needing reinforcing.

Owner:CHINA UNIV OF MINING & TECH

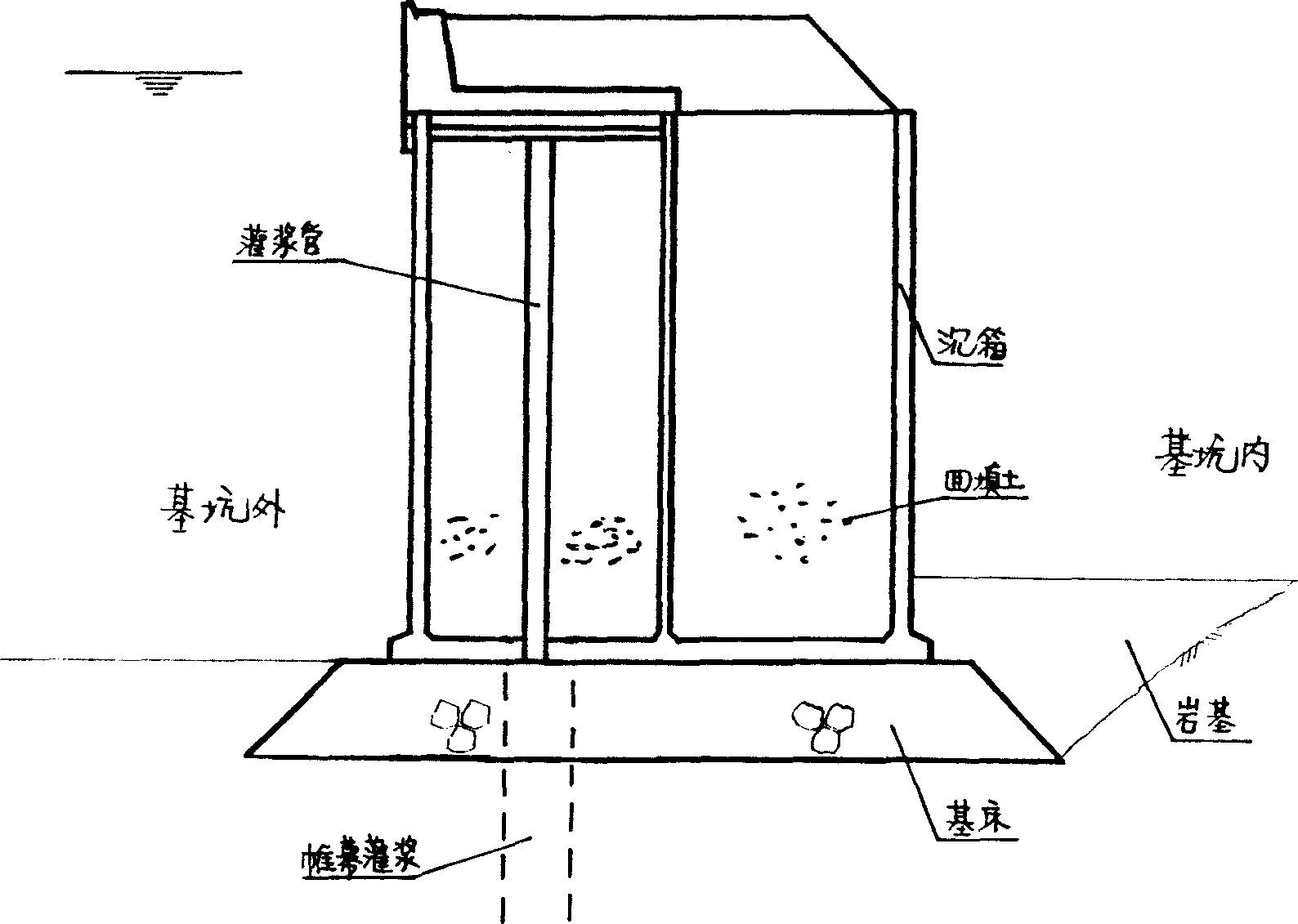

Caisson cofferdam based on prepacked foundation bed

The present invention discloses one kind of caisson coffer based on foundation bed grouting and its construction process. The caisson coffer is constructed through the following steps: digging foundation ditch and desilting, filling rubble and leveling, prefabricating and sinking caisson, grouting foundation bed, grouting curtain, etc. The present invention has the advantages of high stability, easy construction, saving in material, short construction period, less environmental influences, small coffer demolishing workload and low engineering cost.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

