High-strength and high-toughness all-position-welding gas shield flux-cored wire for weather-resistant steel

A high-strength, high-toughness, all-position welding technology, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of deposited metal strength and low-temperature impact toughness, and excellent welding processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

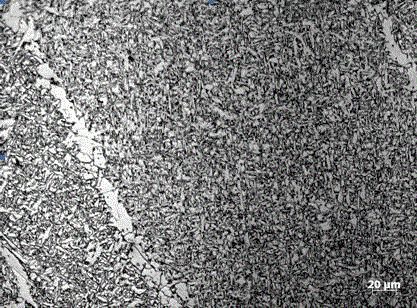

Image

Examples

Embodiment 1

[0029] A high-strength and high-toughness all-position welding gas shielded flux-cored welding wire for weathering steel, the composition of which includes: TiO 2 , SiO 2 , MgO, ZrO 2 , NaF, Al-Mg, Mn-Si, Cu, Ni, Si, Cr, P, borides, the mass parts are: the TiO 2 Conversion value: 4~8, said SiO 2 Conversion value: 0.8~1.5, described MgO conversion value: 0.3~0.5, described ZrO 2 Conversion value: 0.3~0.7, said NaF conversion value: 0~0.3, said Al-Mg conversion value: 0.1~0.6, said Mn-Si conversion value: 0~0.8, said Cu conversion value : 0.2~0.8, the Ni conversion value: 0.1~1.5, the Si conversion value: 0~0.5, the Mn conversion value: 1.0~2.0, the Cr conversion value: 0~0.5, the The above conversion value of boride: 0.01~0.1, the above conversion value of P: below 0.02, and the rest is the basic amount of iron powder.

Embodiment 2

[0031] According to the high-strength and high-toughness all-position welding gas-shielded flux-cored welding wire for weather-resistant steel described in Example 1, the mass fraction is: the described TiO 2 Conversion value: 4, the SiO 2 Conversion value: 0.8, said MgO conversion value: 0.3, said ZrO 2 Conversion value: 0.3, described Al-Mg conversion value: 0.2, described Mn conversion value 1.0, described Cu conversion value: 0.3, described Ni conversion value: 0.3, described boride conversion value: 0.004, the conversion value of P: 0.019, the rest is iron powder.

Embodiment 3

[0033] According to the high-strength and high-toughness all-position welding gas shielded flux-cored welding wire for weathering steel described in embodiment 1 or 2, the mass fraction is: the described TiO 2 Conversion value: 8, the SiO 2 Conversion value: 1.5, described MgO conversion value: 0.4, described ZrO 2 Conversion value: 0.6, described NaF conversion value: 0.3, described Al-Mg conversion value: 0.6, described Mn-Si conversion value: 0.8, described Cu conversion value: 0.7, described Ni conversion value Value: 1.2, described Si conversion value: 0.5, described Mn conversion value 1.2, described Cr conversion value: 0.4, described boride conversion value: 0.008, described P conversion value: 0.015, the rest For iron powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com