Making method for liquid crystal LCOS and laminating apparatus therefor

A technology of liquid crystal display and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, instruments, optics, etc., can solve the problems of low production efficiency, high damage rate, and low finished product, so as to improve production efficiency, ensure product quality, and use materials high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

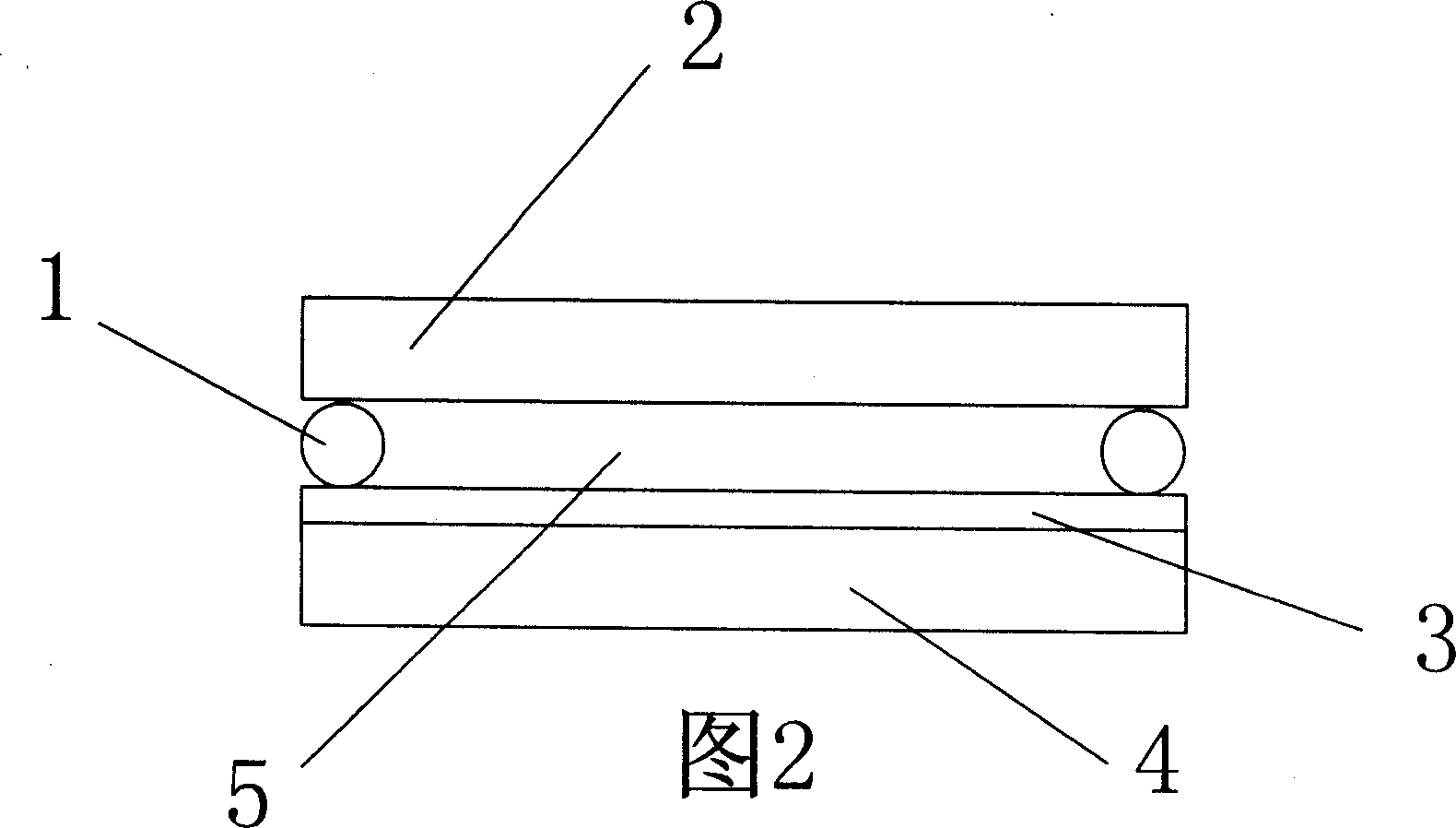

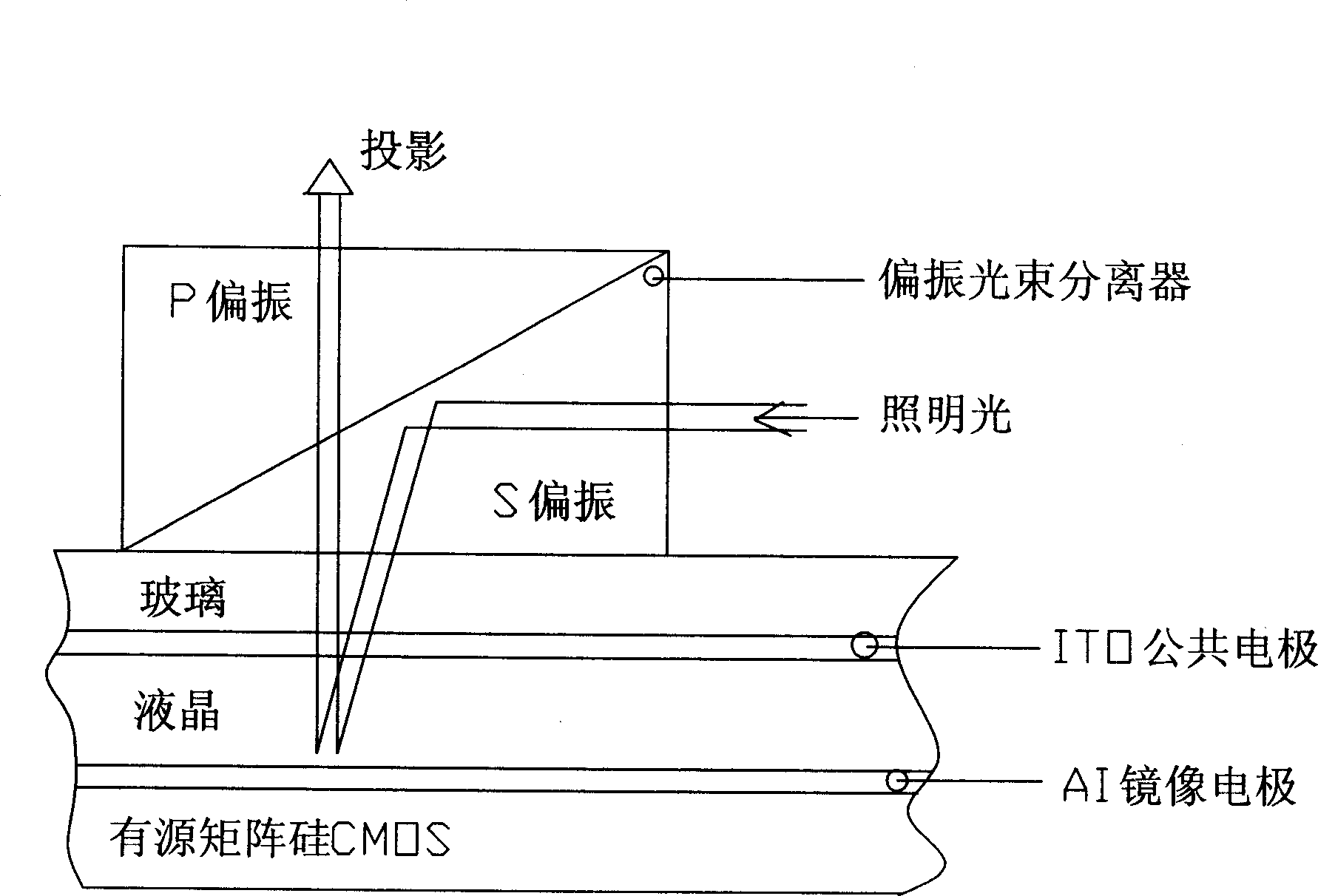

[0036] This is a reflective miniature liquid crystal display, on which is a piece of ITO transparent conductive glass 2 as the common electrode, which is composed of a silicon wafer 4 containing CMOS circuits, the surface is composed