In-situ polymerization type N-P synergistic flame-retardant nylon and preparation method thereof

A synergistic flame retardant and polymerized technology, applied in the field of in-situ polymerized N-P synergistic flame retardant nylon and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

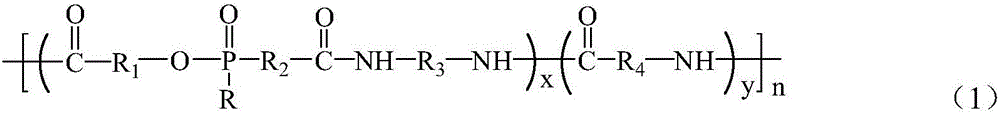

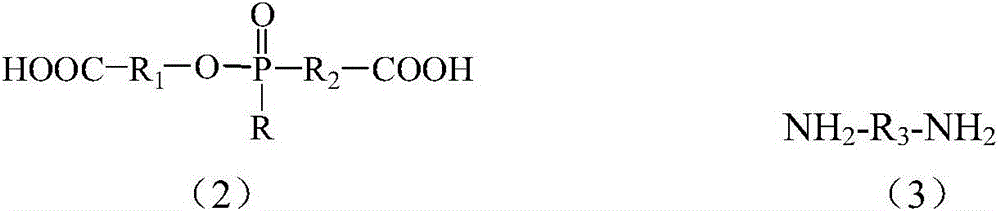

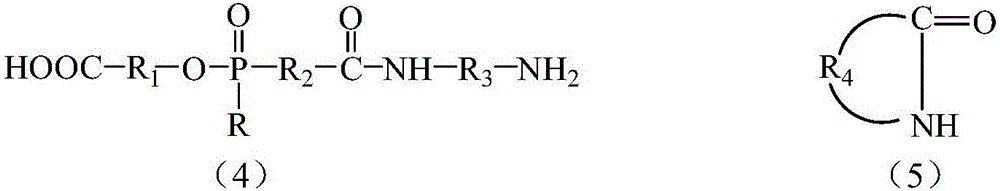

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of in-situ polymerized N-P synergistic flame-retardant nylon of the present invention includes the following steps:

[0070] (A) Reacting an organophosphorus flame-retardant monomer or its derivative with a diamine monomer to make the amino group excessive to prepare a salt or salt solution;

[0071] (B) Let the reaction product of step (A) and the lactam be 1-10wt%, preferably 3-6wt% of the nitrogen-based flame retardant (for example, melamine cyanurate emulsion) relative to the total weight of all polymerized monomers In the presence of the reaction, the in-situ polymerized NP synergistic flame retardant nylon is formed.

[0072] In step (A), preferably, the flame retardant and the diamine monomer are reacted in a molar ratio of 1:0.1-20, preferably 1:0.5-10, more preferably 1:1-2.

[0073] In step (A), preferably, the diamine monomer is slightly excessive, so that the pH of the prepared salt solution is 7-9. The reaction temperature rose from room tem...

Embodiment 1

[0090] The flame-retardant monomer and hexamethylenediamine were stirred and reacted in a small amount of water at a molar ratio of 1:1.3 at 42°C for 0.5h, and the pH of the solution was adjusted to 7.5 to obtain a salt solution.

[0091] MCA accounting for 4% of the total mass of polymerized monomers (including the above-mentioned salts and the following lactam monomers) is emulsified at a high-speed shear in a certain amount of water for 10 minutes to obtain a uniformly dispersed MCA emulsion.

[0092] The caprolactam monomer, the salt solution obtained above (accounting for 4% of the total mass of the caprolactam monomer, excluding the solvent, the same below), the MCA emulsion, the catalyst sodium hypophosphite each accounting for 1‰, and the antioxidant terephthalic acid Amine and molecular weight regulator benzoic acid are added to the reactor, evacuated and filled with nitrogen three times, and finally the pressure in the reactor is maintained at 0.25 MPa. Heat the reaction ...

Embodiment 2

[0095] The flame-retardant monomer and hexamethylene diamine were stirred and reacted in a small amount of water at a molar ratio of 1:1.3 at 50° C. for 0.5 h, and the pH of the solution was adjusted to 7.5 to obtain a salt solution.

[0096] Melamine phosphate, which accounts for 4% of the total mass of polymerized monomers (including the above-mentioned salt and the following lactam monomers), is emulsified at high speed for 10 minutes in a certain amount of water to obtain a uniformly dispersed melamine phosphate aqueous dispersion.

[0097] The caprolactam monomer, the salt solution obtained above (accounting for 4% of the total mass of the caprolactam monomer), the melamine phosphate aqueous dispersion, the catalyst sodium hypophosphite each accounting for 1‰, the antioxidant p-phenylenediamine, the molecular weight adjustment Add benzoic acid to the reactor, evacuated, and filled with nitrogen three times, and finally kept the pressure in the reactor at 0.25MPa. Heat the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flammability rating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com