Water prevention and control process in construction of metallurgical underground mining ore pass fragmenting system

A slip-through system and a technology in construction, applied in the field of water prevention and control technology, can solve problems such as prone to water inrush, landslides, unsatisfactory water control effects, and long exposure time, so as to reduce the period of water prevention and control, increase utilization efficiency and expose The effect of the rate and the number of grouting holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

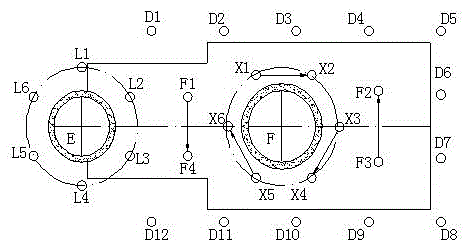

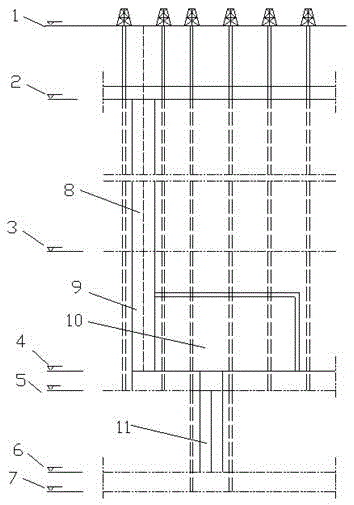

[0025] The invention includes a variety of grouting curtain hole constructions. Among them, only 50% of the grouting curtain holes F1 to F4 in the roof and floor of the crushing chamber and the grouting curtain holes X1 to X6 in the lower mine bin and belt feeding chamber are surface openings. The remaining 50% starts from the bottom plate of the crushing chamber to carry out directional branch hole construction.

[0026] The present invention adopts the following steps:

[0027] a. Carry out grouting curtain construction on the upper chute and upper silo: combined with the design and layout of the slipping system, the upper chute and the upper silo grouting curtain hole are evenly circularly arranged at a position 1.5m outside the upper chute and the upper silo, as shown in the figure The holes L1~L6 shown in, of which L1 and L6 are used as curtain holes on the west side of the crushing chamber, the hole spacing is 3~5m, and the design depth is that the top of the upper chute ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com