Patents

Literature

111results about How to "Change the manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

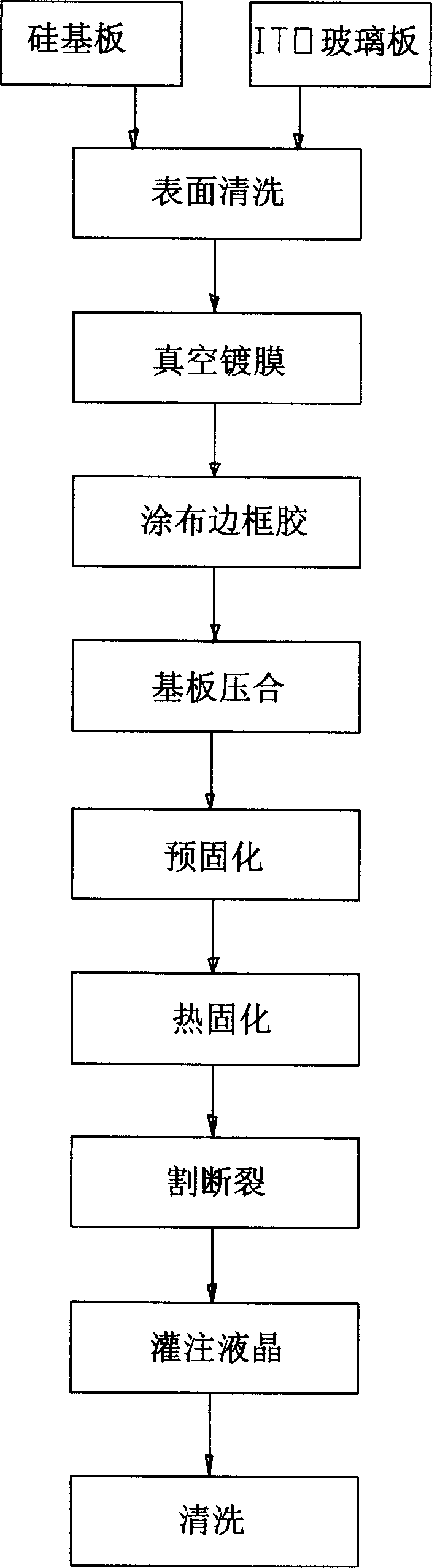

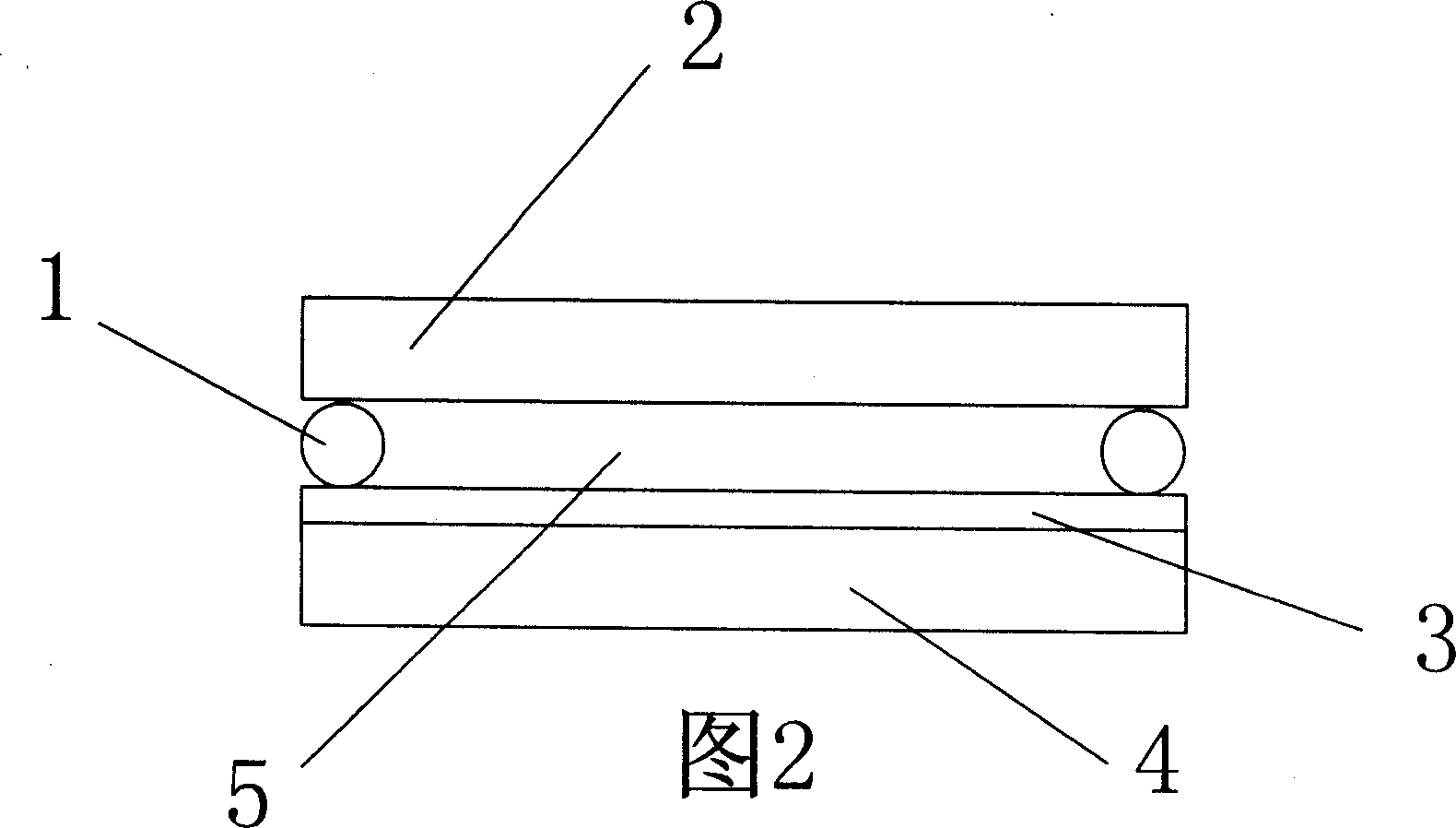

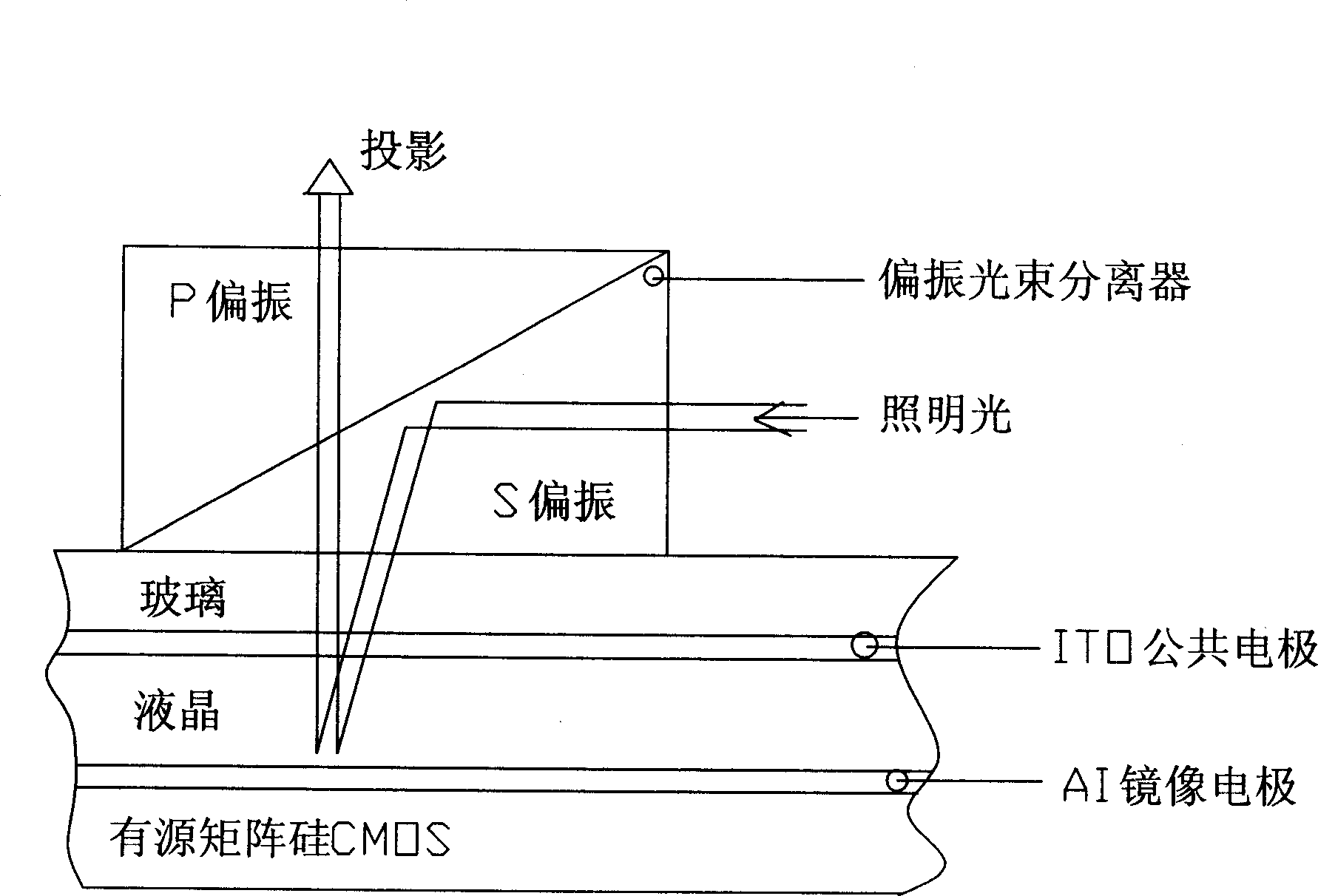

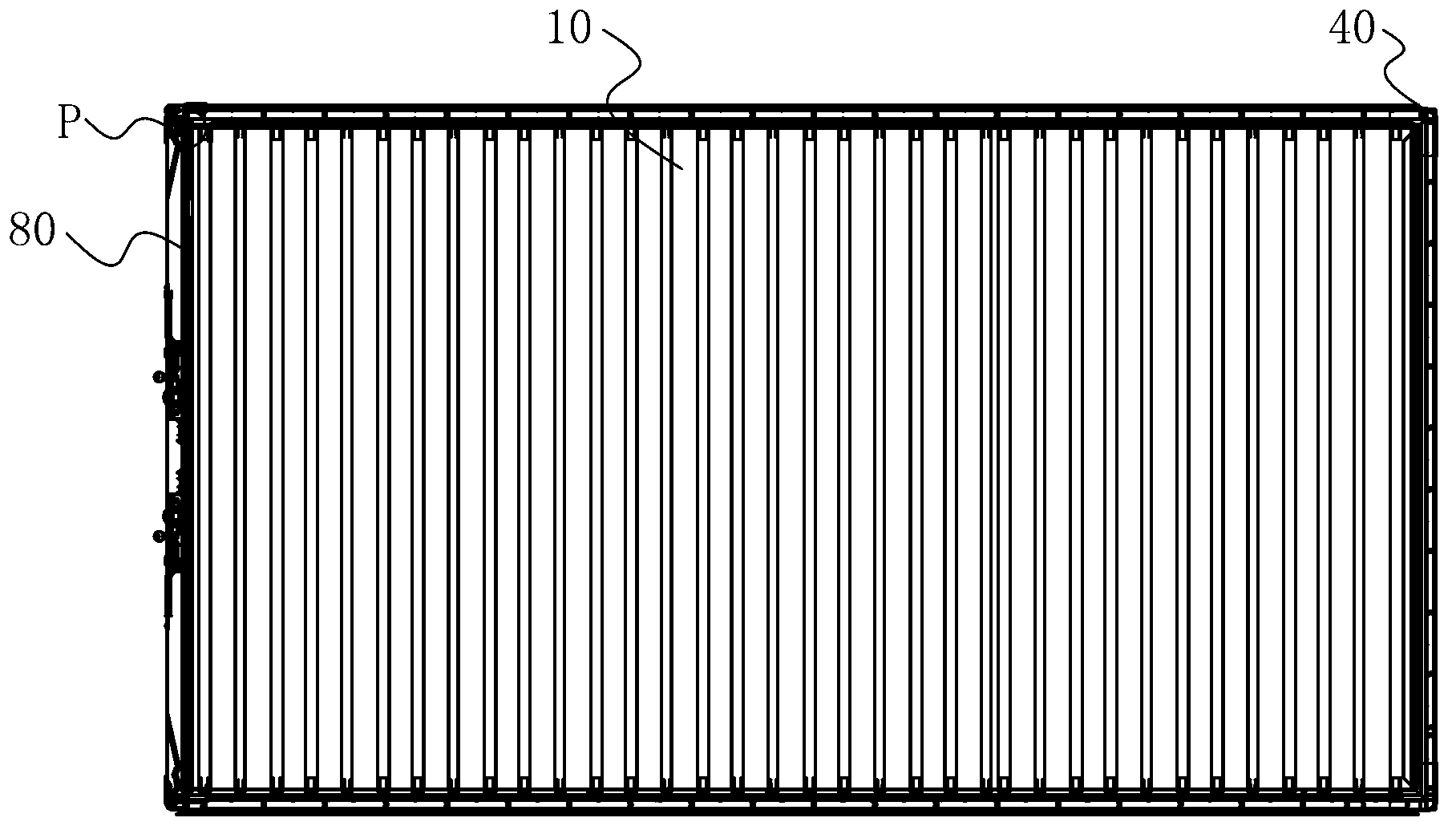

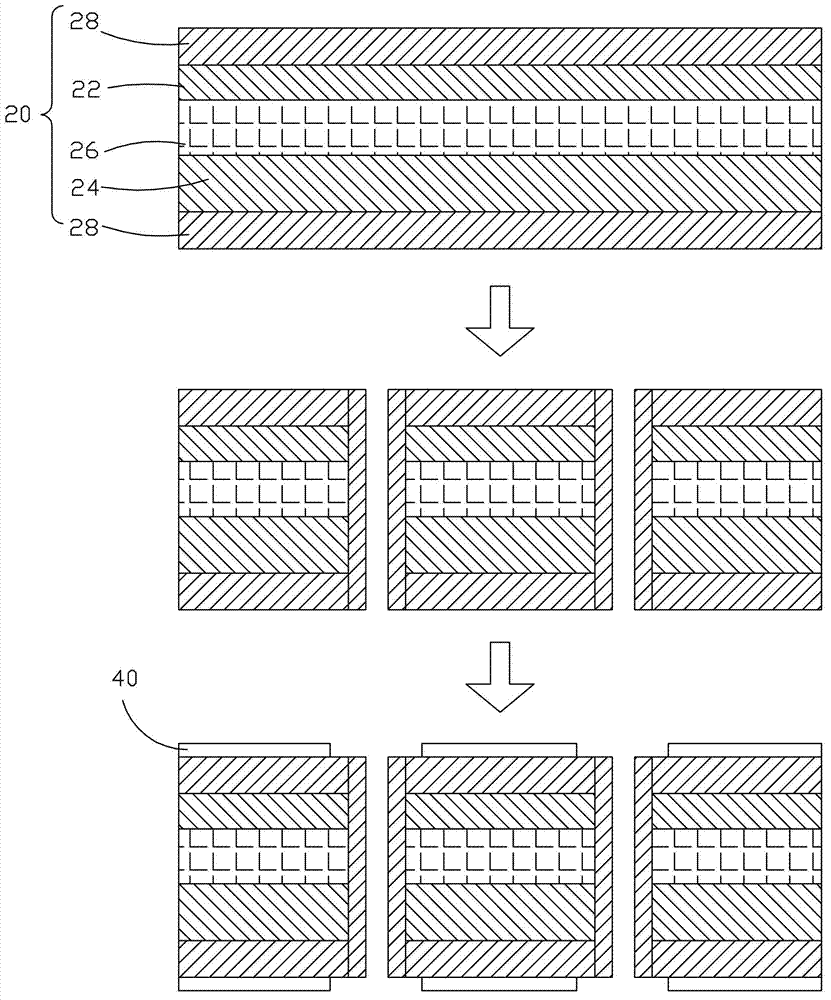

Making method for liquid crystal LCOS and laminating apparatus therefor

InactiveCN1804694AChange the manufacturing processIncrease profitSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

The invention relates to a making method of liquid crystal display LCOS and its pressing device, which makes the LCOS liquid crystal display on an integer silicon base plate. It designs a plurality of LCOS Die integer silicon base plates and ITO glass plates as the common electrode of the silicon base plate liquid crystal display; the working surface coats the corresponding liquid crystal box frame glue on the silicon base plate after cleaning and vacuum coating SiO2 direction film; then it attaches the ITO glass plate on the silicon base plate as an integer after nailed procuring and heat curing; it then dose lower surface cutting and upper surface diamant marks; then it becomes a plurality of liquid crystal boxes which can become the product by charging the liquid crystal into the liquid crystal box.

