Droplet-resistant flame-retardant polyester, nanometer compound material thereof and method for preparing same

A technology of nano-composite materials and flame-retardant polyester, applied in the field of copolyester and its nano-composite materials and their preparation, can solve the problems of intensified market competition, backward production technology, sudden increase in polyester supply, etc. Control and industrial production, good anti-droplet flame retardant effect, good anti-droplet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

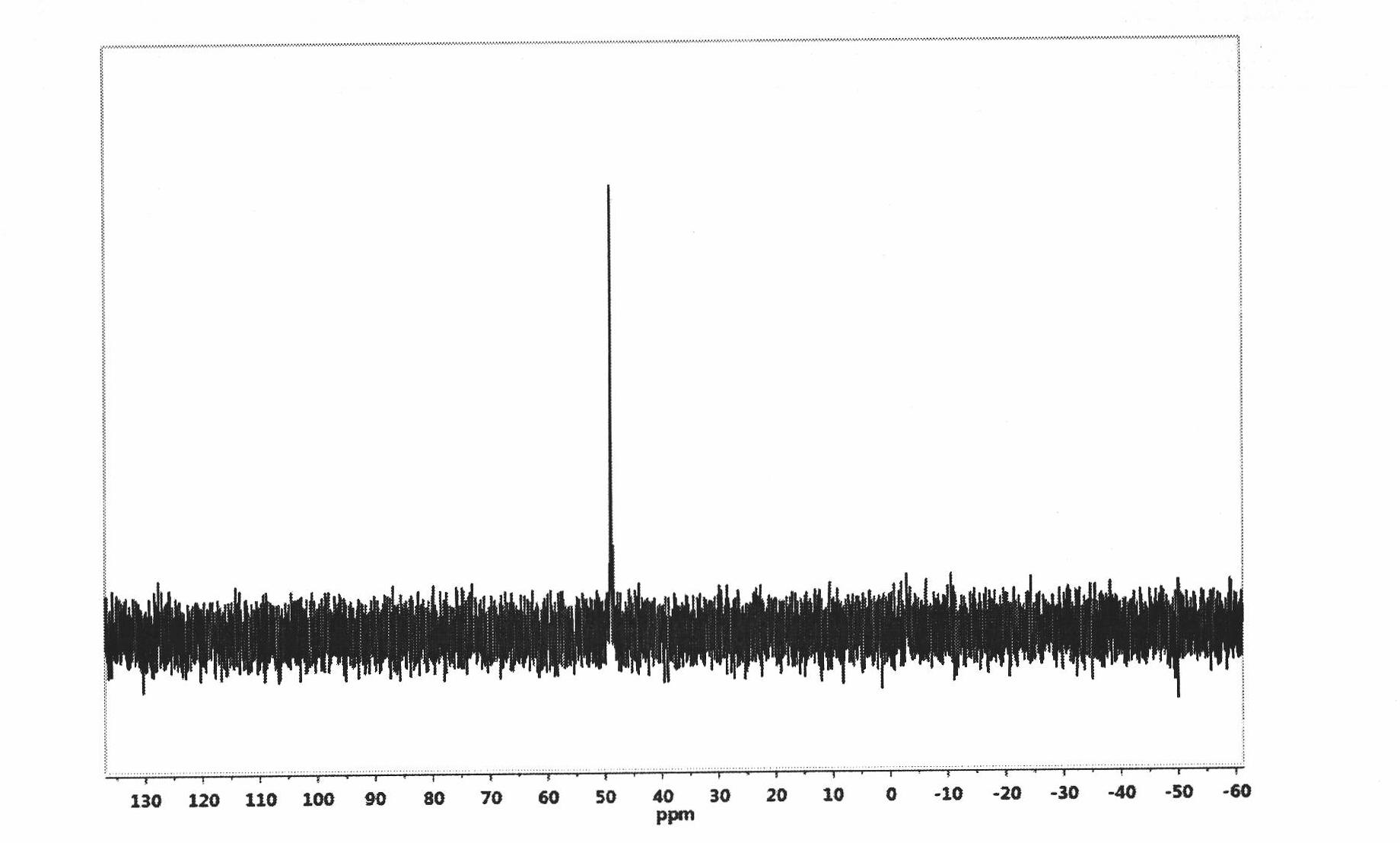

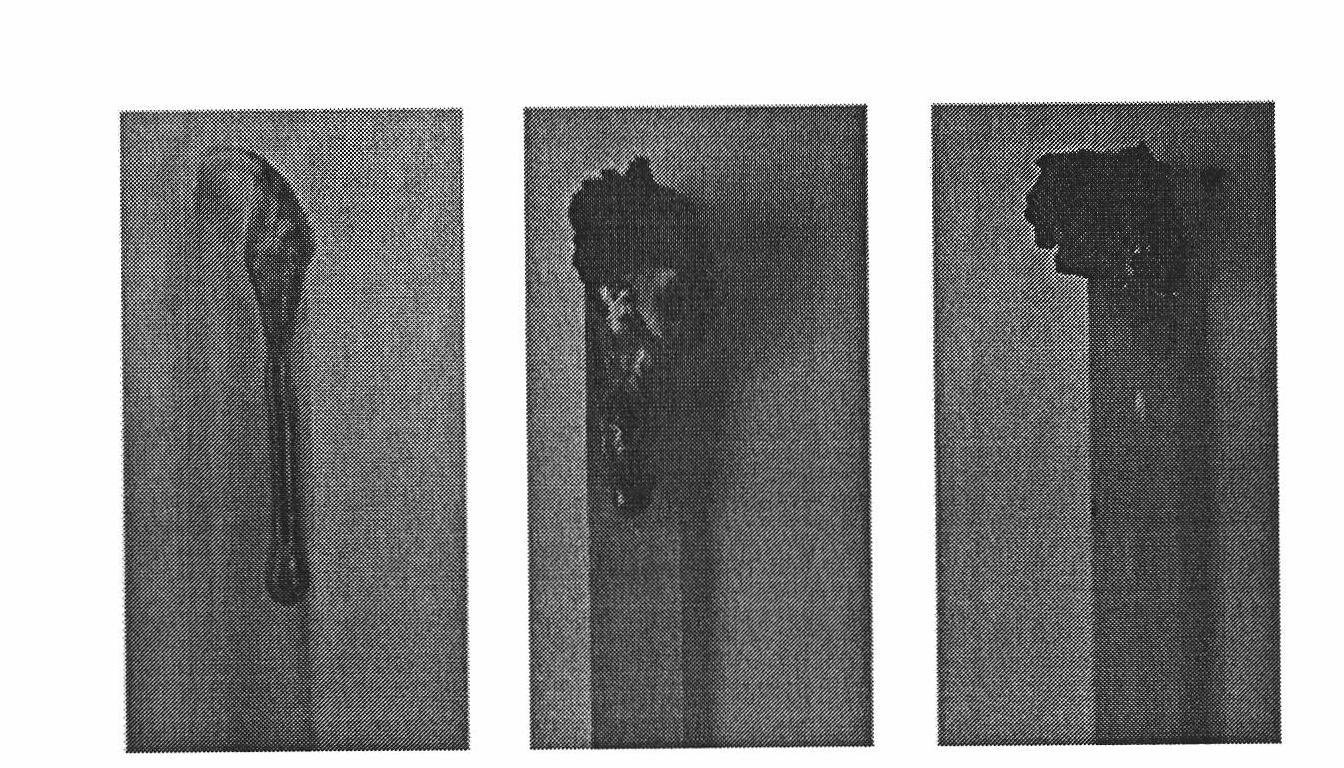

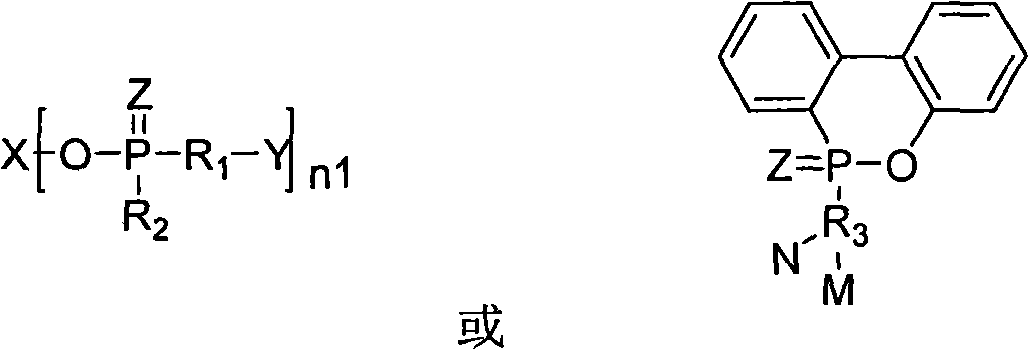

Method used

Image

Examples

Embodiment 1

[0039] 835g terephthalic acid, 425ml ethylene glycol, 0.5g branched monomer triethylene glycol trimesate, 30g flame retardant monomer DPA (9,10-dihydro-oxa-10 phosphophenanthrene -propionic acid) and 0.301g of antimony trioxide were added to the reaction kettle, first filled with nitrogen to remove the air in the kettle, then pressurized to 0.1Mpa, and raised the temperature to 240°C within 2h, and continued to raise the pressure to 0.3-0.4MPa, Esterification reaction for 2 hours; after maintaining the temperature and pressure for 1.5 hours, gradually increase the temperature to 260°C, and maintain the water outlet speed, and reduce the pressure to normal pressure after about 0.5 hours, and the esterification reaction ends. Thereafter, the