Chemical improvement curtain and well point dewatering foundation pit water stop structure and construction method

A technology of chemical improvement and well point dewatering, applied in chemical instruments and methods, infrastructure engineering, excavation, etc., can solve the problems of complex construction technology of water-stop structure and long time for water-stop to exert its effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

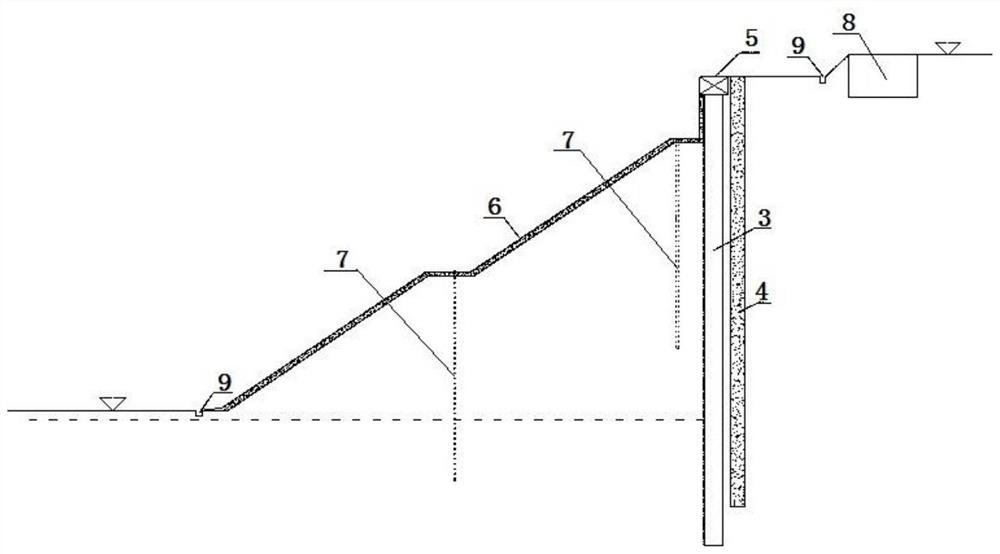

[0070] This embodiment discloses a chemically improved curtain and a foundation pit water-stopping structure for dewatering at well points, including a foundation pit retaining structure 3 , a chemically improved grouting curtain 4 , crown beams 5 , slope concrete 6 and a dewatering well 7 .

[0071] see figure 1 , the chemically modified grouting curtain 4 is arranged in the soil body at the upper port of the foundation pit, and the chemically modified grouting curtain 4 is formed by injecting a chemical modification reagent into silt for construction, and the chemical modification reagent is a mixed solution of water glass and aluminum dihydrogen phosphate , the mixed solution of calcium lignosulfonate and water or the mixed solution of sodium polyacrylate and water, the present embodiment just adopts the mixed solution of calcium lignosulfonate and water, and the mass ratio of calcium lignosulfonate and water is 10: 90~15:85, according to the ratio of calcium lignosulfonate...

Embodiment 2

[0081] This embodiment discloses a construction method based on a chemically improved curtain and well point dewatering foundation pit water stop structure described in Embodiment 1, including the following steps:

[0082] 1) Level the site to the design elevation.

[0083] 2) Construction of the foundation pit retaining structure 3 is carried out at a predetermined position, and the construction of the crown beam 5 is completed on the upper end of the foundation pit retaining structure 3 . Wherein, the foundation pit supporting and retaining structure 3 is a plurality of bored piles arranged at intervals or construction method piles, and this embodiment adopts several bored piles arranged at intervals.

[0084] 3) Construction of the chemically improved grouting curtain 4 includes the following sub-steps:

[0085] 3-1) Configure the chemical modification reagent. Wherein, the chemical improvement reagent is a mixed solution of water glass and aluminum dihydrogen phosphate, ...