Owner:SHENZHEN KECHUANG DIGITAL DISPLAY TECH

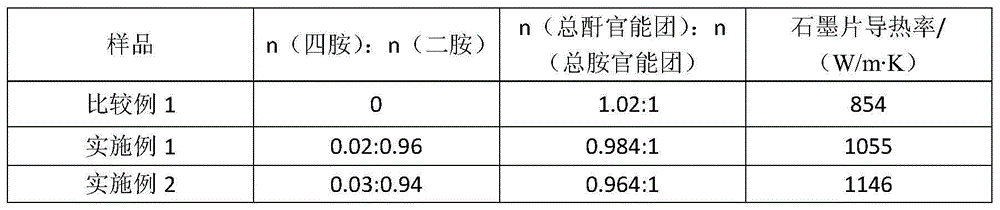

Droplet-resistant flame-retardant polyester, nanometer compound material thereof and method for preparing same

The invention discloses droplet-resistant flame-retardant polyester. The flame-retardant polyester is prepared by random copolymerization of a branched monomer, terephthalic acid or dimethyl terephthalate, ethylene glycol and flame-retardant monomer, wherein the branched monomer is an aliphatic compound or aromatic compound having three or more functional groups; and the flame-retardant monomers adopts any of the following structures. The invention also discloses a method for preparing the droplet-resistant flame-retardant polyester, a nanometer compound material containing the droplet-resistant flame-retardant polyester and a method for preparing the nanometer compound material. Because the droplet-resistant flame-retardant polyester provided by the invention simultaneously contains the branched monomer and the fire retardant having the droplet-resistant effect, the melt viscosity of the droplet-resistant flame-retardant polyester at the high temperature is greatly improved, the sensitivity of the droplet-resistant flame-retardant polyester to temperature is lowered, and the droplet-resistant effect is good; because of the nanometer effect and the blocking effect, the nanometer compound material shows better droplet-resistant effect; and the polyester and the nanometer compound material can be directly used as raw materials for preparing fibers, engineering plastics, films and the like.

Owner:SICHUAN UNIV

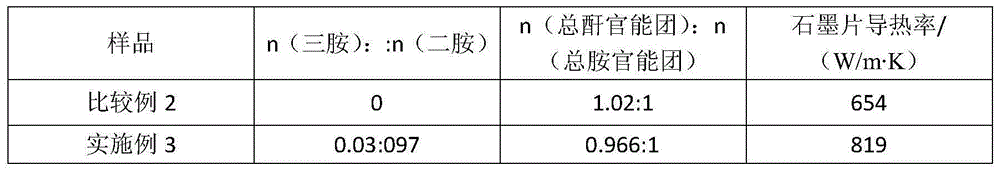

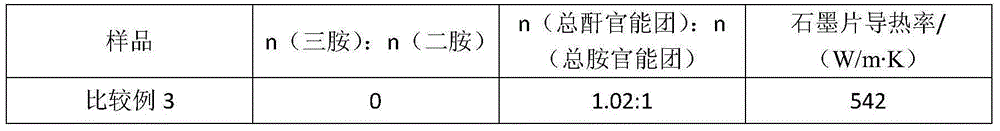

Preparation method for polyimide thin film

The invention discloses a preparation method for a polyimide thin film comprising a local crosslinking structure. The polyimide thin film comprising the local crosslinking structure is prepared by the steps: by selecting an aromatic organic dianhydride monomer and an aromatic organic diamine monomer and matching with a small amount of polyamine monomer, firstly synthesizing polyamide acid comprising partial crosslinking structure; then coating the polyamide acid; and then carrying out thermal imidization. The preparation method disclosed by the invention is simple in process of preparing the polyimide thin film and graphite film. A conventional polyimide thin film preparation process is not changed, a trace amount of polyamine serving as a local crosslinking core is added to an original formula of preparing polyimide to synthesize the polyimide thin film comprising the local crosslinking structure, so that a good effect on the prepared graphite film can be obtained, and therefore, the heat conductivity of the graphite film is improved.

Owner:NANJING UNIV OF SCI & TECH

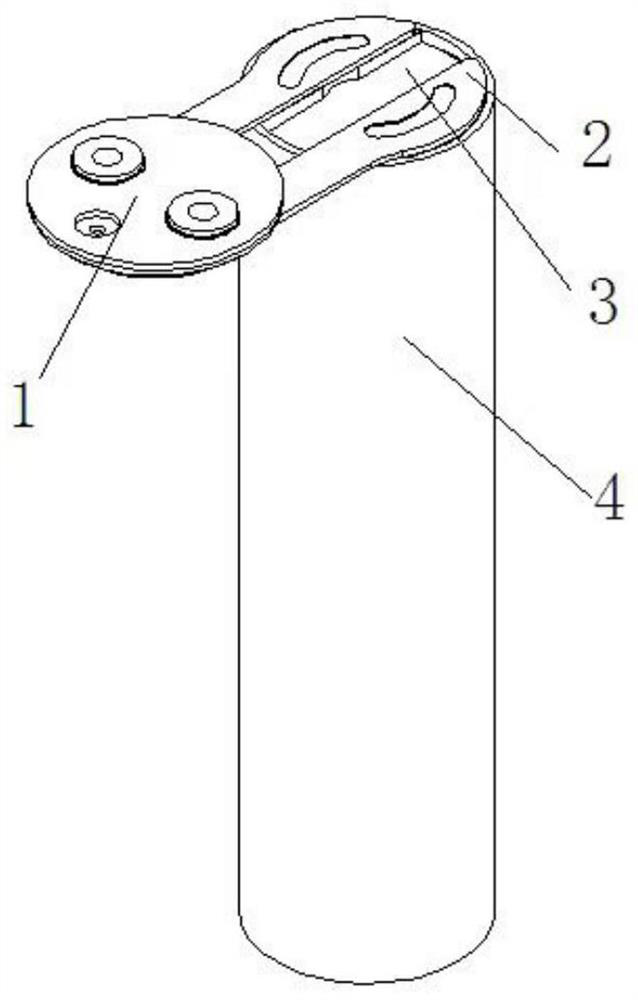

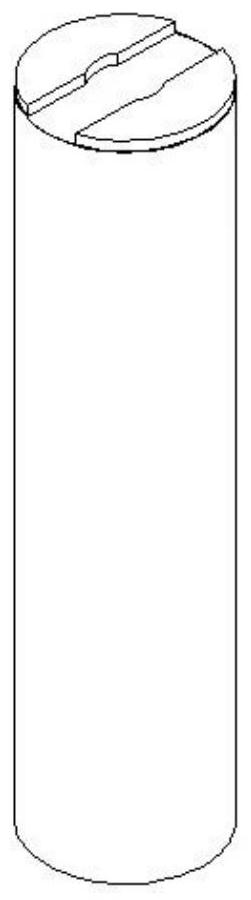

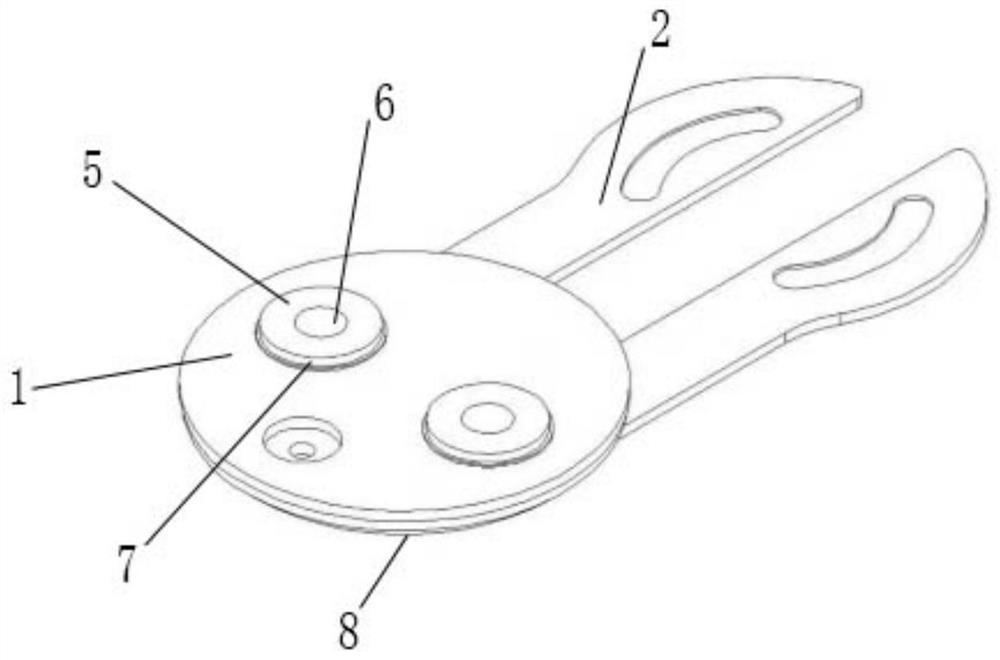

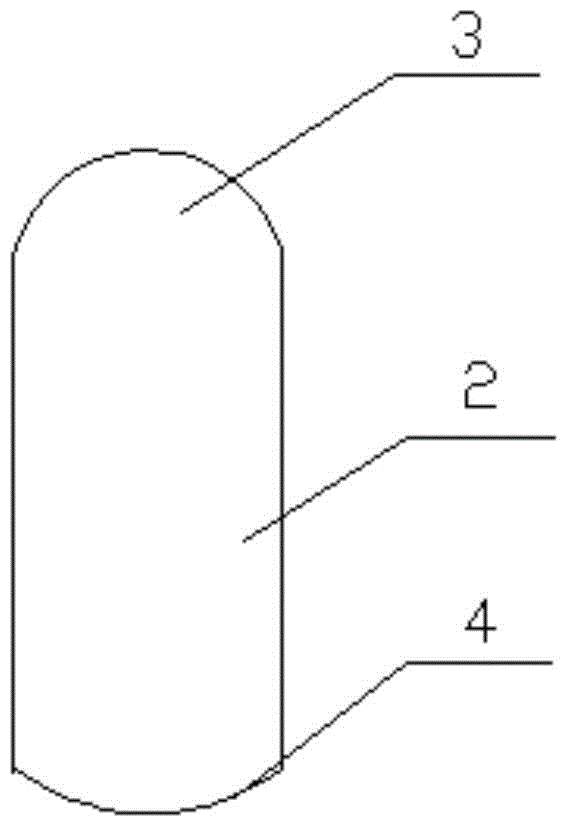

Cylindrical battery and manufacturing method thereof

ActiveCN112542641ALower the altitudeReduce weightFinal product manufactureSmall-sized cells cases/jacketsPole pieceLaser cutting

The invention discloses a cylindrical battery and a manufacturing method thereof, which relate to the field of lithium ion battery manufacturing. The structure is simple. The height of a roll core canbe reduced to a certain extent by arranging a tab on one end surface of the roll core, and meanwhile, only one end of a shell can be opened and sealed, so that the overall weight of the cylindrical battery is reduced; according to the manufacturing method of the cylindrical battery, compared with a pole piece using full tabs in the prior art, the laser cutting of the pole piece is additionally arranged on the process, and through the cooperation of the laser cutting and the subsequent welding and kneading process of the tabs, a positive tab area, a negative tab area and a non-tab area can beformed at one end of a roll core formed by winding a positive plate and a negative plate, and a non-welding area between tabs is omitted, so that the contact compactness between the positive tab and the negative tab after winding is reduced, and the speed of infiltrating the positive plate and the negative plate by electrolyte can be increased during subsequent injection of the electrolyte; and the production efficiency of the cylindrical battery is effectively improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

