Water-based anticorrosive coating containing nanocellulose/reduced graphene oxide composite material, and preparation method thereof

A technology of nano-cellulose and anti-corrosion coatings, applied in the direction of cellulose coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of organic solvent-based coatings and difficult anti-corrosion performance, and achieve low cost, good anti-corrosion performance, Effect of improving dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The invention provides a kind of preparation method of water-based anticorrosion paint, comprises the following steps:

[0089] A) After mixing the reduced graphene oxide, nanocellulose and water for the first time, the reduced graphene oxide / nanometer cellulose aqueous dispersion is obtained;

[0090] B) After mixing the reduced graphene oxide / nanocellulose aqueous dispersion obtained in the above steps, the aqueous resin and the filler, a mixture is obtained;

[0091] C) After mixing the mixture obtained in the above steps and the auxiliary agent again, a water-based anticorrosion coating is obtained.

[0092] The present invention can correspond to the selection, composition and ratio of the raw materials required in the above preparation process, as well as the corresponding optimization principles, and the selection, composition and ratio of the corresponding raw materials in the aforementioned water-based anticorrosion coatings, as well as the corresponding optimi...

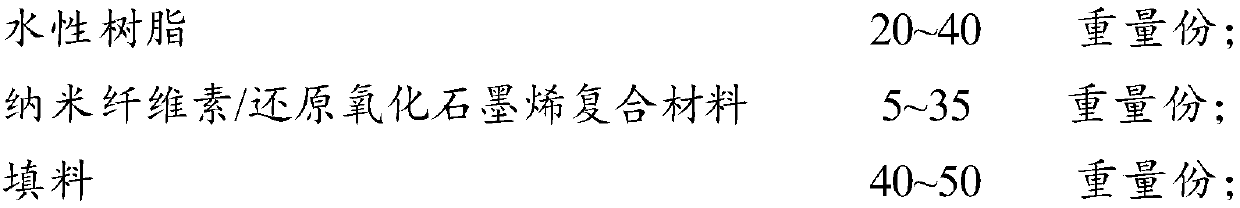

Embodiment 1

[0123] The nanocellulose / reduced graphene oxide water-based anticorrosion coating of the present embodiment includes two components A and B, and the mass ratio of the A component and the B component is 5:1, wherein the formula ratio of each component, see Table 1, Table 1 is the nanocellulose / reduced graphene oxide water-based anti-corrosion coating formulation provided by the embodiment of the present invention.

[0124] Table 1

[0125]

[0126] Concrete preparation steps are as follows:

[0127] (1) Add nanocellulose and reduced graphene oxide into deionized water, ultrasonically disperse in a 200W ultrasonic cleaner for 3 hours to obtain reduced graphene oxide / nanocellulose aqueous dispersion, add filler and water-based resin to the above dispersion system , placed in a stirring tank to stir and mix evenly, the rotation speed is 2500r / min, the stirring time is 60min, and the temperature is room temperature.

