Patents

Literature

43results about How to "Reduce droplet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen-phosphorus expanded type flame retardant and preparation method for application in aqueous polyurethane coating

ActiveCN110343413AImprove flame retardancyKeep the original natureFireproof paintsGroup 5/15 element organic compoundsChemistrySodium methoxide

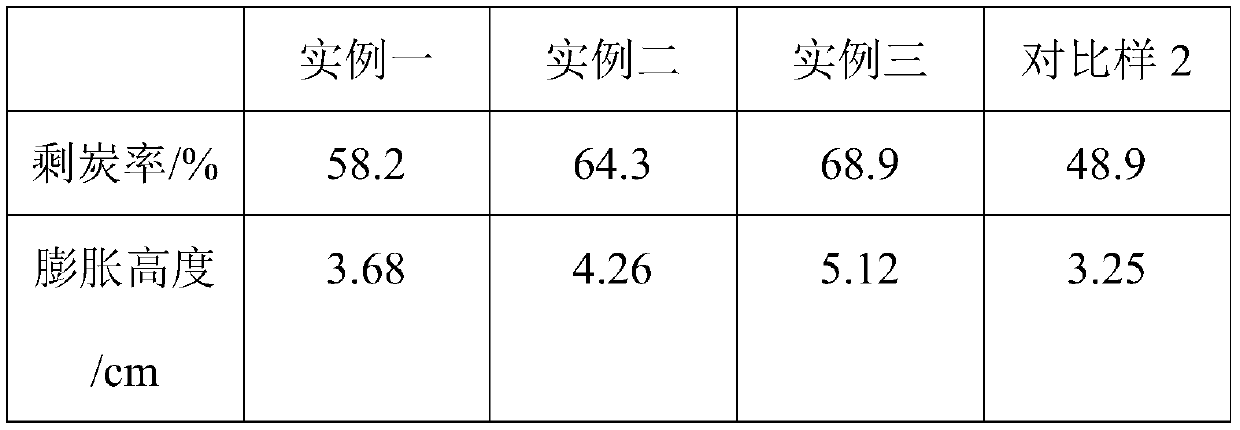

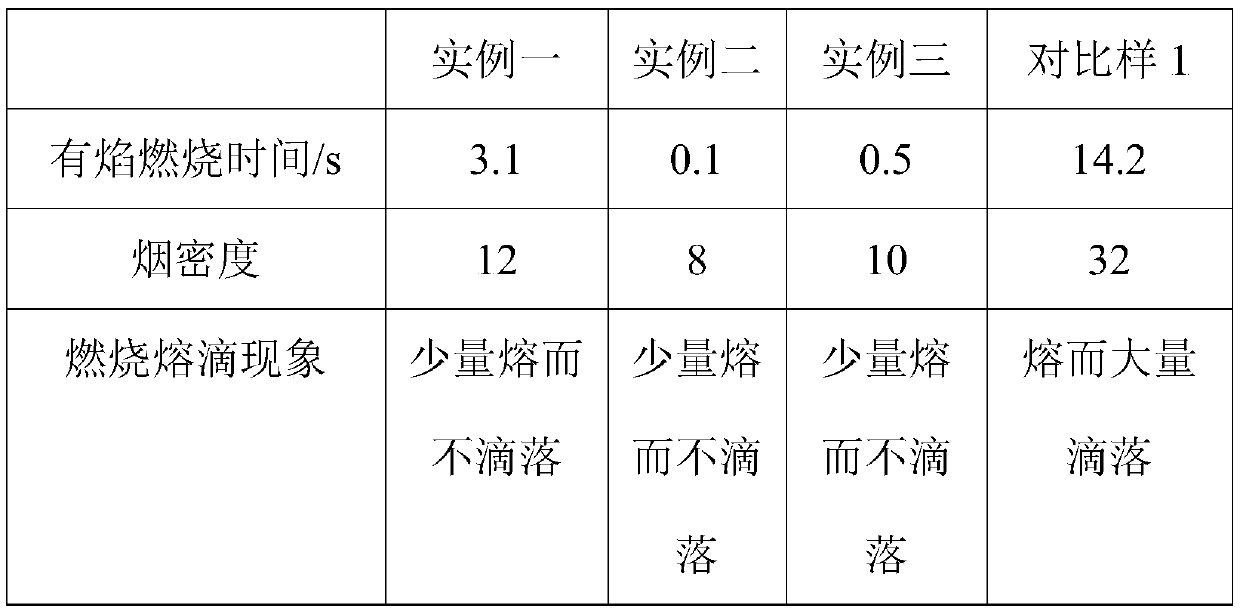

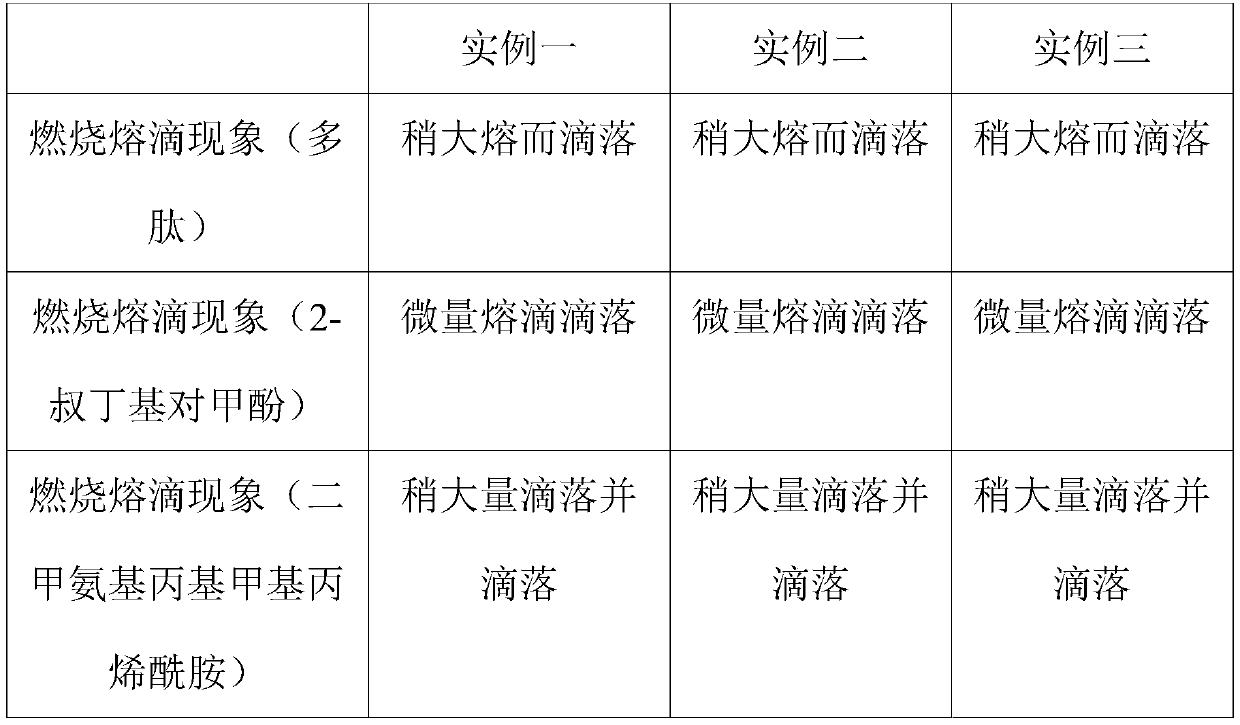

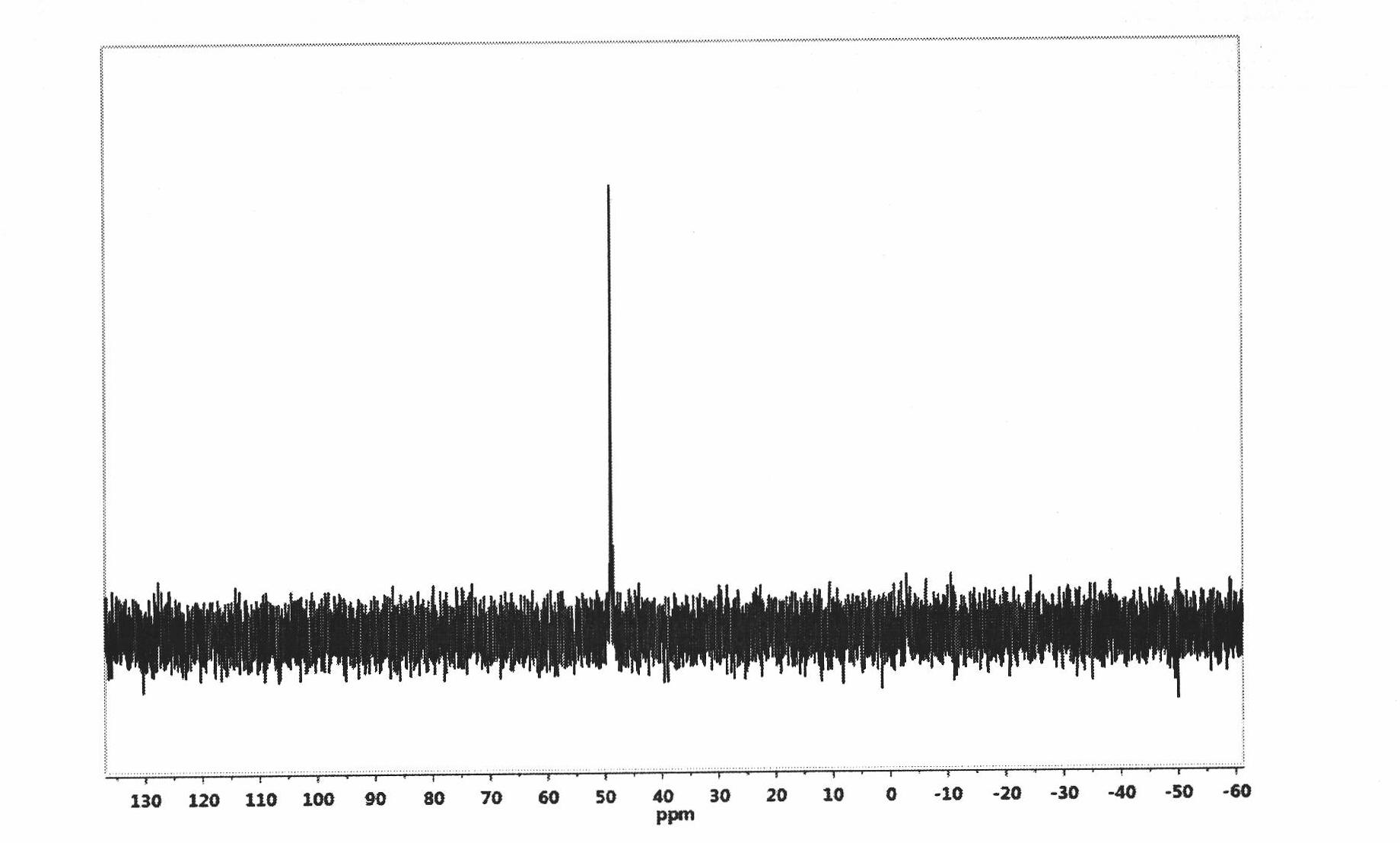

The invention relates to preparation of a nitrogen-phosphorus expanded type flame retardant and a method for application in preparing an aqueous polyurethane coating. The method comprises the following steps: mixing dimethyl phosphate, and alkali catalysts, namely sodium methoxide and acrylamide, performing a reaction so as to obtain an intermediate, adding a charcoal formation agent and a substance A, keeping the pH value of the solution to 6.5-7.0 in the stirring process, further adding a substance B and a substance C, performing a continuous stirring reaction, and performing concentration so as to obtain the nitrogen-phosphorus expanded type flame retardant; and preparing the aqueous polyurethane coating from the nitrogen-phosphorus expanded type flame retardant. By adopting the flame retardant provided by the invention, flame can be rapidly choked, and the flame retardancy of the nitrogen-phosphorus expanded type flame retardant can be improved by releasing smoke, controlling flamecombustion time and controlling densities of charcoal layers. In addition, the nitrogen-phosphorus expanded type flame retardant is grafted with polyurethane, so that the flame retardancy of the polyurethane can be further improved.