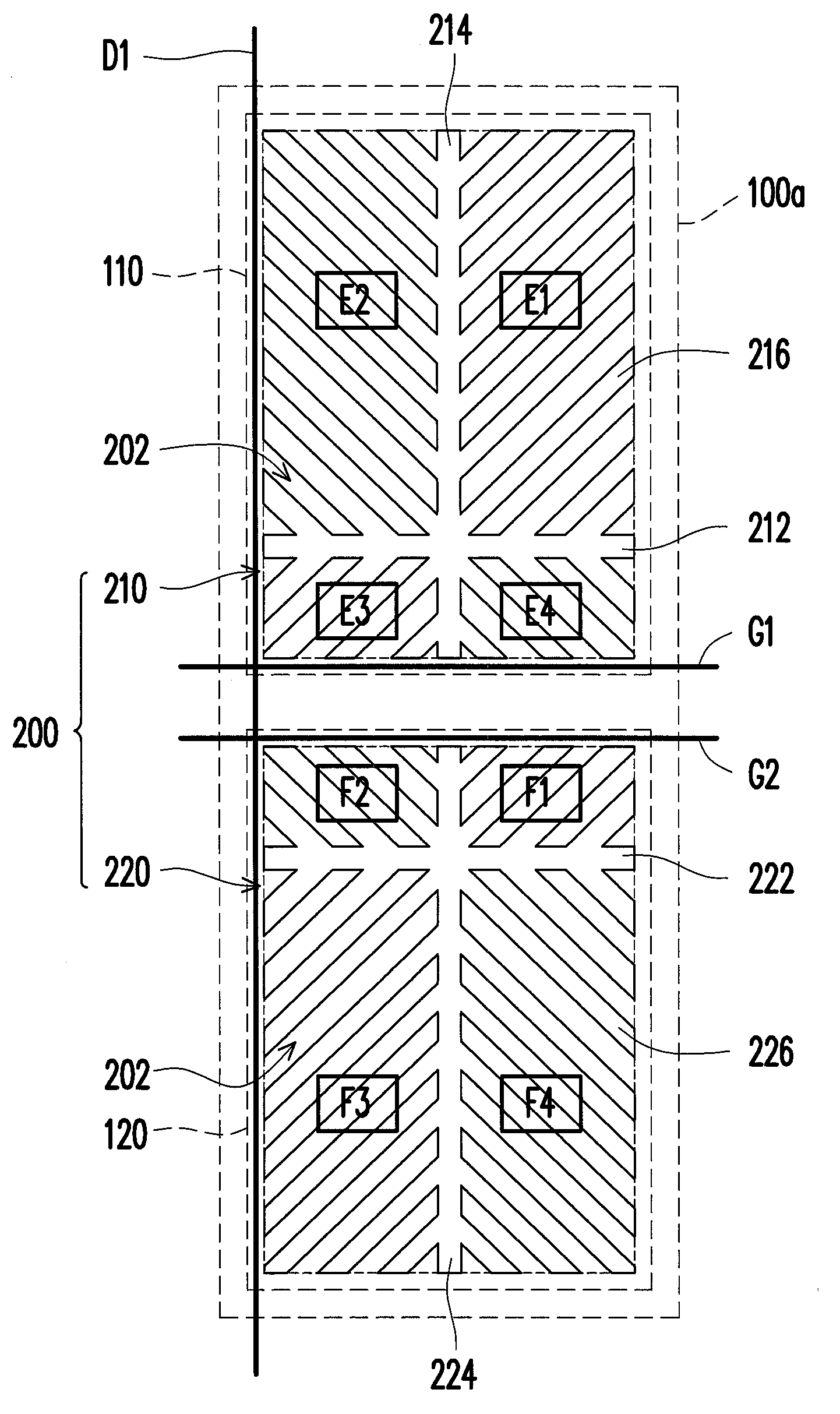

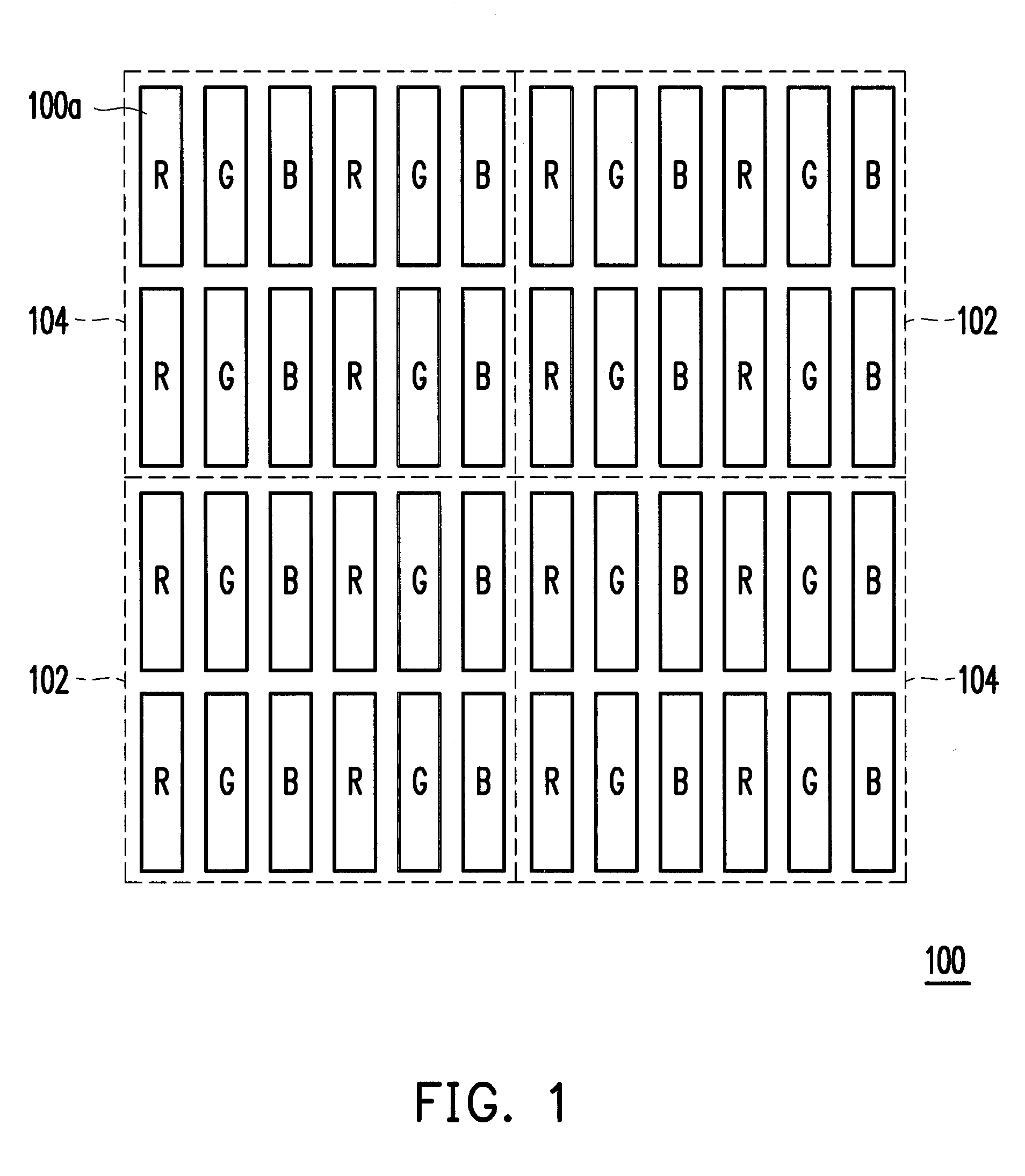

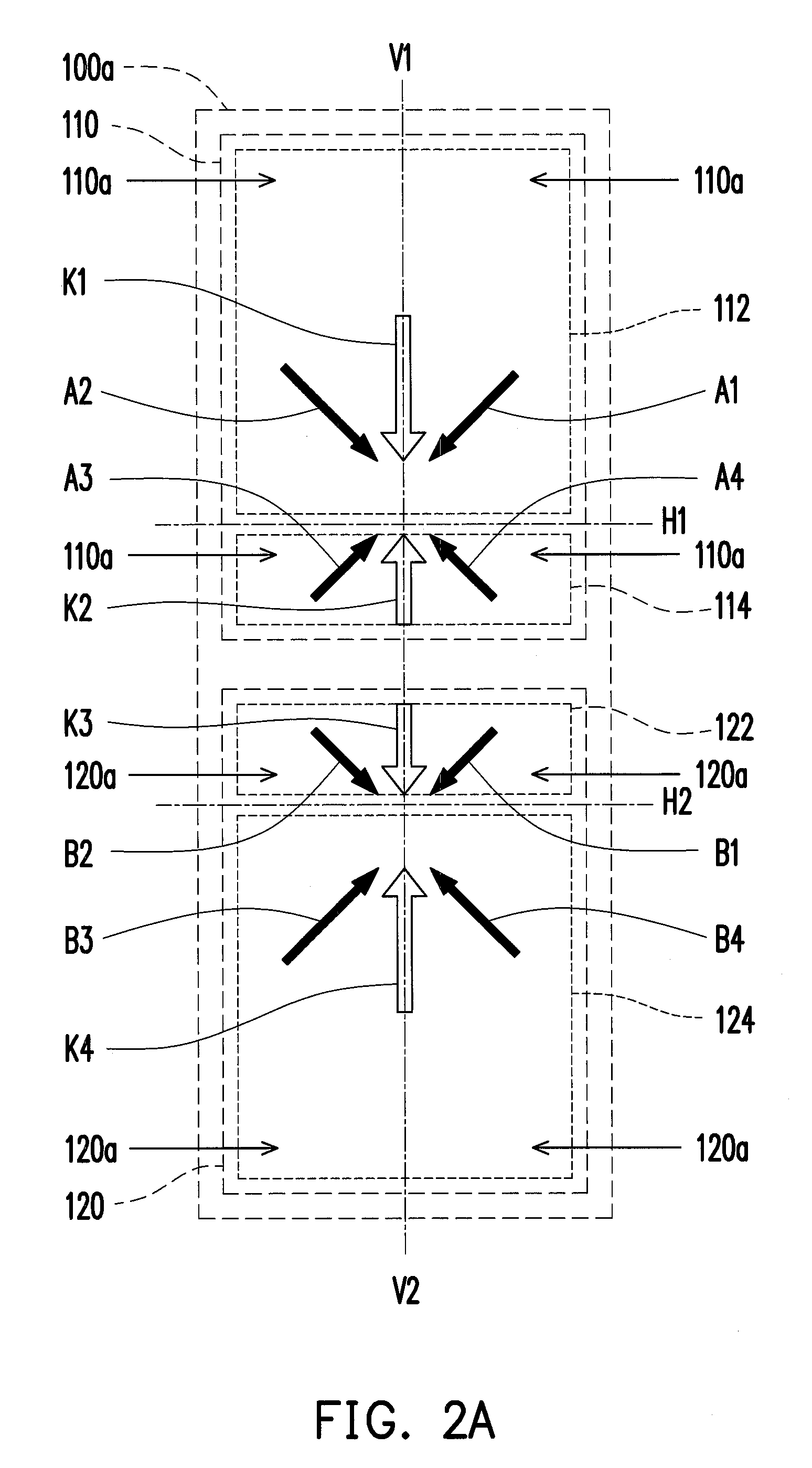

Liquid crystal display panel

ActiveUS20120281174A1Improve display qualitySacrifice aperture ratioStatic indicating devicesNon-linear opticsLiquid-crystal displayComputer science

A liquid crystal display (LCD) panel is provided. A pixel structure of the LCD panel has an asymmetrical liquid crystal alignment. The LCD panel is divided into an array of display blocks. When the LCD panel is in a narrow viewing angle display mode, some of the display blocks are disabled or darkened so that a displayed image is interfered by the disabled or darkened display blocks when it is viewed from the side. Thereby, an anti-peep effect is achieved.

Owner:OPTRONIC SCI LLC

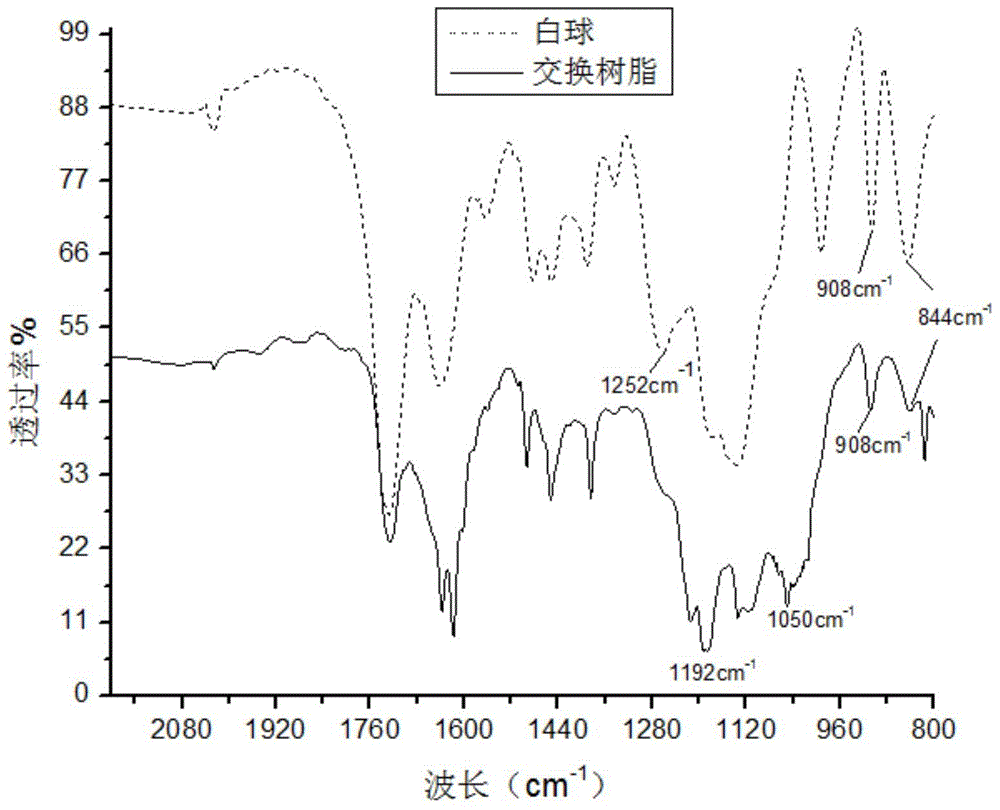

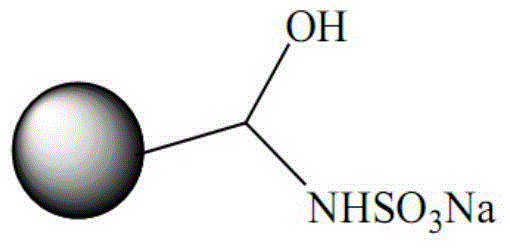

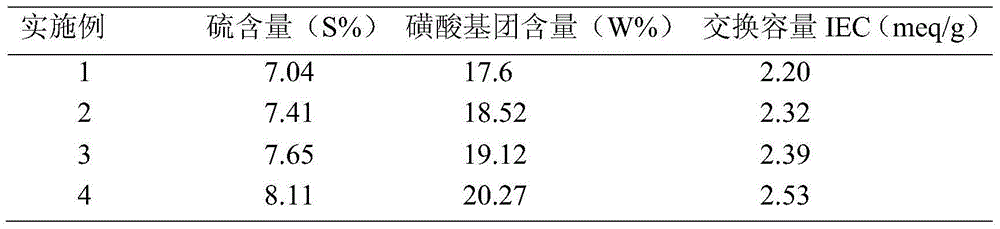

New sulfonic acid type strong-acidity cation exchange resin and preparation method thereof

ActiveCN104437676AReduced service lifeChange the manufacturing processCation exchangersIonIon exchange

The invention relates to a sulfonic acid type strong-acidity cation exchange resin. Random crosslinking copolymer beads of acrylic glycidol ester and divinylbenzene are used as a framework, an amino sulfonic group introduced by an epoxy group of a glycidol part in a copolymer through an open loop is used as a functional group, and the quality ratio of a construction unit of the acrylic glycidol ester to a construction unit of the divinylbenzene in the copolymer is 70:30-93:7. In the preparation process of the resin, a concentrated sulfuric acid, a fuming sulfuric acid and a chlorosulfonic acid, with strong oxidizing properties are not used as a sulfonating reagent, and the problem of environmental pollution caused by the discharge of a great deal of a waste acid and the problem of production safety in the traditional technology are solved. The sulfonic acid type strong-acidity cation exchange resin is spheroidal particles of which the particle size range is 0.5-1.2 mm, the content of the sulfonic group is 17.6-20.27wt%, and the ion exchange capacity is 2.20-2.53 meq / g.

Owner:SHANGHAI RESIN FACTORY

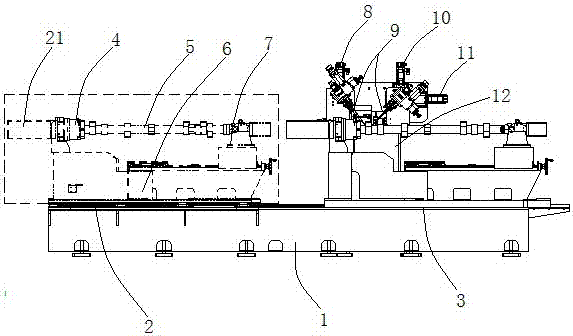

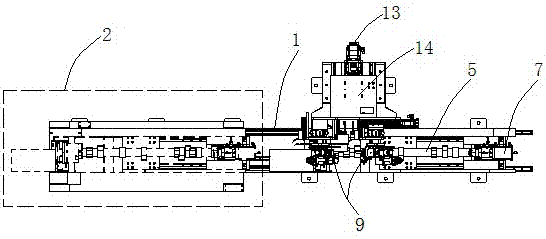

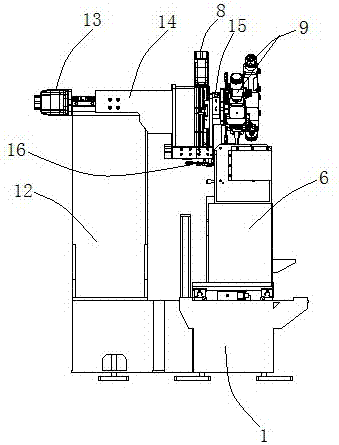

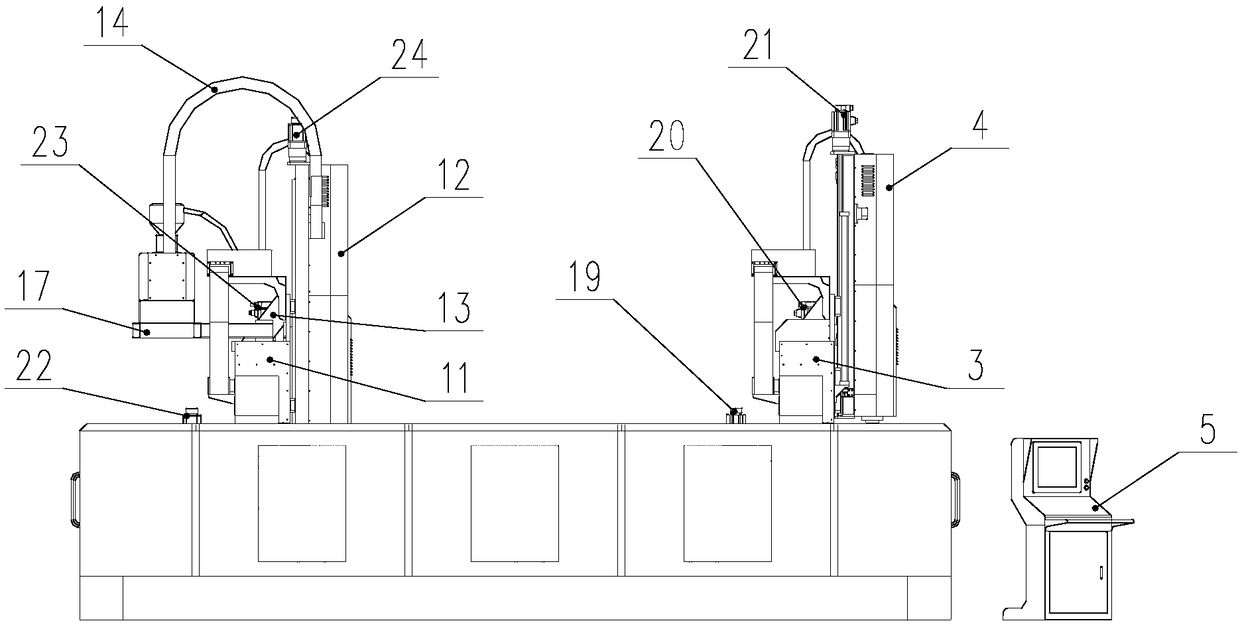

Two-sided laser welding machine for processing camshafts and processing method thereof

ActiveCN107953033ASimple structureRealize automatic detection and positioningLaser beam welding apparatusVertical distanceWelding joint

The invention provides a two-sided welding machine for processing camshafts. The two-sided welding machine comprises a base, wherein an X-axis movable worktable is arranged on the base; a fixing mechanism is arranged on the X-axis movable worktable; a main shaft rotating motor is arranged on the fixing mechanism; a vertical pillar is arranged on one side of the base; a Y-axis movable worktable isarranged on the vertical pillar and is connected with a Z1-axis movable worktable and a Z2-axis movable worktable through a Z1 driving mechanism and a Z2 driving mechanism respectively; the Z1-axis movable worktable and the Z2-axis movable worktable are connected with welding joints through angle rotating mechanisms. Through the two-sided welding machine, two welding joints are used for simultaneously and automatically welding two sides of the camshafts, automatically finding welding positions and automatically adjusting Z-axial vertical distance and Y-axial feeding distance between the welding focal points of the welding joints to the axes of the camshafts and included angles between the welding joints and the axes of the camshafts so as to reach the optimum welding position; the existingcamshafts formed by forging or casting are improved into the camshafts formed by welding.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

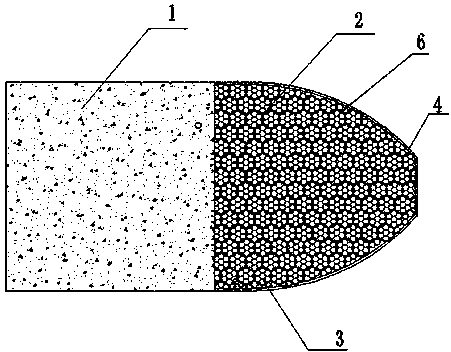

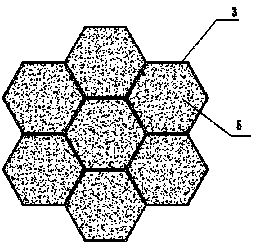

Energy-absorbing road traffic combined anti-collision pier and building method thereof

InactiveCN103993567AMature processing technologyEasy to assembleTraffic signalsRoad signsArchitectural engineeringRoad traffic

The invention discloses an energy-absorbing road traffic combined anti-collision pier which comprises a pier head and a concrete pier body. The pier head comprises a steel plate and a large prism formed by welding and splicing a plurality of round or regular polygon steel tube prisms. The steel plate is located on the periphery of the large prism, extends in the pier body direction and is connected with the pier body. Energy-absorbing materials are injected in gaps in the steel tube prisms, gaps among the steel tube prisms and gaps between the steel plate and the steel tube prisms. By means of the round or regular polygon prisms, people only need to roll the whole steel plate, and a manufacturing process and technology are mature. The aims of collision prevention, energy absorbing and buffering are achieved through a spliced honeycomb structure and filling of metal lead or rubber or other materials. The anti-collision pier breaks whole collision into parts, is convenient to construct and replace, and plays an important role in guaranteeing life safety of traffic drivers and passengers on roads and reducing vehicle property loss.