of array pixels, each pixel is also an electrode, and the material of the electrode is aluminum film , the aluminum film is also a light reflective surface; the liquid crystal 5 is perfused between the glass 2 and the silicon wafer 4, and when the electrodes on the surface of the silicon wafer 4 are under the control of the CMOS circuit, the liquid crystal 5 will work normally in the corresponding electric field.

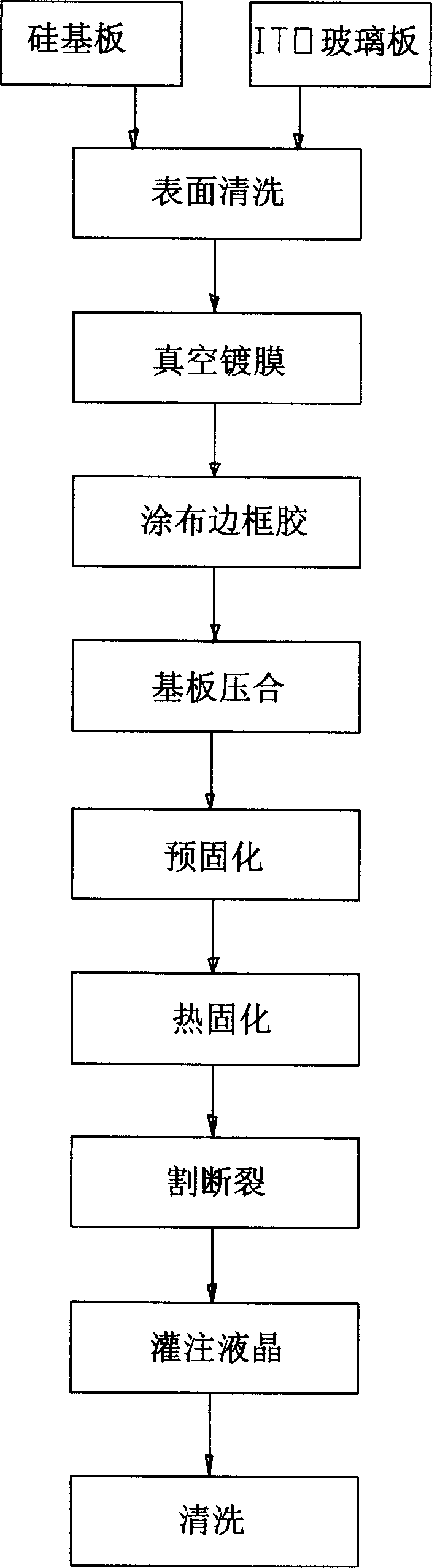

[0037] The main materials of this manufacturing process are to design a whole piece of silicon substrate 7 of multiple LCOS Dies and an ITO glass plate 13 as the common electrode of a silicon-based liquid crystal display. Apply the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com