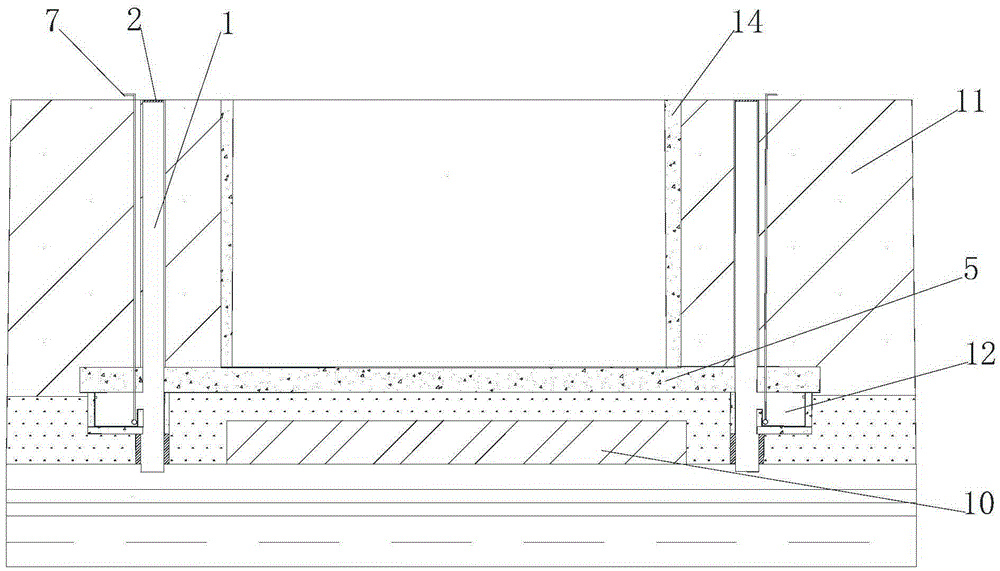

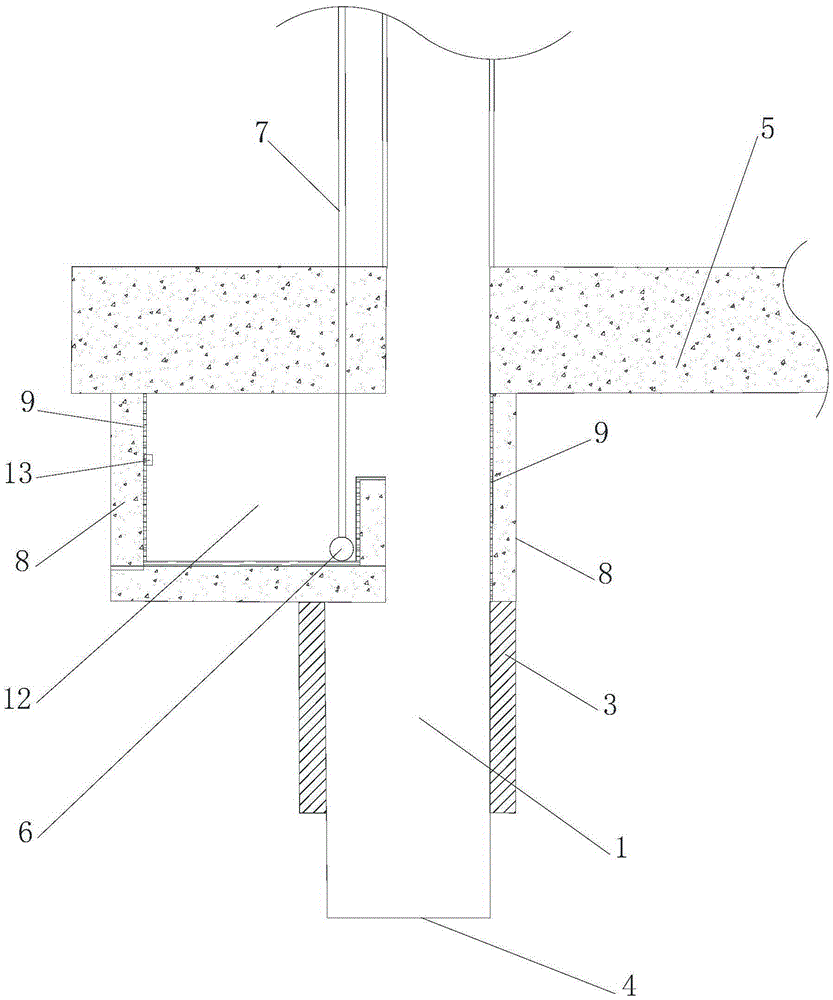

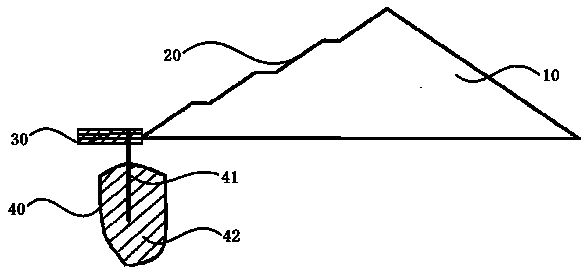

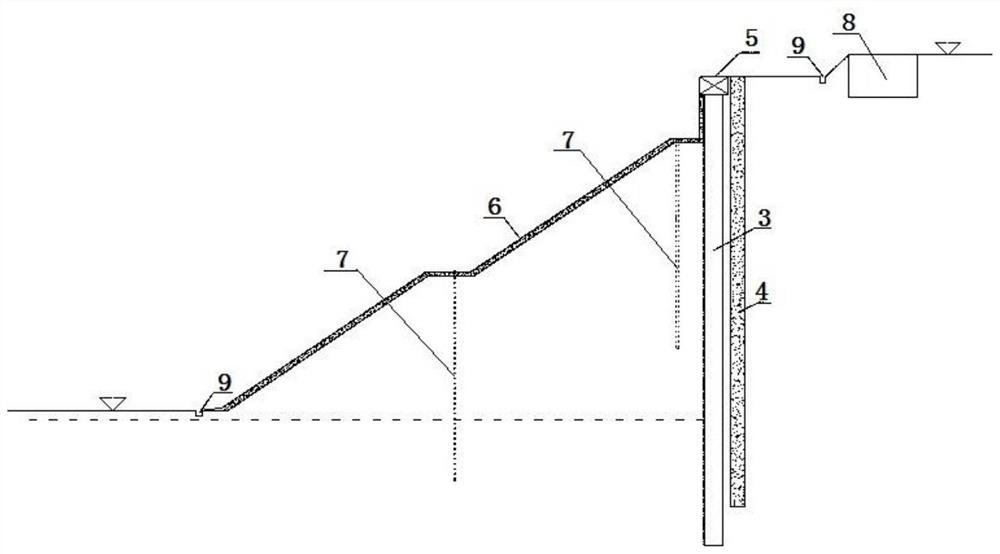

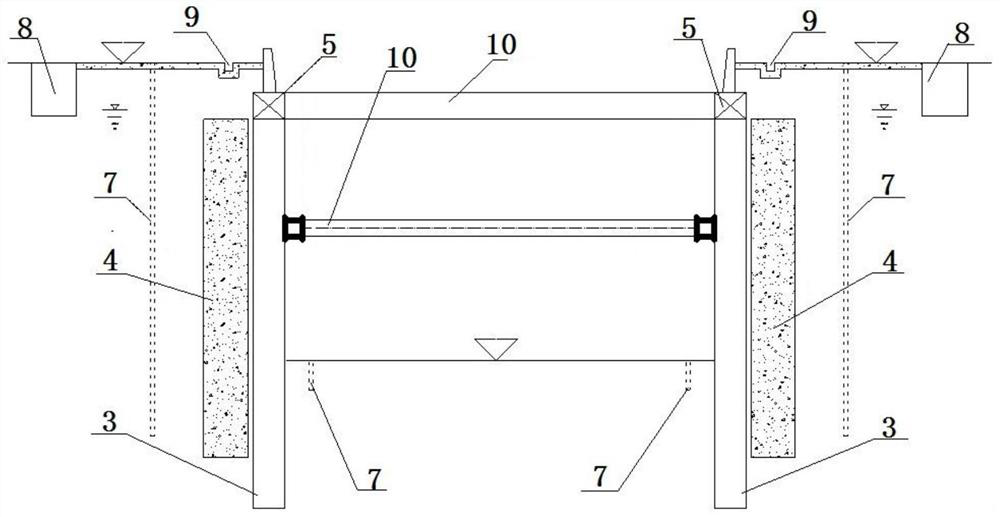

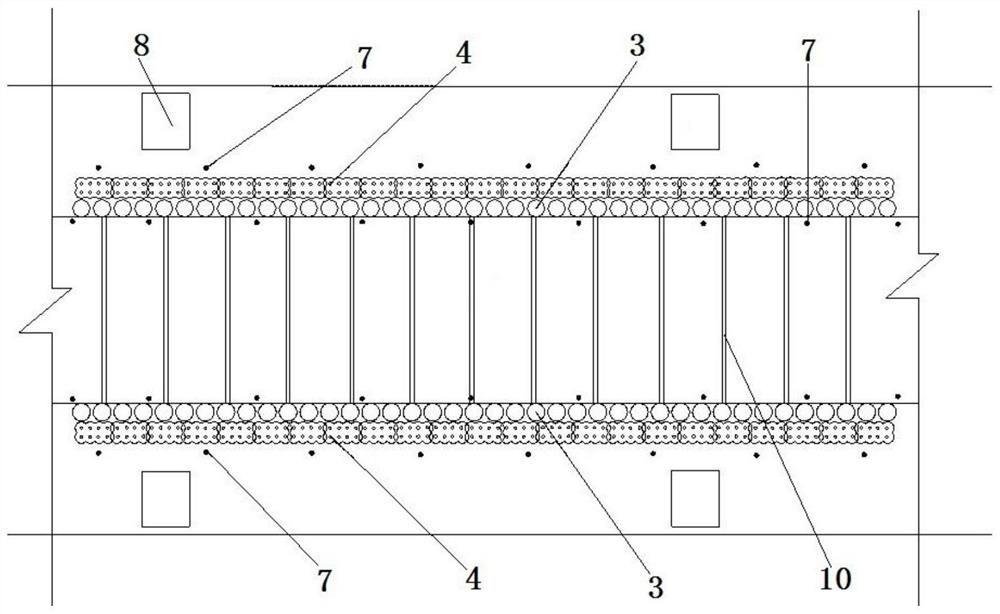

Basement anti-floating system based on low horizontal grout curtain and depressurization through water drawing

The invention relates to a basement anti-floating system based on a low horizontal grout curtain and depressurization through water drawing. The basement anti-floating system comprises a dewatering well structure and the horizontal grout curtain. The dewatering well structure comprises a dewatering well, a water storing pool, a water pump and a water level sensor. The dewatering well is arranged on a basement bottom plate on the periphery of a basement. The well opening of the dewatering well is directly connected to the ground. The bottom of the dewatering well penetrates into the position below the basement bottom plate. The water storing pool is arranged under the basement bottom plate and communicated with the dewatering well. The water pump and the water level sensor are arranged in the water storing pool. The water level sensor is connected with the water pump. The water level sensor is arranged under the basement bottom plate Compared with the prior art, the negativity and passivity of frequently-used methods for resisting the underground water buoyance at present are overcome, and the effect of basement anti-floating is achieved in two aspects that the buoyance of the underground water is reduced and the upper resistance for balancing the underground water buoyance is increased; the basement anti-floating system is suitable for regions where the requirement for the environment is high, the basement buried depth is large and the underground water level is high, and has good market value.

Owner:TONGJI UNIV

Construction method for rapidly conducting impervious curtain grouting in karst pipeline leakage area

The invention discloses a construction method for rapidly conducting impervious curtain grouting in a karst pipeline leakage area. The method comprises the following steps of arranging conventional grouting holes, arranging encrypting holes, arranging detection holes, expanding holes, pouring aggregate and conducting grouting. According to the method, the type of the grouting area is judged firstly according to the conventional grouting holes, then the encrypting holes and the detection holes are respectively formed, so that the upstream direction and the downstream direction of a karst pipeline and the distribution range on the grouting axis are judged, and due to the fact that the aperture of the grouting holes is adjusted, backfilling is carried out on the dry aggregate , and in the pouring process, cement mortar is intermittently poured so that the effect of forming a curtain grouting curtain body can be achieved. Compared with a traditional curtain grouting method, the method has the advantages of being few in consumable material, small in work amount and short in work hour, the construction quality and the construction progress can be greatly improved, and the engineering investment can be effectively controlled.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Impermeable water stopping structure for hydraulic engineering

ActiveCN103628451APrevent penetrationAvoid scourMarine site engineeringStructural engineeringHydraulic engineering

The invention relates to an impermeable water stopping structure for hydraulic engineering. The impermeable water stopping structure comprises a dam body. One side of the water stopping face of the dam body is provided with a step-shaped dam body impermeable layer extending from the dam top to the dam bottom. A dam foundation impermeable layer is arranged in a dam foundation of the bottom of the dam body. An impermeable connecting layer is arranged between the dam foundation impermeable layer and the step-shaped dam body impermeable layer. The dam foundation impermeable layer is of a combined structure comprising a concrete impermeable wall and a grouting curtain. One side of the water stopping face of the dam body is provided with the step-shaped dam body impermeable layer extending from the dam top to the dam bottom, and therefore permeating, washing and wearing of the surface of the dam body from water can be effectively prevented. As the dam foundation impermeable layer is arranged in the dam foundation, the impermeable water stopping structure can effectively prevent seepage of water in a dam, and therefore the impermeability and the durability of the whole dam and the foundation can be ensured.

Owner:日照市三联调水有限公司

Wide-area underwater coal rock pressure-bearing micro-blasting grouting and water blocking method

ActiveCN106761852AIncrease pressure relief spaceIncreased blast energy rangeUnderground chambersTunnel liningWide areaDynamite

The invention discloses a wide-area underwater coal rock pressure-bearing micro-blasting grouting and water blocking method. According to the wide-area underwater coal rock pressure-bearing micro-blasting grouting and water blocking method, a plurality of groups of drill holes are formed in coal rocks, and the deep-hole pressure-bearing micro-blasting technology is applied, so that on the one hand, the pressure relief and crack increasing space inside the coal rocks can be effective enlarged, and on the other hand, the efficient and uniform transmission characteristics of solid-liquid coupling explosion propagation mediums on the loaded circumference inside the holes can be given full play of, the violent dynamic loading effects of dynamite explosion can be reduced, the pressure relief and crack increasing range of the coal rock can be enlarged, large-space and all-around penetration of main and auxiliary water conduction fractures inside coal can be fully achieved, and a large-range fracture borehole structure can be formed; subsequent high-pressure grouting and blocking operations can facilitate comprehensive blocking of the main and auxiliary water conduction fractures inside the coal rocks to form a wide-area grouting curtain and to block surrounding rock water conduction fracture channels at a large area, so that significant water blocking effects can be achieved, and static rock breaking crack increasing under the dynamic loading effects of in-hole dynamite explosion and comprehensive blocking of surrounding rock wide-area water conduction fractures can be achieved.

Owner:CHINA UNIV OF MINING & TECH

Local foundation settlement reinforcement method for steel storage tank ring wall foundation

ActiveCN103643705AProblems Constraining and Reducing Horizontal Lateral DeformationImprove the defect of weak lateral restraintFoundation engineeringStructural engineeringGrout curtain

The invention relates to a local foundation settlement reinforcement method for a steel storage tank ring wall foundation, and mainly solves the problems that the grouting range is not easy to control and lateral restraint of a grouting curtain for a reinforced soil body is weak in the prior art. The local foundation settlement reinforcement method for the steel storage tank ring wall foundation comprises the steps as follows: firstly, the range and the depth of a local foundation settlement area of the steel storage tank ring wall foundation are determined, then a groove is formed in the position with a distance more than 2 m away from the outer side of the steel storage tank ring wall foundation, so that the grouting curtain is arranged, compaction grouting holes are formed in an area between the grouting curtain and the ring wall foundation as well as the local foundation settlement area, and the steel storage tank foundation is reinforced; and the grouting curtain consists of at least one flexible reticular grid layer formed by weaving a hard material and the compaction grouting holes, and one row of compaction grouting holes is formed in each of the left and right of the grid layer. With the adoption of the technical scheme for forming the grouting curtain, the problem is solved very well, and the method is suitable for reinforcing local foundation settlement of the steel storage tank ring wall foundation.

Owner:SINOPEC SHANGHAI ENG +1

Process for safely constructing release hole outside grouting curtain of tunnel

The invention provides a method for safely constructing a release hole outside a grouting curtain of a tunnel. The method comprises the following steps of: 1, designing a release hole according to the detected range of a concentrated water-rich area outside a curtain and the spatial position relationship between the range and a grout-preventing wall; 2, sequentially constructing primary, secondary and tertiary holes in the grouting curtain through the grout-preventing wall, and grouting and sealing primary and secondary casings; inserting release casings into the tertiary casing; mounting a release casing sealing connector with a stop valve on the release casing; 3, connecting a grouting connector which is connected with a double-liquid grouting mixer onto the secondary casing at the end part of the hole, and quantitatively grouting into the gap between the secondary casing and the release casing, stopping grouting when the slurry reaches the boundary of the concentrated water-rich area, closing the double-liquid grouting mixer, and waiting on cement setting; and 4, mounting a water-control valve in an opening state on the release casing at the end part of the hole so that water in the concentrated water-rich area can flow out from the water-control valve along the release casing.

