Method for preparing aluminum trihydride by virtue of high-middle-low-temperature direct pressurization process

A kind of aluminum trihydride, high, medium and low temperature technology, applied in chemical instruments and methods, metal hydrides, inorganic chemistry and other directions, can solve the problems of dangerous aluminum trihydride preparation process, low product yield, many by-products, etc., to achieve convenient scale The effect of chemical industry production, good product yield and purity, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

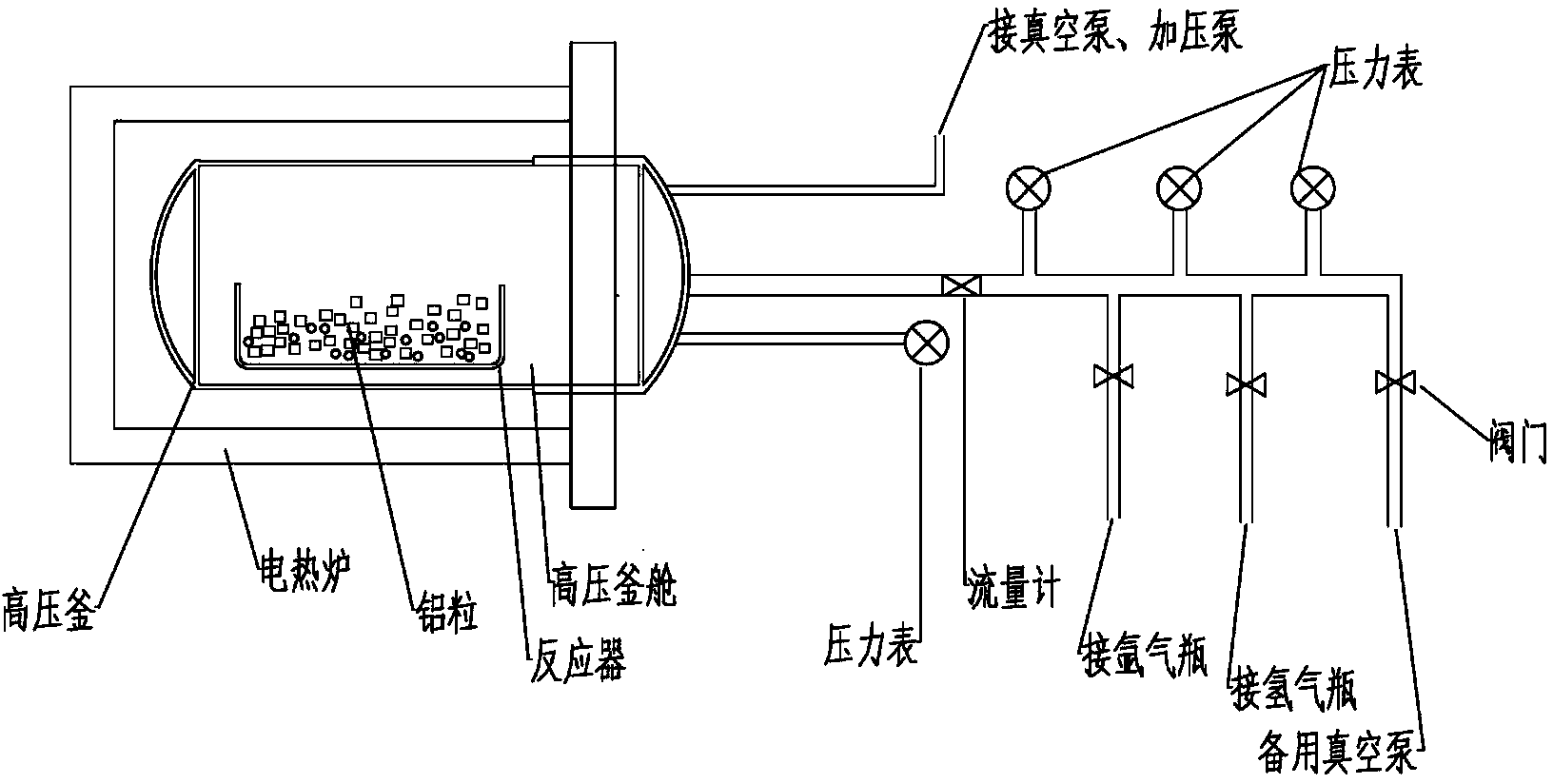

Method used

Image

Examples

Embodiment 1

[0023] Take an aluminum block with a purity of 99.9% and a particle size of 2mm, soak it in a hydrochloric acid solution with a mass fraction of 1% at 10°C for 15 minutes, rinse it with deionized water at room temperature for 5 times, dry it in vacuum, and weigh it under the protection of argon. 1508g, put it into a stainless steel tank reactor, and place it in the high-pressure reactor cabin; pass in argon to replace the gas in the kettle cabin, pump the pressure in the cabin to a negative pressure of 0.012MPa, and pass it into a high-purity 99.999% After the hydrogen is pumped again until the negative pressure in the cabin is 0.008MPa, repeat the operation 3 times; quickly raise the temperature to 506°C at a heating rate of 15°C / min; 300 atmospheres, react for 60 minutes; cool down at a rate of 8°C / min for 38 minutes to 211°C, keep the temperature constant, continue to feed hydrogen, and continue to react for 118 minutes until the pressure in the hydrogen pressure gauge and t...

Embodiment 2

[0025] Take an aluminum block with a purity of 99.9% and a particle size of 5mm, soak it in a hydrochloric acid solution with a mass fraction of 5% at 15°C for 8 minutes, rinse it with deionized water at room temperature for 4 times, dry it in vacuum, and weigh it under the protection of argon. 2498g, put it into a stainless steel tank reactor, and place it in the high-pressure reactor cabin; pass in argon to replace the gas in the kettle cabin, pump the pressure in the cabin to a negative pressure of 0.011MPa, and pass it into a high-purity 99.999% After the hydrogen is pumped again until the negative pressure in the cabin is 0.007MPa, repeat the operation 3 times; quickly raise the temperature to 566°C at a heating rate of 45°C / min; 150 atmospheres, react for 60 minutes; cool down at a rate of 3°C / min for 154 minutes to 143°C, keep the temperature constant, continue to feed hydrogen, and continue to react for 138 minutes until the pressure in the hydrogen pressure gauge and t...

Embodiment 3

[0027] Take aluminum with a purity of 99.9%, polish the surface oxide layer to a metallic luster with fine sandpaper, process it into a small piece with a particle size of 14mm under the protection of argon, weigh 499g, put it into a stainless steel tank reactor, and place it side by side In the high-pressure reaction kettle cabin; replace the gas in the kettle cabin with argon gas, pump the cabin pressure to a negative pressure of 0.013MPa, and then pump high-purity 99.999% hydrogen gas into the cabin to a negative pressure of 0.010MPa again. Repeat the operation 3 times; quickly raise the temperature to 531°C at a heating rate of 25°C / min; feed high-purity hydrogen, adjust the hydrogen pressure in the input tank to 285 atmospheres, and react for 50 minutes; cool down at a rate of 8°C / min After 51 minutes to 148°C, keep the temperature constant, continue to feed hydrogen, and continue to react for 92 minutes until the pressure in the hydrogen pressure gauge and the high-pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com