Owner:YANTAI UNIV

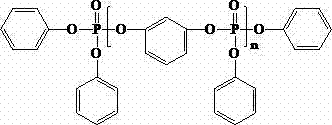

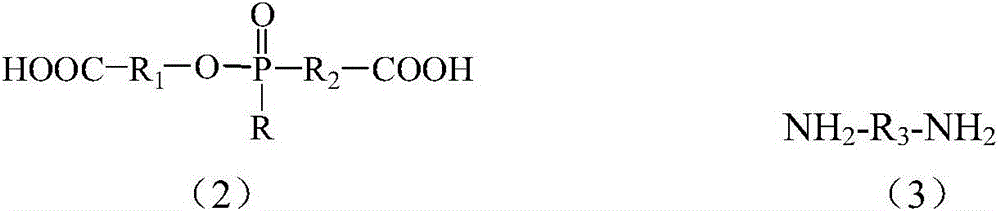

Droplet-resistant flame-retardant polyester, nanometer compound material thereof and method for preparing same

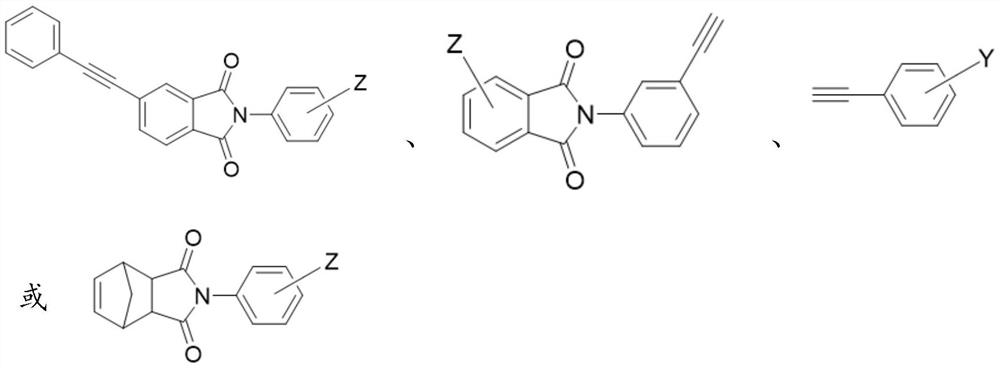

The invention discloses droplet-resistant flame-retardant polyester. The flame-retardant polyester is prepared by random copolymerization of a branched monomer, terephthalic acid or dimethyl terephthalate, ethylene glycol and flame-retardant monomer, wherein the branched monomer is an aliphatic compound or aromatic compound having three or more functional groups; and the flame-retardant monomers adopts any of the following structures. The invention also discloses a method for preparing the droplet-resistant flame-retardant polyester, a nanometer compound material containing the droplet-resistant flame-retardant polyester and a method for preparing the nanometer compound material. Because the droplet-resistant flame-retardant polyester provided by the invention simultaneously contains the branched monomer and the fire retardant having the droplet-resistant effect, the melt viscosity of the droplet-resistant flame-retardant polyester at the high temperature is greatly improved, the sensitivity of the droplet-resistant flame-retardant polyester to temperature is lowered, and the droplet-resistant effect is good; because of the nanometer effect and the blocking effect, the nanometer compound material shows better droplet-resistant effect; and the polyester and the nanometer compound material can be directly used as raw materials for preparing fibers, engineering plastics, films and the like.

Owner:SICHUAN UNIV

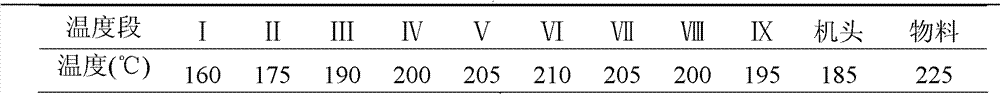

Flame-retardant polylactic acid material of ternary composite flame-retardant system and preparation method thereof

The invention discloses a flame-retardant polylactic acid material of a ternary composite flame-retardant system and a preparation method of the flame-retardant polylactic acid material. The ternary composite flame-retardant system comprises hibiscus cannabinus, nano-zinc oxide and a polymer type phosphorus-containing fire retardant. The preparation method of the flame-retardant polylactic acid material comprises the following steps: (1) performing alkali treatment on the hibiscus cannabinus, and assembling and loading the nano-zinc oxide on the processed hibiscus cannabinus surface; (2) dissolving the polymer type phosphorus-containing fire retardant in chloroform, adding the hibiscus cannabinus loaded with the nano-zinc oxide in the chloroform containing the polymer type phosphorus-containing fire retardant, stirring for a while, adding polylactic acid particles, and when the polylactic acid is completely dissolved and the solution is free of bubbles, forming film on a glass plate, volatilizing at room temperature, and drying; (3) adding the dried thin film in a twin-screw extruder, extruding, cooling and pelletizing the material to prepare the flame-retardant polylactic acid material of the ternary composite flame-retardant system. The flame-retardant polylactic acid material is simple in formula, free of halogen, environment-friendly and high in flame retardant efficiency, can reduce molten drop phenomenon, and effectively reduces further spreading of fire.

Owner:NANJING UNIV OF SCI & TECH

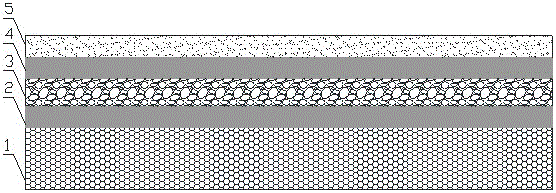

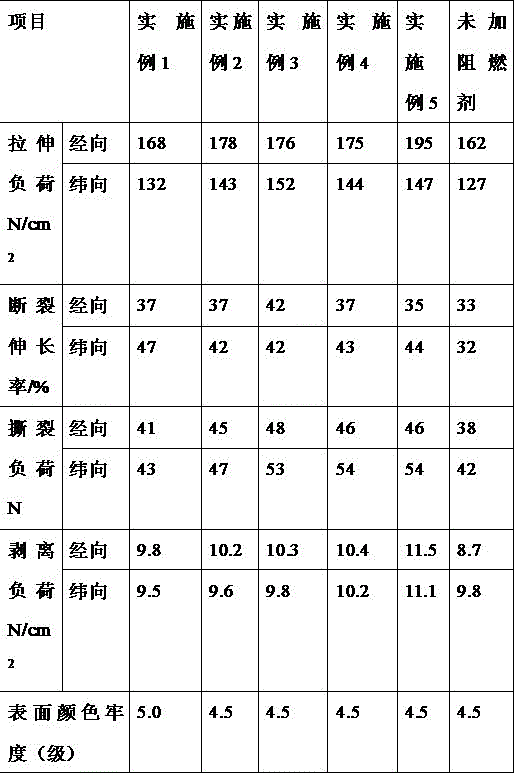

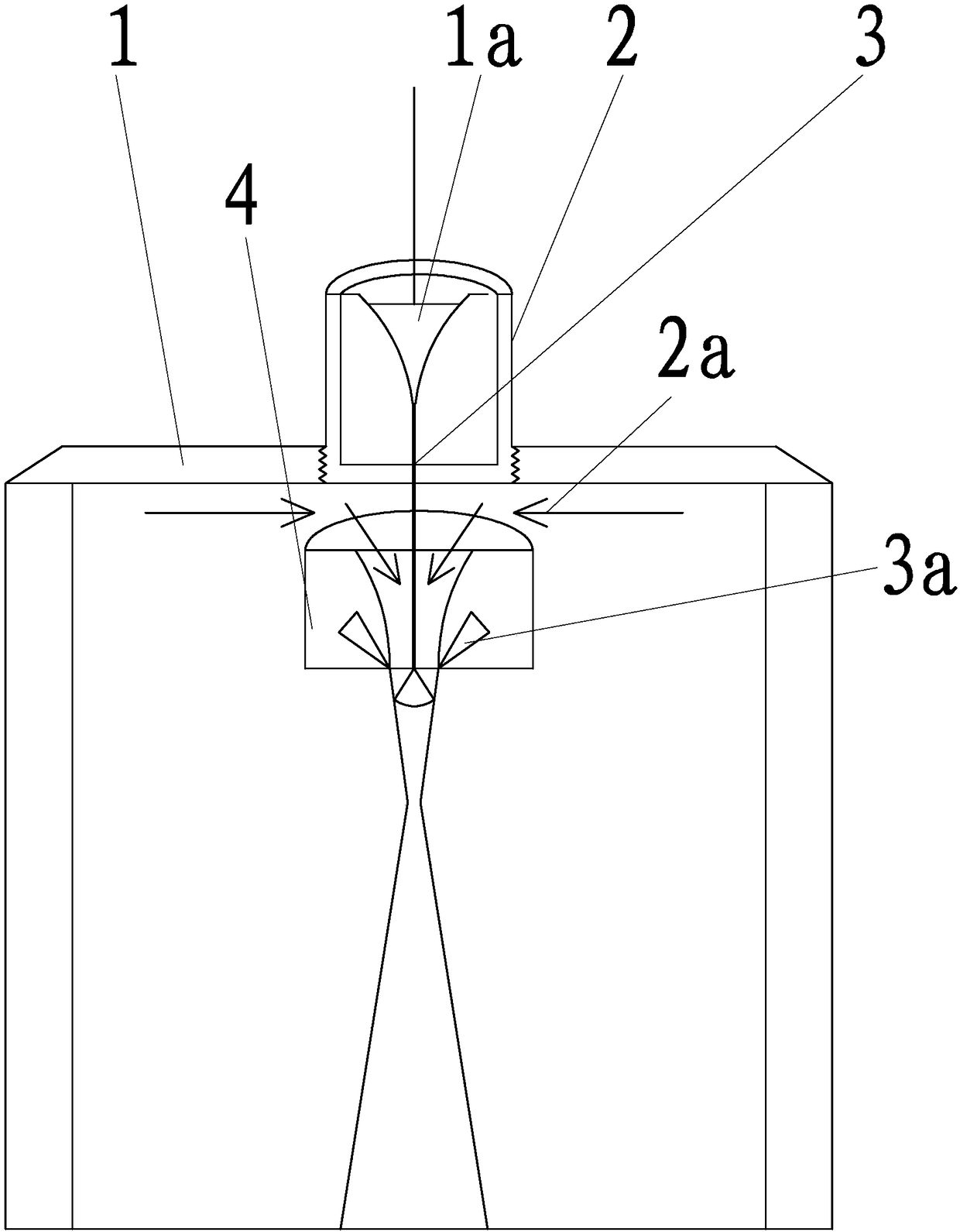

Flame-retardant anti-dripping high-moisture-permeability artificial leather and preparation method thereof

ActiveCN106638015AImprove flame retardant performanceLow smoke productionCoatingsTextiles and paperCombustionFoaming agent

The invention provides flame-retardant anti-dripping high-moisture-permeability artificial leather and a preparation method thereof. The TPU (thermoplastic polyurethanes) artificial leather is formed by compounding of a TPU foaming layer and a TPU leather film face layer on a flame-retardant base cloth layer, wherein the leather film face layer and the foaming layer as well as the foaming layer and the base cloth layer are adhered through a low-melting-point TPU adhesion layer. Each of the leather film face layer, the foaming layer and the adhesion layer realizes film formation by casting after phosphorus-nitrogen intumescent flame retardants and anti-dripping agents are doped into TPU resin particles, and a protein ultrafine powder pore-foaming agent is especially doped into the leather film face layer and the adhesion layer to improve moisture permeability. The high-moisture-permeability artificial leather for clothes is long in flame retardation time, generates no or few molten drops in combustion and can be applied to clothing articles such as clothes, shoes, caps, gloves and the like and used as a fabric for high-temperature-resistant protection garments.