Owner:SHANDONG UNIV

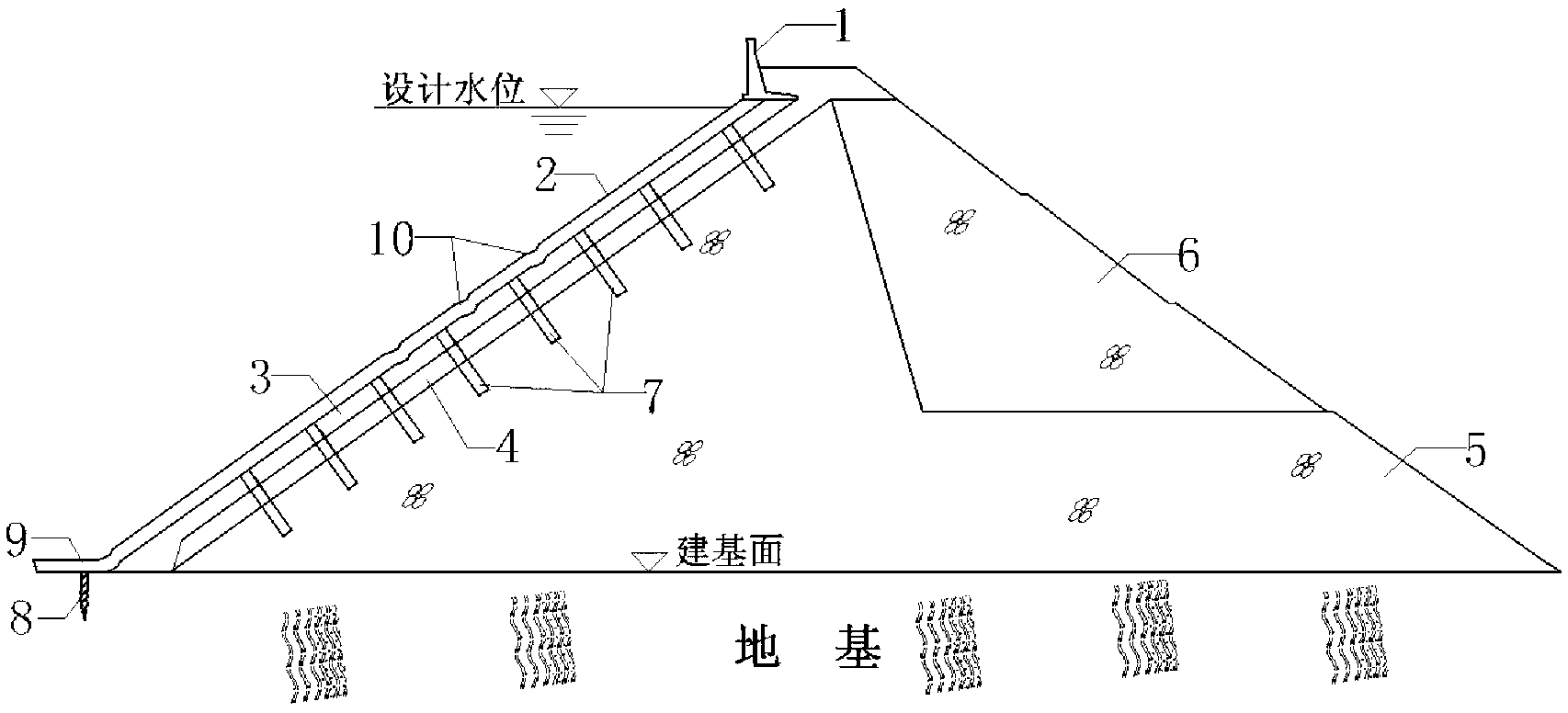

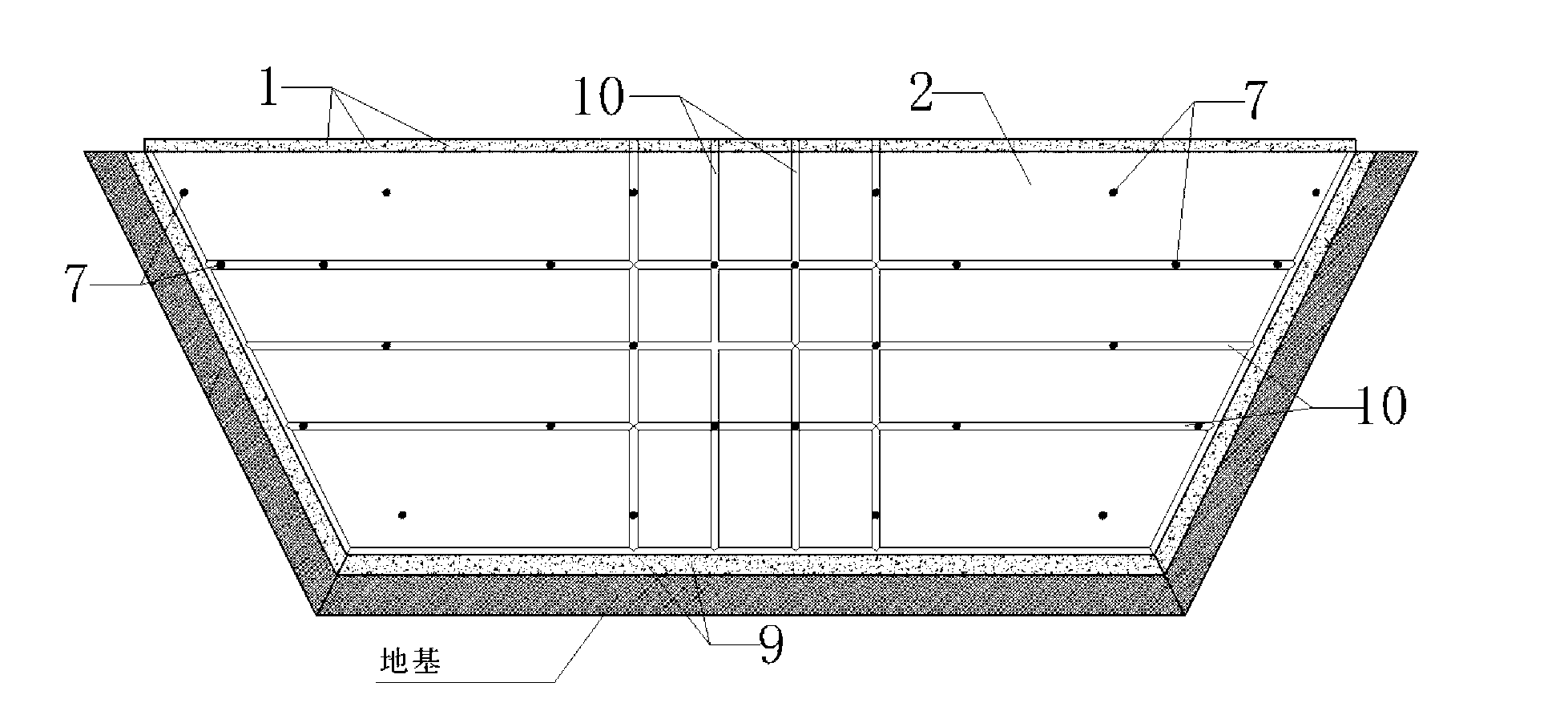

Steel membrane concrete faced rockfill dam

ActiveCN103225285AAvoid influenceGuaranteed crack resistanceEarth-fill damsRock-fill damsCrack resistanceReinforced concrete

The invention discloses a steel membrane concrete faced rockfill dam which consists of a steel membrane concrete faces, a cushion layer zone, a transition zone, a main rockfill zone, a secondary rockfill zone, reinforced concrete toe boards, a wave prevention wall, anti-slip reinforcing steel bars, a grouting curtain and deformed inductive grooves, wherein the steel membrane concrete face is laid on the cushion layer zone of an upstream slope of a rockfill dam body; the top of the dam is provided with a reinforced concrete wave prevention wall; the bottom and the periphery of the dam body are provided with the reinforced concrete toe boards; the bottom at the front end of the dam body is provided with the curtain for grouting; the middle parts and the edges of the steel membrane faces are provided with groove-type deformed inductive grooves; the steel membrane faces on the top of the dam body extend into the reinforced concrete wave prevention wall; the bottom of the dam body and the steel membrane at the side part extend into the reinforced concrete toe boards; and the rear part of the steel membrane is provided with the anti-slip reinforcing steel bars. The steel membrane concrete faced rockfill dam provided by the invention has obvious advantages during the processes of construction, running, management and the like by adopting the steel membrane faces, and especially can well solve influences on faces by the deformation of rockfill materials of the dam body, so that the aspects of face crack resistance and seepage resistance as well as the dam body safety and the like are effectively ensured.