Owner:ZHENGZHOU UNIV

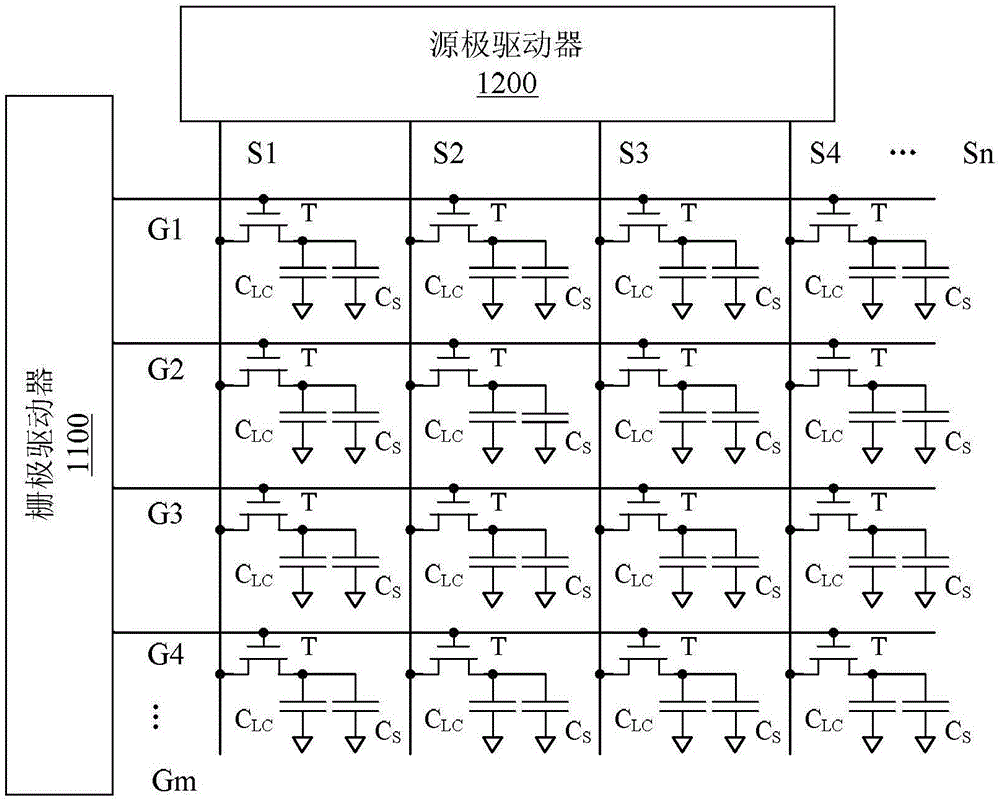

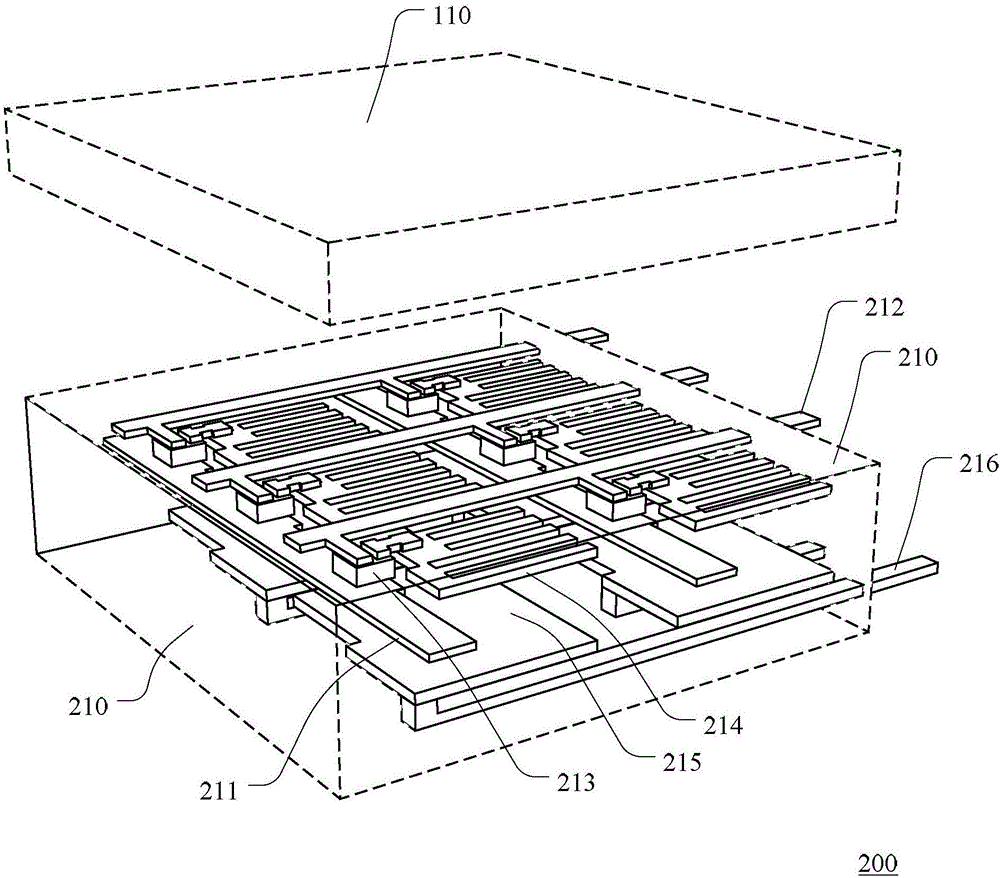

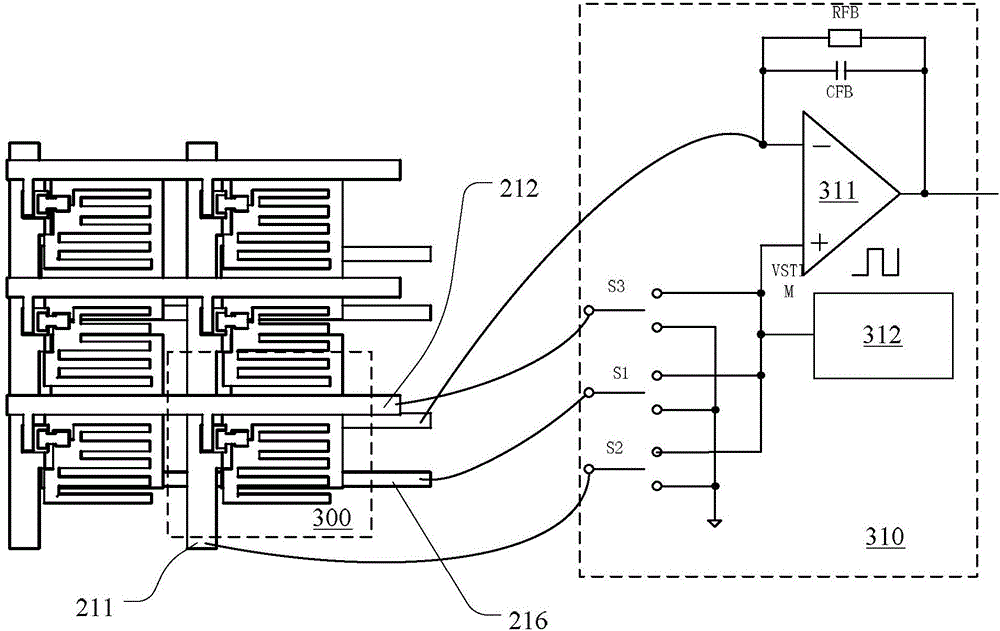

Touch control display panel detection circuit and detection method

ActiveCN106680591ASimple structureLow costCapacitance measurementsStatic indicating devicesSignal onParasitic capacitance

The invention discloses a touch control display panel detection circuit and a detection method. The detection method comprises the following steps: using a plurality of switches to have a plurality of induction wires, a plurality of grid electrode scanning wires and a plurality of source electrode data wires selectively connected to pulse signals or grounded; obtaining a plurality of detection signals according to the signals on the selected induction wires from the plurality of induction wires in different connection states; and based on the plurality of detection signals, determining the parasitic capacitance of the electrodes and the layout wires. The detection method of the invention is capable of detecting the quality of a detection panel and assisting to change the manufacturing technique for increased yield rate. Further, the detection method could simplify the structure of the detection circuit and can even reuse already available touch control detection circuit for the detection of parasitic capacitance, which reduces the circuit detection cost and increases the detection efficiency.

Owner:CHIPONE TECH BEIJINGCO LTD

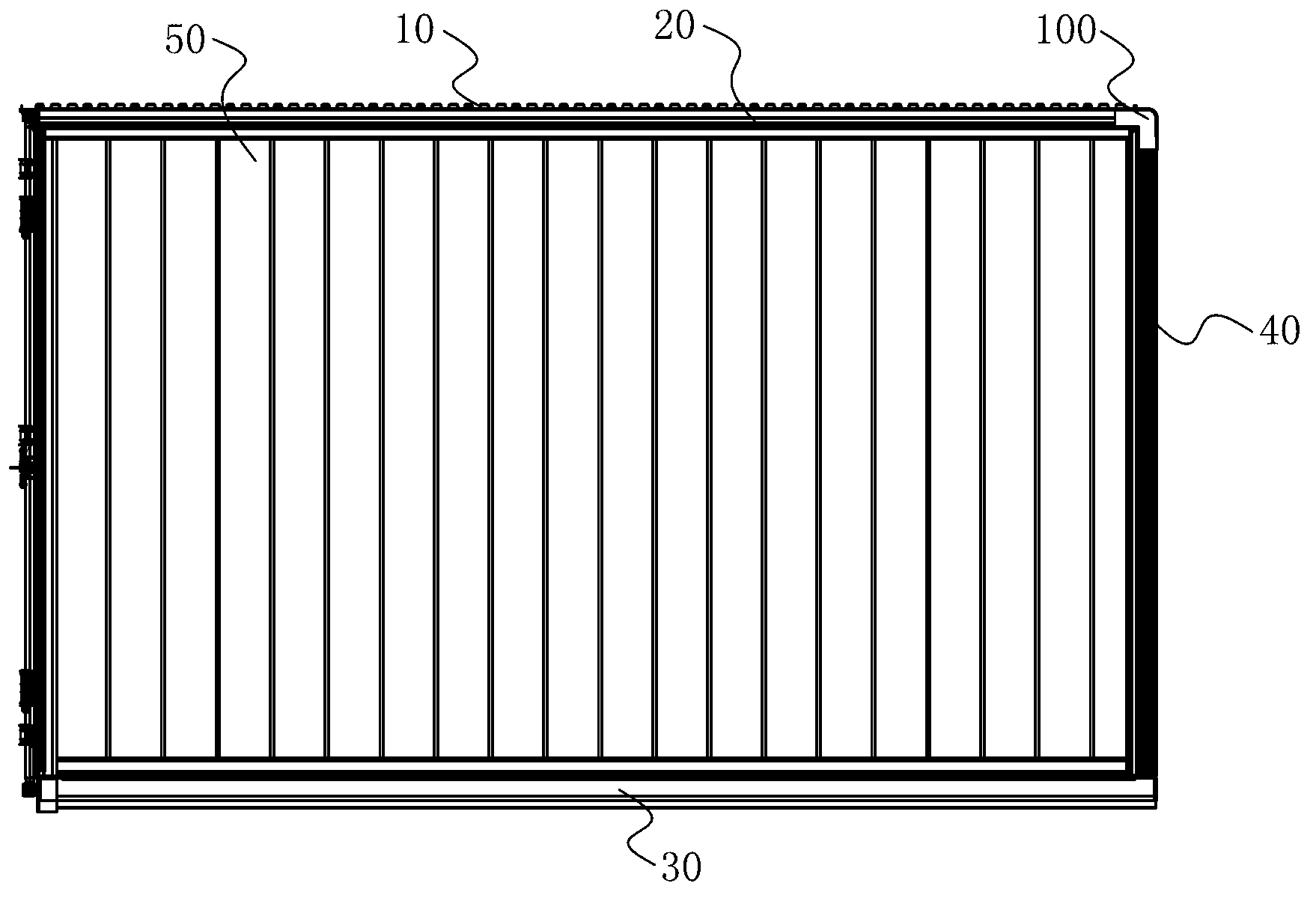

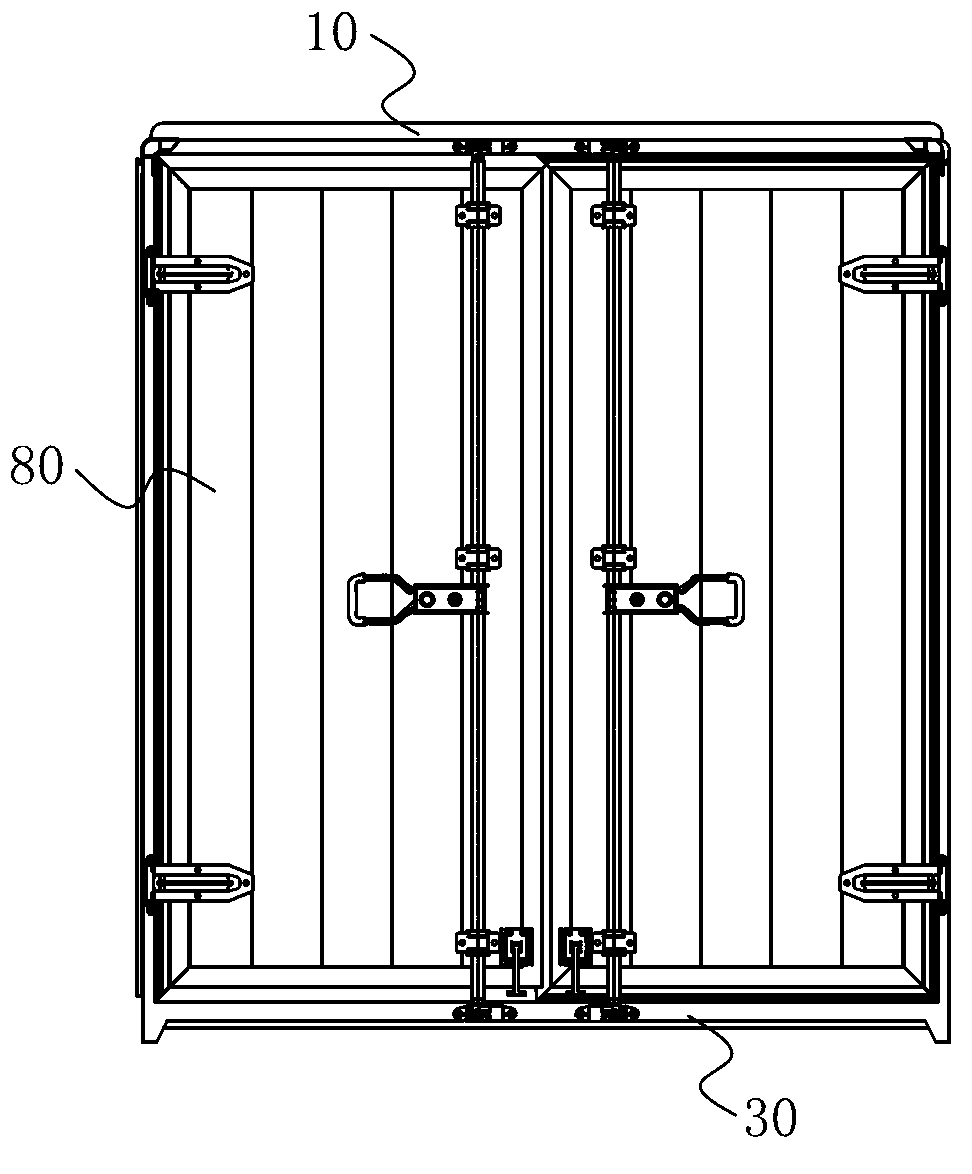

Full aluminum alloy spliced car

ActiveCN103072637AEasy and fast assemblyReduce use costLoading-carrying vehicle superstructuresResource utilizationEngineering

The invention discloses a full aluminum alloy spliced car which comprises a top plate, a bottom plate, a side plate, a front wall plate and a rear door plate. Corresponding L-shaped upper section bar and front section bar are arranged at the connection of the top plate and the side plate as well as the top plate and the front wall plate as connecting pieces. L-shaped column section bars are respectively arranged at the connection of the top plate and the side plate as well as the top plate and the rear door plate as connecting pieces or adjacent pieces. An L-shaped lower section bar is arranged at the connection of the side plate, the front wall plate and the bottom plate. The top plate is formed by splicing a plurality of top plate section bars. Each top plate section bar is provided with a base part and a buckle part axially along the edges of two sides. Each top plate section bar is connected with the buckle part of the adjacent top plate section bar through the base part in a locked manner, and a first top plate rubber plug is arranged between each base part and the corresponding buckle part to enhance connection. The assembly process is improved, the whole vehicle assembly process is simple and convenient, and the production efficiency is improved. Meanwhile, the whole vehicle discarded as useless can be fully recycled, so that the resource utilization ratio is improved, and the using cost of a user is lowered.