Embodiment 3

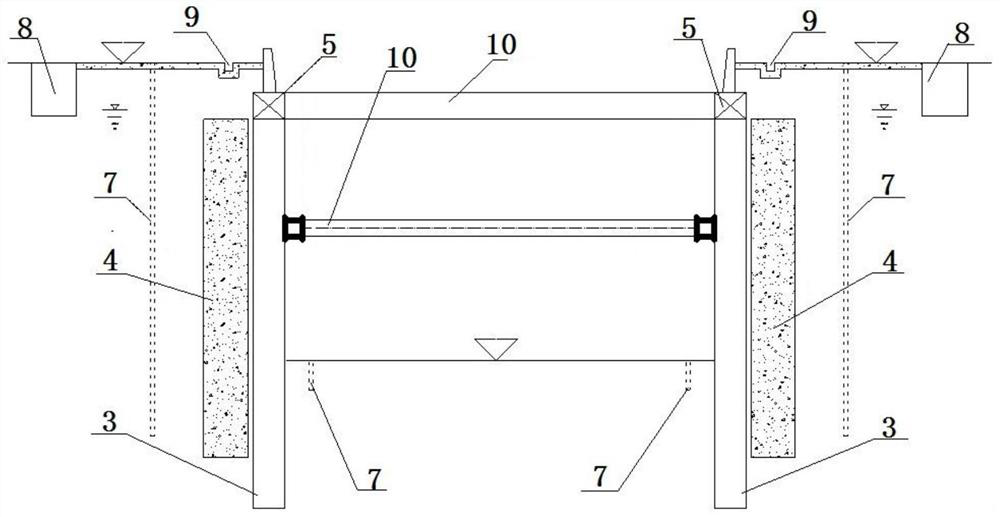

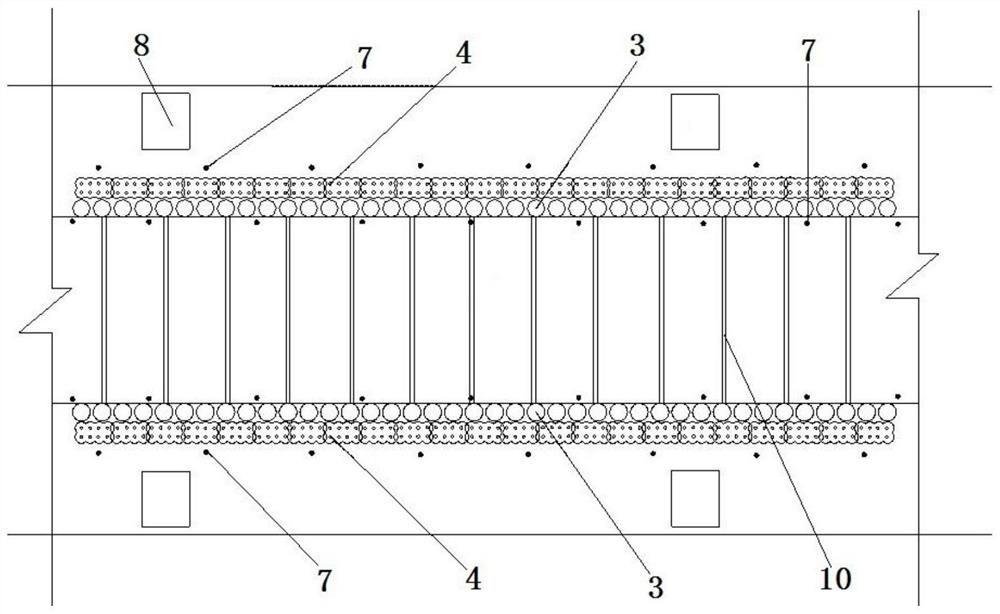

[0104] This embodiment discloses a chemically improved curtain and a foundation pit water-stop structure for dewatering at well points, including a foundation pit support structure 3 , a chemically improved grouting curtain 4 , crown beams 5 , dewatering wells 7 and beams 10 .

[0105] see figure 2 , the foundation pit retaining structure 3 is arranged along the vertical side wall of the foundation pit, and the foundation pit retaining structure 3 is a plurality of bored piles or engineering method piles arranged at intervals, and a crown beam is installed on the top of the foundation pit retaining structure 3 5. A chemically modified grouting curtain 4 is set in the soil outside the foundation pit supporting structure 3 .

[0106] The chemically modified grouting curtain 4 is constructed by injecting chemical modification reagents into silt. The chemical modification reagents are a mixture of water glass and aluminum dihydrogen phosphate, a mixture of calcium lignosulfonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com