Owner:TIANJIN UNIV

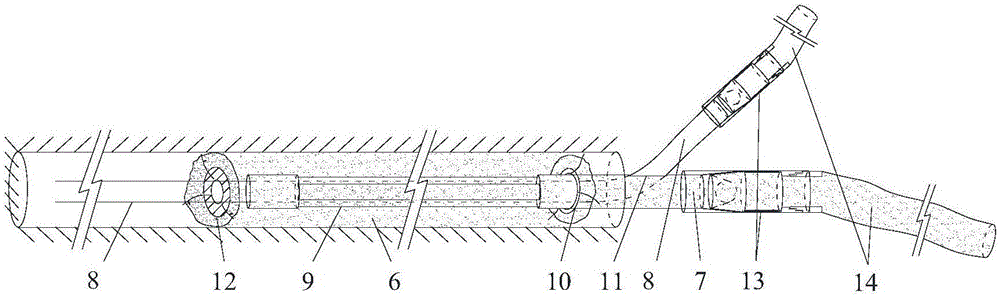

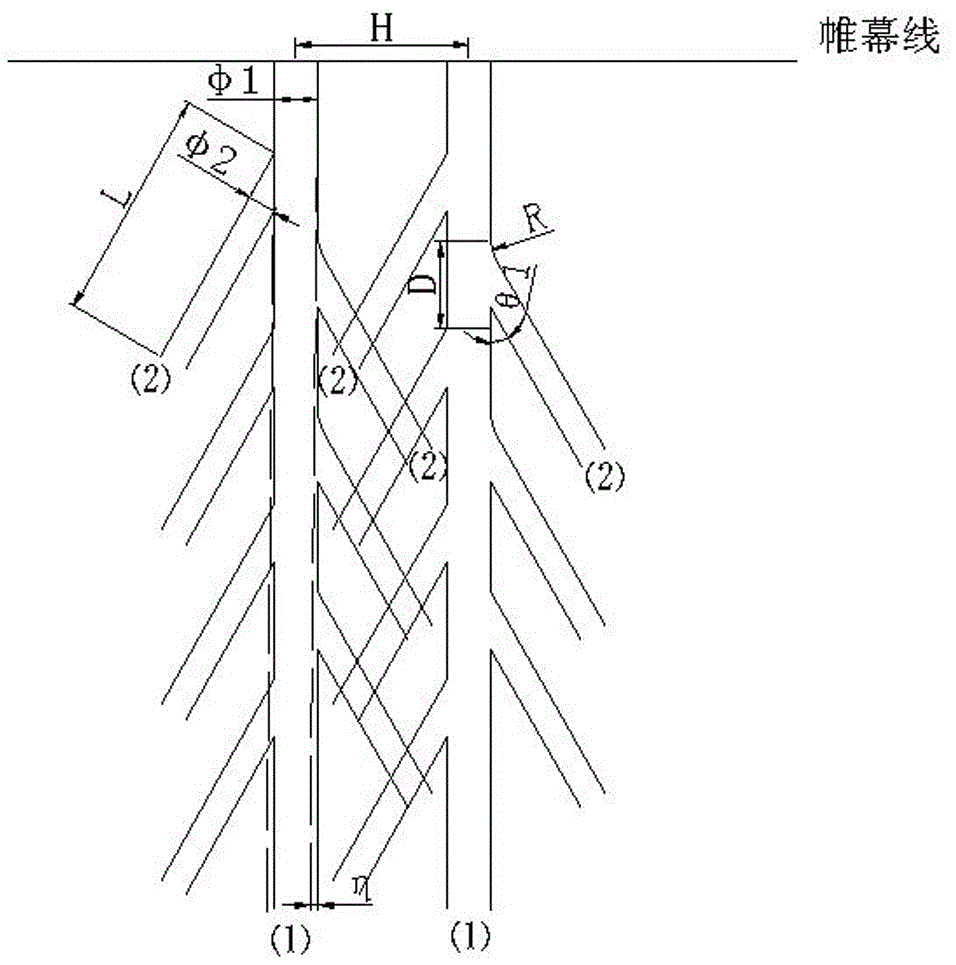

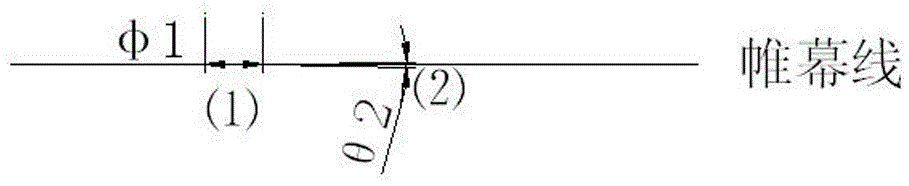

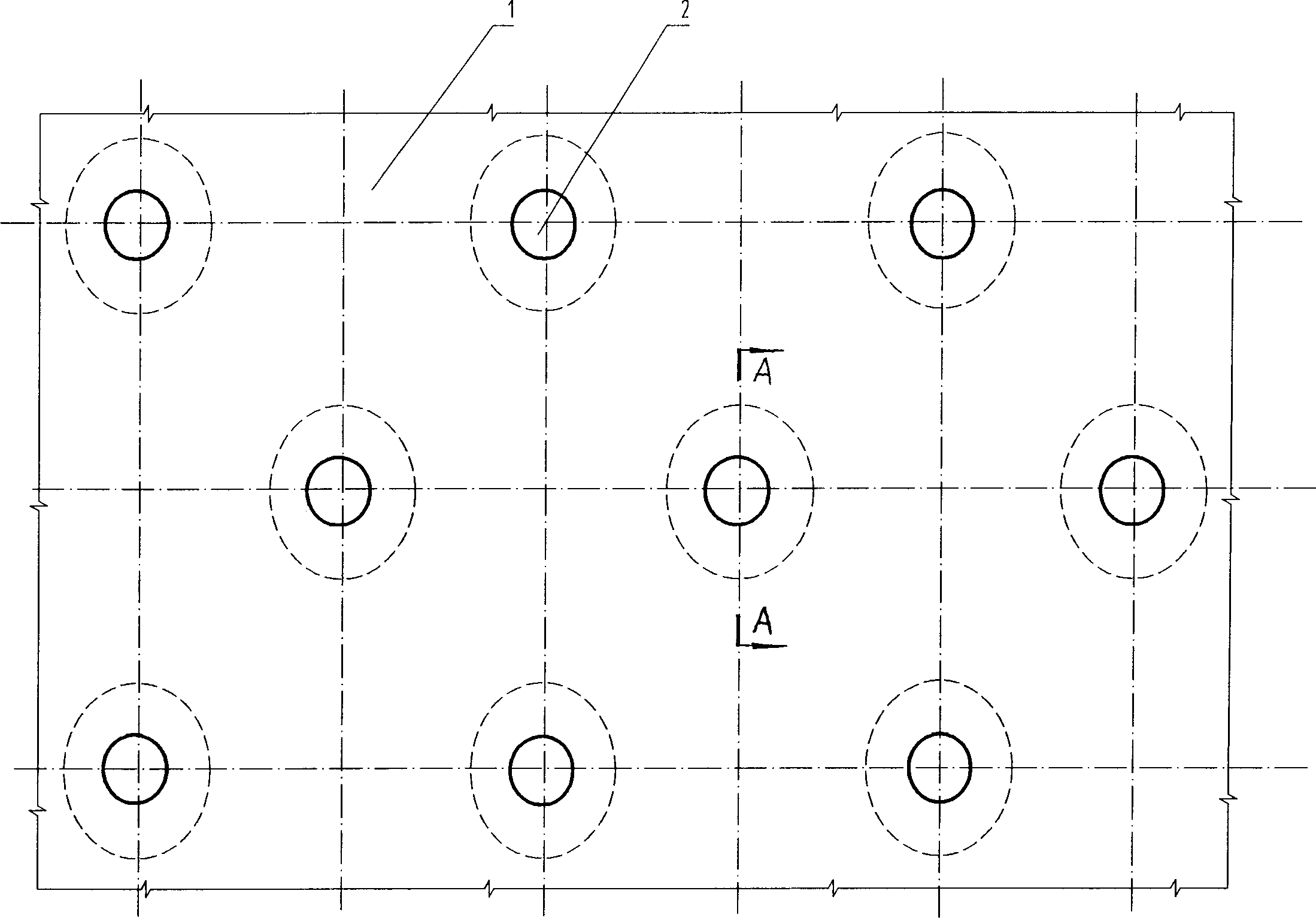

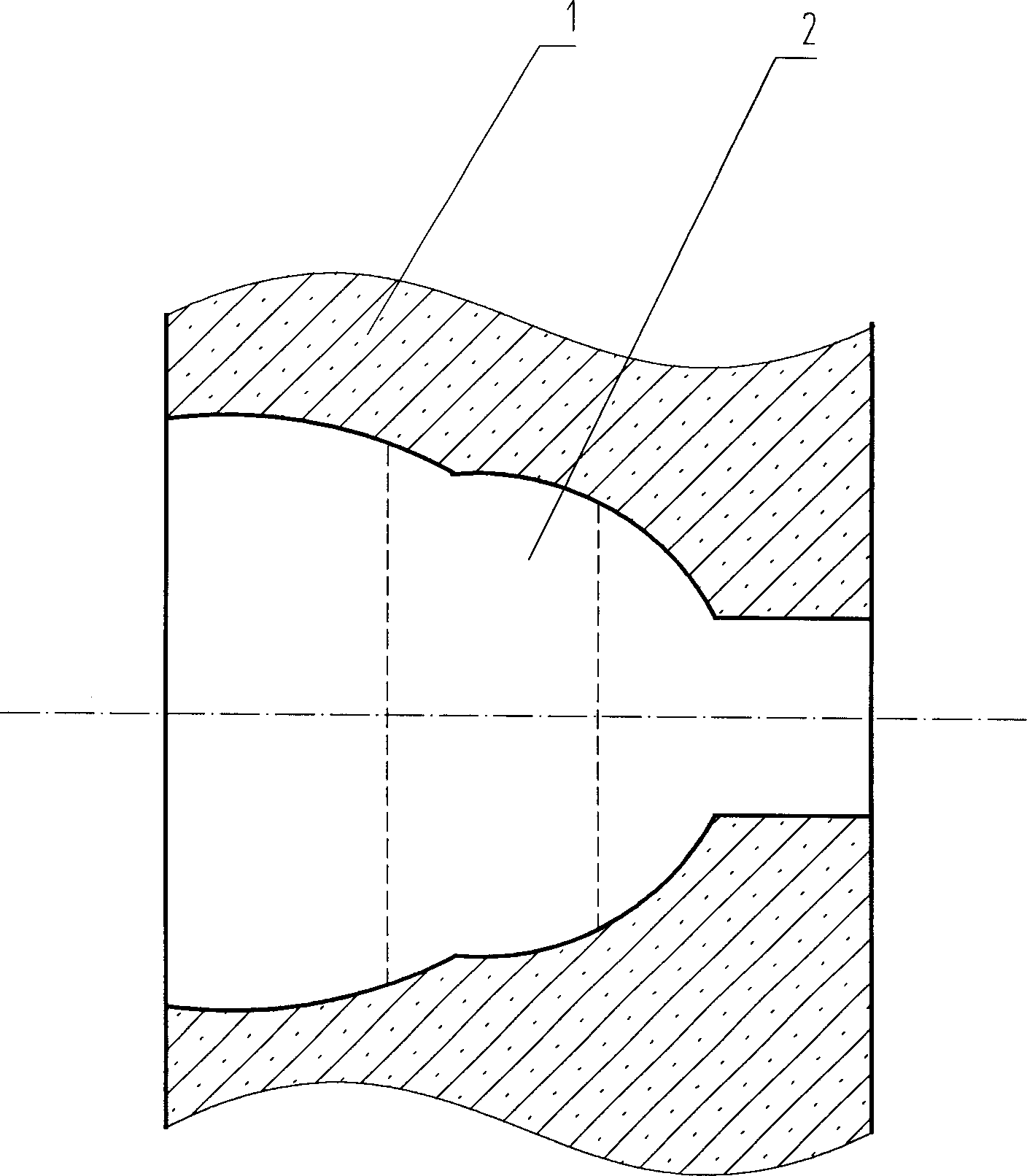

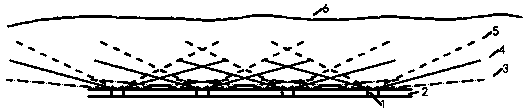

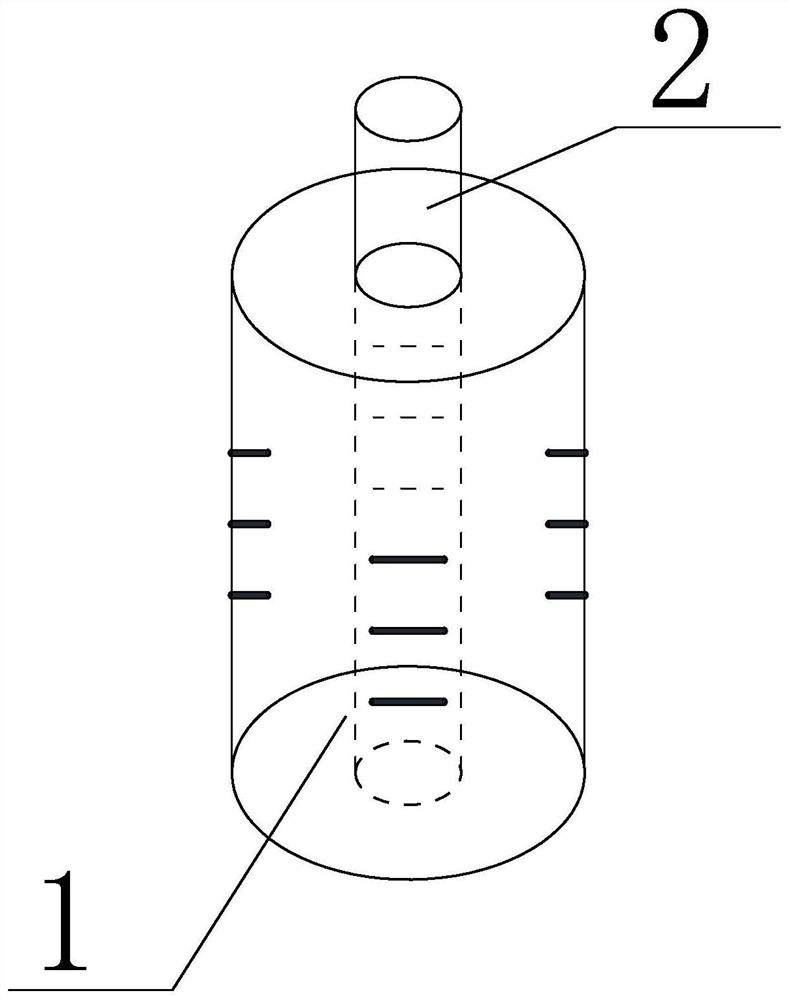

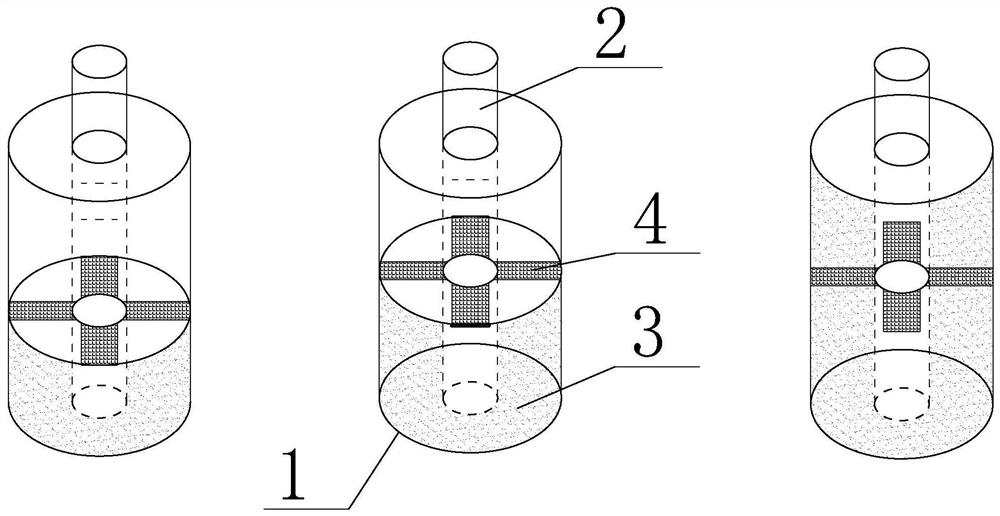

Grouting curtain drilling structure and construction process thereof

ActiveCN106545313AIncrease exposure rateLarge diffusion radiusDrainageSealing/packingSocial benefitsEconomic benefits

The invention provides a grouting curtain drilling structure and a construction process thereof, and relates to the technical field of mine curtain grouting. The grouting curtain drilling structure comprises a plurality of straight grouting holes formed along a curtain line. A plurality of branched grouting holes communicating with the straight grouting holes are further formed in the peripheries, in the height direction, in the straight grouting holes, and the directions of the branched grouting holes radiate and extend towards the peripheries. After grouting, in the curtain line direction, the exposure rate of high-angle water guide cracks can be increased, or water guide cracks in any angle can be exposed. The grouting curtain drilling structure and the construction process have the technical effects that compared with the prior art, the exposure rate of the high-angle water guide cracks can be greatly increased, or the water guide cracks in any angle can be exposed, and therefore the grout dispersion radius is increased, the grouting effect is guaranteed, the number of the straight holes and the drilling workload are greatly reduced, the cost of investment of the mine party is reduced, and great economic benefits and social benefits are achieved. Due to the fact that the distance between the straight holes is increased, it is possible that a tunnel inner curtain grouting manner is adopted for water plugging in mines in lofty mountains and steep hills.

Owner:NORTH CHINA ENG INVESTIGATION INST

Comprehensive control method for underground water resource after being immersed by sea water

InactiveCN1433971AChange the status quoSolve pollutionBarrages/weirsWater/sewage treatment bu osmosis/dialysisDiversion damBedrock

The comprehensive control and treatment method of underground water resource intruded by sea water includes the following steps: surveying the topography and its surface features of control area in overall; finding out the main stream position and direction of alluvial fan of the quaternary system, further finding out the monadnock within nearest distance of left and right banks of main stream position of quaternary system alluvial fan; using connecting line between two monadnocks as central line of grout curtain wall, curtain grouting is started from bedrock and grouting to sea level elevation; setting diversion dam on entrance of river in the control area; setting several sunk well with large gushing water on the main stream position of quaternary system allavial fan at up-stream side of curtain wall.