Owner:ZHONGYUAN ENGINEERING COLLEGE

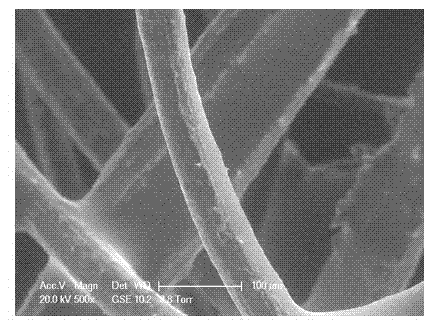

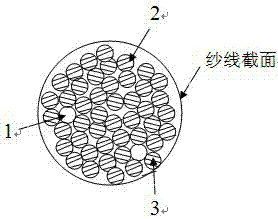

Flame-retardant antistatic yarn and fabric thereof

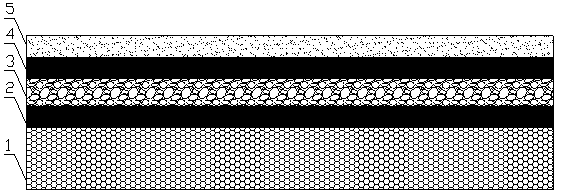

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

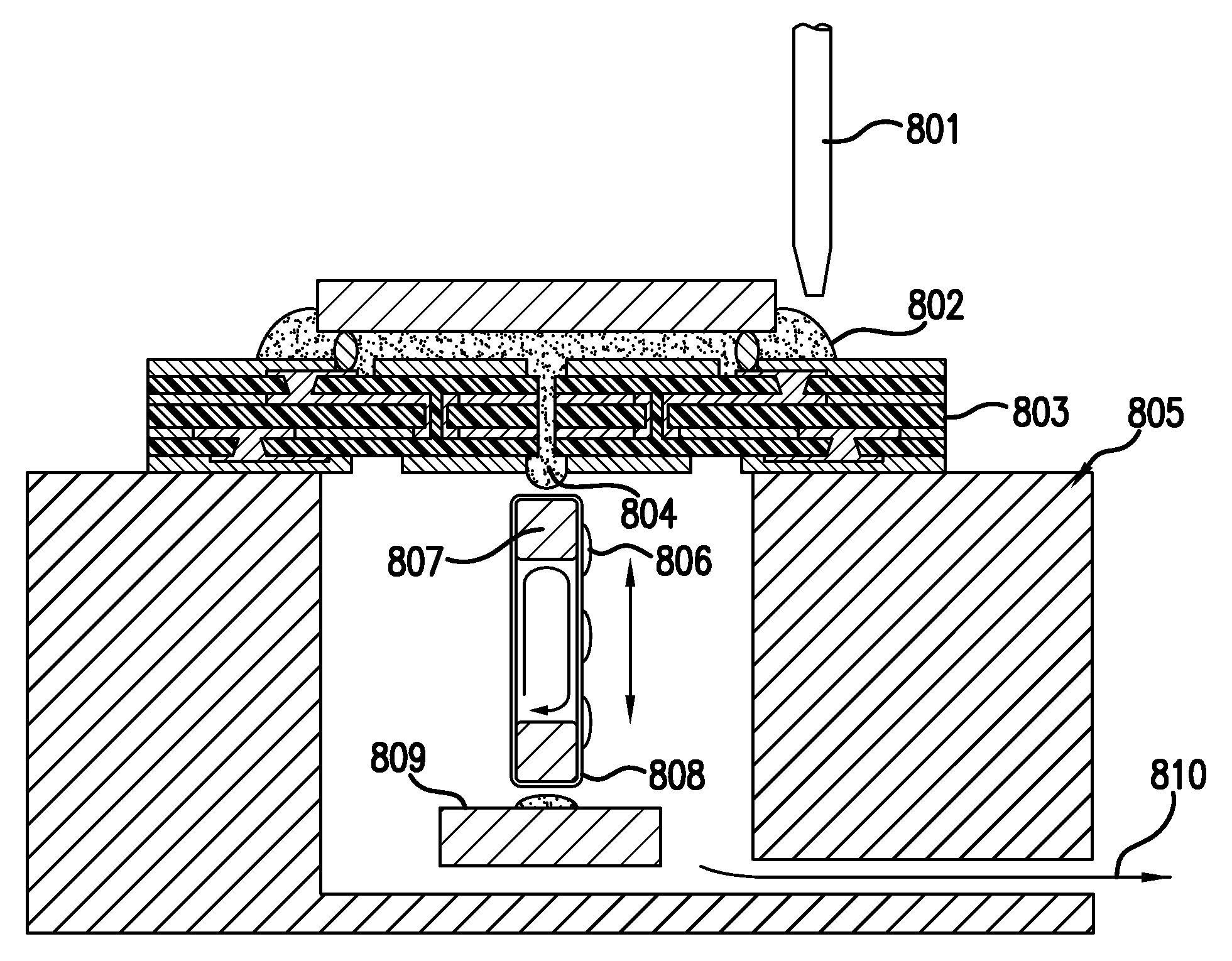

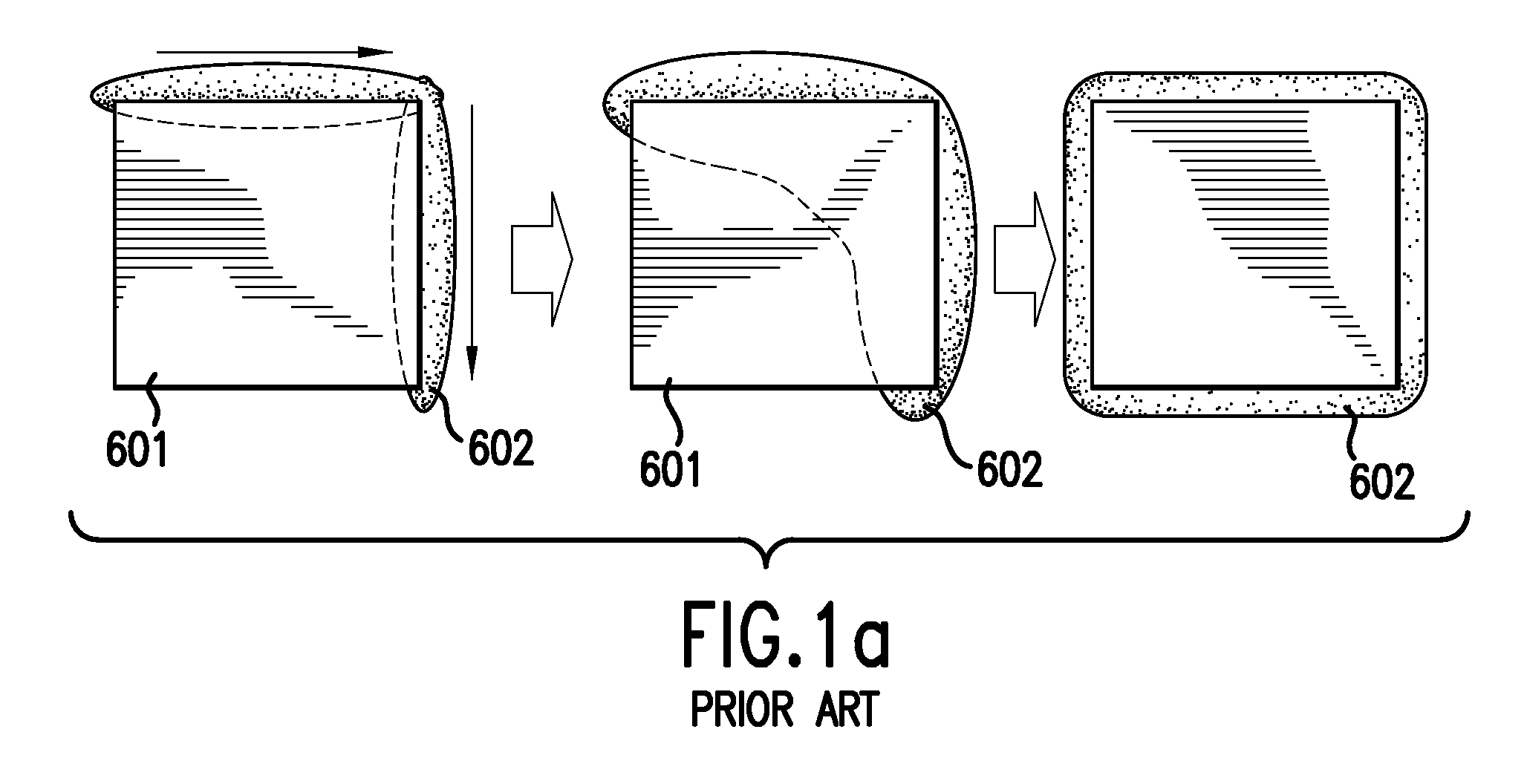

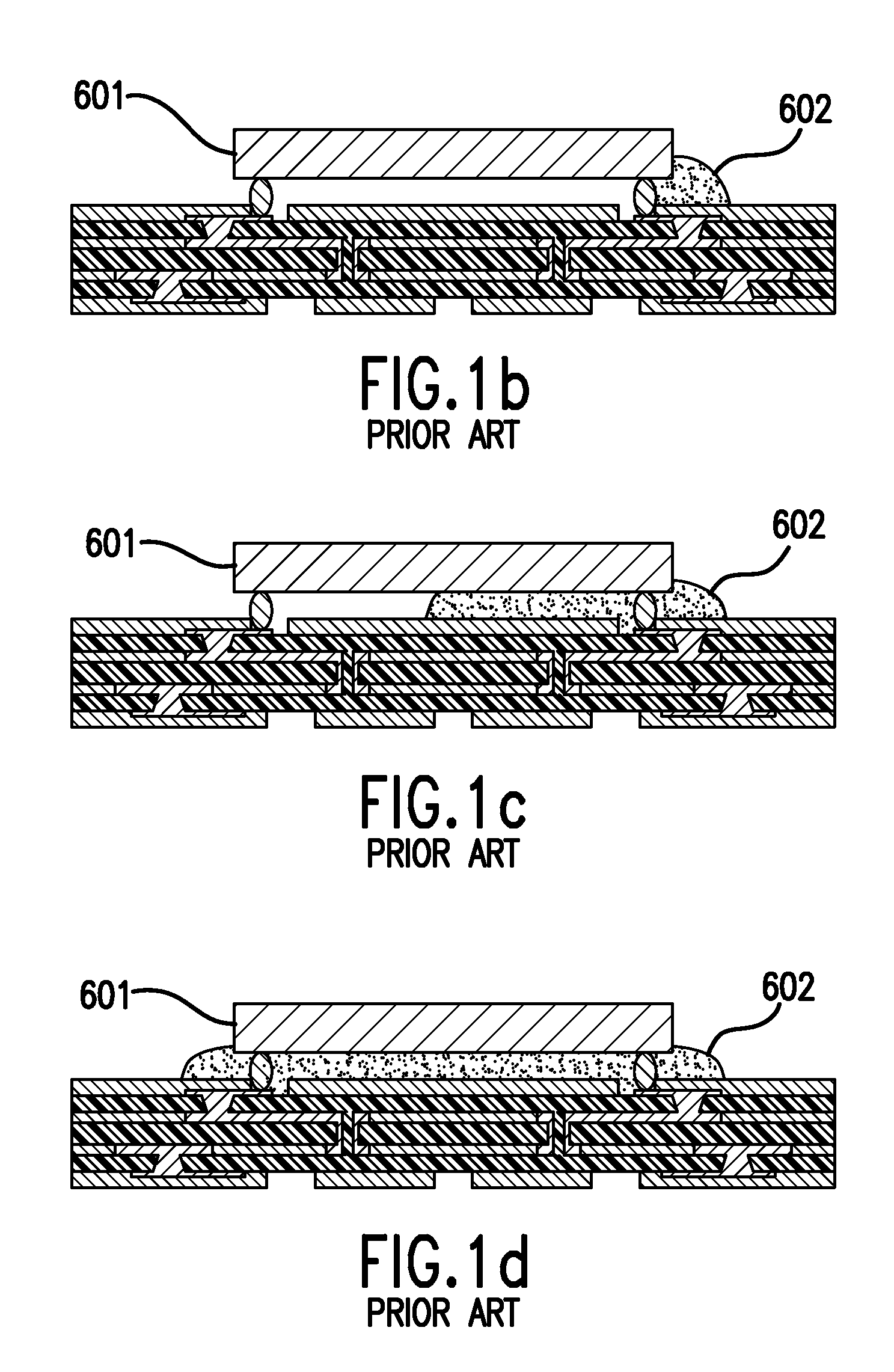

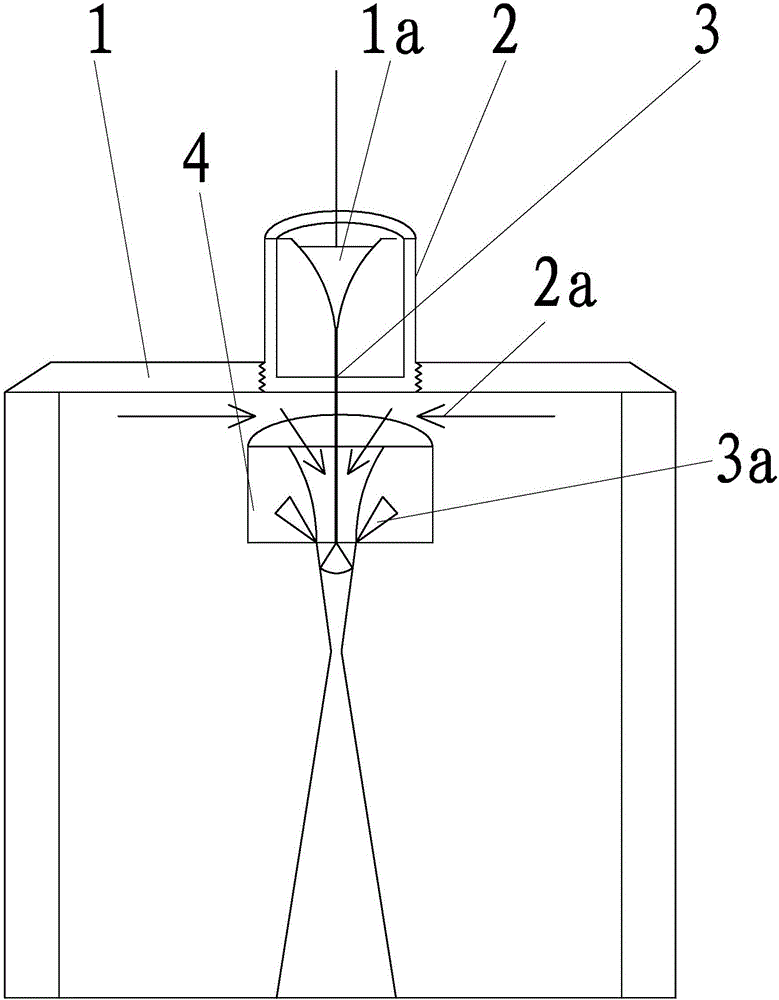

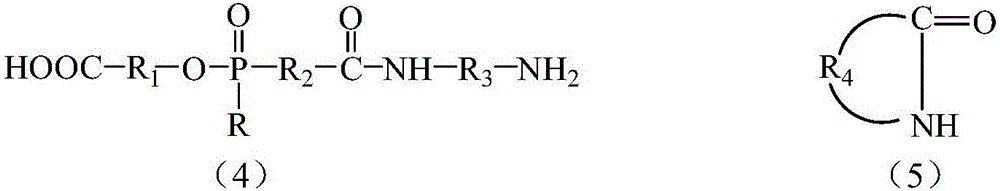

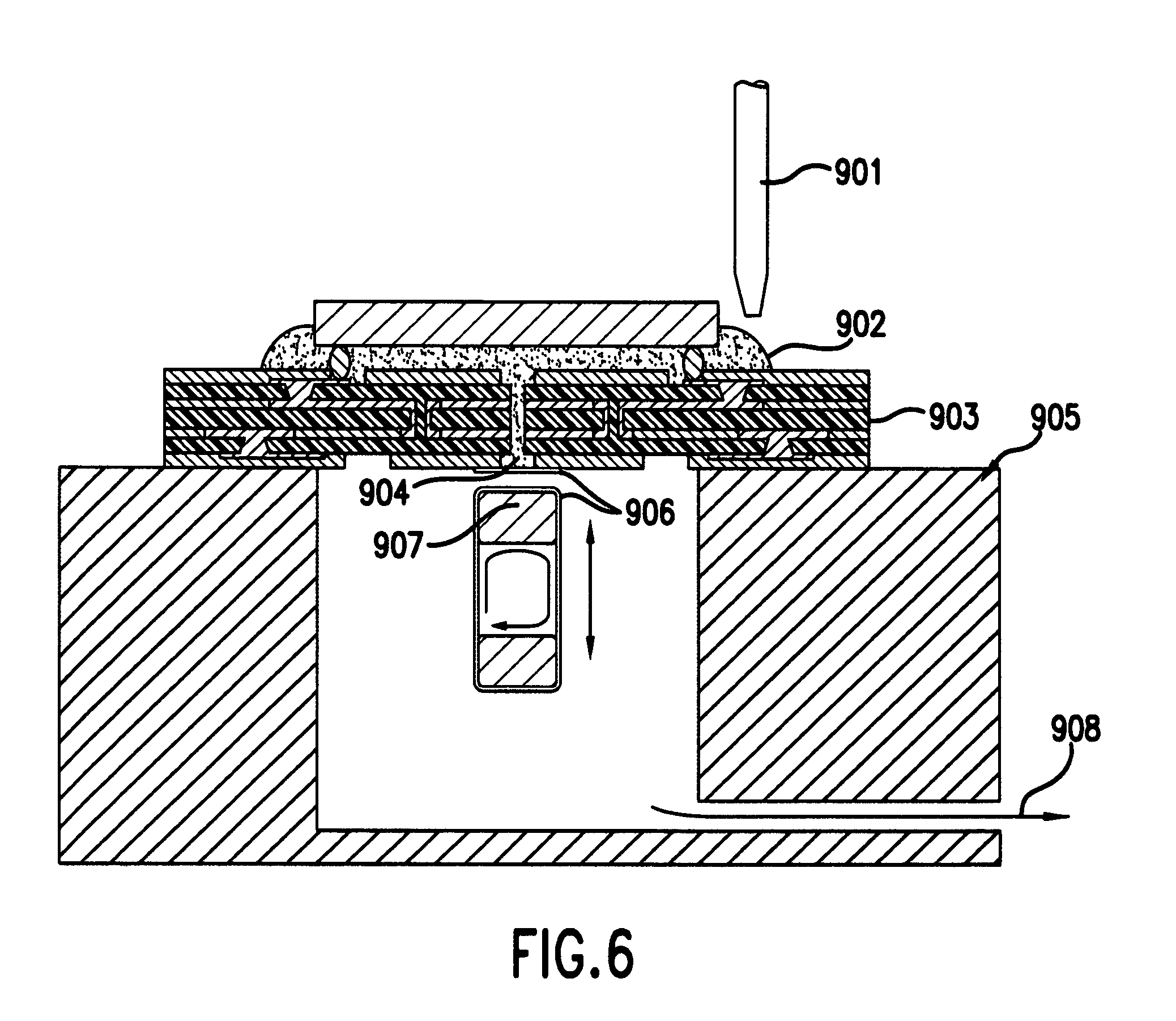

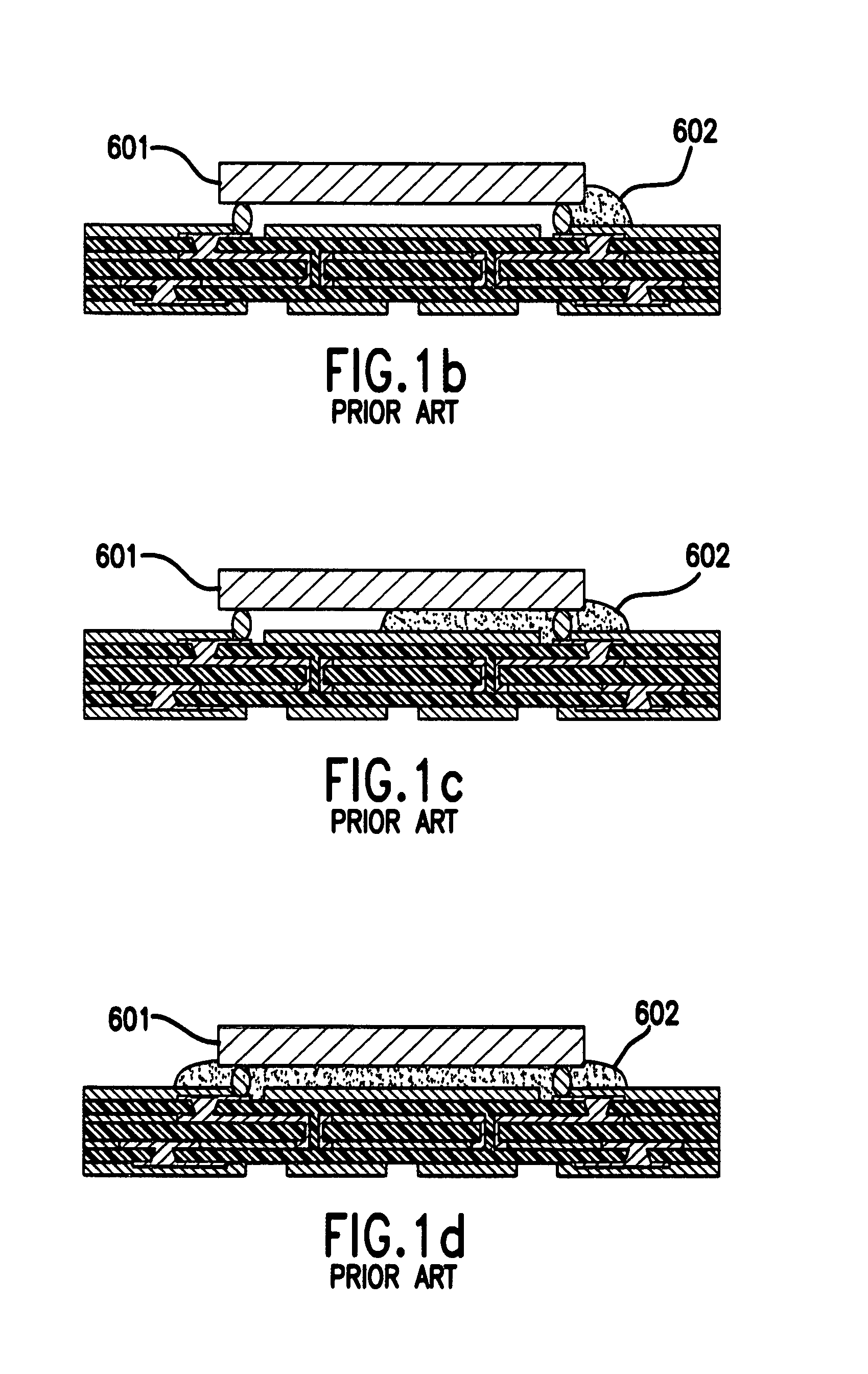

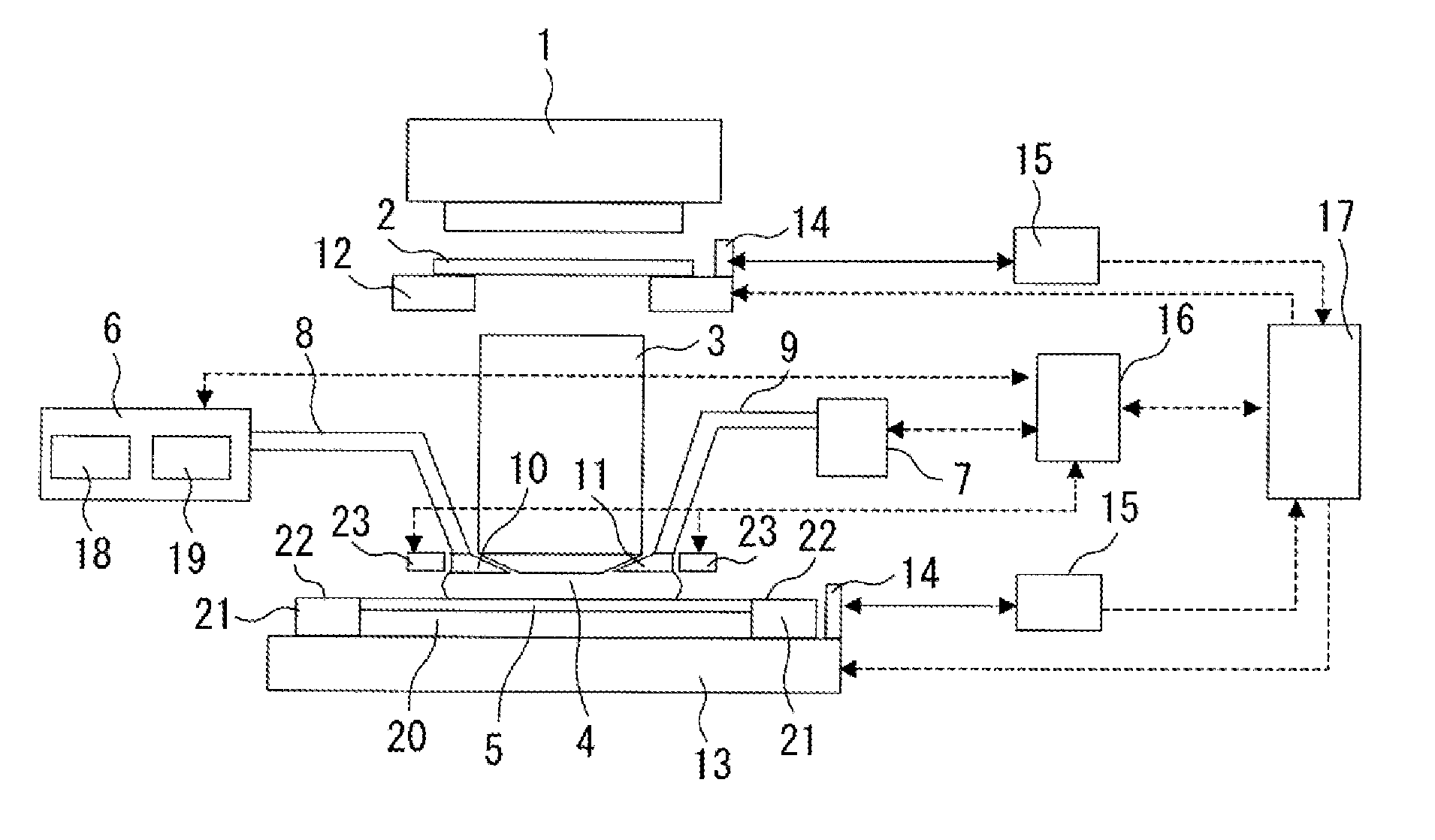

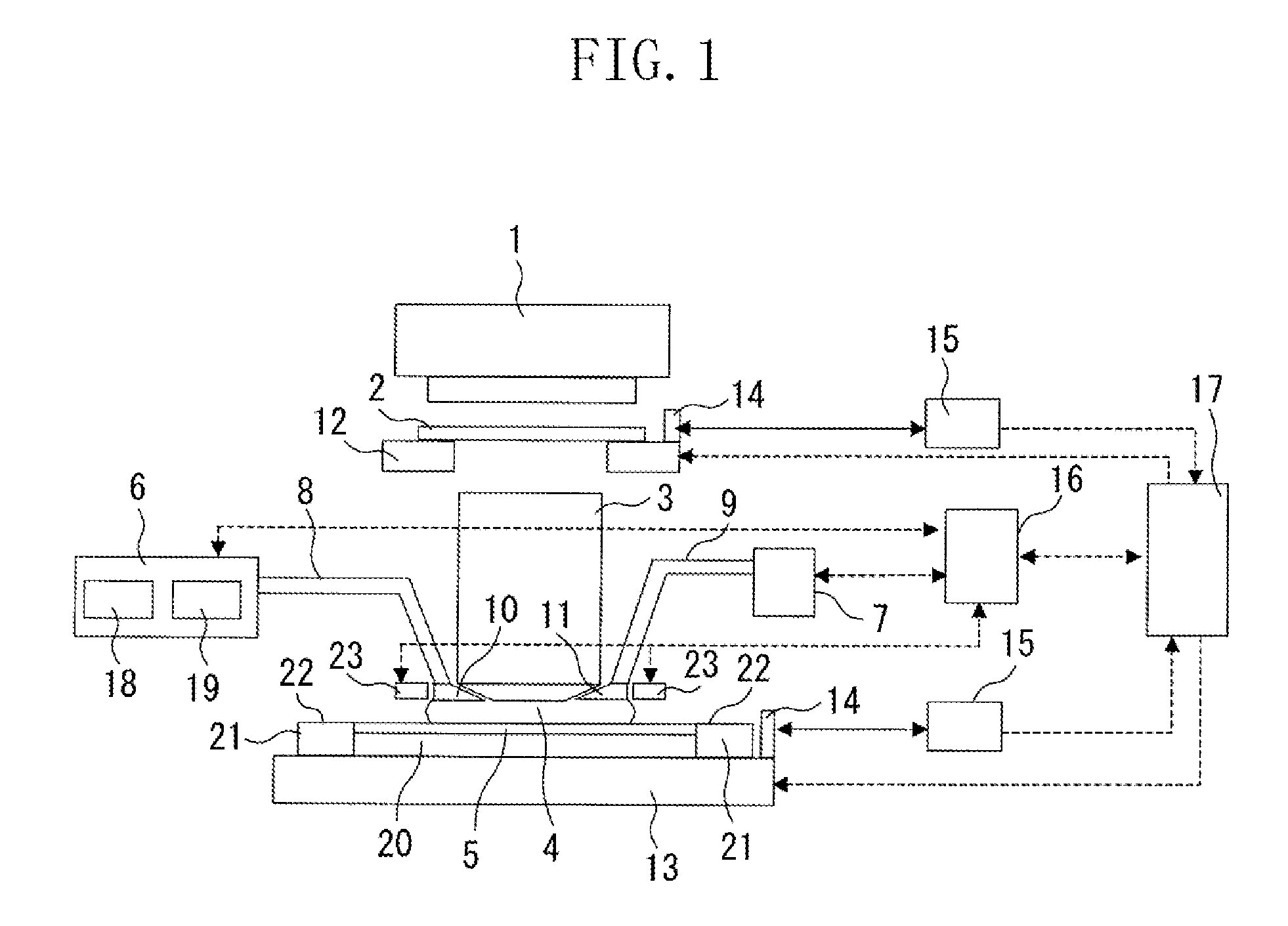

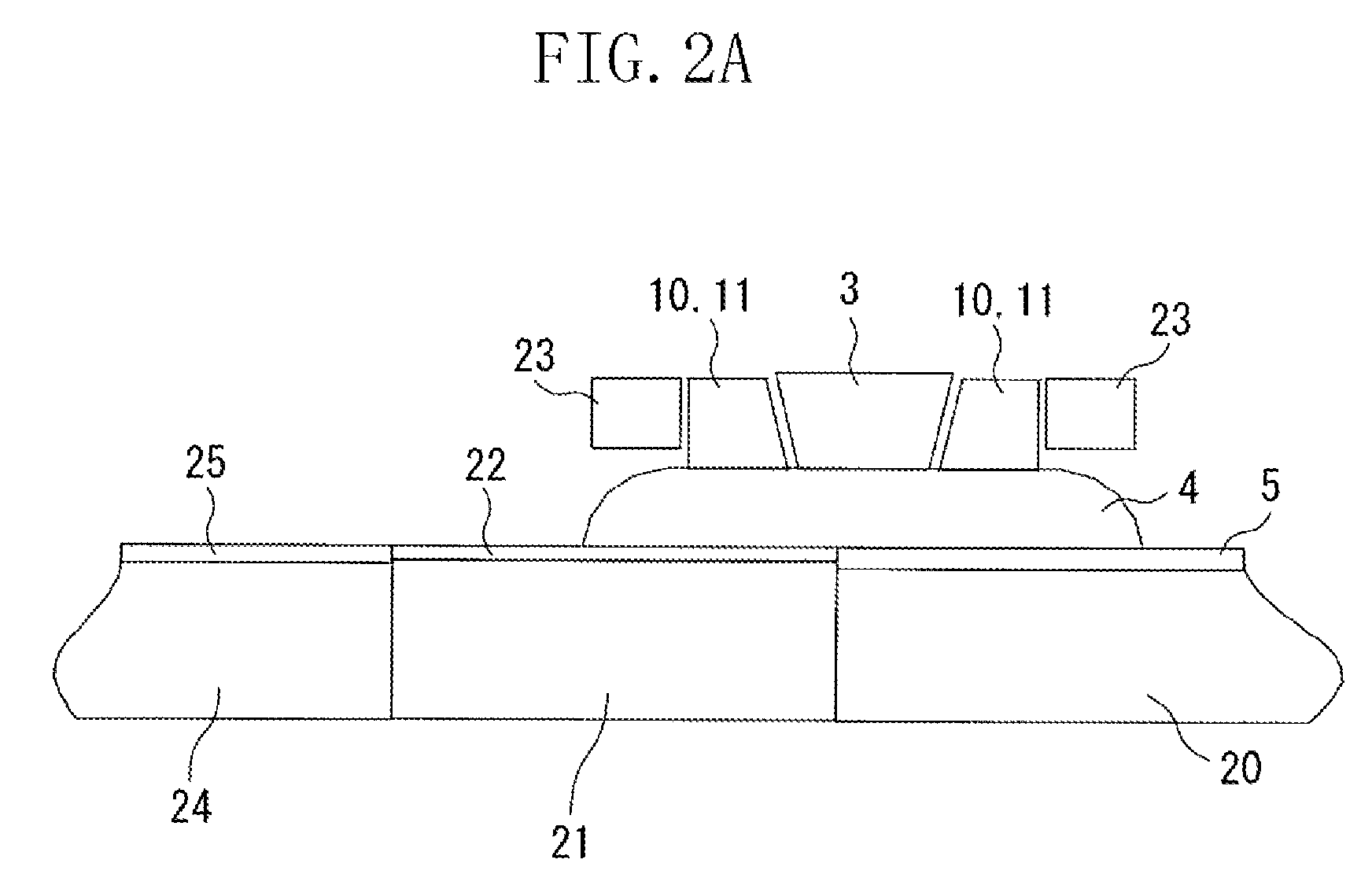

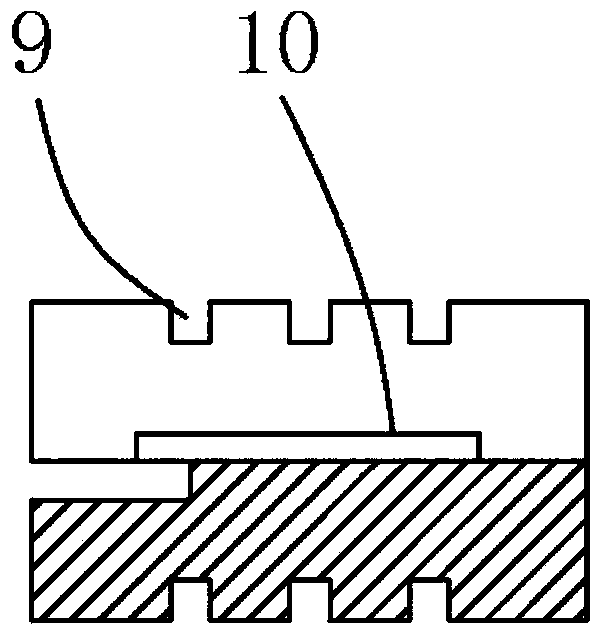

Underfill Air Vent for Flipchip BGA

InactiveUS20090229513A1Reduce voidsReduce dropletVacuum evaporation coatingSolid-state devicesSemiconductor chipEngineering

The invention relates to a system for assembling a flip chip assembly. An underfill resin is dispensed at multiple semiconductor die edges such that vacuum suction provided at a substrate through hole located beneath a stage enables spread of underfill resin from each edge simultaneously for quicker spread and reduction of voids. The excess underfill resin suctioned through the through hole on the underside of the semiconductor die is attracted to reusable tape. The attracted underfill resin is cleaned from a rotating head mechanism by a cleaning pad positioned beneath a lower surface of the head.

