Method for preventing slurry leakage and hole collapse of large-diameter deep-borehole cast-in-situ bored pile by casting curtain method

A technology of bored piles and grouting curtains, which is applied to sheet pile walls, buildings, and foundation structure engineering to achieve thorough treatment, less investment, and prevention of grout leakage and hole collapse accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] This embodiment is used to explain the claims of the present invention, and the protection scope of the present invention is not limited to the description of the following embodiments.

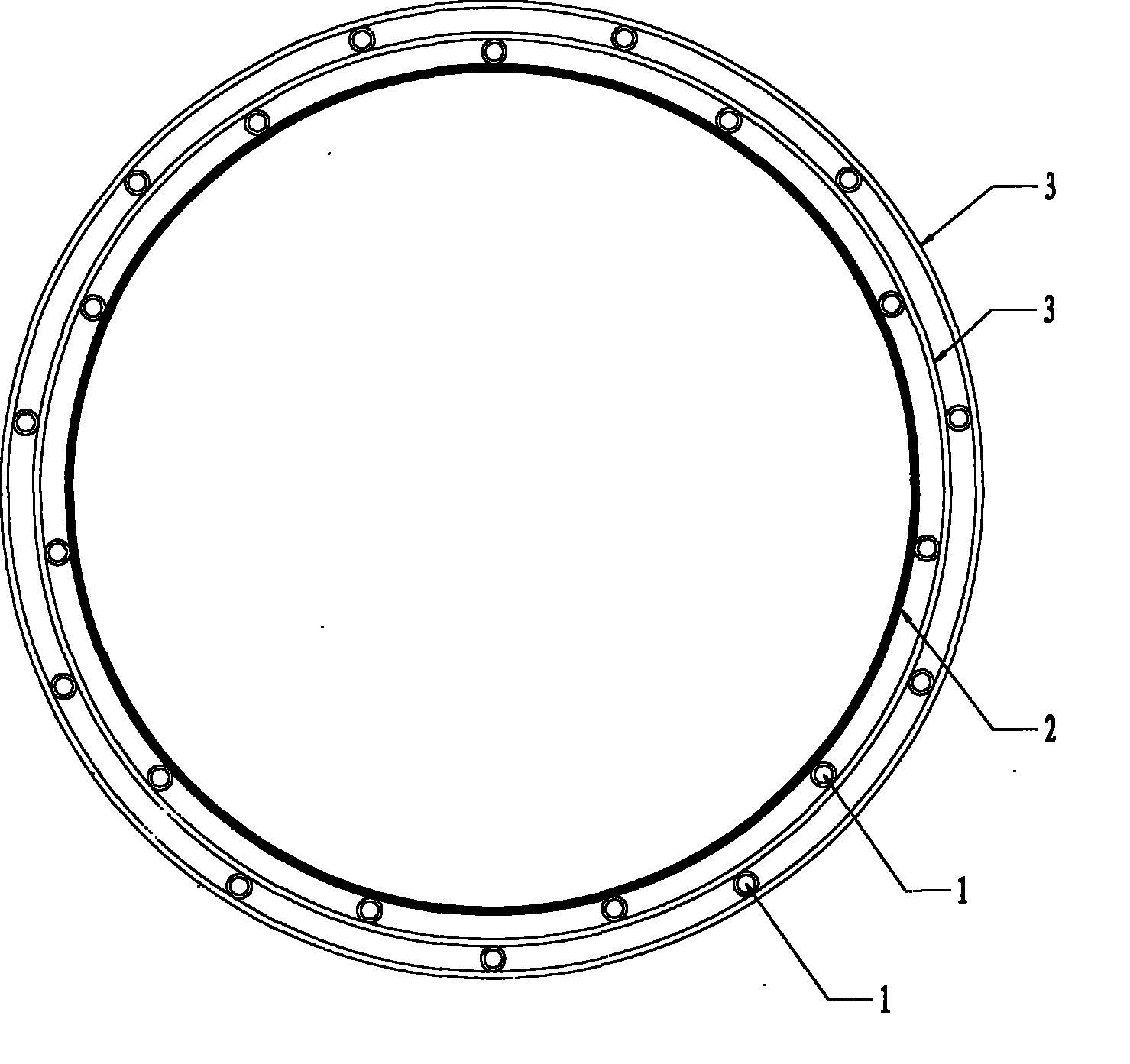

[0013] As shown in the accompanying drawings, grouting positioning rings 3 are arranged on the periphery of the steel casing 2, and the grouting positioning rings 3 can be provided with 1 to 4 circles in the plane, and 1 to 3 layers can be arranged at intervals on the facade. The grouting holes 1 are drilled at intervals along the circumference in the grouting positioning ring 3 .

[0014] The specific construction is as follows:

[0015] 1. Backfill the accident hole with sand to 1m above the location of the grout leakage or hole collapse;

[0016] 2. On the outer side of the steel casing 2, 2-3 grouting hole drill pipe positioning rings 3 are arranged. The positioning ring 3 is a ring concentric with the steel casing 2, and the diameter is 0.3-1m larger than the diameter of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com