polycondensation reaction was carried out at 260-270° C. for 0.5 h in low vacuum, and then the temperature was raised to 275-285° C., and the polycondensation reaction was carried out at high vacuum (pressure < 60 Pa) for 2 hours. Then, the m...

Embodiment 2

[0042] 769g terephthalic acid, 415ml ethylene glycol, 30g branched monomer triethylene glycol trimellitate, 60g flame retardant monomer DPA (9,10-dihydro-oxa-10 phosphorophenanthrene- Propionic acid) and 0.348g ethylene glycol antimony join in the reactor, after carrying out esterification and polycondensation reaction by the step that embodiment 1 provides, condition, discharging, water cooling gets final product.

[0043] The intrinsic viscosity [η] of the flame-retardant polyester was 0.86dL / g, the oxygen index was 35.4%, and the vertical combustion grade was V-0.

Embodiment 3

[0045] 589g terephthalic acid, 410ml ethylene glycol, 50g branched monomer triethylene glycol trimellitate, 150g flame retardant monomer DPP (9,10-dihydro-oxa-10 phosphorophenanthrene- Succinic acid) and 0.348g ethylene glycol antimony join in the reactor, after carrying out esterification and polycondensation reaction by the step that embodiment 1 provides, condition, discharging, water cooling gets final product.

[0046] The intrinsic viscosity [η] of the flame-retardant polyester was 1.02dL / g, the oxygen index was 36%, and the vertical combustion rating was V-0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com