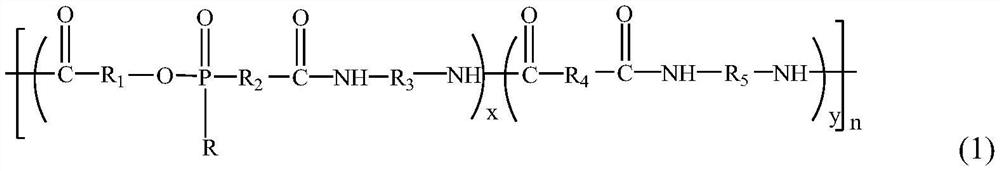

Organic phosphorus copolymerized flame-retardant polyamide composition and preparation method thereof

A polyamide composition and copolymer flame retardant technology, which are applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyamide rayon filaments, and rayon manufacturing, etc., to achieve the effects of controllable viscosity and good anti-drip effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

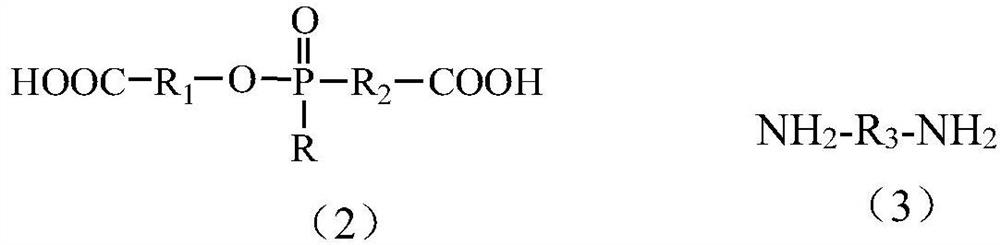

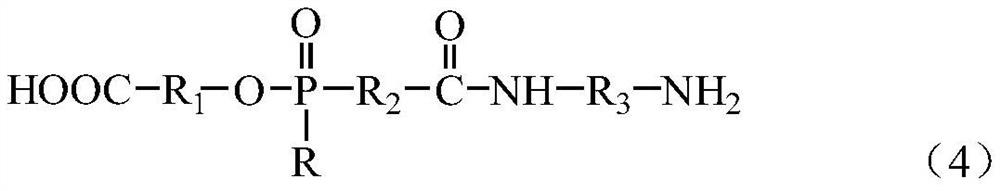

[0066] The preparation method of the organophosphorus-based flame-retardant copolymerized polyamide of the present invention specifically comprises: (1) preparing the flame-retardant copolymerized polyamide by the following steps:

[0067] (A) reacting an organophosphorus flame retardant monomer with a diamine, preferably making the amino group excessive, to generate a salt solution;

[0068] (B) reacting the reaction product of the step (A) with a diacid and a diamine or a dibasic amide salt in the presence of an inorganic nanomaterial to produce an organophosphorus copolymerized flame-retardant polyamide;

[0069] (B') reacting the reaction product of step (A) with diacid and diamine or dibasic amide salt to produce organophosphorus copolymerized flame-retardant polyamide, and then blending the copolymerized flame-retardant polyamide with inorganic nanomaterials.

[0070] In step (A), preferably, the diamine monomer is slightly excessive, so that the pH of the salt solution ...

Embodiment 1

[0088] Stir and react the flame retardant monomer and hexamethylenediamine in an aqueous solution at a molar ratio of 1:1.2 at 40°C for 0.5 h, adjust the pH of the solution to 7.2, and dry to form a salt. Mix 50% nylon 66 salt (hexamethylene adipamide salt) solution with the above-mentioned salt that accounts for 6.0% of the quality of nylon 66 salt (excluding solvent, the same below), account for its quality 4wt% nano-montmorillonite, each account for The catalyst sodium hypophosphite with a ratio of 1wt‰ and the antioxidant p-phenylenediamine were added to the reactor, vacuumed and filled with nitrogen for 5 times, and finally the internal pressure of the reactor was kept at 0.2MPa. Heat the reactor, keep stirring at a high speed, and when the temperature of the reactor reaches 220°C and the pressure is 1.8 MPa, keep the temperature and pressure constant for 1.5 hours. Then the temperature was raised to 250°C, and the pressure was released to normal pressure within 1 hour. ...

Embodiment 2

[0091] Stir and react the flame retardant monomer and hexamethylenediamine in an aqueous solution at a molar ratio of 1:1.3 at 50°C for 1 hour, and adjust the pH of the solution to 7.8. Adipic acid and hexamethylenediamine are configured according to a molar ratio of 1:1.2, and the above-mentioned salt solution (calculated as salt) accounting for 7% of its weight and nano-talc accounting for 4wt% of its weight, each accounting for 1‰ The catalyst toluenesulfonic acid, the antioxidant 2,6-di-tert-butyl-4-methylphenol, and 35% deionized water were added to the reactor, vacuumed, filled with nitrogen for 3 times, and finally kept the reaction The pressure inside the kettle is 0.3MPa. Heat the reactor, keep stirring at a high speed, and when the temperature of the reactor reaches 215°C and the pressure is 1.7 MPa, keep the temperature and pressure constant for 1.6 hours. Then the temperature was raised to 240°C, and the pressure was released to normal pressure within 1.5 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com