Owner:孙继勇 +1

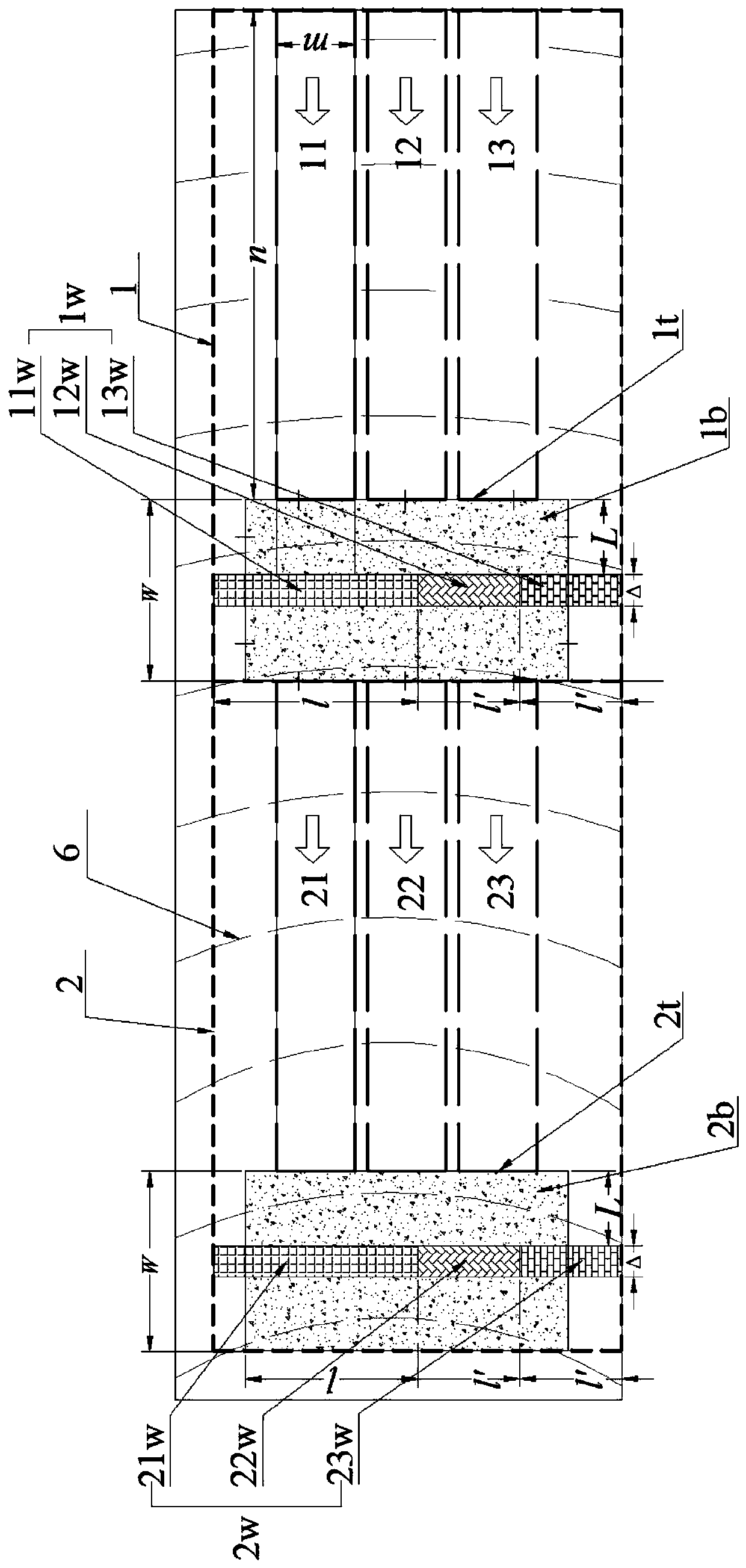

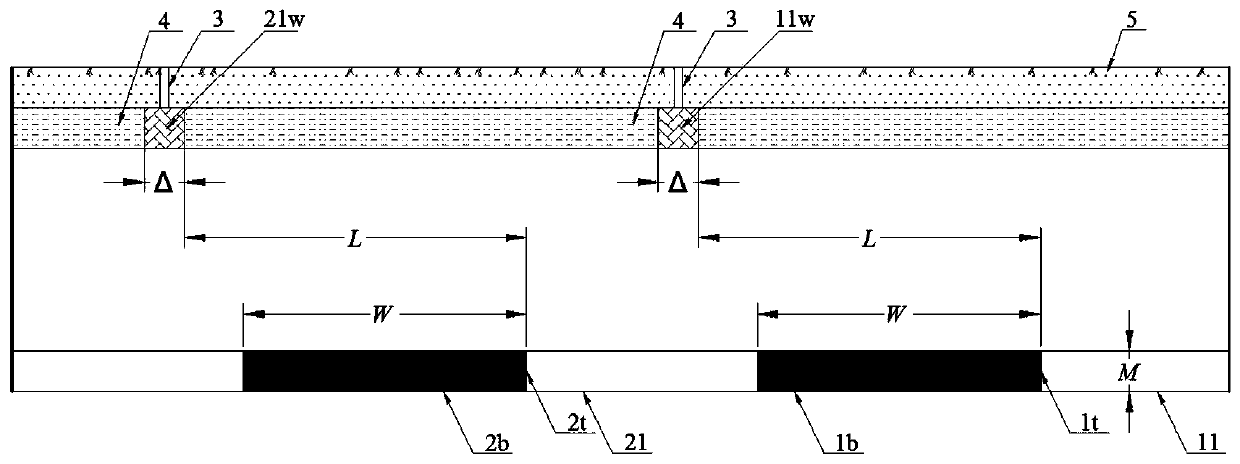

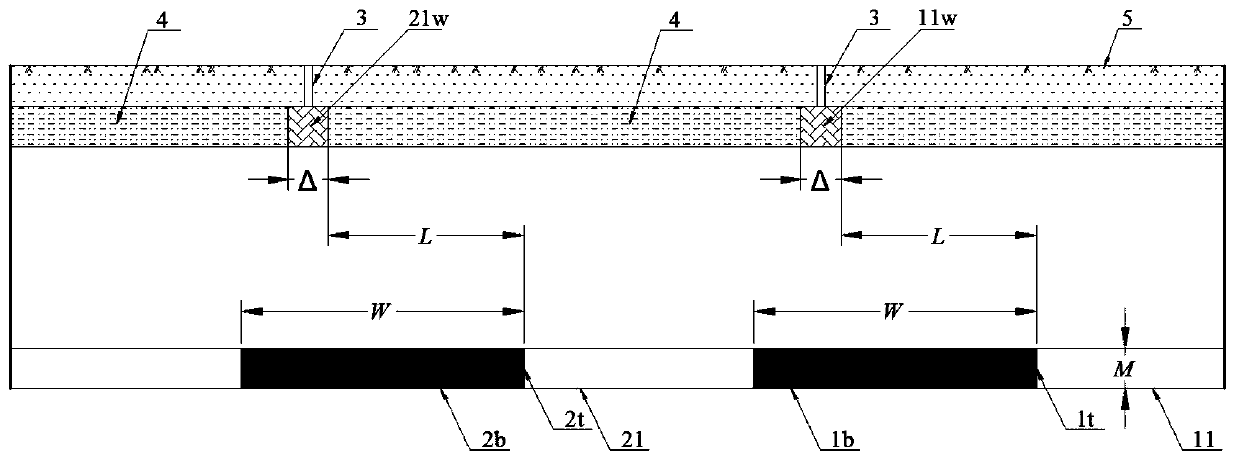

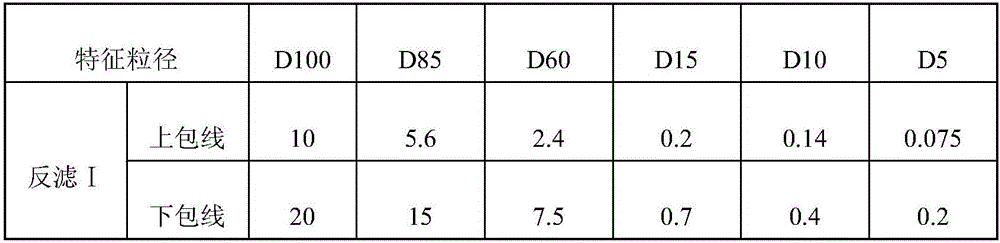

Water-bearing layer segmented grouting curtain water-holding mining method

ActiveCN110159267AAffecting Ecological ChangesPreventing changes affecting the ecology of the earth's surfaceUnderground miningSurface miningWater flowWater holding

The invention discloses a water-bearing layer segmented grouting curtain water-holding mining method. A water-bearing layer and a coal seam are included. The method includes the steps that a, basic geological parameters are acquired, mining engineering design is carried out, and the direction of underground flow and the position and the size of a first mining area grouting curtain are determined;b, the first mining area grouting curtain is prefabricated in the water-bearing layer above a first protective coal pillar in the flow upstream direction, and then a first mining area is normally stoped until the first mining area is stoped; c, a second mining area grouting curtain is prefabricated in the water-bearing layer, and then a second mining area is stoped; d, the first mining area grouting curtain is removed by recovering the first protective coal pillar or mining the second mining area; and e, a second protective coal pillar 2b and the second mining area grouting curtain 2w are treated according to the working manners of the steps b, c and d, and the rest can be done in the same manner until the whole coal seam is completely mined. Water-holding coal mining is achieved by establishing the curtains, the grouting curtains are automatically removed, and the situation that the curtains cut off supply conditions for a long time, so that the earth surface ecology changes is avoided.

Owner:CHINA UNIV OF MINING & TECH

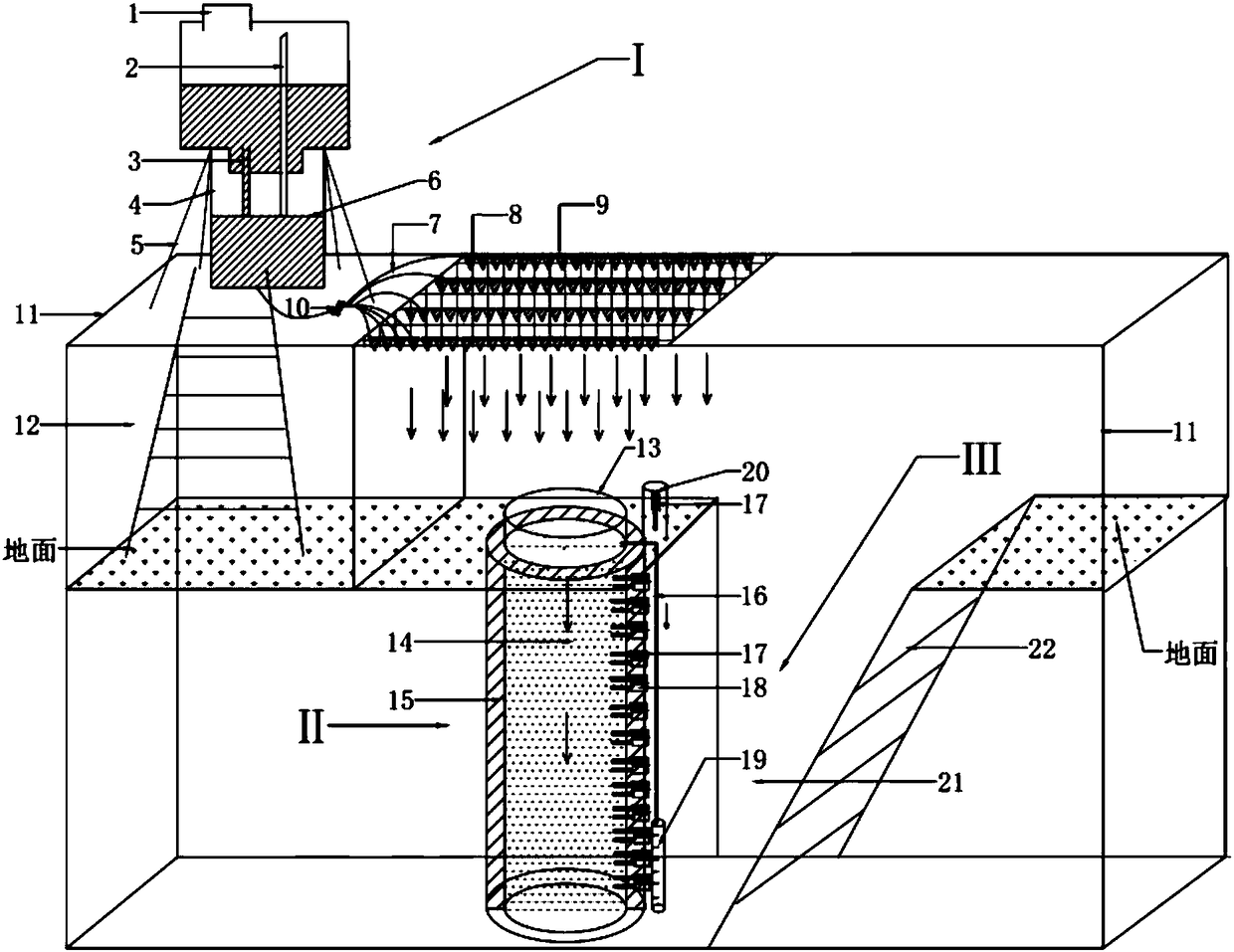

Device for in-situ rainfall infiltration parameter testing and testing method

ActiveCN108169100AAvoid side streamAvoid interferencePermeability/surface area analysisEngineeringGrout curtain

The invention discloses a device for in-situ rainfall infiltration parameter testing and a testing method. The device comprises a water supply system and an infiltration area, wherein a water supply bottom comprises a water tank and a sealed water tank arranged above the water tank; a gas inlet tube and a water outlet tube are arranged at the bottom of the sealed water tank; both the gas inlet tube and the water outlet tube extend into the water tank; a rain droplet simulation device comprises an iron wire net and a plurality of water dropping holes in the iron wire net; the bottom of the water tank is communicated with the water dropping holes through connecting water tubes. A water supply system for simulating different rainfall intensities is established, and compared with a conventional rainfall simulator, the device is very economic and practical and convenient to operate; in an effective infiltration area, a testing area soil body is isolated from a peripheral soil body by usinga grouting curtain method, water is prevented from lateral flowing in the infiltration process, interference of external environments such as evapotranspiration is also avoided, and meanwhile the timethat moisture is completely discharged from wet soil in a research area under natural conditions can be also acquired.