Owner:重庆勇图机械工业有限公司

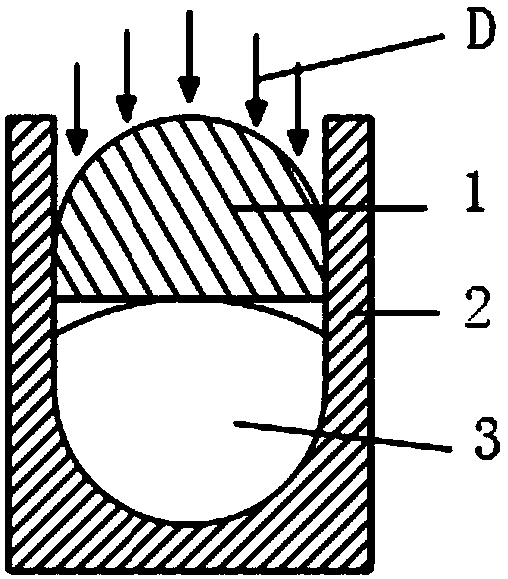

Solar water heater tank inner container

InactiveCN101254635AHigh thermal efficiencyReduce heat lossSolar heat devicesCoatingsCross-linkMetallic materials

An inner shell of water tank of solar water heater is once molded by rotationally molding modified cross-linked polythene. The specific manufacture process comprises the following steps: adding modified cross-linked polythene powder into an integral steel mold; disposing the mold horizontally in an oven; heating while rotating simultaneously in both axial direction and radial direction with an axial rotation speed of 1 to 20 rpm and a radial rotation speed of 5 to 50 rpm; changing the rotation direction every 5 to 10 min; increasing the temperature in the oven to 160 to 260 DEG C within 10 min; keeping the temperature for 15 to 40 min; stopping heating; taking the mold out of the oven; cooling; rotating the mold until the surface temperature of the mold is reduced to 30 to 40 DEG C; opening one end of the mold; and taking out the inner shell. The inner shell made of metal substitute material can improve the heating efficiency of the solar water heater, reduce heat loss and prolong the heat preservation time, and has the advantages of acid and alkaline resistance, no corrosion, no fouling, no leakage, and prolonged service life.

Owner:马俊亮

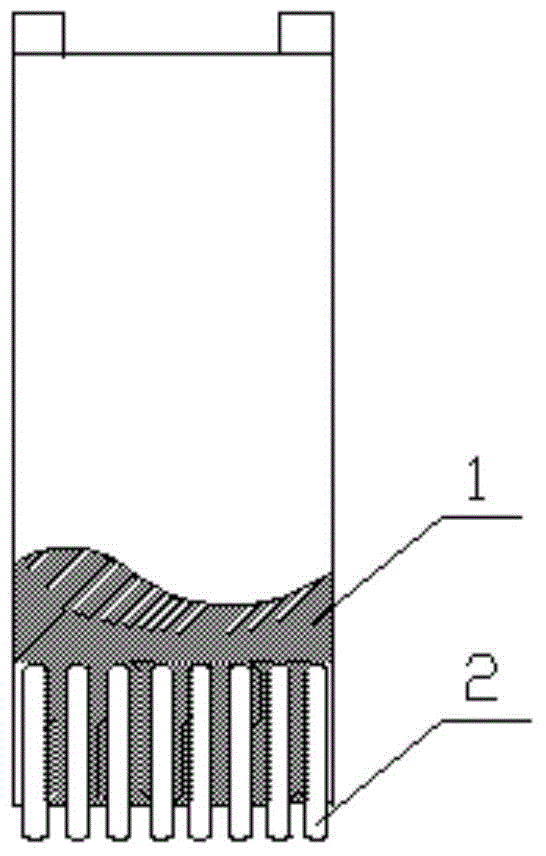

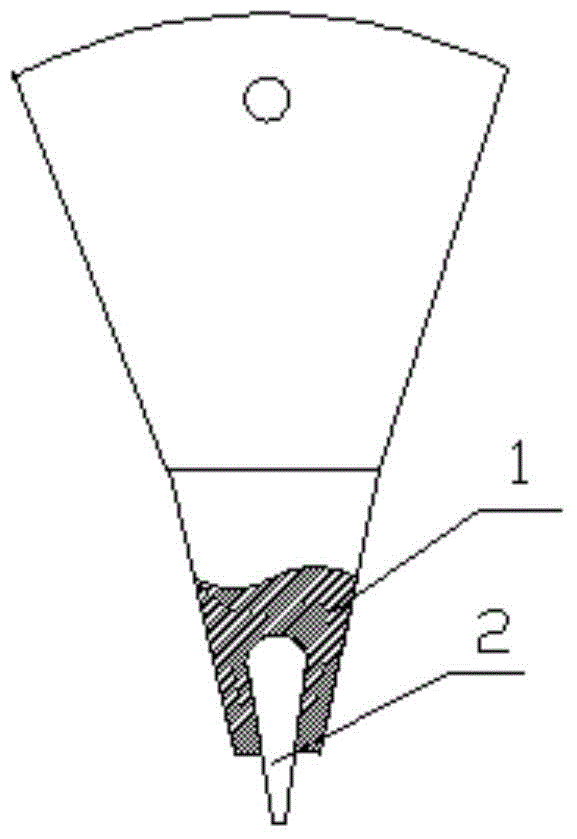

Excavator bucket tooth and preparation process of excavator bucket teeth

InactiveCN103602908AExtended service lifeChange the manufacturing processSoil-shifting machines/dredgersShock resistanceEngineering

The invention discloses an excavator bucket tooth which comprises two parts, namely a tooth seat and a plurality of tooth tips, wherein the tooth seat and the plurality of tooth tips are cast independently; the tooth tips are fixed at the front end of the tooth seat side by side; a gap is formed between every two adjacent tooth tips; the roots of the tooth tips are circular; the heads of the tooth tips are in circular arc shapes; the thicknesses of each toot tip is slowly reduced from the root to the head; the bucket tooth is divided into the two parts, namely the tooth seat and the tooth tips which are cast independently, each tooth tip is coated in the tooth seat, the contact area between each tooth tip and the tooth seat is enlarged, the bonding strength of each tooth tip and the tooth seat is greatly improved, and the possibility of falling off of the tooth tips is reduced; due to the creative shapes, the tooth tips can keep sharp all the time; when the excavator bucket tooth is used for excavation, time and labor are saved, and the service life of the bucket tooth is prolonged; components and a preparation process of the bucket tooth are changed, so that the high wearing resistance and shock resistance of the bucket tooth are realized.

Owner:SOUTHEAST UNIV

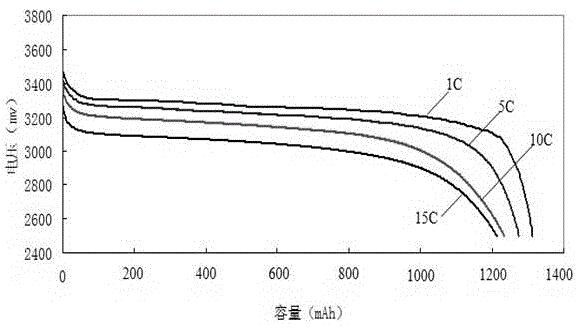

High-current lithium manganese button battery and preparation method thereof

PendingCN108461820AShorten the lengthImprove space utilizationCell electrodesFinal product manufacturePower flowManganese

The invention discloses a high-current lithium manganese button battery and a preparation method thereof and belongs to the technical field of button batteries. The battery comprises a positive electrode cover, a negative electrode cover, a battery cell and electrolyte, wherein the battery cell and electrolyte are arranged in a sealed cavity formed between the positive electrode cover and the negative electrode cover; the battery cell is formed by stacking a positive plate, a diaphragm and a negative plate and folding; the positive plate consists of an aluminum net and manganese electrode materials laminated on the positive and reverse sides of the aluminum net, the reverse side of the positive plate is provided with N sub-positive plates separated by fold, and the positive side of the positive plate is provided with a positive electrode and (N-1) continuous sub-positive plates formed by exposing the aluminum net; the negative plate consists of a copper net and lithium electrode materials laid on the positive and reverse sides of the copper net, the positive side of the negative plate is provided with a negative electrode and (N-1) continuous sub-negative plates formed by exposingthe copper net, and the reverse side of the negative plate is provided with N continuous sub-negative plates; the diaphragm is arranged between the positive plate and the negative plate, so that the sub-positive plates and the sub-negative plates are separated and combined in a preset manner to be sequentially folded in the same direction along the fold so as to form the battery cell.

Owner:YICHANG LIJIA TECH

Whitening speckle-removing spot-removing nourishing powder

InactiveCN101129325APromote circulationEfficient removalCosmetic preparationsToilet preparationsRhizomeAstragalus Root

The invention discloses a face nourishing cream for removing leukoplakia, which is prepared from the following medicinal raw materials (by weight portion): white fungus 1-15 parts, astragalus root 1-18 parts, root of Dahurain angelica 1-20 parts, fragrant solomonseal rhizome 1-20 parts, ginseng 1-25 parts, poria cocos wolf 1-22 parts.

Owner:惠中兴

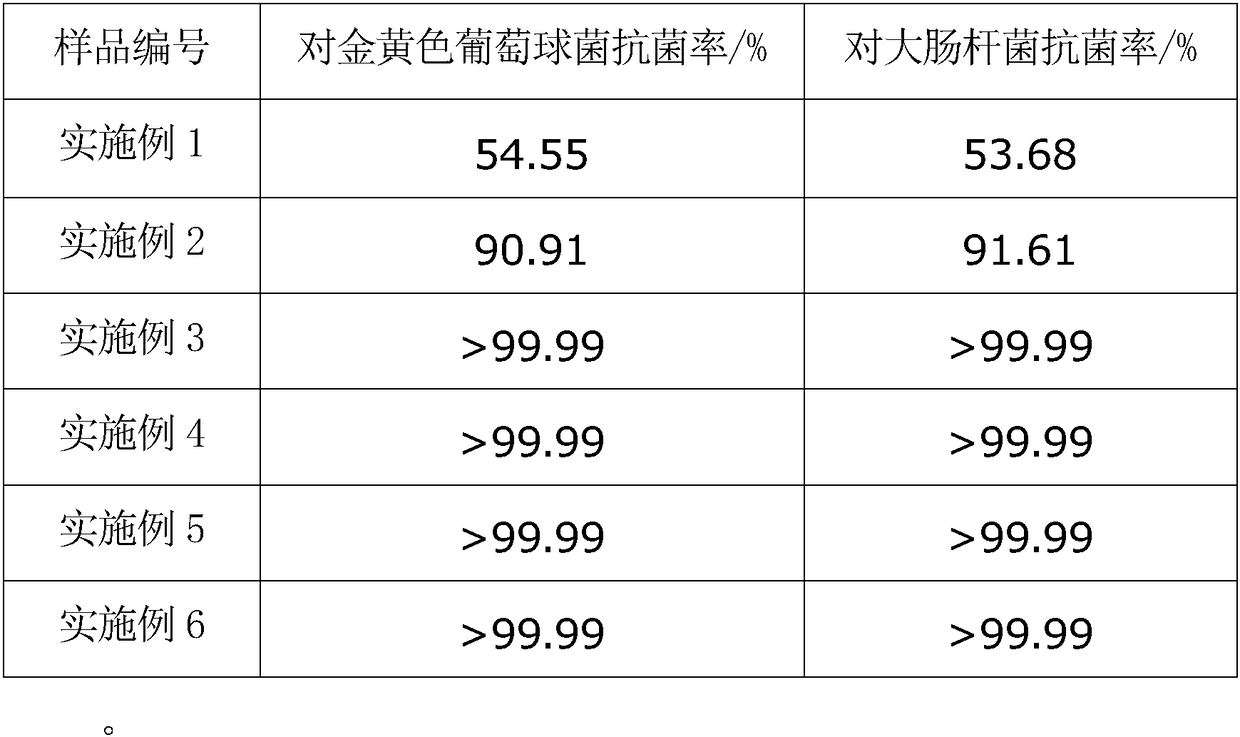

High-efficiency soft PVC antibacterial plastic and preparation method thereof

The invention discloses a high-efficiency soft PVC antibacterial plastic, comprising, based on the weight part, 100 parts of PVC resin, 0.4 to 0.8 part of zinc pyrithione, 40 to 60 parts of DOP, 0.1 to 0.3 part of Hst, 0.5 to 1.0 part of CaSt, 1.0 to 1.5 parts of calcium-zinc compound stabilizing agent, 0.6 to 0.8 part of methyl tin181 and 5 to 15 parts of filling. The invention also discloses a preparation method for the high-efficiency soft PVC antibacterial plastic. The invention has the advantages: the antibacterial property is high, the antibacterial plastic can effectively inhibit the growth of gram positive and negative bacteria and the mould, the zinc pyrithione is taken as the antiseptic, the production is simple, the cost is lower and the performance is steady.

