Fuel cell catalyst slurry and application thereof

A catalyst slurry and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of unreasonable structure of electrode catalytic layer and gas diffusion layer, large concentration polarization loss in high current density area, reaction gas and liquid state Problems such as large water transfer resistance, to achieve the effect of ensuring consistency and repeatability, favorable pore size distribution, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

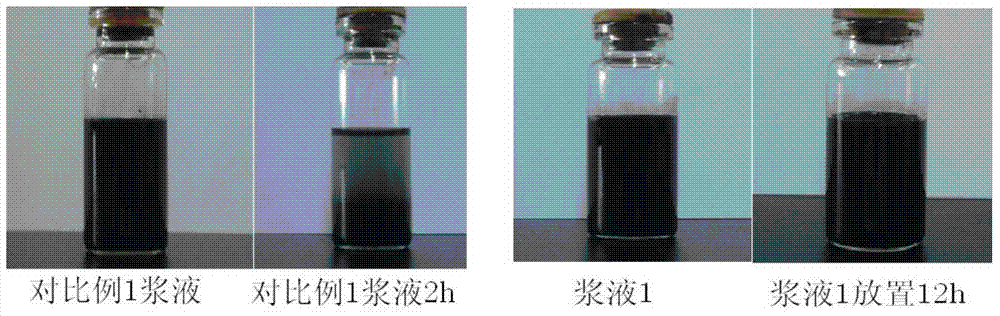

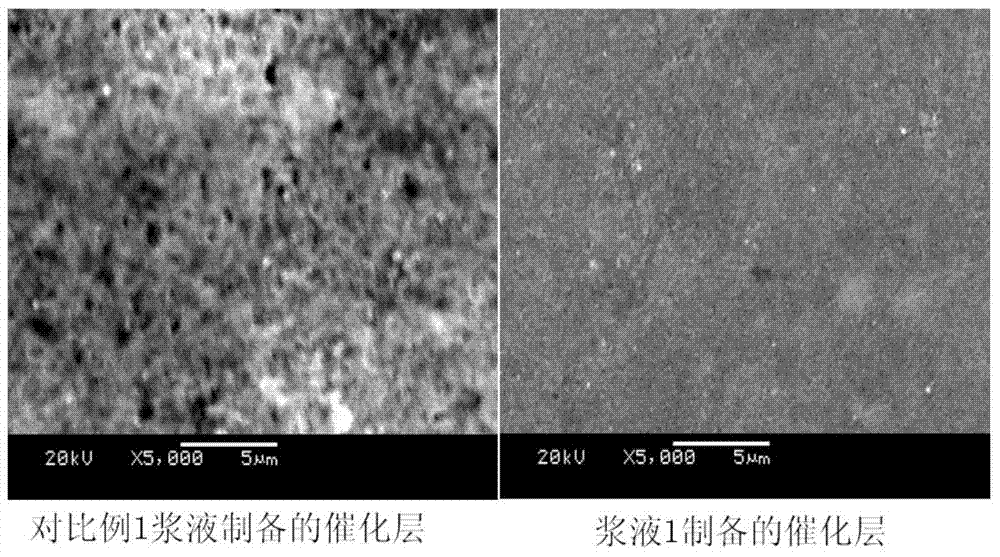

[0028] Slurry 1 consists of catalyst 60%Pt / C, conductive polymer The solution and solvent are prepared by mixing and stirring water, ethylene glycol and n-propanol, and the sum of the mass of the organic solvent ethylene glycol and n-propanol in the solvent accounts for 66% of the total mass of the solvent. The viscosity of the catalyst slurry was 720 mPa·s, the solid content was 21 wt%, and the catalyst concentration was 17 wt%. Take 10 mL of the prepared slurry and put it in a small bottle to stand still, and observe whether the slurry settles after standing for a long time. A cathode catalytic layer for direct methanol fuel cells was prepared on the surface of the PTFE membrane by brushing the slurry 1, and the prepared catalytic layer was analyzed by a scanning electron microscope to observe its morphology and uniformity. After the catalytic layer printed on the surface of the PTFE membrane was dried, it was transferred to the surface of the Nafion115 membrane to form a ...