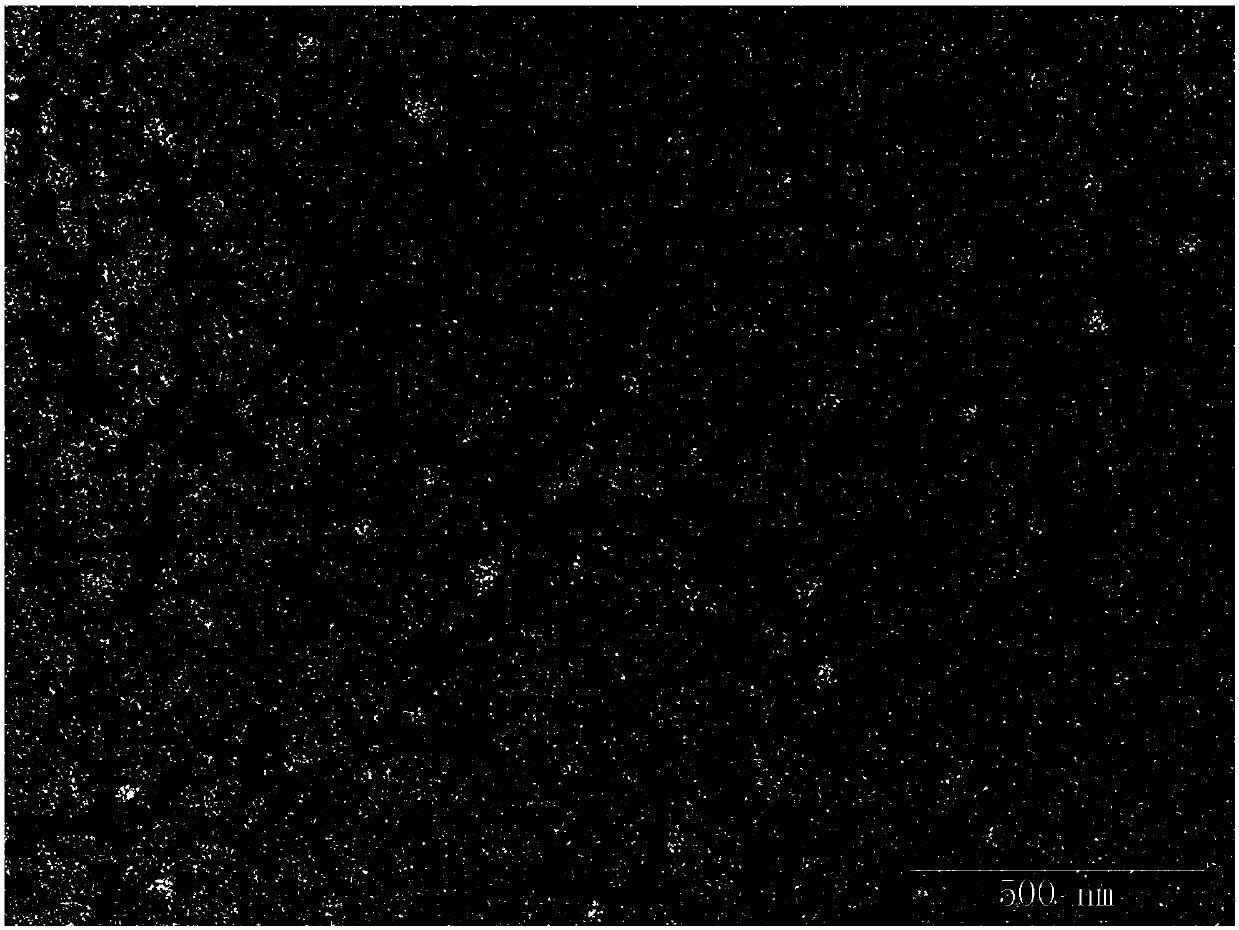

[0128] see figure 1 , figure 1 The transmission electron ...

Embodiment 2

[0143] The nanocellulose / reduced graphene oxide water-based anticorrosion coating of the present embodiment includes two components A and B, and the mass ratio of the A component and the B component is 5:1, wherein the formula ratio of each component, see Table 1, Table 1 is the nanocellulose / reduced graphene oxide water-based anti-corrosion coating formulation provided by the embodiment of the present invention.

[0144] Concrete preparation steps are as follows:

[0145] (1) Add nanocellulose and reduced graphene oxide into deionized water, ultrasonically disperse in a 200W ultrasonic cleaner for 4 hours to obtain reduced graphene oxide / nanocellulose aqueous dispersion, add filler and water-based resin to the above dispersion system , placed in a stirring tank to stir and mix evenly, the rotating speed is 2500r / min, the stirring time is 60min, and the temperature is room temperature;

[0146] (2) Add dispersant, defoamer, and leveling agent to the above mixing system in seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com