A flame-retardant, droplet-resistant, high-moisture-permeable artificial leather and its preparation method

An artificial leather and anti-melt droplet technology, applied in the field of artificial leather, can solve the problems of easy generation of melt droplets, uncomfortable wearing, poor flame retardant effect, etc. burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

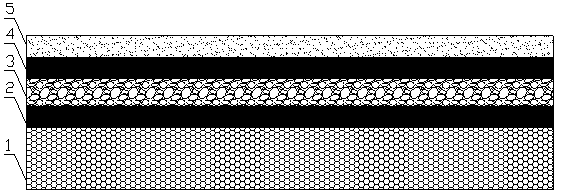

[0027] The artificial leather is compounded by a film surface layer 1, an adhesive layer I2, a foam layer 3, an adhesive layer II4 and a base cloth layer 5.

[0028] The manufacture method of the artificial leather of the present embodiment, concrete steps are as follows:

[0029] (1) Preparation of film surface layer 1:

[0030] Put 100 parts of TPU resin, 1 part of porogen, 1 part of "nitrogen-phosphorus" halogen-free intumescent flame retardant, 1 part of PTFE powder, 1 part of colorant, and 1 part of anti-aging agent into a high-speed mixer for mixing Evenly, the stirring temperature is 100°C; put the stirred material into the casting machine and cast it into a film to form the film surface layer 1, and the temperature of the casting machine does not exceed 230°C;

[0031] (2) Preparation of adhesive layer I2 and adhesive layer II4:

[0032] Put 100 parts of TPU hot-melt adhesive resin with a softening point of 105°C, 1 part of superfine protein powder, 1 part of "nitrog...

Embodiment 2

[0046]The artificial leather is compounded by a film surface layer 1, an adhesive layer I2, a foam layer 3, an adhesive layer II4 and a base cloth layer 5.

[0047] The manufacture method of the artificial leather of the present embodiment, concrete steps are as follows:

[0048] (1) Preparation of film surface layer 1:

[0049] In parts by weight, put 100 parts of TPU resin, 10 parts of porogen, 10 parts of "nitrogen-phosphorus" halogen-free intumescent flame retardant, 3 parts of PTFE powder, 3 parts of colorant, and 1 part of anti-aging agent into a high-speed mixer for mixing Evenly, the stirring temperature is 110°C; the stirred material is added to the casting machine and cast to form a film to form the film surface layer 1, and the temperature of the casting machine does not exceed 230°C;

[0050] (2) Preparation of adhesive layer I2 and adhesive layer II4:

[0051] Put 100 parts of TPU hot-melt adhesive resin with a softening point of 105°C, 10 parts of ultrafine pro...

Embodiment 3

[0060] The artificial leather is compounded by a film surface layer 1, an adhesive layer I2, a foam layer 3, an adhesive layer II4 and a base cloth layer 5.

[0061] The manufacture method of the artificial leather of the present embodiment, concrete steps are as follows:

[0062] (1) Preparation of film surface layer 1:

[0063] In parts by weight, put 100 parts of TPU resin, 20 parts of porogen, 10 parts of "nitrogen-phosphorus" halogen-free intumescent flame retardant, 5 parts of PTFE powder, 5 parts of colorant, and 2 parts of anti-aging agent into a high-speed mixer for mixing Evenly, the stirring temperature is 120°C; put the stirred material into the casting machine and cast it into a film to form the film surface layer 1, and the temperature of the casting machine does not exceed 230°C;

[0064] (2) Preparation of adhesive layer I2 and adhesive layer II4:

[0065] Put 100 parts of TPU hot-melt adhesive resin with a softening point of 105°C, 20 parts of ultrafine prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com