LDPE flame retardant composite material and preparation method thereof

A technology of low-density polyethylene and flame-retardant composite materials, which is applied in the field of flame-retardant materials and their preparation, and can solve problems such as poor thermal stability and mechanical properties of materials, low flame-retardant efficiency of intumescent flame retardants, and large combustion smoke , to achieve excellent thermal stability, high flame retardant efficiency, and small combustion smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A low-density polyethylene flame-retardant composite material consisting of the following components by weight:

[0025] Linear low density polyethylene: 80 parts;

[0026] 20 parts of low-density polyethylene branched maleic anhydride;

[0027] 20 parts of melamine coated ammonium polyphosphate (MAPP);

[0028] 10 parts of pentaerythritol (PER);

[0029] 3 parts of organically modified montmorillonite (OMMT);

[0030] Nylon 6 (PA6) is 100 parts;

[0031] Antioxidant 168 2 parts.

[0032] And adopt following preparation method:

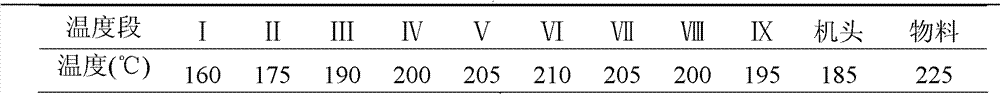

[0033] (1) Add nylon 6, linear low-density polyethylene, low-density polyethylene grafted maleic anhydride, and organically modified montmorillonite to a high-speed mixer, stir and mix for 5 minutes, and discharge the stirred mixture into twin-screw extrusion machine extrusion;

[0034] (2) melamine-coated ammonium polyphosphate and pentaerythritol are mixed in parts by weight;

[0035] (3) Mix the materials in steps (1) and (2), add an...

Embodiment 2

[0037] A low-density polyethylene flame-retardant composite material consisting of the following components by weight:

[0038] Linear low density polyethylene: 80 parts;

[0039] 20 parts of low-density polyethylene branched maleic anhydride;

[0040] 20 parts of melamine coated ammonium polyphosphate (MAPP);

[0041] 10 parts of pentaerythritol (PER);

[0042] 4 parts of sodium montmorillonite (Na-MMT);

[0043] Nylon 6 (PA6) is 95 parts;

[0044] Antioxidant 168 2 parts.

[0045] And adopt following preparation method:

[0046] (1) Add nylon 6, linear low-density polyethylene, low-density polyethylene grafted maleic anhydride, and sodium montmorillonite to a high-speed mixer, stir and mix for 10 minutes, and discharge the stirred mixture into a twin-screw extruder squeeze out

[0047] (2) melamine-coated ammonium polyphosphate and pentaerythritol are mixed in parts by weight;

[0048] (3) Mix the materials in steps (1) and (2), add antioxidant 168, extrude and granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com