Flame-retardant polylactic acid material of ternary composite flame-retardant system and preparation method thereof

A polylactic acid material and ternary composite technology, which is applied in the flame retardant field of polylactic acid material, can solve the problems of increased cost and large amount of addition, and achieve the effects of reducing burning droplets, promoting char formation, and strong interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

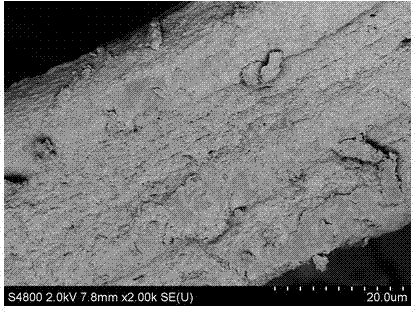

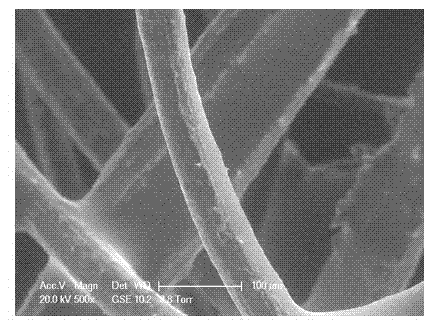

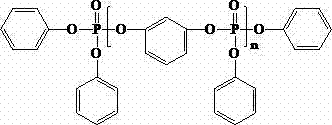

[0030] Embodiment 1: Take by weighing 6.6g RDP, dissolve completely in 120ml chloroform, add the kenaf of 2.4g loading nano-zinc oxide therein and continue magnetic stirring for 0.5h, treat to disperse evenly, add 21g polylactic acid pellet wherein, continue to stir until Polylactic acid is completely dissolved without air bubbles, coated on a glass plate, and volatilized at room temperature; the dried product is added to a miniature conical twin-screw extruder, and the extrusion temperature is 175°C in the first zone, 177°C in the second zone, and 177°C in the third zone , 176°C in the fourth zone, after extrusion, cooling, and granulation, the flame-retardant polylactic acid material of the ternary composite flame-retardant system was obtained. According to the standard test method of GB / T2406-1993, the limiting oxygen index was 31.2%.

Embodiment 2

[0031] Example 2: Weigh 4.05g RDP, dissolve it completely in 120ml chloroform, add 0.45g kenaf loaded with nano-zinc oxide and continue magnetic stirring for 0.5h, until it is evenly dispersed, add 25.5g polylactic acid pellets to it, and continue stirring Until the polylactic acid is completely dissolved without air bubbles, coat a film on a glass plate and volatilize at room temperature; add the dried product to a miniature conical twin-screw extruder, and the extrusion temperature is 175°C in the first zone, 177°C in the second zone, and 177°C in the third zone ℃, four zones 176 ℃, after extrusion, cooling and granulation, the flame-retardant polylactic acid material of the ternary composite flame-retardant system was prepared. According to the standard test method of GB / T2406-1993, the limiting oxygen index was 30.6%.

Embodiment 3

[0032] Example 3: Weigh 3.6g RDP, dissolve it completely in 120ml chloroform, add 0.9g kenaf loaded with nano-zinc oxide and continue magnetic stirring for 0.5h, until it is evenly dispersed, add 25.5g polylactic acid pellets to it, and continue stirring Until the polylactic acid is completely dissolved without air bubbles, coat a film on a glass plate and volatilize at room temperature; add the dried product to a miniature conical twin-screw extruder, and the extrusion temperature is 175°C in the first zone, 177°C in the second zone, and 177°C in the third zone ℃, four zones 176 ℃, after extrusion, cooling and granulation, the flame-retardant polylactic acid material of the ternary composite flame-retardant system was prepared. According to the standard test method of GB / T2406-1993, the limiting oxygen index was 29.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com