Owner:GLOBALFOUNDRIES INC

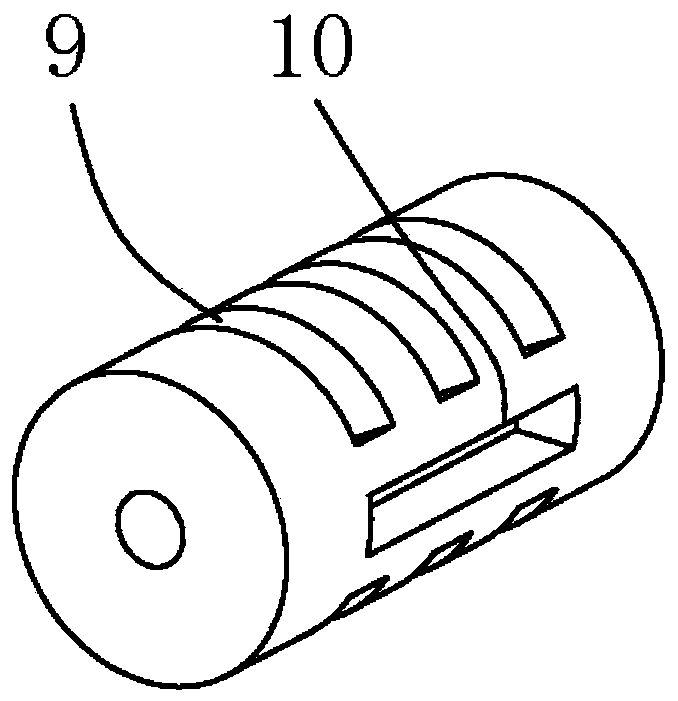

High-magnetoconductivity soft magnetic alloy powder, inductance piece and preparation methods thereof

ActiveCN106205934AReduce power lossSolve the problem of low magnetic permeability and large power lossTransformers/inductances detailsMagnetic materialsApparent densityInductor

The invention discloses high-magnetoconductivity soft magnetic alloy powder. The alloy consists is prepared from the following components in parts by mass: 25.0 to 80.0 parts of Fe, 3.0 to 8.0 parts of Si, 15 to 55 parts of Ni, 1.0 to 7.0 parts of B and 1.0 to 5.0 parts of P. The invention further discloses an inductance piece prepared from the high-magnetoconductivity soft magnetic alloy powder, a preparation method of the high-magnetoconductivity soft magnetic alloy powder and a preparation method of the inductance piece. By the adoption of the preparation method disclosed by the invention, the soft magnetic alloy powder with various particle sizes can be prepared, and the soft magnetic alloy powder is high in magnetoconductivity, lower in power loss, higher in apparent density, high in tap density, lower in oxygen content, high in product pressing performance and high in magnetic ring density. Due to small oxygen content, few impurities, small carbon content, uniform alloy components and high sphericity degree, the high-magnetoconductivity soft magnetic alloy powder can be widely used as a raw material of a novel sintered inductor.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

Iron-silicon-chromium soft magnetic powder, preparation method and application thereof

The invention discloses iron-silicon-chromium soft magnetic powder, a preparation method and application thereof. The preparation method comprises the following steps: 1) iron-silicon-chromium soft magnetic alloy powder raw materials are added in a medium-frequency induction furnace for atmospheric smelting to obtain alloy liquid; and 2) under the condition of nitrogen protection, the alloy liquid is fed in an atomization tower; in the feeding process, two atomization mediums of ultrahigh-pressure atomization water and low-pressure vortex gas synchronously acts on the alloy liquid; and the alloy liquid is strongly crushed as a lot of fine metal molten drops, and is cooled and condensed as the iron-silicon-chromium soft magnetic alloy powder. The iron-silicon-chromium soft magnetic powder with high loose packing density, high tap density, low oxygen content and higher inductance value and magnetic conductivity can be prepared; and the iron-silicon-chromium soft magnetic powder can serve as a raw material of a micro inductor, and is widely applied.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