Owner:CHANGAN UNIV

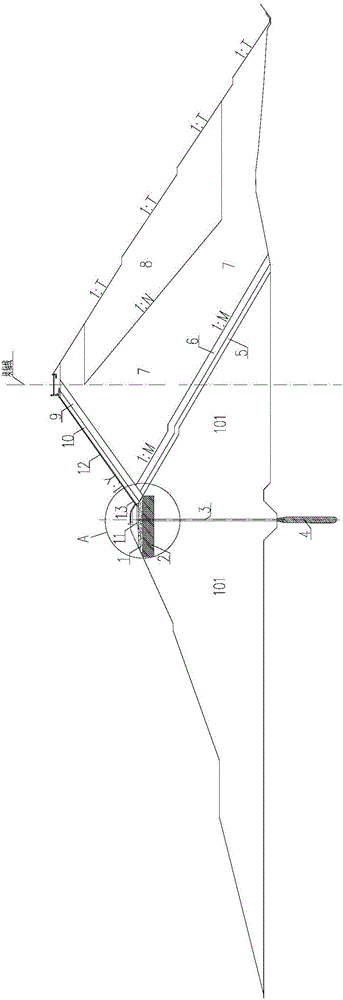

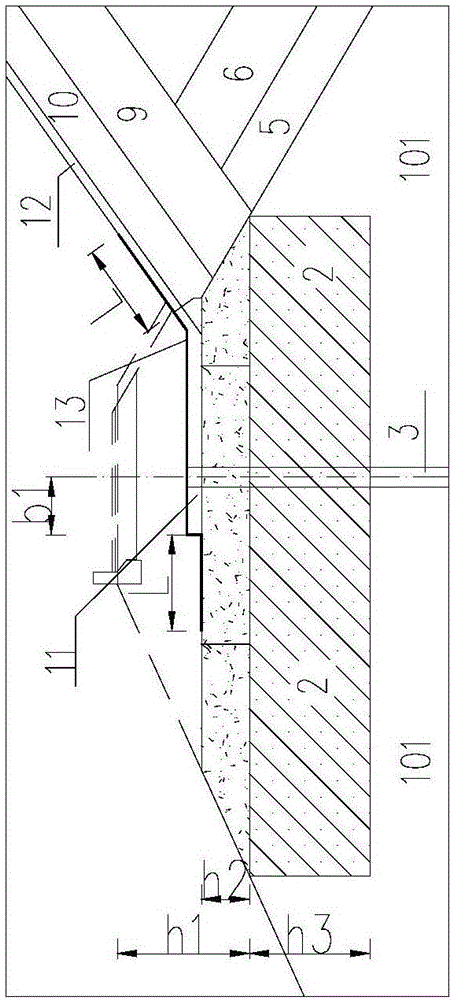

Stage construction method for perpendicular anti-seepage structure of toe boards of concrete faced rockfill dam

ActiveCN105648988ASolve the problem of construction timingProblems Affecting PourEarth-fill damsRock-fill damsBedrockOn board

The invention relates to a stage construction method for a perpendicular anti-seepage structure of toe boards of a concrete faced rockfill dam. The stage construction method aims at solving the problem of cross interference of construction periods of the toe boards and an anti-seepage wall, and the time limit for a project is effectively shortened. According to the technical scheme, the anti-seepage structure is arranged on coverage layer foundations with high water permeability or bed rock with the high permeable rate and poor groutability; and the anti-seepage structure comprises the first-stage toe boards, the second-stage toe boards, the concrete anti-seepage wall and a grouting curtain. The construction method includes the following steps that (1) the first-stage toe boards on the upstream and the downstream of the concrete anti-seepage wall are constructed, T-shaped anti-seepage wall slots are reserved in the middles of the first-stage toe boards, and meanwhile joint bars are embedded on the first-stage toe boards; (2) the concrete anti-seepage wall is constructed, and curtain grouting pipes are embedded inside the concrete anti-seepage wall; (3) scabbling is carried out on concrete on the surfaces of the first-stage toe boards, the T-shaped second-stage toe boards are poured at the top of the concrete anti-seepage wall, and structure seams ranging from 5 cm to 10 cm are reserved between the second-stage toe boards and the top face of the concrete anti-seepage wall; and (4) the grouting curtain is constructed through the curtain grouting pipes embedded into the concrete anti-seepage wall.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

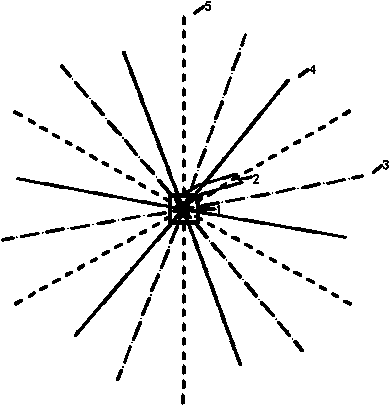

Water prevention and control process in construction of metallurgical underground mining ore pass fragmenting system

InactiveCN105545330AIncrease the areaIncrease spanUnderground chambersShaft sinkingPunchingGrout curtain

The invention discloses a water prevention and control process in construction of a metallurgical underground mining ore pass fragmenting system, and belongs to the technical field of underground metal mine water prevention and control methods. According to the technical scheme, grouting curtain construction is conducted on an upper ore storage bin, a jack shaft, a smashing chamber, a lower ore storage bin, a belt ore supply chamber and the like, through the direction-fixed branch hole construction technology and the less-footage more-punching method, the utilization efficiency and exposing rate of grouting holes are increased, and therefore the optimal grouting effect is achieved; meanwhile, ground pre-grouting construction is conducted on the ore pass fragmenting system in the shaft excavation period, the construction period can be saved, and the construction safety in the digging process is ensured. The situation that in the construction of a traditional ore pass fragmenting system, the water control concept is detected through working face grouting is broken through, and a new concept is provided for water prevention and control of large modern metallurgical mines with complex hydrogeological conditions. The water prevention and control period in the mine construction can be remarkably shortened, the safety coefficient in the construction process is increased, engineering investment is reduced, and the construction speed is increased.