Owner:ZHEJIANG UNIV OF TECH

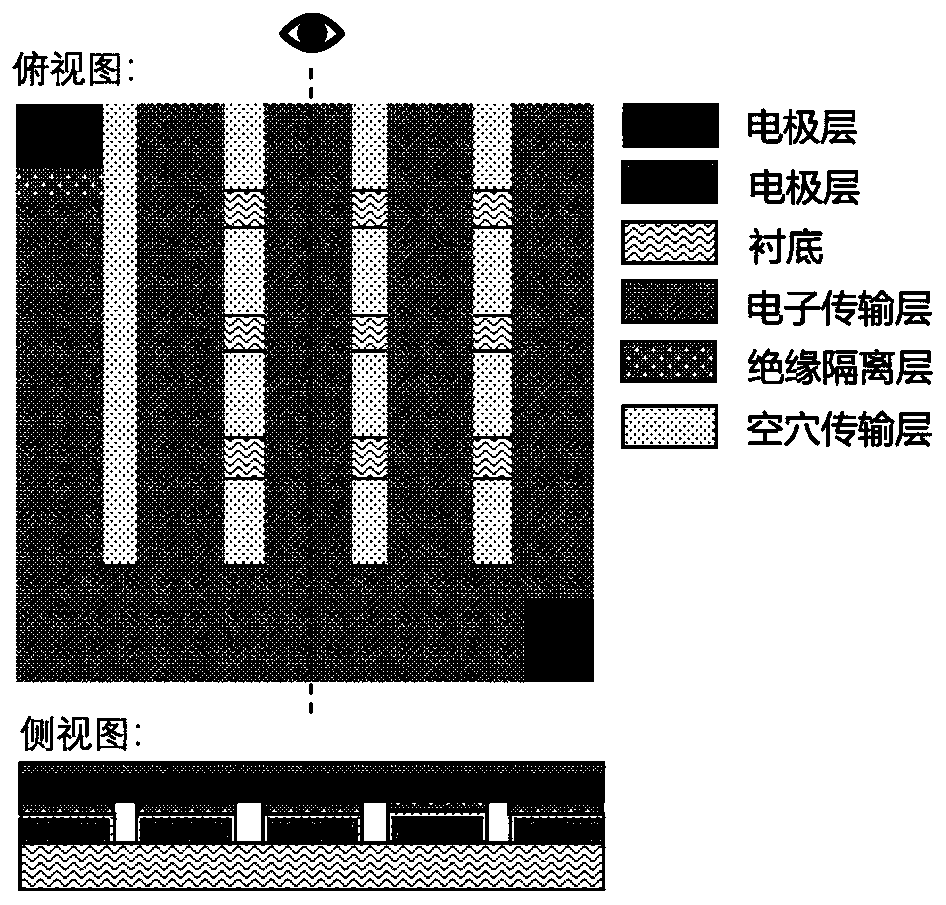

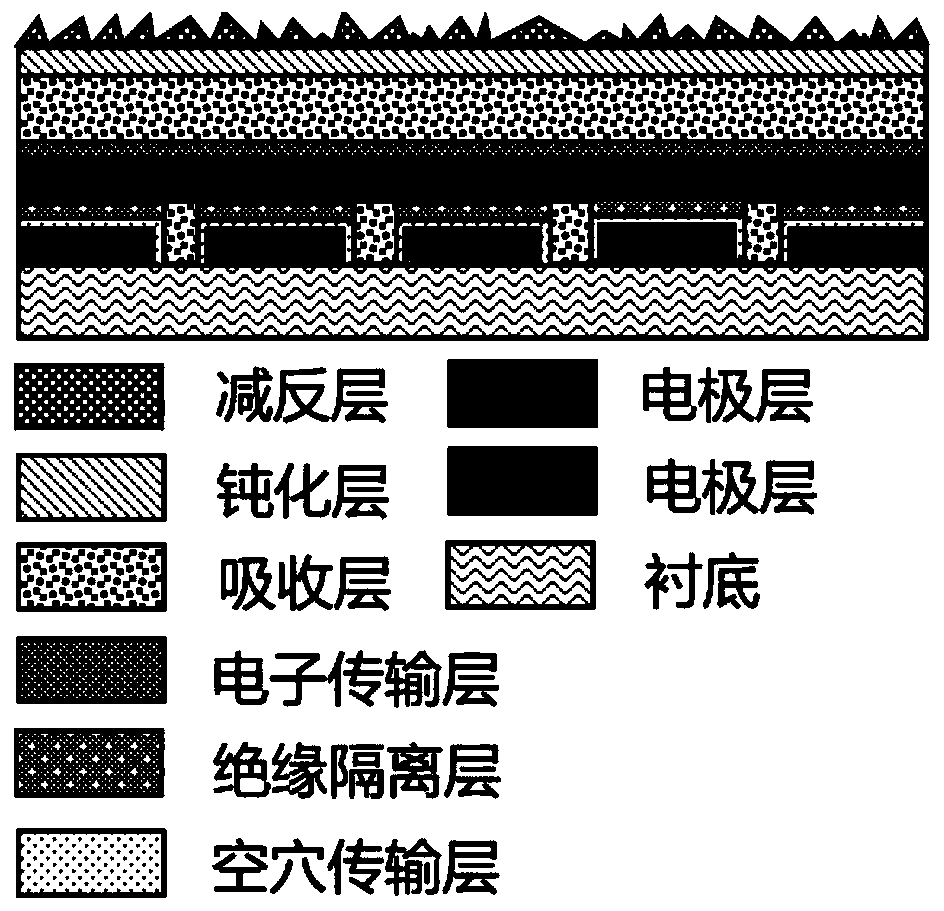

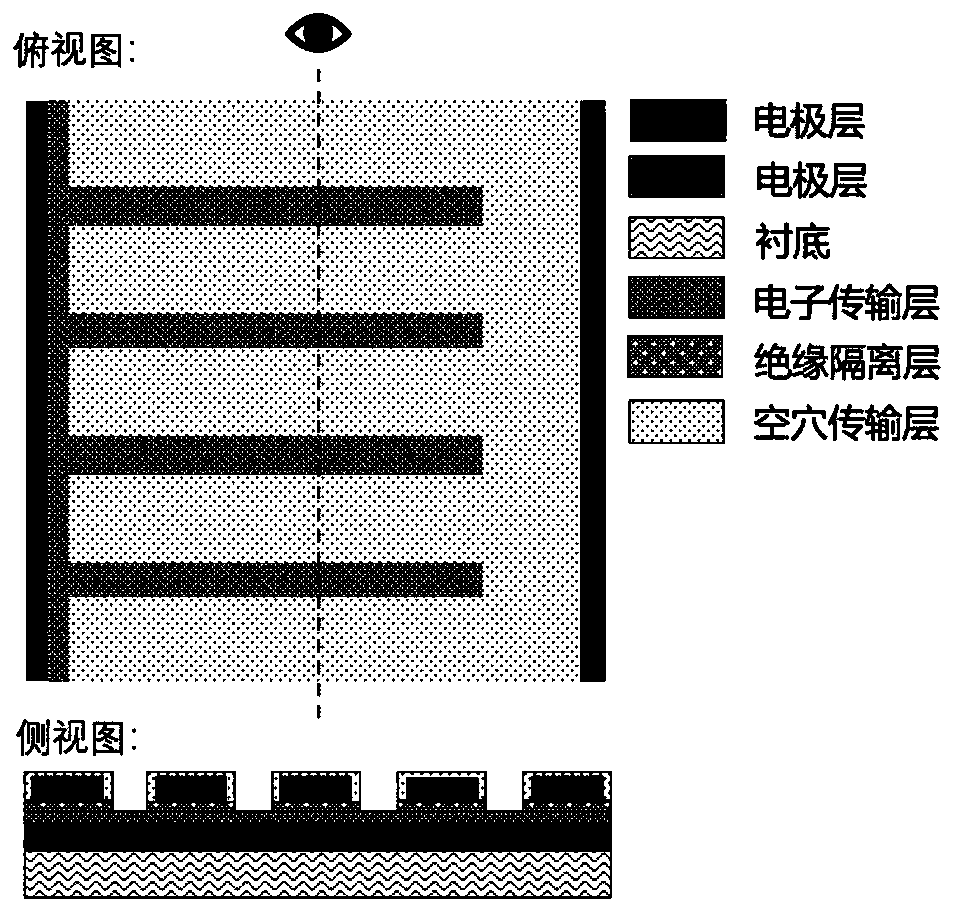

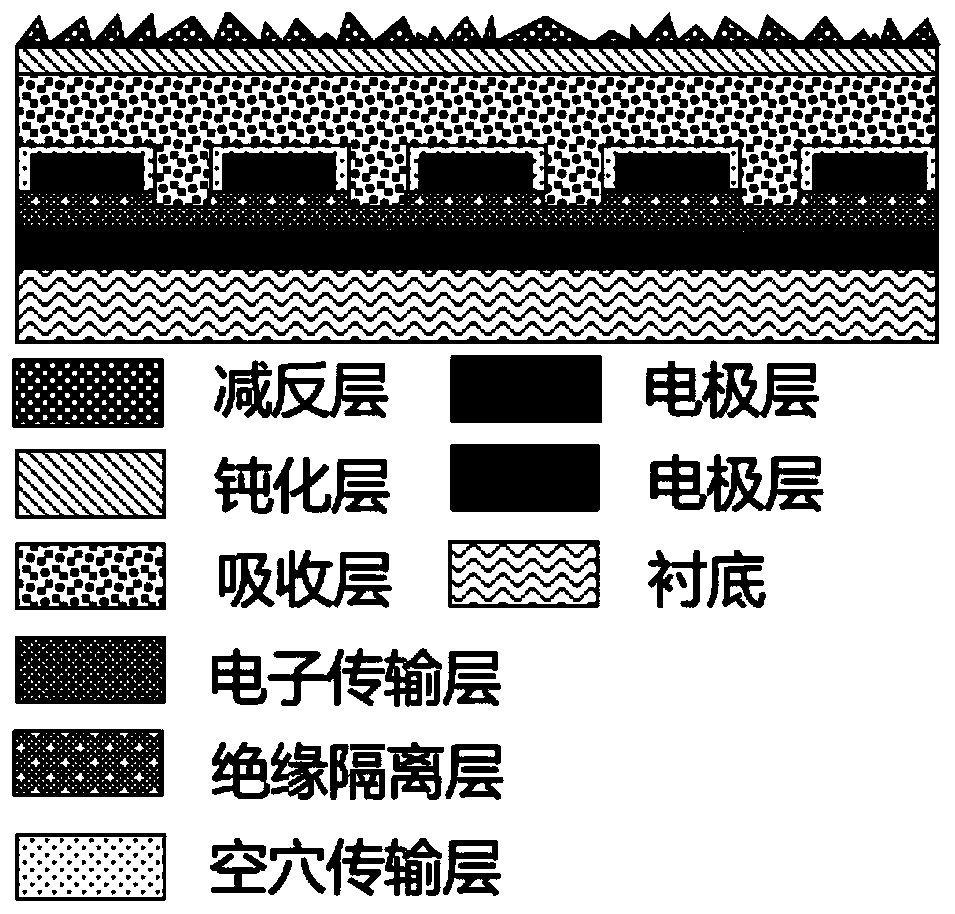

Positive interdigital full-back contact perovskite solar cell and preparation method thereof

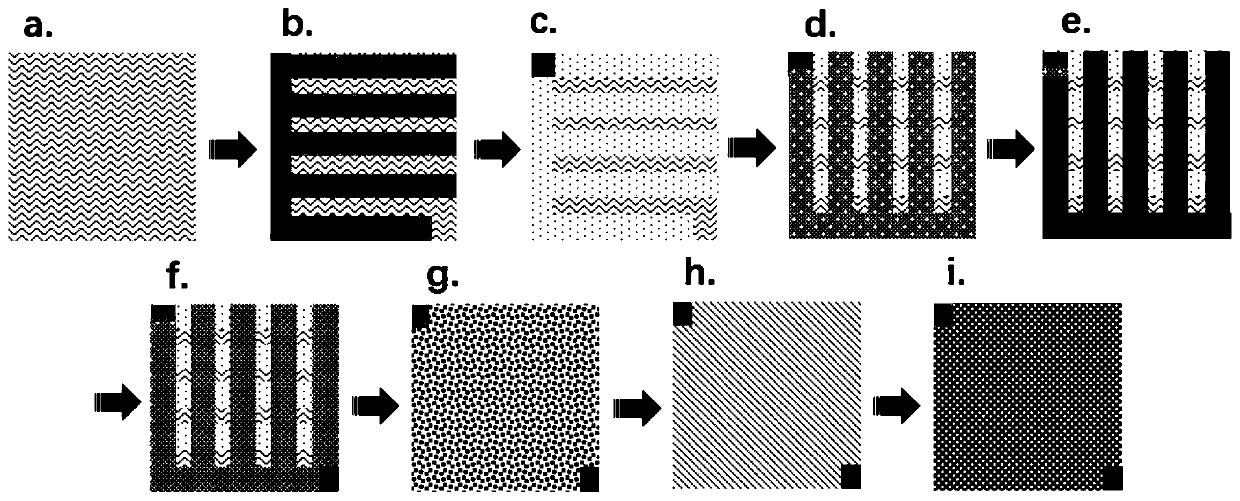

PendingCN111293222AAvoid occlusionIncrease profitFinal product manufactureSolid-state devicesPerovskite (structure)Single crystal

The invention discloses a positive interdigital full-back contact perovskite solar cell structure. The structure sequentially comprises the following components from bottom to top: 1) a substrate; 2)a positive electrode; 3) a hole transport layer; 4) an insulating isolation layer; 5) a negative electrode; 6) an electron transport layer; 7) a perovskite absorption layer; 8) a passivation layer; and 9) anti-reflection protective layer. The solar cell is characterized in that the positive electrode and the negative electrode are orthogonally arranged but not connected on the backlight surface ofthe cell, and are separated from each other by means of insulating material filling and the like; the perovskite absorption layer can be made of a polycrystalline or monocrystalline perovskite material; the passivation layer adopts PMMA, PEAI and other compounds to reduce surface interface defects and carrier recombination of the perovskite absorption layer; the anti-reflection protective layer is a low-refractive-index compact film or a suede-structure anti-reflection film. The solar cell structure disclosed by the invention can avoid the shading loss of the light-facing surface electrode and the parasitic absorption of a charge transfer layer or the substrate, improve the conversion efficiency of the perovskite solar cell and improve the appearance of the solar cell.

Owner:NANKAI UNIV

Whitening, speckle removing, acne removing nutrient night-cream

InactiveCN101385695APromote circulationEfficient removalCosmetic preparationsToilet preparationsTremellaMedicine

The invention discloses a nutritious night cream for whitening and eliminating freckles and acnes, belongs to cosmetics, and in particular relates to a nutritious night cream for whitening and eliminating freckles and acnes. The nutritious night cream is made by processing the effective components extracted from the following parts of raw materials by weight: 1-15 parts of white fungus, 1-18 parts of milk vetch, 1-20 parts of dahurian angelica, 1-20 parts of dried solomonseal, 1-25 parts of white ginseng and 1-22 parts of tuckahoe. Compared with other products for whitening and eliminating freckles, the nutritious night cream has the benefits of eliminating freckles and acnes, whitening and beautifying. The product is a pure Chinese materia medica preparation, and natural, nontoxic and good for both inner tissues and skin.

Owner:惠中兴

Inorganic nano antibacterial thermoplastic elastomer and preparation method thereof

The invention discloses inorganic nano antibacterial thermoplastic elastomer and a preparation method thereof. The antibacterial thermoplastic elastomer is prepared from the following ingredients in mass percent: 15 to 30% of SEBS, 10 to 30% of rubber filling oil, 10 to 25% of polypropylene, 1 to 2% of inorganic nano antibacterial powder, 0.1 to 0.5% of coupling agent, 0.1 to 0.5% of surface active agent and 0 to 2% of other additives. The inorganic nano antibacterial thermoplastic elastomer disclosed by the invention is a material having the advantages of excellent antibacterial effect, highstrength, high rebound resilience, injection molding characteristic, strong antibacterial capacity, wide antibacterial range, safety and no toxicity to the human body, no stimulation to the skin, no allergenicity, durability, effectiveness, no attenuation or failure in a short time, environmental friendliness, no toxicity, safety and wide application range.

Owner:倍肯(浙江)科技发展有限公司

Stacked and spliced interdigital full-back contact perovskite solar cell and preparation method thereof

PendingCN111312901AAvoid occlusionIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingElectrical batteryEngineering

The invention discloses a stacked and spliced interdigital full-back contact perovskite solar cell. The cell sequentially comprises the following components from bottom to top: 1) a substrate; 2) a positive electrode; 3) a hole transport layer on the positive electrode; 4) an insulating isolation layer; 5) a negative electrode; 6) an electron transport layer on the negative electrode; 7) a perovskite absorption layer; 8) a passivation layer; and 9) an antire-flection protective layer. The solar cell is characterized in that the positive electrode and the negative electrode are arranged on thebacklight surface of the cell in an up-and-down overlapping manner, an upper electrode does not completely cover a lower electrode, and the positive electrode and the negative electrode are separatedfrom each other through insulating material filling and the like. The passivation layer can reduce surface defects and carrier recombination caused by the surface defects; and the anti-reflection protective layer plays a role in reducing light loss and protecting the perovskite layer at the same time. The stacked and spliced interdigital full-back-contact perovskite solar cell disclosed by the invention can completely avoid the shading loss of the front electrode and the parasitic absorption of a carrier transport layer or the transparent conductive substrate, and improve the light utilizationefficiency and photoelectric conversion efficiency of the perovskite solar cell.

