Preparation method of flame-retardant PET fiber

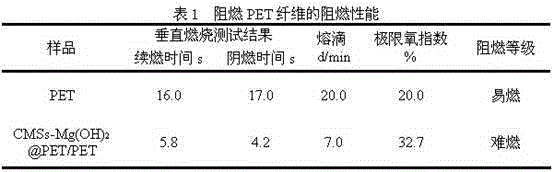

A fiber and carbon-coated technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, fiber processing, melt spinning, etc. Dispersibility and compatibility, droplet and smoke reduction, effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

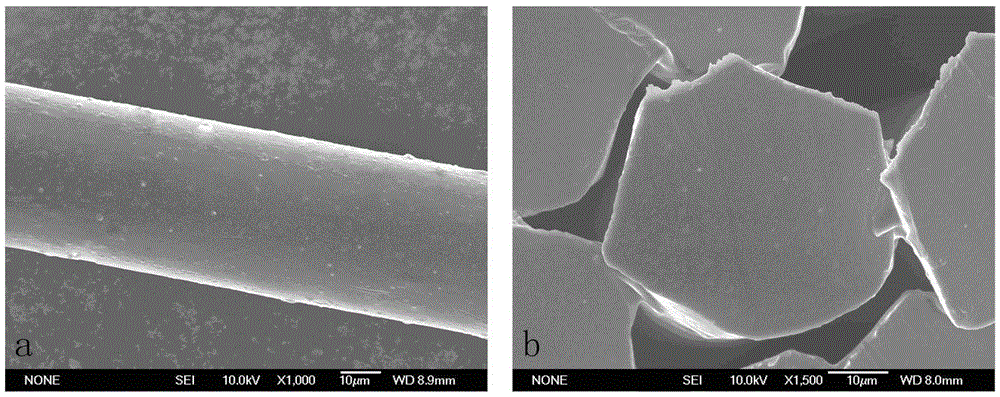

Examples

Embodiment Construction

[0019] The following embodiments are only preferred technical solutions of the present invention, and are not used to limit the present invention in any way. For those skilled in the art, the present invention can have various modifications and changes. Any modification, equivalent replacement, improvement, etc., made within the spirit and principle of the present invention shall be included in the protection scope of the present invention.

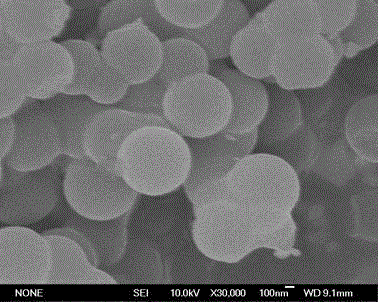

[0020] Add 10 g of carbon microspheres to 100 mL of absolute ethanol, and disperse for 10 minutes with ultrasonic waves at a frequency of 40 KHz to obtain a suspension of carbon microspheres.

[0021] The above-mentioned carbon microsphere suspension was added to 300 mL ammonia water, heated to 40° C. with stirring, and 500 mL of 0.4 mol / L magnesium chloride aqueous solution was dropped at a dropping rate of 3 mL / min. After the addition, the stirring was continued for 2 hours. The reactants were taken out and washed with absolute ethanol and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com