Embodiment 2

[0030] Slurry 2 is made of catalyst 40%Pt / C, conductive polymer The solution is prepared by mixing and stirring the solvent water, glycerol and n-propanol, and the mass of the organic solvent glycerin and n-propanol in the solvent accounts for 40% of the total mass of the solvent. The viscosity of the catalyst slurry is 1000 mPa·s, the solid content is 60 wt%, and the catalyst concentration is 55 wt%. The slurry was prepared by screen printing on the surface of carbon paper to form a proton exchange membrane fuel cell (PEMFC) cathode GDE (Gas Diffusion Electrode), and the prepared cathode catalytic layer, anode catalytic layer and corresponding diffusion layer were assembled into MEA and single Battery. The results show that the catalyst slurry has good stability, which can ensure the consistency and repeatability of batch preparation.

Embodiment 3

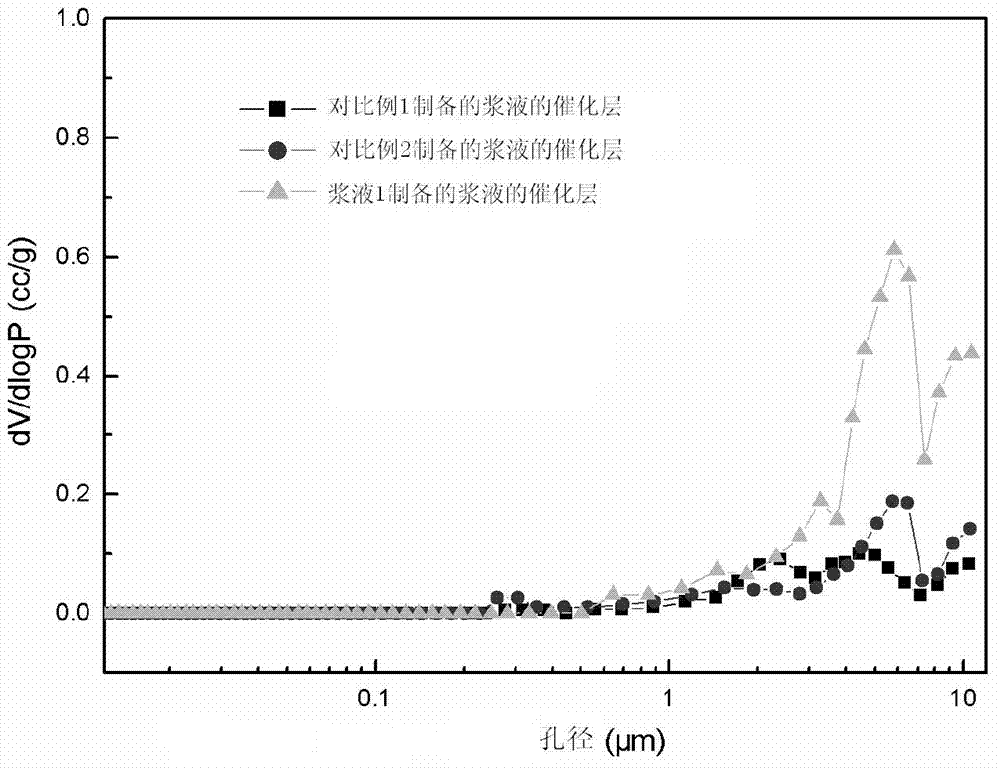

[0032] Slurry 3 is made of catalyst PtRu black, conductive polymer The solution is prepared by mixing and stirring the solvent water and isopropanol, and the organic solvent content in the solvent is 90%. The viscosity of the catalyst slurry is 100 mPa·s, the solid content is 5 wt%, and the catalyst concentration is 4 wt%. The viscosity of the slurry was 100 mPa·s. The slurry was prepared by screen printing on the surface of carbon paper to form a DMFC cathode GDE (Gas Diffusion Electrode), and the above prepared cathode catalytic layer, anode catalytic layer and corresponding diffusion layer were assembled into an MEA and a DMFC single cell. The catalyst in the catalyst slurry is uniformly dispersed, the catalyst utilization rate of the prepared catalytic layer is high, and the pore size distribution of the catalytic layer is favorable for gas-liquid mass transfer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com