Owner:NANKAI UNIV

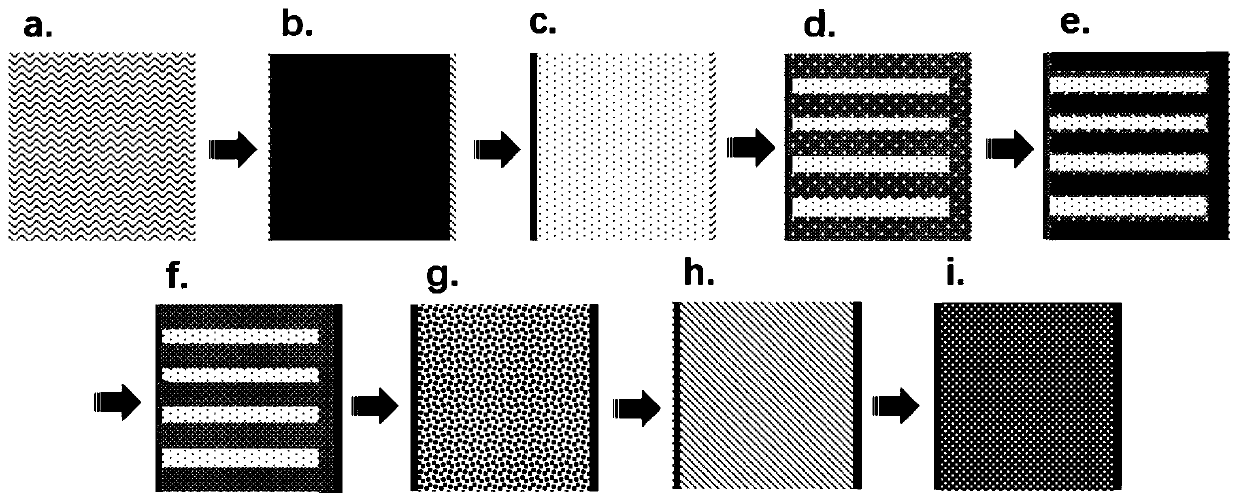

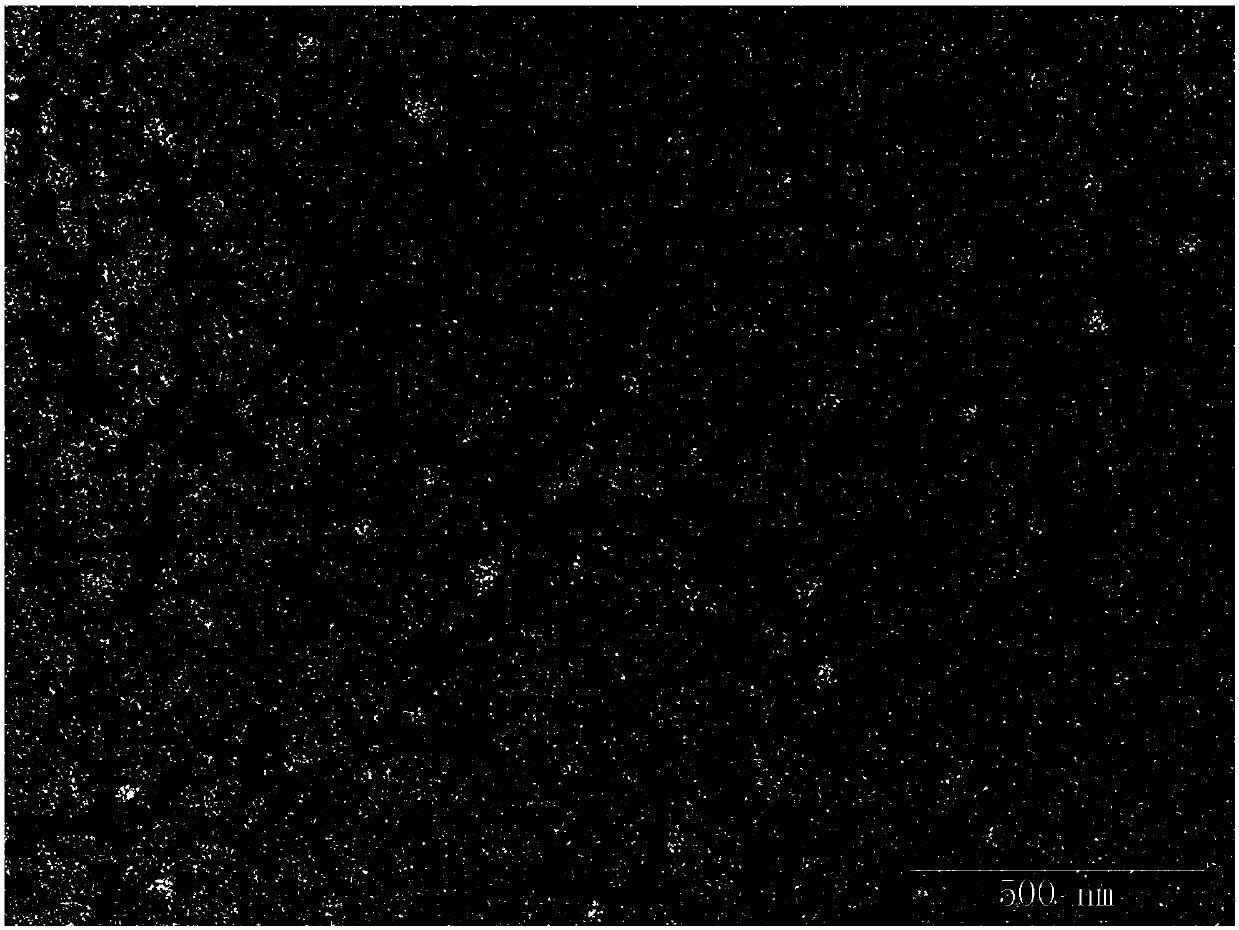

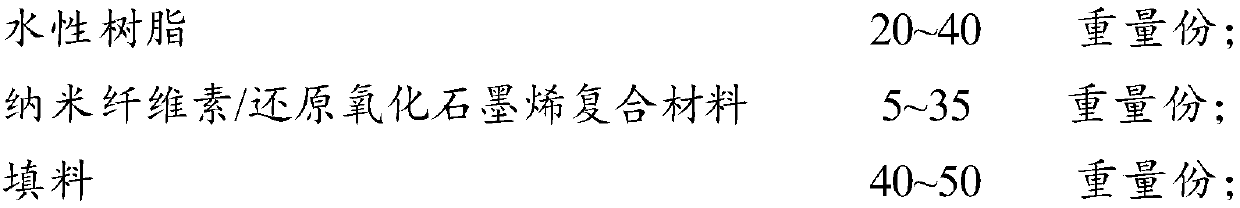

Water-based anticorrosive coating containing nanocellulose/reduced graphene oxide composite material, and preparation method thereof

InactiveCN110577792AImprove performanceImprove anti-corrosion performanceCellulose coatingsAnti-corrosive paintsDispersityWater based

The invention provides a water-based anticorrosive coating. The water-based anticorrosive coating contains a water-based resin and a nanocellulose / reduced graphene oxide composite material. Nanocellulose and reduced graphene oxide are specially selected and are compounded to form the nanocellulose / reduced graphene oxide composite material, and the nanocellulose / reduced graphene oxide composite material cooperates with the water-based resin coating, so the super-large specific surface area and good comprehensive properties such as light, electricity, heat and chemical stability of the reduced graphene oxide are utilized; and the addition of the nanocellulose improves the dispersity and the stability of the reduced graphene oxide, so the reduced graphene oxide is well and stably dispersed inthe water-based coating matrix, thereby the anticorrosion effect, mechanical properties and the heat stability of the water-based coating are improved, and the water-based anticorrosion material hasthe advantages of excellent comprehensive effects, long service life and broad application prospect, and is a nanocellulose / reduced graphene oxide water-based anticorrosive coating having the characteristics of greenness, environmental protection, good anticorrosive property and excellent mechanical properties.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

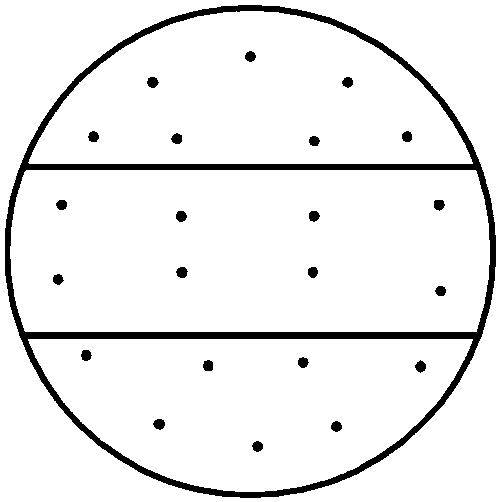

Sample preparation method of cylindrical soil sample for cohesive soil tensile strength experiment

ActiveCN107941586AChange the manufacturing processEliminate weak pointsPreparing sample for investigationStress distributionTension stress

The invention discloses a sample preparation method of a cylindrical soil sample for a cohesive soil tensile strength experiment. Three layers of cohesive soil are filled in a mold in the axial direction of the cylindrical soil sample, and each layer is compacted after filling; at the same time, the end strength of each layer is strengthened by a method for inserting reinforcing ribs at the end ofeach layer of the soil sample, so that the layered contact surface of the soil sample is parallel to a direction in which a tensile force is applied. According to the method provided by the invention, by strengthening the end strength of the sample and eliminating the strength defect of the sample in a tensile direction, the goal that the sample is destroyed in a tensile stress distribution areato obtain a real value of the tensile strength of the soil sample is achieved.

Owner:HOHAI UNIV

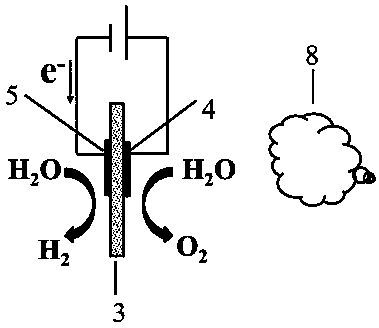

Electrochemical mask

ActiveCN111109719AResolve failureAchieve oxygenation effectProtective garmentElectrodesElectrolysisOxygen enhanced

The invention relates to an electrochemical mask which comprises a middle filter layer and an outer surface layer positioned outside the middle filter layer. The electrochemical mask further comprisesan electrochemical membrane electrode layer positioned on the inner side of the middle filter layer. The electrochemical membrane electrode layer comprises a moisture absorption inner surface layer,a cathode hydrogen evolution layer arranged on the outer side face of the moisture absorption inner surface layer and an anode oxygen evolution layer arranged on the inner side face of the moisture absorption inner surface layer, and the cathode hydrogen evolution layer and the anode oxygen evolution layer are connected with a power source arranged on the mask through wires respectively. Moisturein breathing steam is absorbed through the mask moisture absorption inner surface layer, an ion channel between the cathode hydrogen evolution layer and the anode oxygen evolution layer is communicated, water in the breathing steam is electrolyzed into oxygen and hydrogen, and the problem that the mask loses efficacy due to breathing steam in the mask wearing process is solved; meanwhile, oxygen is supplied back to the human body, and oxygen is increased for a mask wearer; and a conventional mask preparation process is not changed, the process is simple, the preparation cost is low, and the mask is a special functional mask.

Owner:UNIV OF JINAN

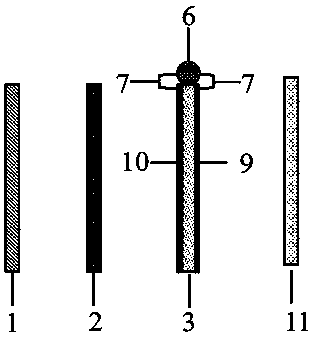

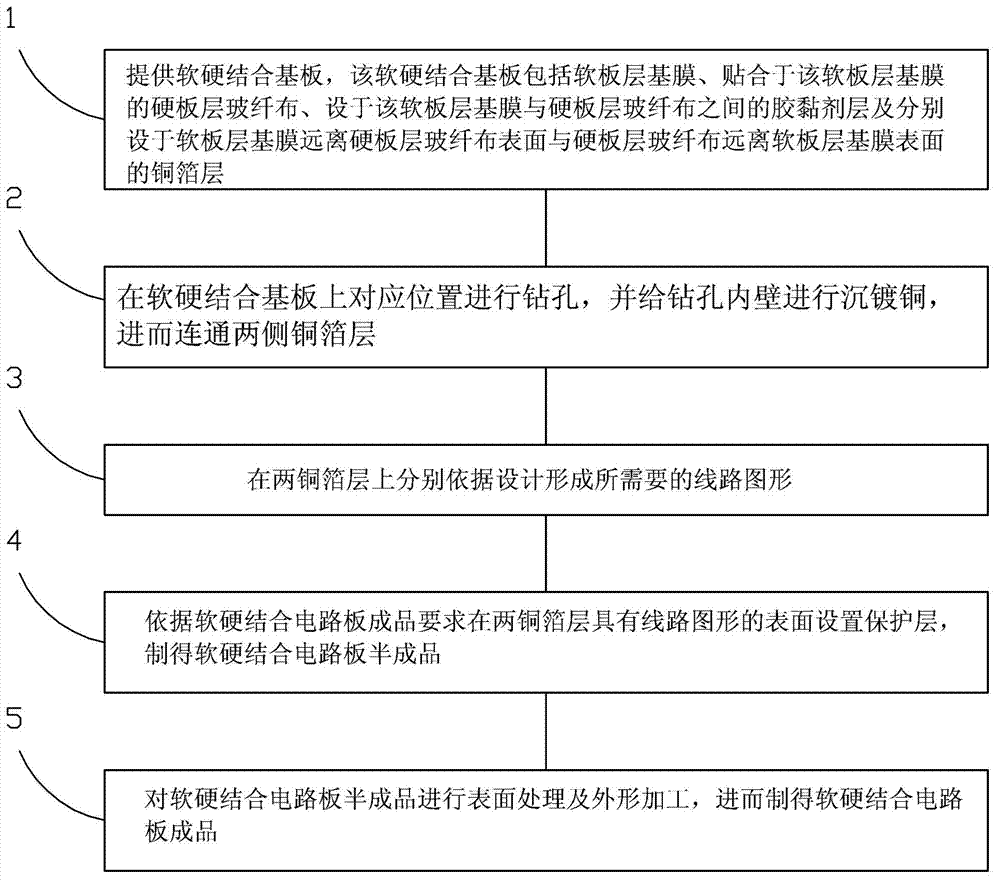

Manufacturing method of rigid-flexible combined circuit board

InactiveCN102791086AChange the manufacturing processReduce manufacturing costMultilayer circuit manufacturePrinted element electric connection formationGlass fiberEngineering

The invention provides a manufacturing method of a rigid-flexible combined circuit board, comprising the following steps of: step 1, providing a rigid-flexible combined substrate, wherein the rigid-flexible combined substrate comprises a flexible plate layer basic film, rigid plate layer glass fiber cloth adhered to the flexible plate layer basic film, an adhesive layer arranged between the flexible plate layer basic film and the rigid plate layer glass fiber cloth, and two copper coil layers which are respectively arranged on the surface of the flexible plate layer basic film, which is far away from the surface of the rigid plate layer glass fiber cloth, and on the surface of the rigid plate layer glass fiber cloth, which is far away from the flexible plate layer basic film; step 2, drilling at a corresponding position of the rigid-flexible combined substrate and carrying out copper sinking plating on the inner wall of a drilled hole to communicate the copper foil layers at the two sides; step 3, respectively forming needed line patterns on the two copper foil layers according to the design; step 4, arranging protection layers on the surfaces of the two copper coil layers, which are provided with the line patterns, according to the requirements of a finished product of the rigid-flexible combined circuit board, so as to manufacture a rigid-flexible combined circuit board semi-finished product; and step 5, carrying out surface treatment and appearance machining on the rigid-flexible combined circuit board semi-finished product so as to manufacture the rigid-flexible combined circuit board finished product.

Owner:GUANGDONG SHENGYI SCI TECH

Chinese medicine cosmetic

InactiveCN102451153APromote circulationEfficient removalCosmetic preparationsToilet preparationsPolygonum odoratumAdditive ingredient

The invention discloses a skin-whitening nourishing cream, belonging to cosmetics and more particular relating to a night nourishing cream for whitening skin and removing freckles and acnes. The skin-whitening nourishing cream is prepared by extracting effective ingredients of the following raw materials in parts by weight: 1-20 parts of white tremella fuciformis, 1-10 parts of cartialgenous, 1-20 parts of rhizoma typhonii, 1-20 parts of radix polygonati officinalis, 1-25 parts of white ginseng and 1-20 parts of tuckahoe. The skin-whitening nourishing cream disclosed by the invention has the beneficial effects of removing freckles and acnes, whitening skin and beautifying skin in comparison with other products for whitening skin and removing freckles. The product disclosed by the invention is a pure Chinese medicine preparation and is natural and nontoxic, thus both inside and outside can be given into consideration.