Owner:HEBEI IRON & STEEL GRP MINING

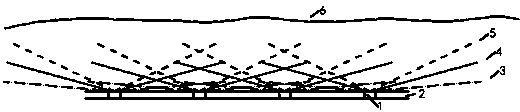

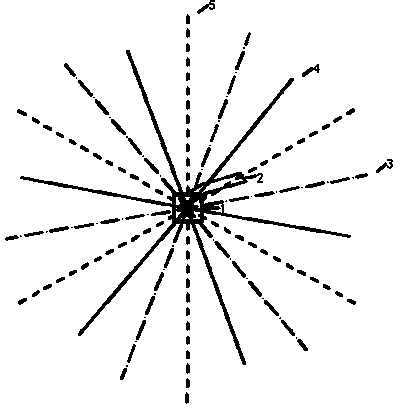

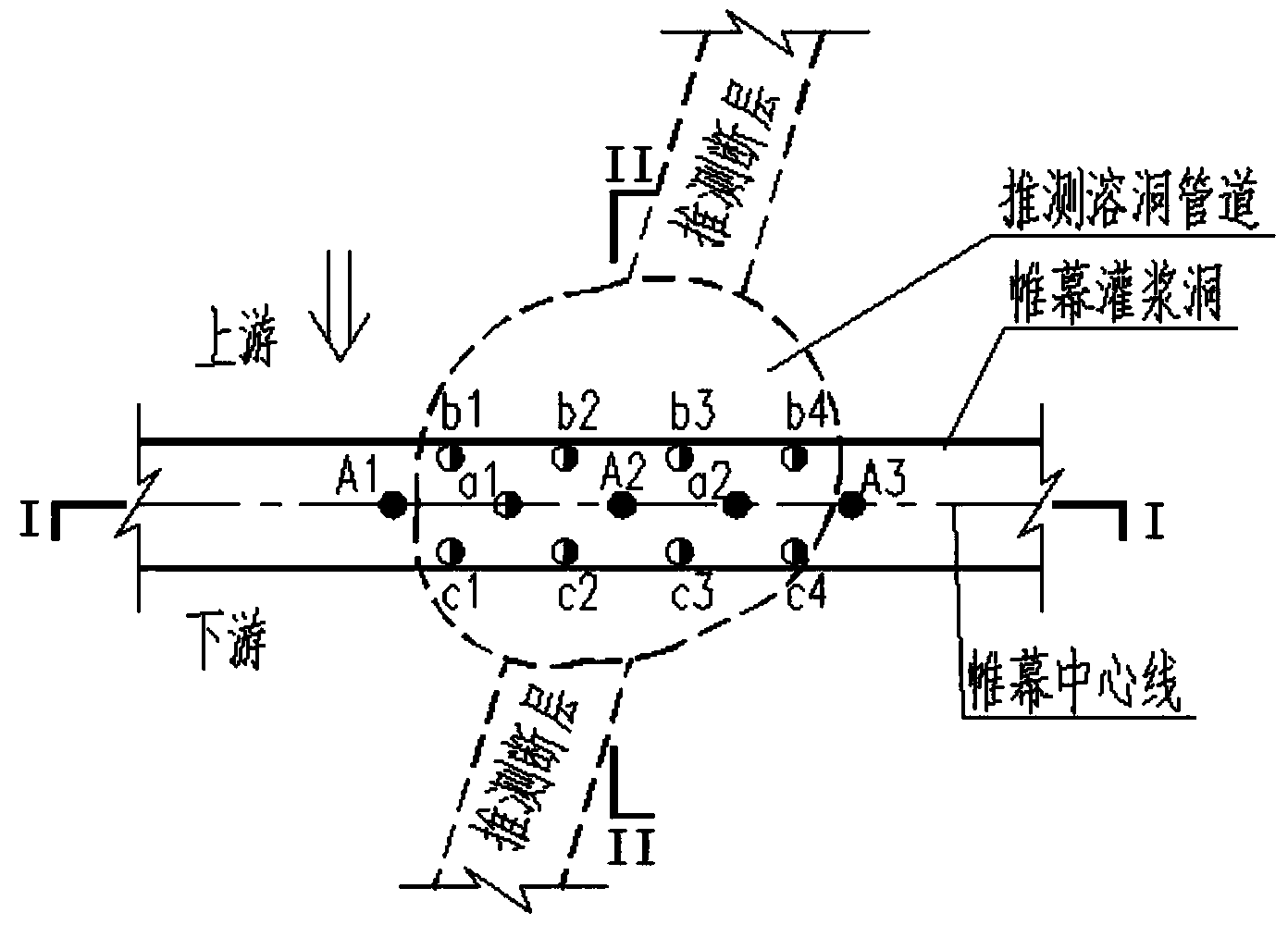

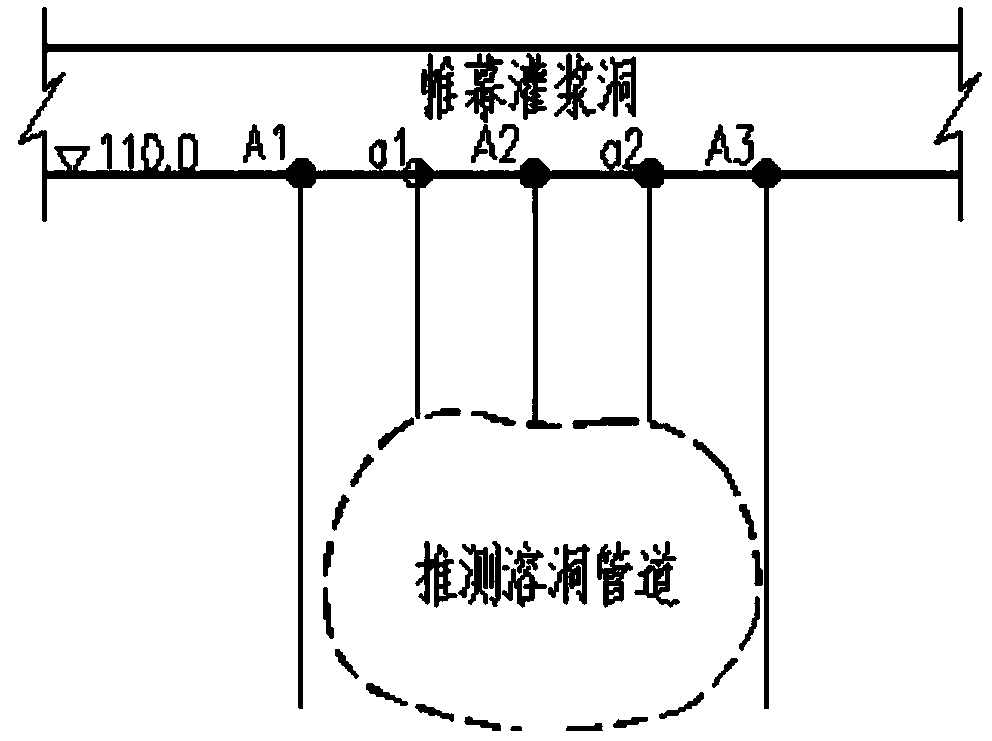

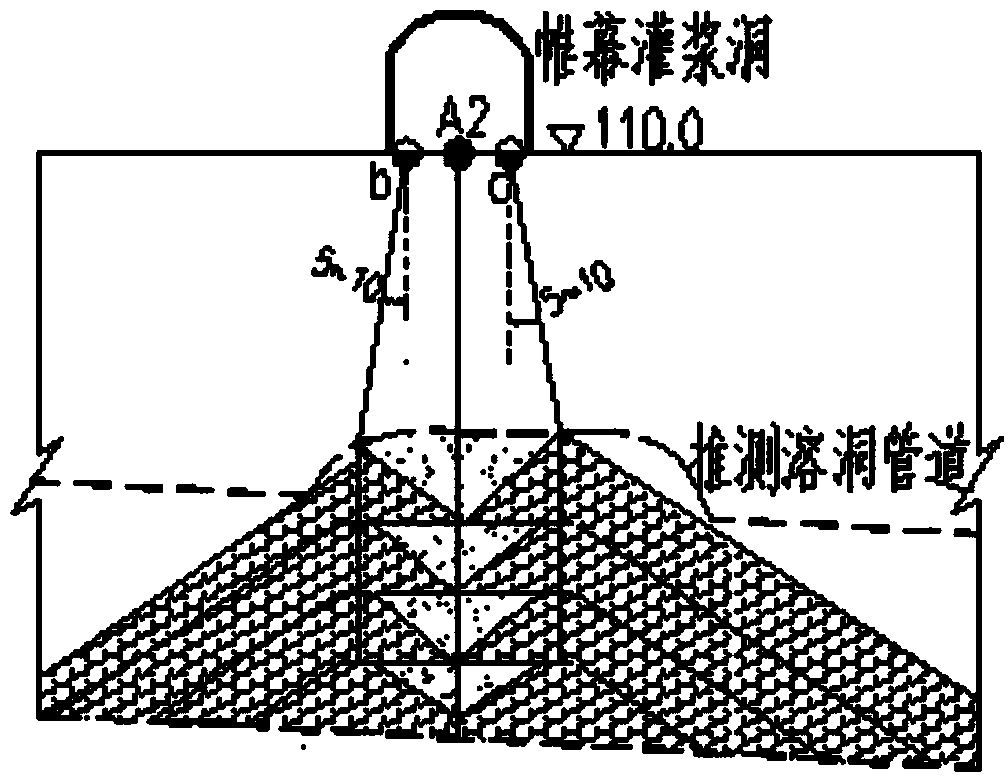

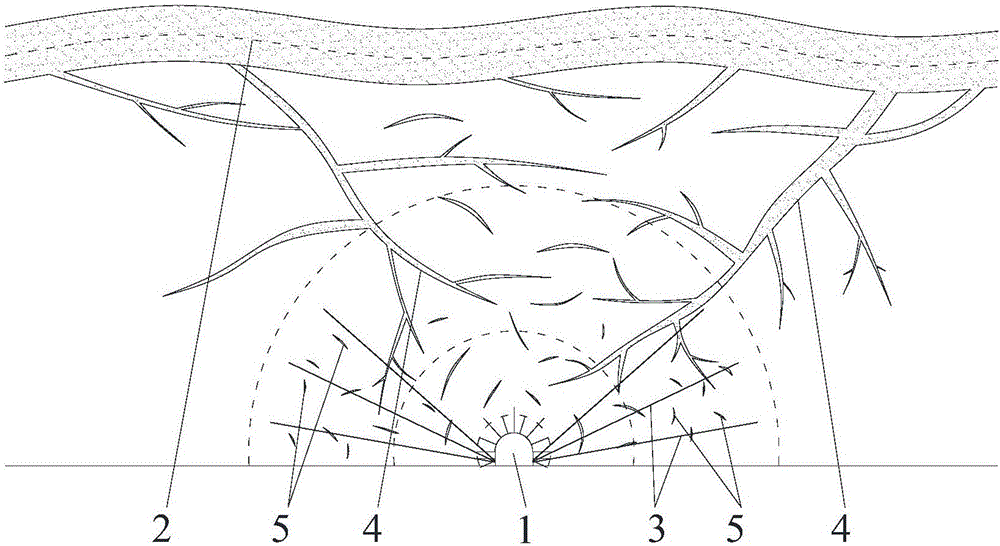

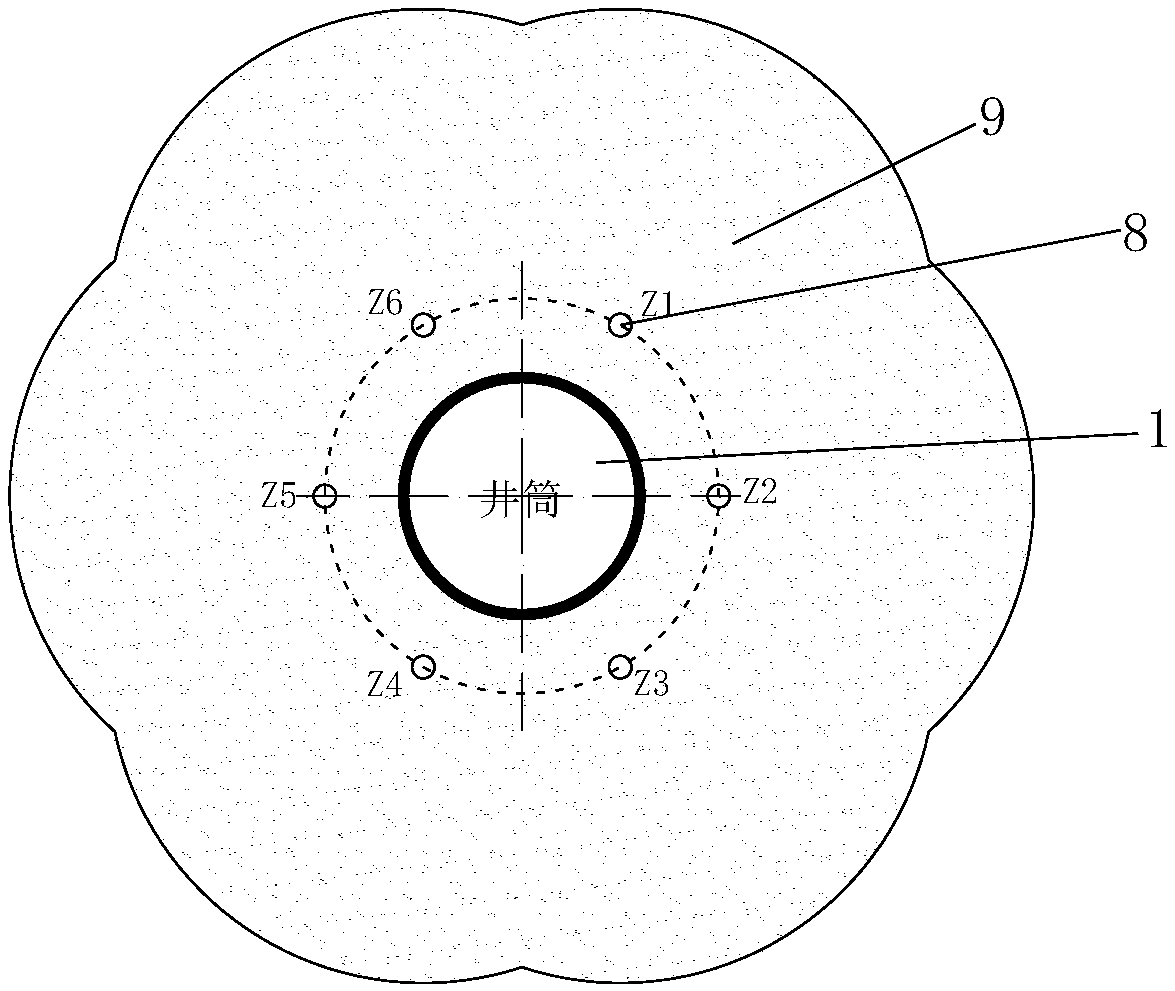

Curtain grouting technology for ore body roof karst fracture development and strong water-rich ore deposit

ActiveCN103967506AGuarantee safe miningReduce drainage costsUnderground chambersTunnel liningElevation angleGeomorphology

The invention discloses a curtain grouting technology for an ore body roof karst fracture development and strong water-rich ore deposit. According to the technical scheme, firstly, upward exploration and injection holes are distributed, six upward exploration and injection holes with an elevation angle of five degrees, six upward exploration and injection holes with an elevation angle of 15 degrees and six upward exploration and injection holes with an elevation angle of 25 degrees are distributed in each chamber, the exploration and injection holes are designed with the chambers as base points, all the exploration and injection holes of all the lengths are evenly distributed in the plane with a stagger angle of 60 degrees, the hole depth is 50 m, and the exploration and injection holes with the elevation angle of five degrees, the exploration and injection holes with the elevation angle of 15 degrees and the exploration and injection holes with the elevation angle of 25 degrees are evenly distributed in the plane with a stagger angle of 20 degrees; secondly, downward exploration and injection holes are distributed, the outward and downward exploration and injection holes with the angles of -5 degrees,-30 degrees and -60 degrees are distributed in end chambers, the hole depth is 50 m, all the downward exploration and injection holes are evenly distributed symmetrically in the plane, and the included angle is 10 degrees; thirdly, according to the requirement of accurate mining engineering, grouting is carried out, and a grouting curtain is formed. The grouting curtain with the high water plugging rate is built under a mine according to roof karst fractures, the functions of water separation and reinforcement can be achieved, ore bodies are released safely and efficiently under the protection of the grouting curtain, and technical guarantees are provided for safe and efficient mining of the mine.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Reverse construction method of deep foundation pit in upper soft and lower hard water-rich stratum

The invention discloses a reverse construction method of a deep foundation pit in upper soft and lower hard water-rich stratum. The reverse construction method comprises the following steps that step(1) underground continuous wall construction is carried out; step (2) construction of split-type hole drilling cast-in-place piles in row is carried out; step (3) grouting curtain construction at theinterface of soft and hard stratum is carried out; step (4) the small foundation pit of a first floor is excavated, and core soil is pre-reserved; step (5) a water drainage resistance structure layeris arranged, and initial supporting and protecting are carried out; step (6) the reserved core soil in the first layer foundation pit is excavated; step (7) a first support system is arranged; and step (8) the stability of the protecting structure is determined through monitoring measurement results, if the monitoring measurement results are normal, then the next cycle is carried out, the step (4)to the step (7) are repeated until the foundation pit is closed. Through the combined action of the inner and outer protecting structure of the foundation pit and the rational design of the excavation method, and the deep foundation pit engineering in the upper soft and lower hard water-rich stratum can achieve effective water-stopping and deformation control effects on the basis of safe and efficient excavation.

