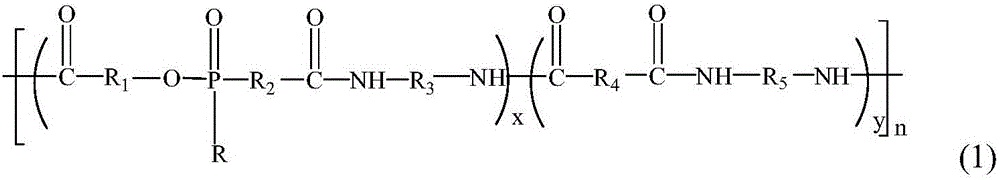

In-situ polymerization type N-P synergistic flame-retardant nylon and preparation method thereof

A synergistic flame-retardant and polymeric technology, applied in the field of in-situ polymerized N-P synergistic flame-retardant nylon and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

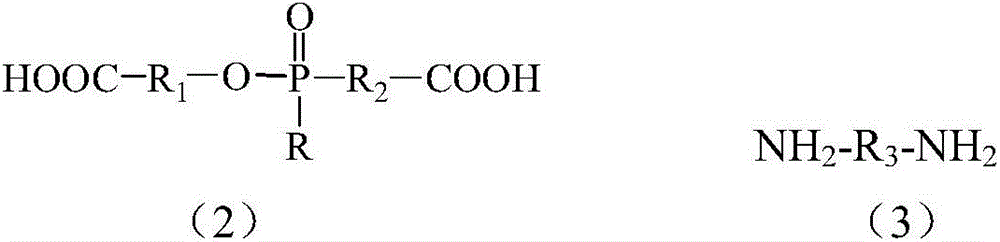

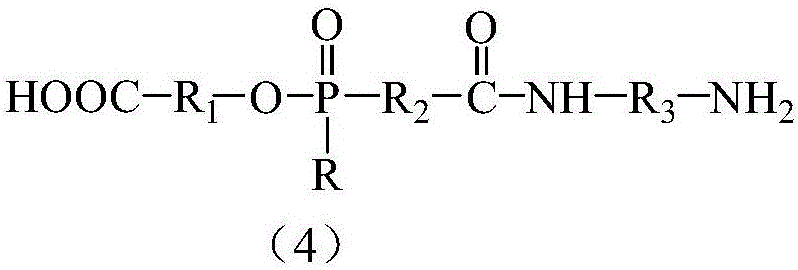

[0069] The preparation method of in-situ polymerized N-P synergistic flame-retardant nylon of the present invention specifically comprises the following steps:

[0070] (A) Reaction of organophosphorus flame retardant monomers with diamines, preferably with excess amino groups, to form salts;

[0071] (B) make the reaction product of step (A) and diacid and diamine or dibasic amide salt in the presence of 1-10wt% relative to the total weight of all polymerized monomers, preferably 3-6wt% nitrogen-based flame retardant The following reaction is used to prepare in-situ polymerized N-P synergistic flame-retardant nylon.

[0072] In step (A), preferably, the diamine monomer is slightly excessive, so that the pH of the salt solution is 7-9. The reaction temperature rose from room temperature to 40-70°C within 5-20 minutes.

[0073] Preferably, the diamine monomers described in step (A) are hexamethylenediamine, decanediamine, nonanediamine, undecanediamine, dodecanediamine, aliph...

Embodiment 1

[0089] Stir the flame retardant monomer and hexamethylenediamine in an aqueous solution at 40°C for 0.5h at a molar ratio of 1:1.2, adjust the pH of the solution to 7.2, and obtain a salt solution.

[0090] High-speed shear emulsification of 4% MCA accounting for the total mass of polymerized monomers (including the above-mentioned salt solution and the following nylon 66 salt) in a certain amount of water for 10 minutes to obtain a uniformly dispersed MCA emulsion.

[0091] Mix the nylon 66 salt (hexamethylene adipamide salt) solution with the salt solution obtained above, the MCA emulsion, and the catalyst hypophosphorous acid each accounting for 1‰ Add sodium, antioxidant p-phenylenediamine, and 40% deionized water to the reactor, vacuumize it, and fill it with nitrogen for 5 times, and finally keep the internal pressure of the reactor at 0.2MPa. Heat the reactor, keep stirring at a high speed, and when the temperature of the reactor reaches 220°C and the pressure is 1.8 MP...

Embodiment 2

[0094] Stir and react the flame retardant monomer and hexamethylenediamine in an aqueous solution at a molar ratio of 1:1.3 at 50°C for 1 hour, and adjust the pH of the solution to 7.8.

[0095] 3% MCA accounting for the total mass of polymerized monomers was emulsified in a certain amount of water at high speed for 6 minutes to obtain a uniformly dispersed MCA emulsion.

[0096] Adipic acid and hexamethylenediamine are configured according to a mass ratio of 1:1.3, and the above-mentioned salt solution, MCA emulsion, catalyst toluenesulfonic acid and antioxidant Agent 2, 6-di-tert-butyl-4-methylphenol, and 35% deionized water were added to the reactor, vacuumed and filled with nitrogen for 3 times, and finally the internal pressure of the reactor was kept at 0.3 MPa. Heat the reactor, keep stirring at a high speed, and when the temperature of the reactor reaches 215°C and the pressure is 1.7 MPa, keep the temperature and pressure constant for 1.6 hours. Then the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com