Owner:惠中兴

Fermented crisp biscuits

InactiveCN105123851AChange the manufacturing processGreat tasteDough treatmentPre-baking dough treatmentFlavorSucrose

The invention relates to fermented crisp biscuits. The biscuits are prepared from the following raw materials in compounding ratio: 80-70g of all-purpose flour, 18-12g of cane sugar, 8-12g of edible oil, 7-3g of corn starch, 2-4g of whole milk powder, 3-5g of shortening, 0.8-1.2g of instand dry yeast, 0.08-0.12g of table salt, 0.4-0.8g of baking soda, 1-3mL of water, 1-3mL of milk and half of an egg. The fermented crisp biscuits disclosed by the invention have the crispness of crisp biscuits, have the special flavor of fermented biscuits, new crisp biscuit products are increased, and the mouth feel of the crisp biscuits is improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

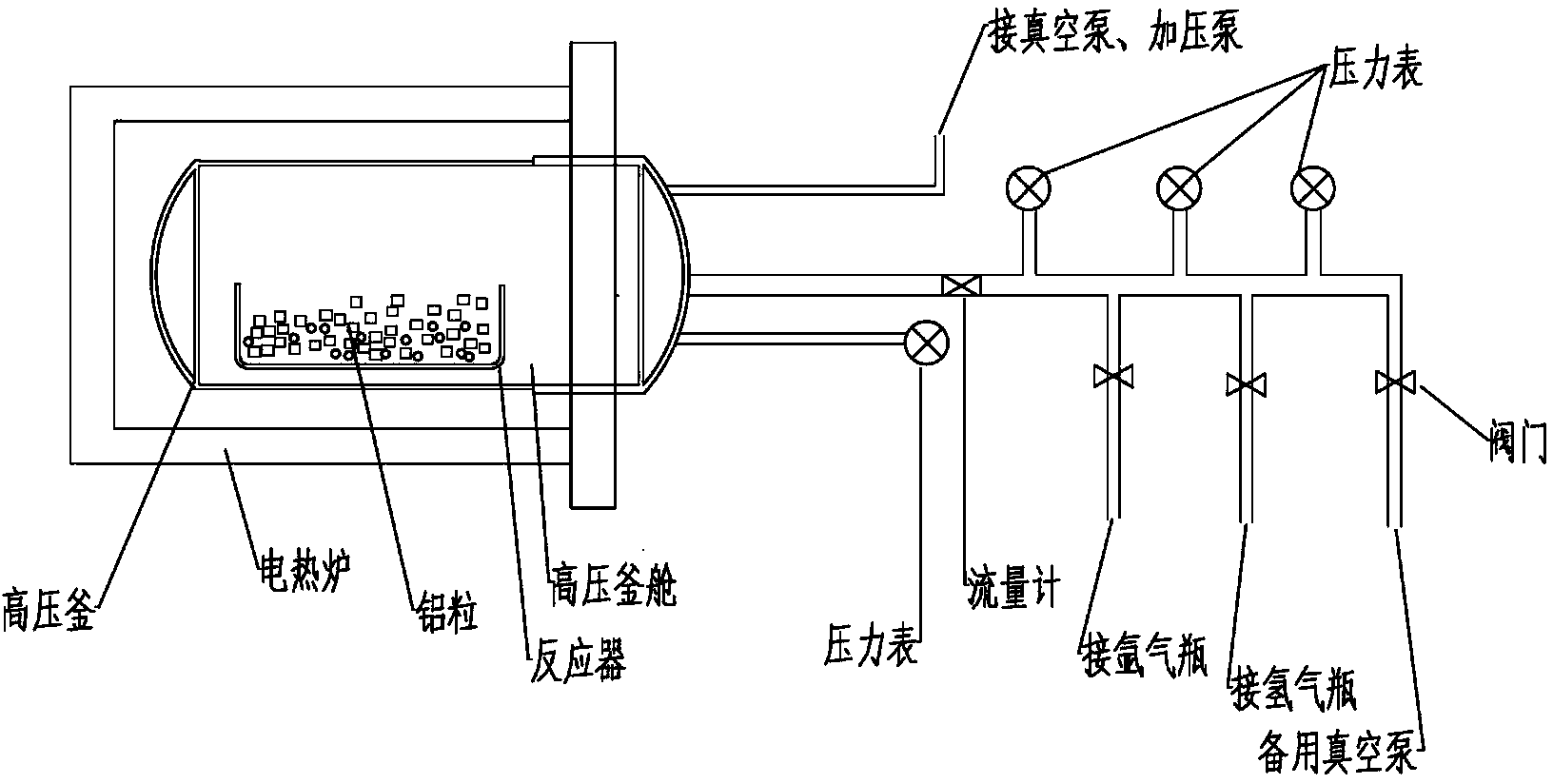

Method for preparing aluminum trihydride by virtue of high-middle-low-temperature direct pressurization process

ActiveCN104229736AChange methodChange the manufacturing processMetal hydridesEnvironmental resistanceProduction line

The invention relates to a method for preparing aluminum trihydride by virtue of a high-middle-low-temperature direct pressurization process, belonging to the field of hydrogen metal material preparation. Aluminum trihydride is prepared by reacting metal aluminum and hydrogen at high temperature. By adopting the method disclosed by the invention, the problems of aluminum trihydride industrial large-scale preparation techniques and preparation purity can be solved, no complex production device is used, required preparation devices are simple and easy to purchase, and safe construction of an aluminum trihydride production line can be achieved under an existing factory condition; a preparation process is simple and easy to operate, has inert gas protection in a preparation process, and is safe and reliable; a product is relatively good in yield and purity and good in stability, and can be stored for a long time; 'three wastes' cannot be generated in a production process, and harms to the human body and environment cannot be caused, so that the method is environmental friendly, and has important significance in industrial large-scale safe preparation and large-scale application of high-purity aluminum trihydride.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

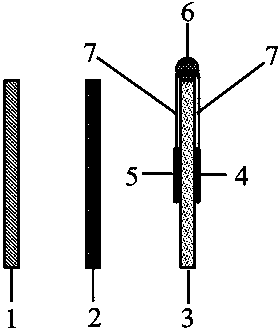

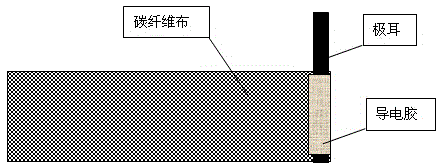

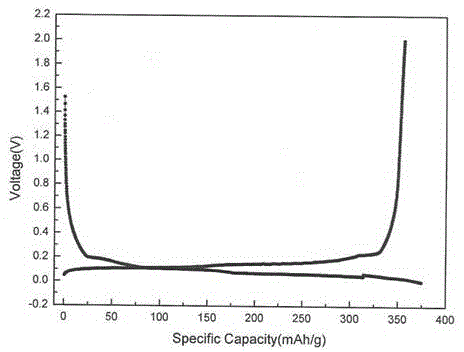

Method for carrying out manufacturing by serving carbon fiber cloth as lithium ion battery cathode slice

InactiveCN104538590AChange the manufacturing processReduce manufacturing costCell electrodesManufacturing technologyCarbon fibers

A method for carrying out manufacturing by serving carbon fiber cloth as a lithium ion battery cathode slice comprises the steps that carbon fiber spinning asphalt is adopted as raw materials, and through protofilament manufacturing, protofilament pre-oxidation, stretch breaking and strip manufacturing, and spinning and weaving, pre-oxidation silk cloth is obtained; finally, carbonization, graphitization, slitting and pole lug welding are carried out, and the lithium ion battery cathode slice completely different from that of an existing manufacturing technology is obtained. The cathode slice manufactured through the method is adopted, so that a traditional manufacturing technology of the lithium ion battery cathode slice is changed, part of auxiliary materials and part of production equipment are omitted, and the production cost is greatly reduced; carbon cellosilk is interwoven in an intricate mode to form a good conductive network, the conductive performance is excellent, internal resistance of a final finished product battery can be greatly reduced, and the large-current charging and discharging requirements of a lithium ion power battery are met.

Owner:江西华昊新能源有限公司

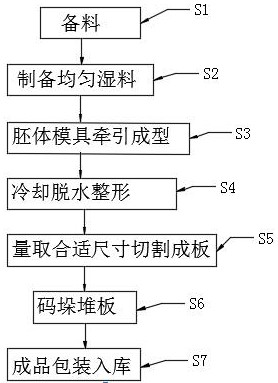

Fly ash plate and preparation method thereof

The invention discloses a fly ash plate which is composed of the following materials in parts by weight: 80 parts of fly ash, 15 parts of PVC, 5 parts of a coupling agent, 50 parts of polyvinyl chloride, 5 parts of triethanolamine, 10 parts of a calcium-zinc composite stabilizer, 5 parts of a foaming regulator, 0.5-10 part of NC, 2 parts of PE wax, 3-5 parts of NNO, 1 part of JY-0, 15 parts of silane, 5 parts of a diffusant, and 15 parts of water. The fly ash plate is simple in structure, convenient to operate, reasonable in design, free of formaldehyde, zero in release, free of radiation, free of pollution and free of bulging, has the characteristics of moisture prevention, mildew prevention, water prevention, insect prevention, corrosion prevention, static prevention, flame retardance, impact resistance, deformation resistance, wear resistance, easiness in cleaning and the like, is energy-saving, environment-friendly and stable in quality, can be recycled and reused, and has wide application prospects. The fly ash plate can be widely applied to the fields of office, civil use, hotels, schools and other furniture, decoration boards and the like, can replace natural wood and composite boards, and meets the national environment-friendly and healthy industrial development direction and the policy requirements of local governments.

Owner:新疆远疆环保科技有限公司

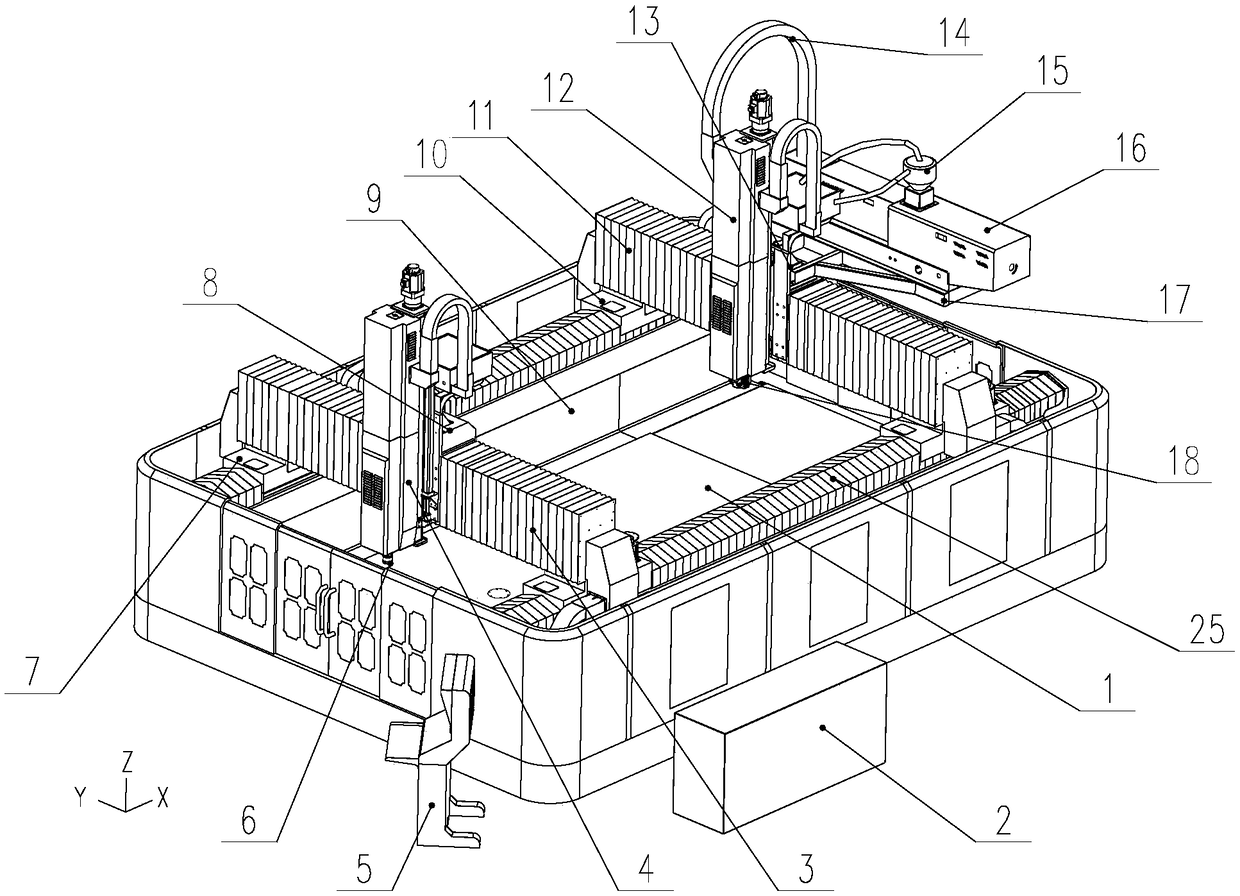

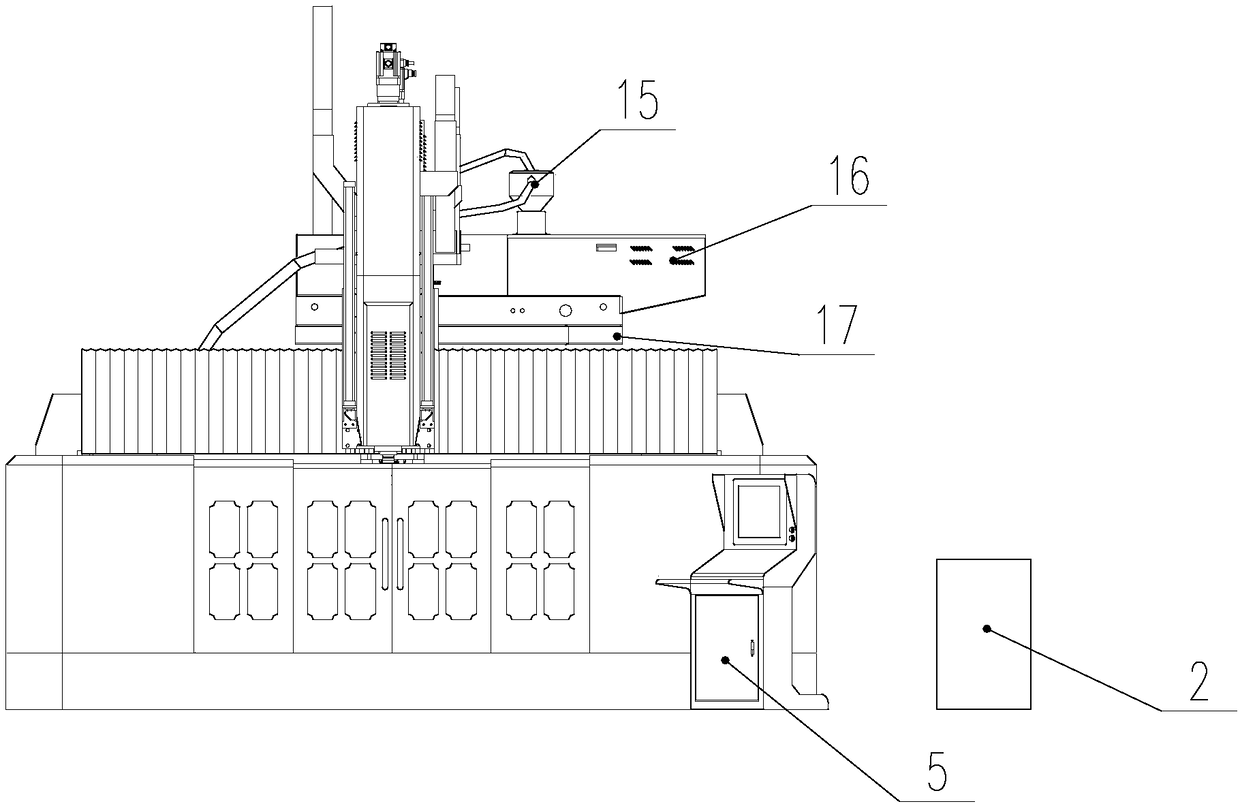

Thermoplastic plastic industrial-grade 3D printing and milling composite processing machine tool

PendingCN108501367AChange the manufacturing processShorten the production cycleManufacturing heating elements3D object support structuresThermoplasticEngineering

The invention provides a thermoplastic plastic industrial-grade 3D printing and milling composite processing machine tool which mainly comprises a lathe bed, a milling device and a 3D printing device,wherein the milling device and the 3D printing device are mounted on the lathe bed through an overpass type double-independent gantry structure; the overpass type double-independent gantry structurecomprises a first gantry and a second gantry which are mounted on the lathe bed and can be moved in a reciprocation manner in an X direction, and a double-gantry driving device capable of respectivelydriving the first gantry and the second gantry to make reciprocation movement in the X direction; a milling spindle of the milling device is mounted on a Y1 transverse beam of the first gantry and iscapable of being moved in a Y direction and a Z direction respectively in the reciprocation manner; a nozzle of the 3D printing device is mounted on a Y2 transverse beam of the second gantry and is capable of being moved in the Y direction and the Z direction respectively in the reciprocation manner. By adopting the machine tool, a conventional cast wooden mold manufacturing and machining processcan be changed, the production cycle of a cast wooden mold can be shortened, the production cost can be reduced, the service life of the wooden mold can be prolonged, and the problem that a mold manufacturing company has a great deal of raw material cost can be reduced.

Owner:SHANDONG CHENCAN MACHINERY INC CO

Bitter melon antihypelipidemic bean product and its manufacturing method

InactiveCN101077151ARefreshing tasteUnique tasteMetabolism disorderFood preparationPear juiceNutritional composition

The present invention is one kind of blood sugar reducing balsam pear-bean product and its making process, and aims at increasing the nutritious components and health functions of bean product. The blood sugar reducing balsam pear-bean product is produced with soybean milk, balsam pear juice, Chinese yam juice and tuckahoe juice in certain volume proportion. It may be made into blood sugar reducing balsam pear bean curd, dried blood sugar reducing balsam pear bean curd, blood sugar reducing balsam pear bean curd jelly, blood sugar reducing balsam pear bean milk and other forms.

Owner:HEILONGJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com