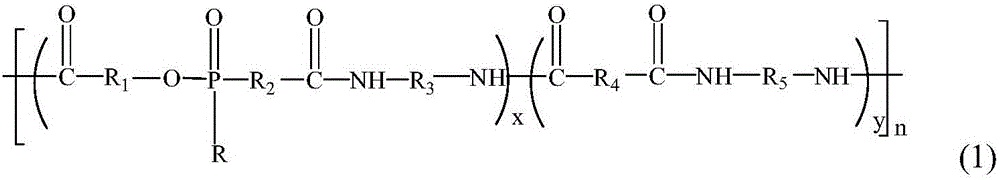

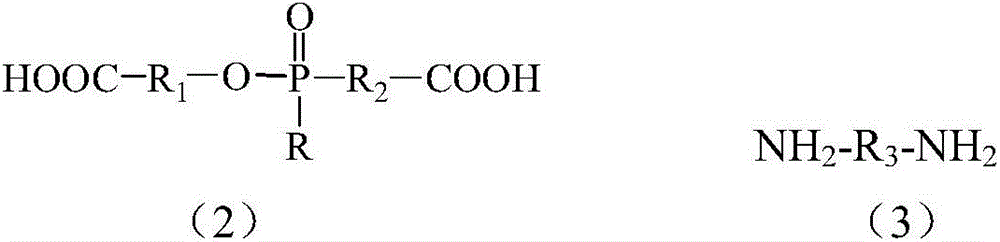

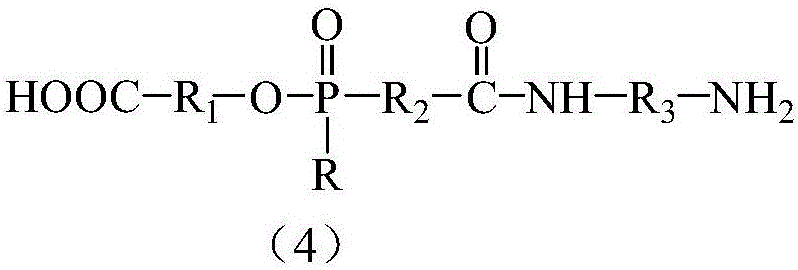

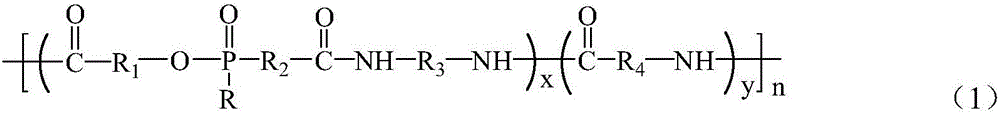

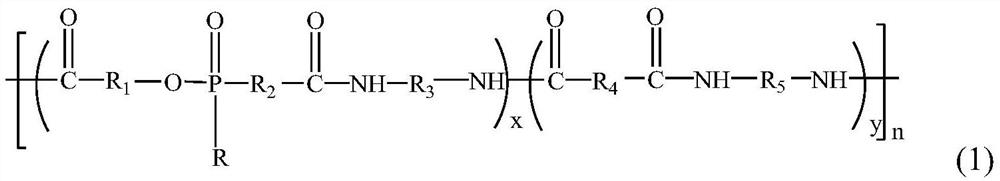

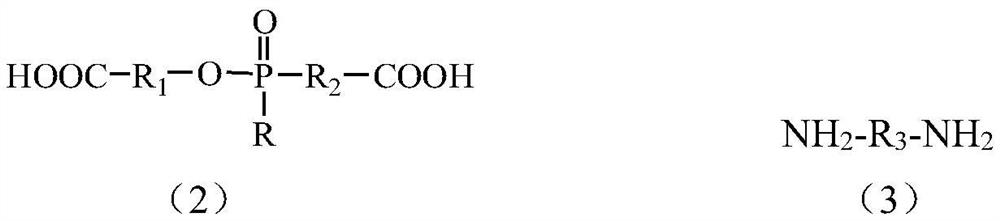

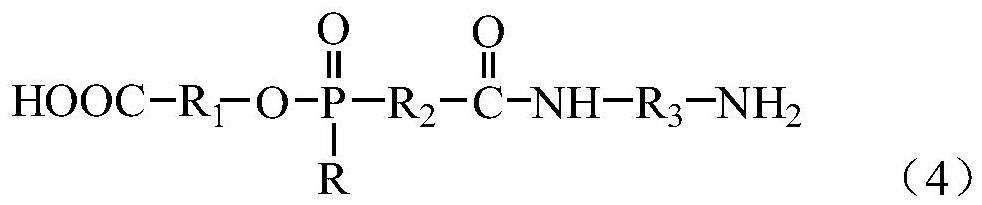

In-situ polymerization type N-P synergistic flame-retardant nylon and preparation method thereof

InactiveCN106497027ASolve the problem of not being able to achieve a higher degree of aggregationViscosity is easy to controlAntioxidantIn situ polymerization

The invention discloses in-situ polymerization type N-P synergistic flame-retardant nylon and a preparation method thereof. The preparation method provided by the invention particularly comprises the following steps: (A) carrying out a reaction between organic phosphorus flame-retardant monomers and diamine monomers to form salt; (B) emulsifying a nitrogen flame retardant and dispersing to obtain nitrogen flame retardant emulsion; (C) adding diacid and diamine or binary amide salt or a solution thereof, the prepared salt or a solution thereof, the nitrogen flame retardant emulsion, an antioxidant and a catalyst into a reaction kettle, and performing in-situ polymerization under the inert atmosphere by regulating and controlling reaction temperature and pressure intensity to prepare the required N-P synergistic flame-retardant nylon. The N-P synergistic flame-retardant nylon prepared by the method reduces the total amount of the required added flame retardant due to the synergistic effect. The viscosity can be controlled in the whole preparation process, a product with excellent mechanical property and flame retardance can be obtained, the vertical combustion test can reach UL-94 V-0 level, and the limit oxygen index is 28 percent or higher.

Owner:CHENGDU TALY TECH CO LTD +1

In-situ polymerization type N-P synergistic flame-retardant nylon and preparation method thereof

InactiveCN106433103ASolve the problem of not being able to achieve a higher degree of aggregationViscosity is easy to controlIn situ polymerizationAntioxidant

The invention discloses an in-situ polymerization type N-P synergistic flame-retardant nylon and a preparation method thereof. The preparation method comprises the following steps: (1) reacting an organophosphorus flame-retardant monomer with a diamine monomer to form salt; (2) emulsifying and dispersing a nitrogen flame retardant, so as to obtain a nitrogen flame retardant emulsion; and (3) adding a lactam monomer, the salt prepared in the step (1), an antioxidant, the nitrogen flame retardant, a catalyst and a molecular weight adjusting agent into a reaction kettle, and performing in-situ polymerization by regulating reaction temperature and pressure under inert atmosphere, so as to obtain the needed N-P synergistic flame-retardant nylon material. According to the prepared in-situ polymerization type flame-retardant nylon, the content of the flame retardant needing to be added is reduced due to the synergistic effect, the viscosity during the whole preparation process is controllable, the product with both excellent mechanical performance and flame-retardant performance can be obtained, the vertical burning test can achieve the UL94 V-0 grade, and the limiting oxygen index is more than 28%.

Owner:CHENGDU TALY TECH CO LTD +1

Method of underfill air vent for flipchip BGA

InactiveUS7791209B2Faster underfillingReduce processLine/current collector detailsSemiconductor/solid-state device detailsEngineeringSemiconductor

Owner:GLOBALFOUNDRIES INC

Preparation and application method of flame-retardant and wear-resistant low-voc polyurethane coating

ActiveCN112646475BImprove rigidityImprove wear resistanceFireproof paintsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a method for preparing and applying a flame-retardant, wear-resistant and low-VOC polyurethane coating. Polyester diol, isocyanate, and dibutyltin dilaurate are added to a reaction vessel, and the polyurethane coating is stirred and reacted at 75-90°C to obtain a polyurethane coating. Polymer, add hydrophilic chain extender dimethylolpropionic acid, nitrogen phosphorus intumescent flame retardant, acetone solvent to the polyurethane prepolymer, stir and react at 70~90℃ for 1~2h; then add triethyl Emulsify with amine and water for 20~60min, then add substance A and epoxy-terminated polyether silicone oil, adjust the pH to 6.5, stir and react at 70~80°C to obtain a flame-retardant, wear-resistant and low-VOC polyurethane coating, and the obtained polyurethane film can be burned in a flame Aspects such as time, droplet resistance are obviously superior to due to prior art.

Owner:YANTAI UNIV

Halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke

InactiveCN104479210AReduce migration speedReduce dosagePlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxideLead phosphate

The invention discloses a halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke. The insulating material is prepared from the following raw materials in parts by weight: 80-150 parts of cross-linked polyethylene, 10-30 parts of magnesium hydroxide, 5-9 parts of aluminium hydroxide, 1-2 parts of lead sulfate tribasic, 0.5-0.9 part of dibasic lead phosphate, 0.3-0.7 part of paraffin, 20-50 parts of phthalate and 5-15 parts of nano-montmorillonite. The insulating material provided by the invention has the advantages of being light in weight, good in toughness, small in flame and low in burning speed, having no molten drop and less smoke, being anti-migration, good in char forming characteristics, easy in processing and the like.

Owner:GUIZHOU MINGHCOO WIRE & CABLE CO LTD

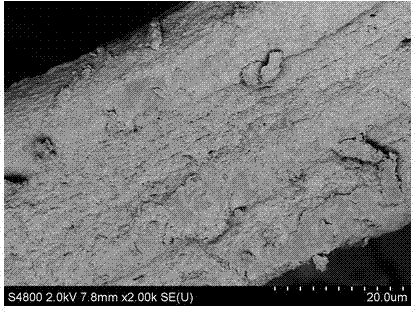

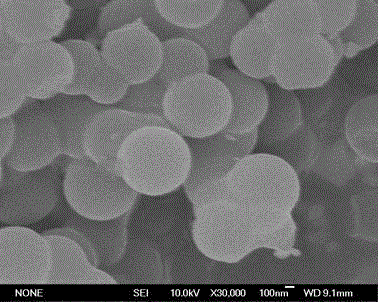

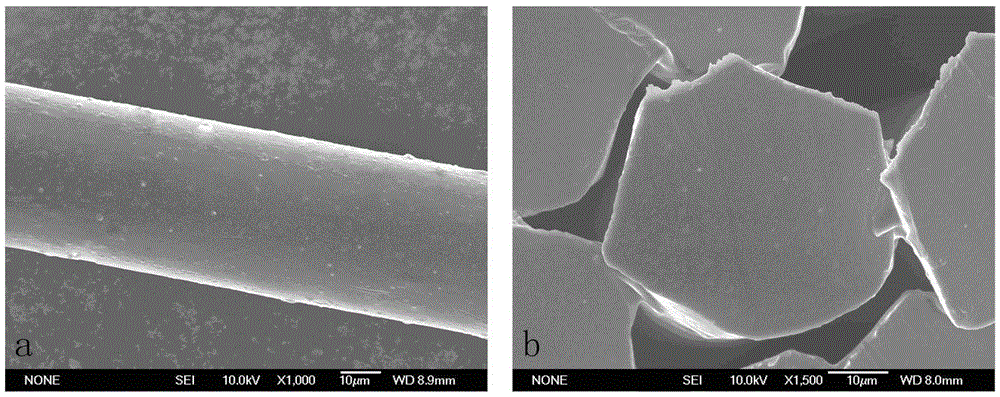

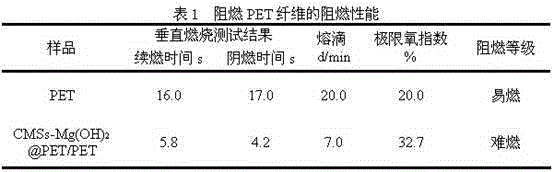

Preparation method of flame-retardant PET fiber

ActiveCN105401252AImprove flame retardant performanceDestruction of physical and chemical propertiesFlame-proof filament manufactureArtificial filament heat treatmentFiberDispersity

The invention relates to a preparation method of flame-retardant PET fiber. The preparation method comprises the following steps: first, wrapping a magnesium hydroxide coated carbon microsphere flame retardant with a PET layer to obtain an encapsulated magnesium hydroxide coated carbon microsphere flame retardant, so as to effectively improve the dispersity and the compatibility of the flame retardant in a polymer substrate, and improve the spinnability of a material; second, adding 1 wt% of the encapsulated magnesium hydroxide coated carbon microsphere flame retardant in the preparation process of PET fiber, carrying out melt blending and spinning to prepare magnesium hydroxide coated carbon microsphere / polyethylene glycol terephthalate fiber, and adjusting the melt blending and spinning technology reasonably to further improve the spinnability of the flame-retardant PET fiber. The flame-retardant PET fiber prepared according to the preparation method has the advantages that not only is the flame retardant property improved, but also the own physical and chemical properties of fiber are prevented from being damaged; the limited oxygen index of the obtained fiber can reach up to 30 percent or higher; the molten drop quantity and the smoke quantity are greatly reduced; the mechanical property and the hygroscopicity are favorable; requirements of environmental protection and practical use are met.

Owner:TAIYUAN UNIV OF TECH

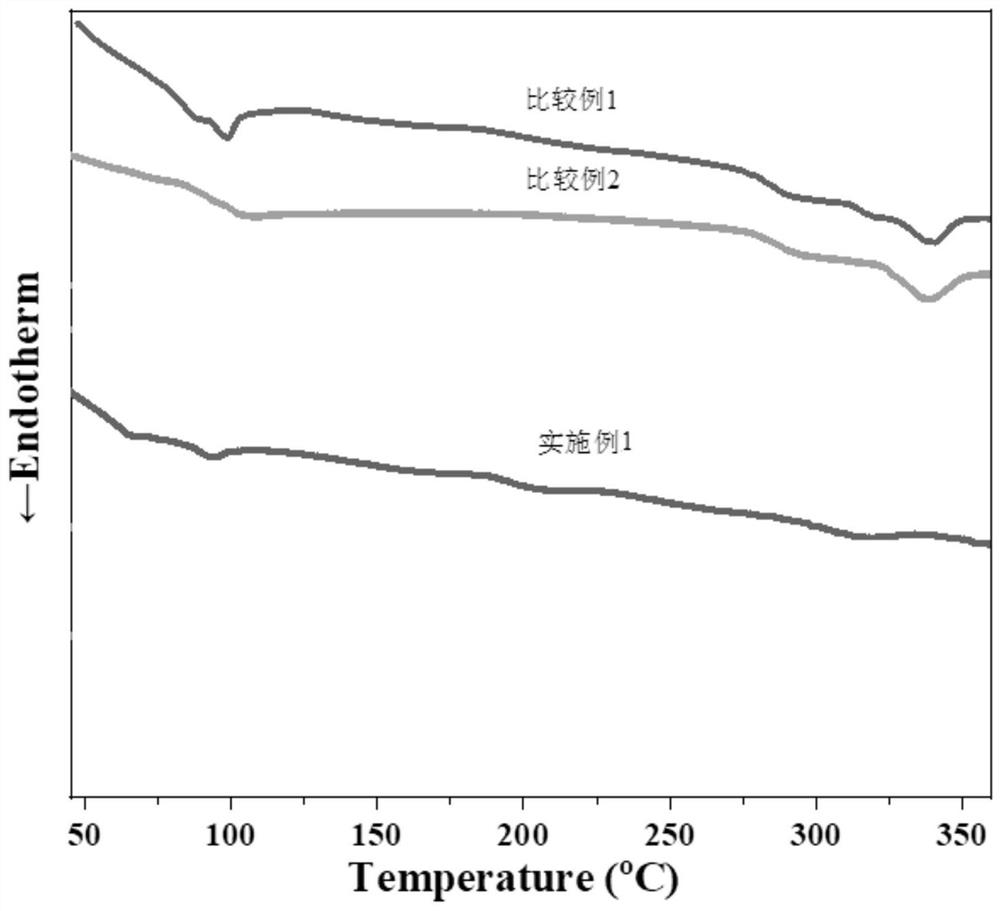

Preparation and application method of flame-retardant wear-resistant low-VOC polyurethane coating

ActiveCN112646475AImprove rigidityImprove wear resistanceFireproof paintsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a preparation and application method of a flame-retardant wear-resistant low-VOC polyurethane coating. The preparation method comprises the following steps: adding polyester glycol, isocyanate and dibutyltin dilaurate into a reaction container, stirring at 75-90 DEG C for reaction to obtain a polyurethane prepolymer; adding a hydrophilic chain extender dimethylolpropionic acid, a nitrogen-phosphorus intumescent flame retardant and an acetone solvent into the polyurethane prepolymer, and stirring and reacting for 1-2 hours at the temperature of 70-90 DEG C; and adding triethylamine and water for emulsification for 20-60min, then, adding the substance A and epoxy-terminated polyether silicone oil, adjusting the pH to 6.5, performing stirring and reaction at 70-80 DEG C to obtain the flame-retardant wear-resistant low-VOC polyurethane coating. The obtained polyurethane film is obviously superior to the polyurethane film in the prior art in the aspects of flame combustion time, molten drop resistance and the like.

