Cement mortar suitable for anti-seepage reinforcement of water-rich karst large-cavity strata

A large-pore, cement technology, applied in the field of cement mortar, can solve the problems of inability to effectively control the seepage flow, small plastic viscosity and yield stress, and limited range of cut-off seepage channels, and achieve good slurry stability and strong resistance to water flow. Effects of flushing properties, adjustable pulp controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

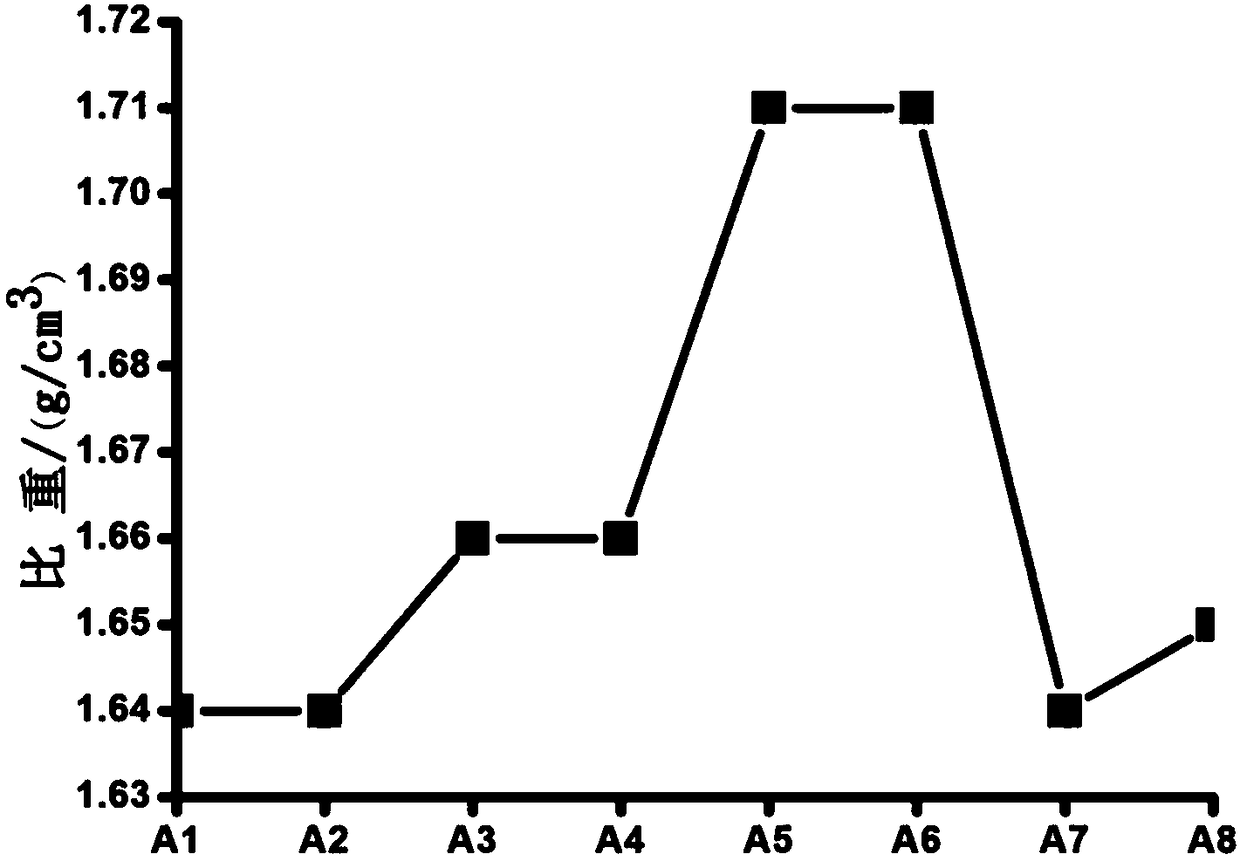

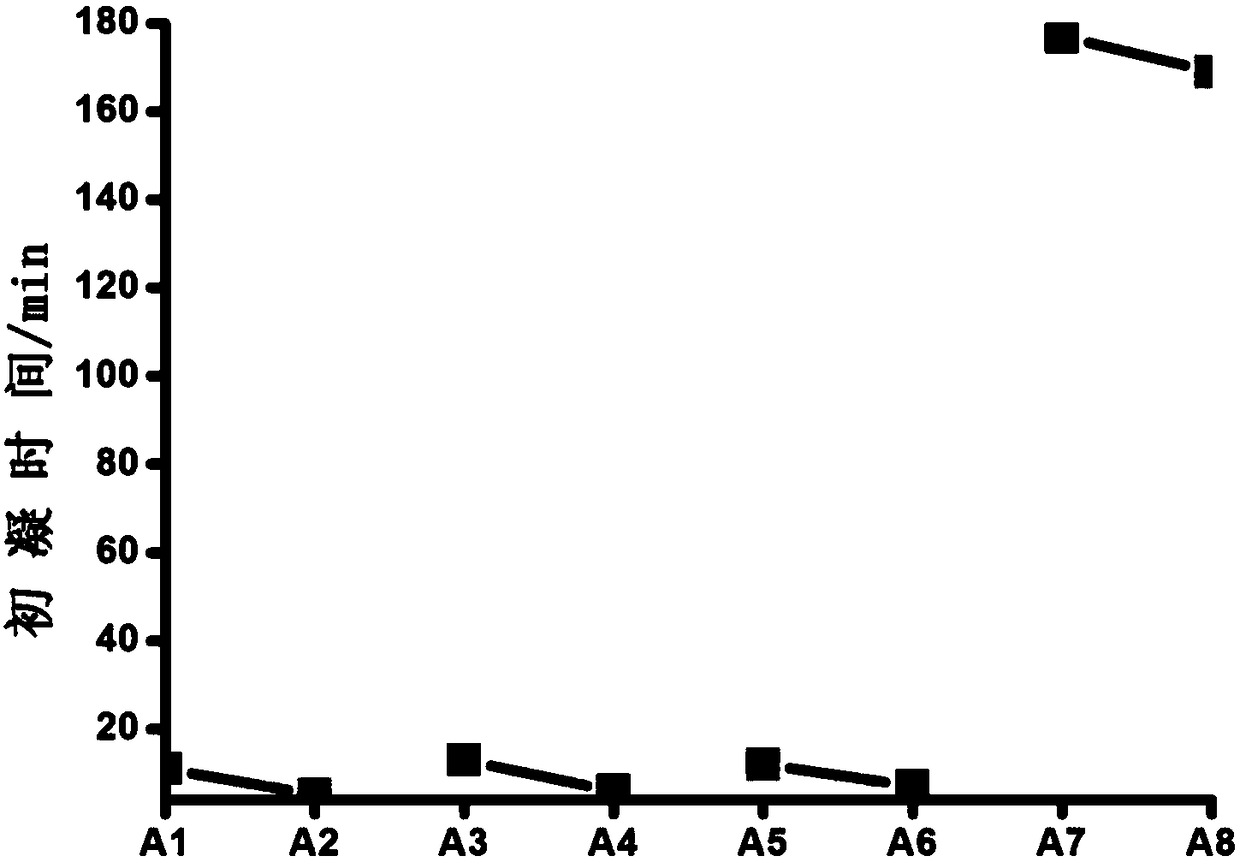

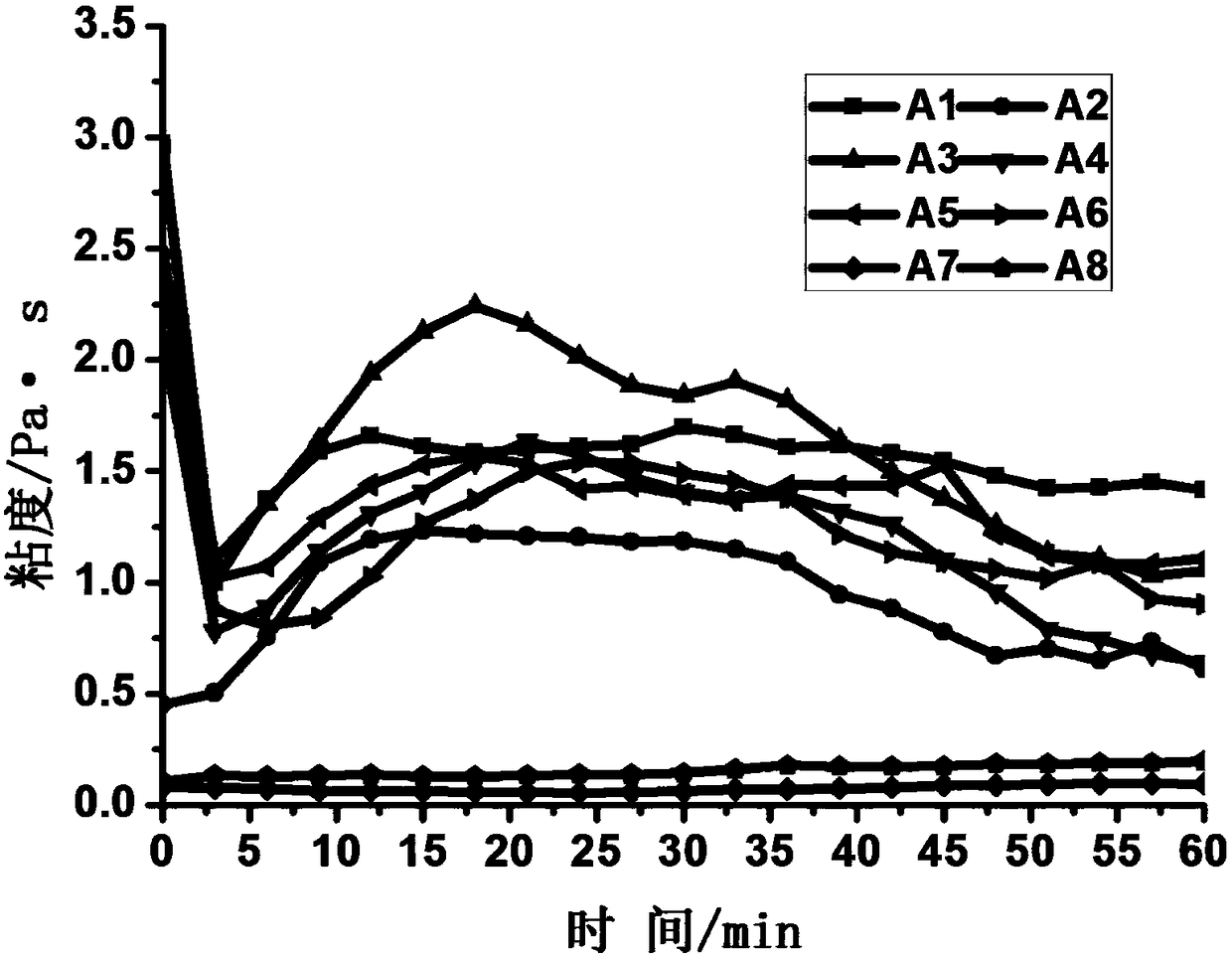

[0030] A cement mortar slurry suitable for anti-seepage and reinforcement of water-rich karst macroporous formations, the composition of which includes water, cement, sand and a modifier, and the weight ratio of the water, cement, sand and modifier is 1: 1: 0.4~0.75: 0.01~0.0125, the modifier components are mineral additives. In this example, eight groups of proportioning schemes in the following table 1 are selected, among which A1-A6 are schemes with modifiers added, and A7-A8 are Comparative experiment without adding modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com