Owner:FUJIAN UNIV OF TECH

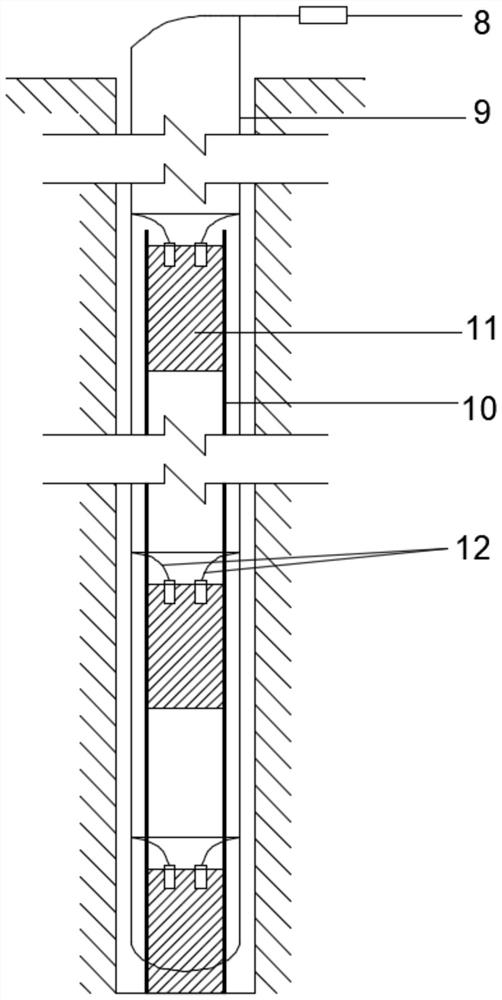

Vertical shaft fracture type grouting curtain excavation unloading analog simulation test system and method

ActiveCN112268768AStrong unloading rangeReal Excavation Unloading Stress PathPreparing sample for investigationMaterial strength using tensile/compressive forcesStructural engineeringSlurry

The invention discloses a vertical shaft fracture type grouting curtain excavation unloading analog simulation test system and method. The method comprises the steps: pouring a prefabricated fracturethick-wall cylindrical vertical shaft surrounding rock sample; manufacturing a vertical shaft fracture type grouting curtain sample; performing initial three-dimensional ground stress loading reduction on the vertical shaft fracture type grouting curtain; carrying out shaft fracture type grouting curtain excavation unloading simulation; and monitoring the excavation unloading effect of the vertical shaft fracture type grouting curtain. The sample preparation method provided by the invention can be used for preparing vertical shaft fracture type grouting curtain samples with different fractureoccurrences and different slurry types. According to the provided unloading test method, excavation and unloading simulation of the vertical shaft grouting curtain under different ground stress levelsand different unloading rates can be carried out, and the deformation damage law and damage degradation characteristics of the fractured grouting curtain under vertical shaft excavation and unloadingare reproduced. The system and method are suitable for experimental study of vertical shaft grouting curtain water plugging effectiveness and excavation unloading effect in mine construction. A simulation test of a high ground stress, a strong unloading amplitude and a real excavation unloading stress path can be realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Construction method for forming waterproof grouting curtain on water-rich pore rock stratum by blasting

PendingCN111852513ATo achieve the purpose of constructionImprove economySurveyUnderground chambersDetonatorSoil science

The invention relates to a construction method for forming a waterproof grouting curtain on a water-rich pore rock stratum by blasting. The method comprises the steps of constructing a plurality of blasting drilling holes in the periphery of a shaft until reaching a water-tight stratum, and drilling a water pumping inspection hole in the center of the shaft until reaching the water-tight stratum;lowering a seamless steel pipe into each blasting drilling hole; placing a plastic pipe filled with a water-resistant explosive and a detonator into each blasting drilling hole in sequence, initiatingthe explosives through detonating pipes, and pulling and cracking the water-rich pore rock stratum between the drilling holes through blasting to form a circle of through grouting cracks or crushingthe rock stratum to form a good grout penetration channel; perforating and grouting the blasted drilling holes; before and after grouting, pumping water to check changes of the water inflow of the shaft; and after the complete waterproof grouting curtain is formed, excavating the shaft. According to the construction method, the through cracks or the good grout penetration channel is formed by drilling hole blasting, the water-proof curtain is formed by grouting, and a channel for seepage of water at the pore rock stratum section into the shaft is cut off, so that the purpose of shaft construction under the condition of no water or a small amount of water is achieved.

Owner:CHINA UNIV OF MINING & TECH

Mixed dam type structure with homogeneous earth and rockfill dam and concrete faced rockfill dam and construction method

InactiveCN106759133ASimple structural designEasy constructionEarth-fill damsGasketsGeomembraneBedrock

The invention relates to a mixed dam type structure with a homogeneous earth and rockfill dam and a concrete faced rockfill dam and a construction method. The mixed dam type structure with the homogeneous earth and rockfill dam and the concrete faced rockfill dam is simple in structural design, convenient to construct, safe and reliable, and has good economy and high practicability. According to the technical scheme, the structure is provided with the original homogeneous earth and rockfill dam and the concrete faced rockfill dam, wherein unconsolidated soil with a certain thickness is excavated out from the top of the original homogeneous earth and rockfill dam; the concrete faced rockfill dam is arranged on a downstream side of the original homogeneous earth and rockfill dam and consists of a main rockfill zone, a secondary rockfill zone, a transition layer, a concrete faced bottom cushion layer and a concrete face; the transition layer, the concrete faced bottom cushion layer and the concrete face are successively paved on parts, which are close to a slope of the top side of the original homogeneous earth and rockfill dam, of the rockfill zones; a filter material layer and a transition material layer are successively arranged between the homogeneous earth and rockfill dam and the main rockfill zone; a consolidation grouting layer, a concrete slab and a toe board which is in lap joint with the bottom of the concrete face are successively arranged on the top of the original homogeneous earth and rockfill dam from bottom to top; a geomembrane covers the top of the toe board; a homogeneous earth and rockfill dam diaphragm wall which penetrates into bed rock is vertically arranged in the original homogeneous earth and rockfill dam; the top of the diaphragm wall penetrates through the toe board; and the bottom of the diaphragm wall is connected with a grouting curtain.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Method for preventing slurry leakage and hole collapse of large-diameter deep-borehole cast-in-situ bored pile by casting curtain method

The invention discloses a method of grout curtain to prevent mud leakage and hole collapse of the large diameter deep hole bored cast-in-place pile. A grouting locating ring is arranged on the outside of the steel casing of the bored pile. A plurality of holes are drilled along the circumference at intervals between the steel casing grouting locating ring and the grouting holes are injected with cement slurry. The slurry completely spreads and fills gaps and is fixedly connected with a loose permeable layer, which can form a high strength waterproof curtain. The method can solve the problems of the mud leakage and hole collapse of the large diameter deep hole bored cast-in-place pile. The cement slurry is injected into the loose permeable layer and is fixedly mixed with the loose permeable layer to fill gaps and form a ring of high strength stop water curtain. The invention has the advantages that plugging results are good, problems are solved completely, the problems of mud leakage and hole collapse will not happen again in subsequent construction, the construction speed is rapid, input is low, incident handling costs can be greatly reduced. Meanwhile, the method can be applied to prevent the incidents of mud leakage and hole collapse while loose permeable layers of silty sand, drift sand, pebble soil and other soil are drilled.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Chemical improvement curtain and well point dewatering foundation pit water stop structure and construction method

PendingCN113373950AIncrease the internal friction angleImprove cohesionProtective foundationBuilding constructionsWater stopGrout curtain

The invention discloses a chemical improvement curtain and a well point dewatering foundation pit water stop structure and a construction method. The method comprises the following steps that (1) a site is leveled to the designed elevation; (2) a foundation pit supporting and retaining structure is constructed, and a crown beam is installed at the upper end of the foundation pit supporting and retaining structure; (3) a chemically-improved grouting curtain is constructed; (4) a plurality of dewatering wells are excavated on the inner side of the chemically-improved grouting curtain, and a water suction pump is installed; and (5) the foundation pit is excavated, and graded sloping treatment is conducted till the depth of the foundation pit meets the design requirement; and the water suction pump continuously operates in the excavation process, so that the underground water level is 2.8-3.0 m below the working face. The chemically-improved grouting curtain water stop and well point dewatering foundation pit water stop combined structure is more suitable for foundation pit water stop in a water-rich silt area, and instability caused by the characteristics of large water content, low strength, large compressibility, large water permeability and the like of silt engineering can be effectively dealt with.

Owner:杭州交投建设工程有限公司 +1

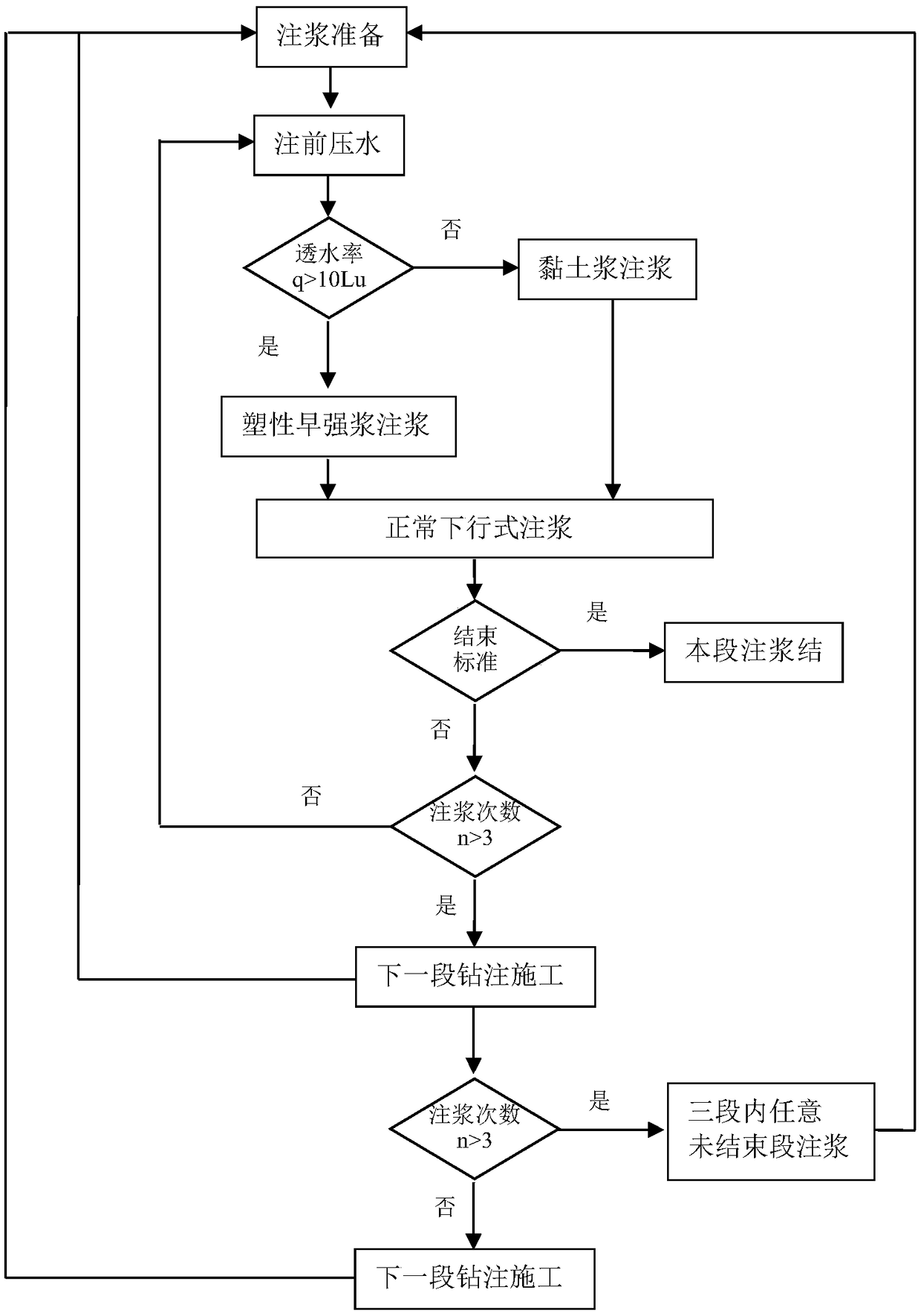

Grouting technology for controlling water-stop curtain of dolomite vertical shaft of large-thickness water-rich lamp shadow group

The invention discloses a grouting technology for controlling the water-stop curtain of a dolomite vertical shaft of a large-thickness water-rich lamp shadow group, which comprises the following stepsof: tapping by using a water source drilling machine on the ground, and drilling a grouting hole; preparing grouting a material; mixing and grouting. According ot the invention, firstly, plastic early strength slurry is used for filling a structural surface or a structural belt or other mian water guide networks, which are with larger opening degree and are in the periphery of the grouting hole,and then a mixed grouting method is used, the setting time of the slurry is increased while ensuring the construction efficiency; that the plastic early-strength slurry has sufficient setting time isensured to increase the setting time of the slurry, that the unsolidified calculus body is extruded away from the grouting curtain of a designed shaft under the grounting pressure, which wastes the grouting material, is avoided; when the main water guide network is filled, that is, the grouting pressure rises, the clay cement slurry is used to fill a secondary water guide fissure network, so thata permanent grouting curtain is formed, and one third of the grouting material is saved compared with a prior grouting method, and the planned construction period is one fifth in advance.

Owner:BEIJING CHINA COAL MINE ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com