Owner:YANTAI UNIV

Flame-retardant antistatic nylon material and preparation method thereof

The invention discloses a flame-retardant antistatic nylon material. The nylon material is prepared by mixing, in parts by weight, 60-85 parts of polyamide, 5-25 parts of a toughening agent, 10-20 parts of a mixed agent of antimony trioxide and 1,2-bis(pentabromophenyl) ethane, 0.5-1 part of an antistatic agent and 0.1-0.5 part of an antioxidant, wherein the polyamide has a relative viscosity of 2-3. Mechanical properties of the prepared flame-retardant antistatic nylon 6 meet requirements for preparation of mining machinery tools, and flame retardancy and antistatic level both meet requirements of the MT113-85 standard, and are at a domestic advanced level. The material has permanent flame retardant and antistatic properties, the problem of difficult production is overcome, and popularization of the material becomes possible. The mining machine tools prepared by the material are light in weight, easy to shape and process, and low in price.

Owner:平顶山市科隆新材料有限公司

Method for preparing flame-retardant polyurethane synthetic leather

InactiveCN106273997AImprove compatibilityMake up for poor compatibilityLamination ancillary operationsSynthetic resin layered productsWater solubleButadiene-styrene rubber

The invention discloses a method for preparing flame-retardant polyurethane synthetic leather. The method comprises the following steps: extruding a thermoplastic polyurethane and styrene-butadiene-styrene segmented copolymer, a styrene-ethylene-butene-styrene segmented copolymer, a polyamide type thermoplastic elastomer, colorant and a substance A by using an extruder at 90-370 DEG C so as to prepare a polyurethane film which is 0.8mm in thickness; before the modified polyurethane film is cooled, performing composite pressing on the polyurethane film and a piece of flame-retardant base cloth by using an extrusion roller at the pressure of 1.0Mpa, embossing by using a roller with textures at the pressure of 0.2Mpa, cooling so as to prepare primary synthetic leather, performing surface treatment on the prepared primary synthetic leather in a water-soluble silicon oil solution of 90 DEG C, and drying in an oven of 110 DEG C, thereby obtaining the flame-retardant polyurethane synthetic leather. The flame retardancy of the prepared flame-retardant polyurethane synthetic leather can be of a grade of good or higher.

Owner:广州益合康科技材料有限公司

High-strength and high-toughness all-position-welding gas shield flux-cored wire for weather-resistant steel

InactiveCN105081609ASimple welding processHigh strengthWelding/cutting media/materialsSoldering mediaBorideSlag (welding)

The invention discloses a high-strength and high-toughness all-position-welding gas shield flux-cored wire for weather-resistant steel. The mechanical properties are generally not ideal when titania slag type flux-cored wire performs welding under the full CO2 gas shielding atmosphere, and particularly under high strength, the low-temperature impact toughness cannot be ensured. The high-strength and high-toughness all-position-welding gas shield flux-cored wire comprises, by mass, 4-8 parts of TiO2, 0.8-1.5 parts of SiO2, 0.3-0.5 part of MgO, 0.3-0.7 part of ZrO2, 0-0.3 part of NaF, 0.1-0.6 part of Al-Mg, 0-0.8 part of Mn-Si, 0.2-0.8 part of Cu, 0.1-1.5 part of Ni, 0-0.5 part of Si, 1.0-2.0 parts of Mn, 0-0.5 part of Cr, 0.01-0.1 part of boride, less than 0.02 part of P and the balance iron powder according to the equivalent value. The high-strength and high-toughness all-position-welding gas shield flux-cored wire is applied to weather-resistant steel.

Owner:HARBIN WELDING INST LTD

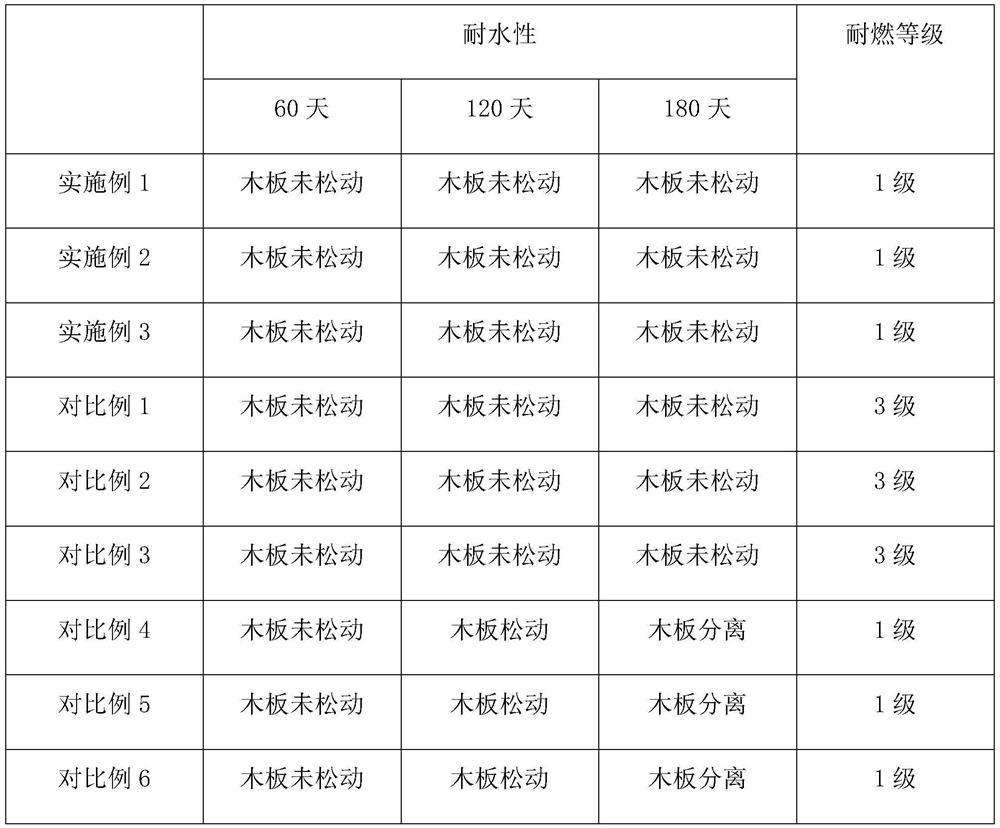

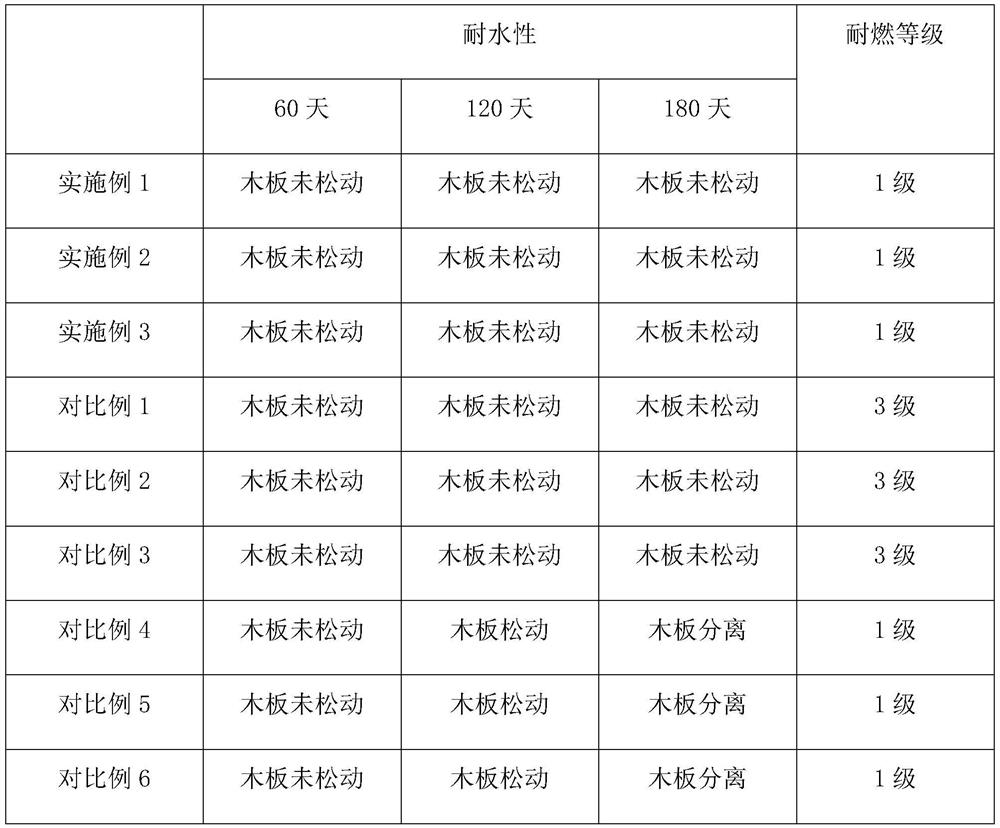

Water-based formaldehyde-free adhesive for flame-retardant composite board and preparation method thereof

ActiveCN113004857AHigh tensile strengthImprove wear resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesiveMaterials science

The invention discloses a water-based formaldehyde-free adhesive for a flame-retardant composite board and a preparation method thereof. The adhesive is mainly prepared from a fumaric acid-aluminum complex, a 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide compound, a microencapsulated isocyanate and defatted bean flour. During high-temperature combustion, isocyanate generated by decomposition of defatted bean flour and isocyanate generated by decomposition of polyurethane react with fumaric acid to form an imine structure, the 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and the imine structure are subjected to an addition reaction to generate a nitrogen-containing compound, the nitrogen-containing compound is thermally decomposed during combustion to generate ammonia inert gas, the combustible gas concentration and the combustion rate are reduced; the nitrogen-containing compound is subjected to a nitrogen-containing reaction to form a nitrogen-containing flame retardant, and the concentration and combustion rate of combustible gas are reduced. The nitrogen-containing compound is combusted to form a carbon layer, molten drops are reduced, and the flame retardant property is improved. The adhesive prepared by the method improves the water resistance on the basis of a water-based adhesive, does not contain aldehyde groups, does not release formaldehyde to pollute the environment, has good flame retardant property, can effectively slow down the combustion rate of the composite board, and has very high practicability and production value.

Owner:上海德万家企业发展(集团)有限公司

Method for producing flame-retardant fiber from vinylon production line and obtained flame-retardant fiber

ActiveCN107557897AAchieve flame retardant functionHigh strengthFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolyvinyl alcohol

The invention relates to a method for producing a flame-retardant fiber from a vinylon production line and an obtained flame-retardant fiber. The method comprises the following steps: a) dissolving polyvinyl alcohol in water so as to obtain a spinning solution; b) adding an aqueous solution of a tetrahydroxymethyl phosphorus compound; c) spinning by using a mirabilite wet method, and performing condensation and stretching so as to obtain a primary fiber; d) drying the primary fiber obtained in the step c) so as to obtain a flame-retardant precursor fiber; e) performing ammonia fumigation on the flame-retardant precursor fiber obtained in the step d) so as to obtain an ammonia fumigation fiber; f) oxidizing the ammonia fumigation fiber obtained in the step e); and g) randomly performing washing, oiling and drying, thereby obtaining the flame-retardant fiber.

Owner:宁夏全宇新材料有限公司 +1

Immersion exposure apparatus and device manufacturing method

An immersion exposure apparatus which exposes a substrate through a liquid includes an illumination optical system, a projection optical system, a chuck, a liquid support plate, a stage, and a liquid repellency recovery unit. The illumination optical system illuminates an original with exposure light from exposure light sources. The projection optical system projects a pattern of the original onto the substrate. The chuck holds the substrate. The liquid support plate supports a liquid together with the substrate held by the chuck. A surface of the liquid support plate includes a surface of a metal oxide. The stage is provided with a chuck and the liquid support plate and is movable. The liquid repellency recovery unit is configured to recover the liquid repellency of the surface of the metal oxide with regard to the liquid.

Owner:CANON KK

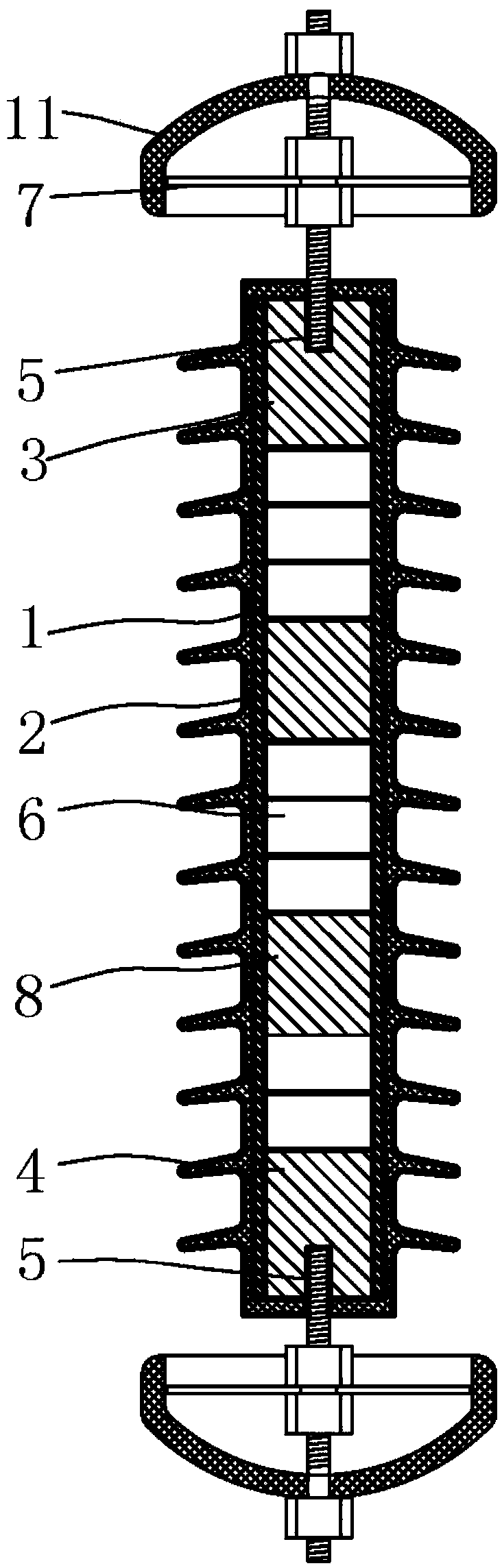

Power distribution type lightning arrester preventing sparks in pressure release process

PendingCN109346254AIncrease insulation lengthImprove pressure resistanceOther resistor networksResistor terminals/electrodesOvervoltageTorsional strength

The invention provides a power distribution type lightning arrester preventing sparks in a pressure release process. When thunder and lightning and overvoltage occur, an overvoltage arc release path is formed by arc control panels under the point effect, overvoltage is rapidly released, and accordingly, lines and the lightning arrester are protected; by means of semi-ring grooves and longitudinalgrooves in the surfaces of upper electrodes, lower electrodes and intermediate electrodes, recombination of the electrodes and a casing is facilitated, adhesive force of the electrodes and the casingcan be improved, damp air is prevented from entering the casing, the risk of flash explosion is reduced, overall mechanical strength can be improved when the upper electrodes, the lower electrodes andthe intermediate electrodes are combined with components such as resistor discs, the casing and the like, bending resistance and torsional strength of the lightning arrester are improved, and the probability of disassembly of the lightning arrester in a pressure release process is greatly reduced; the electrodes are made of stainless steel instead of common aluminum or aluminum alloys, the electrode melting point is increased to 1,360 DEG C or higher from about 660 DEG C, and the probability of melt dropping of the electrodes is reduced.

Owner:襄阳市三三电气有限公司

In-situ polymerization type N-P synergistic flame-retardant nylon and preparation method thereof

InactiveCN112812555ASolve the problem of not being able to achieve a higher degree of aggregationViscosity is easy to controlNylon materialPolymer science

The invention discloses in-situ polymerization type N-P synergistic flame-retardant nylon and a preparation method thereof. The preparation method specifically comprises the following steps: (A) reacting an organic phosphorus flame-retardant monomer with a diamine monomer to form a salt; (B) emulsifying and dispersing a nitrogen flame retardant to obtain a nitrogen flame retardant emulsion; and (C) adding diacid and diamine or binary amide salt or a solution thereof, the prepared salt or a solution thereof, the nitrogen flame retardant emulsion, an antioxidant and a catalyst into a reaction kettle, and carrying out in-situ polymerization in an inert atmosphere by regulating and controlling the reaction temperature and pressure to prepare the required N-P synergistic flame-retardant nylon material. According to the prepared in-situ polymerization type flame-retardant nylon, due to the synergistic effect, the total amount of the flame retardant needing to be added is reduced. The viscosity in the whole preparation process is controllable, a product with excellent mechanical property and flame retardant property can be obtained, the vertical combustion test can reach UL-94V-0 level, and the limit oxygen index is 28% or above.

Owner:CHENGDU TALY TECH CO LTD +1

A flame-retardant, droplet-resistant, high-moisture-permeable artificial leather and its preparation method

ActiveCN106638015BImprove flame retardant performanceLow smoke productionCoatingsTextiles and paperCombustionFoaming agent

Owner:ZHONGYUAN ENGINEERING COLLEGE

High magnetic permeability soft magnetic alloy powder, inductance part and preparation method thereof

ActiveCN106205934BReduce power lossHigh Intrinsic Insulation ResistanceTransformers/inductances detailsMagnetic materialsApparent densityInductor

The invention discloses high-magnetoconductivity soft magnetic alloy powder. The alloy consists is prepared from the following components in parts by mass: 25.0 to 80.0 parts of Fe, 3.0 to 8.0 parts of Si, 15 to 55 parts of Ni, 1.0 to 7.0 parts of B and 1.0 to 5.0 parts of P. The invention further discloses an inductance piece prepared from the high-magnetoconductivity soft magnetic alloy powder, a preparation method of the high-magnetoconductivity soft magnetic alloy powder and a preparation method of the inductance piece. By the adoption of the preparation method disclosed by the invention, the soft magnetic alloy powder with various particle sizes can be prepared, and the soft magnetic alloy powder is high in magnetoconductivity, lower in power loss, higher in apparent density, high in tap density, lower in oxygen content, high in product pressing performance and high in magnetic ring density. Due to small oxygen content, few impurities, small carbon content, uniform alloy components and high sphericity degree, the high-magnetoconductivity soft magnetic alloy powder can be widely used as a raw material of a novel sintered inductor.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

Method for fiber-reinforced modified wood-plastic decorative plate

InactiveCN110092970AImproved pull-out strengthImprove the bonding strength of the interfaceFibre typesAmmonium polyphosphateChemistry

The invention discloses a method for fiber-reinforced modified wood-plastic decorative plates, the method comprises the following steps: dispersing a silane coupling agent in an ethanol solution, soaking aramid fiber therein, washing with deionized water, and drying in an oven to obtain silane coupling agent modified ammonium polyphosphate; adding organically modified zirconium phosphate and n-butylamine into deionized water, oscillating in a water bath, adding carboxymethyl chitosan, stirring at constant temperature under microwave, washing with deionized water and ethanol, centrifuging, anddrying under vacuum to obtain modified zirconium phosphate; drying regenerated high density polyethylene, putting into a mixer for mixing and melting, adding an antioxidant, silane coupling agent modified ammonium polyphosphate, the silane coupling agent modified ammonium polyphosphate and the modified zirconium phosphate, finally adding modified wood flour for uniform mixing, paving in a mold, putting into a hot press for preheating, starting hot pressing, and then putting into a cold press for cold pressing to prepare the wood- plastic decorative plate.

Owner:马鞍山卓凡新材料科技有限公司

LDPE flame retardant composite material and preparation method thereof

InactiveCN102050987BBurn less smokeReduce dropletLow-density polyethyleneLinear low-density polyethylene

The invention discloses LDPE (low density polyethylene) flame retardant composite material which is composed of following components by weight: 70 to 90 of linear LDPE, 10 to 20 of LDPE-g-MAH (maleic anhydride grafted low density polyethylene), 10 to 30 of melamine resin coated ammonium polyphosphate, 5 to 15 of pentaerythrite, 1 to 5 of montmorillonite, 660 to 110 of nylon and 1 to 4 of antioxidising agent. The invention further provides a preparation method of the LDPE flame retardant composite material. The flame retardant composite material prepared by the preparation method overcomes thedefects of large combustion smog and more molten drops of halogenated flame retardant, low flame retardant efficiency, large additive amount and poor thermal stability and mechanical properties of materials of expanding type flame retardant. When the flame retardant property of the composite material is improved, the additive amount of the flame retardant is reduced, the mechanical properties of composite material are improved, and the requirement of practical application is satisfied.

Owner:KANGTAI PLASTIC SCI & TECH GRP

Thermotropic aromatic liquid crystal copolyester and preparation method thereof

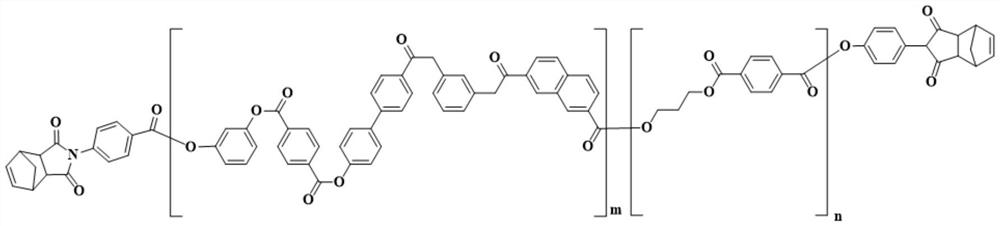

ActiveCN112608459AReduce dropletExcellent flame retardant and anti-dripping propertiesPhenyl-acetyleneChemistry

The invention discloses a thermotropic aromatic liquid crystal copolyester and a preparation method thereof, the thermotropic aromatic liquid crystal copolyester comprises a main chain formed by copolymerization of a rigid mesogenic unit and polyester granules, and an end sealing group is a phenylacetylene or norbornene acetylene group; the mesogenic unit is prepared from resorcinol, terephthalic acid and 2, 7-naphthalic acid; and 4 '-hydroxybiphenyl-4-carboxylic acid contains a terminal carboxyl group A and a terminal hydroxyl group B at the same time. The thermotropic aromatic liquid crystal copolyester disclosed by the invention has lower melting processing temperature and flame-retardant anti-dripping performance, and can effectively reduce life and property loss caused by fire, so that the thermotropic aromatic liquid crystal copolyester has a wide application prospect in the fields of civil textiles and high-temperature protective materials, in addition, the molecular weight is controllable in the polymerization process, the preparation process is simpler, more convenient, efficient and environment-friendly, and no harmful gas is generated during combustion.

Owner:上海航永光电新材料有限公司

Water-based formaldehyde-free adhesive for flame-retardant composite board and preparation method thereof

ActiveCN113004857BHigh tensile strengthImprove wear resistanceNon-macromolecular adhesive additivesProtein adhesivesPolymer scienceAdhesive

The invention discloses a water-based formaldehyde-free adhesive for a flame-retardant composite board and a preparation method thereof. The adhesive is mainly made of fumaric acid-aluminum complex, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide complex, microencapsulated isocyanate, defatted soybean powder; high temperature When burning, defatted soy flour decomposes to produce isocyanate and polyurethane decomposes to produce isocyanate and fumaric acid to form imine structure, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and phosphaphenanthrene-10-oxide The amine structure undergoes an addition reaction to produce nitrogen-containing compounds. The nitrogen-containing compounds thermally decompose during combustion to produce ammonia inert gas, which reduces the concentration of combustible gases and the combustion rate. The nitrogen-containing compounds burn to form a carbon layer, which reduces molten droplets and improves flame retardancy. . The adhesive prepared by the present invention has improved water resistance on the basis of water-based adhesives, does not contain aldehyde groups, does not release formaldehyde to pollute the environment, and has good flame retardancy, which can effectively slow down the burning rate of the composite board. It has high practicality and production value.

Owner:上海德万家企业发展(集团)有限公司

A kind of preparation method of FeSiCr soft magnetic powder

ActiveCN105945294BPowder with high oxygen contentGood sphericityMagnetic materialsUltra high pressureIntermediate frequency

The invention discloses a preparation method of iron-silicon-chromium soft magnetic powder. The steps of the preparation method are as follows: 1) adding iron-silicon-chromium soft magnetic alloy powder raw materials into an intermediate frequency induction furnace, and smelting in the atmosphere to obtain alloy liquid; 2) under the condition of nitrogen protection Then, the alloy liquid is sent to the atomization tower. During the feeding process, the two atomization media, ultra-high pressure atomized water and low-pressure vortex gas, act on the alloy liquid at the same time, and the alloy liquid is strongly broken into a large number of small metal melts. drops, and then cools and solidifies into Fe-Si-Cr soft magnetic alloy powder. It can prepare Fe-Si-Cr alloy powder with high bulk density, high tap density, low oxygen content, high inductance value and magnetic permeability. It can be widely used as a raw material for miniature inductors.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com