Fly ash plate and preparation method thereof

A technology for fly ash and board, applied in the field of fly ash board and its preparation, can solve the problems of low cost performance, consumption of large trees, poor environmental performance of boards, etc., meeting huge social needs, broad market prospects, and convenient processing and cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] see figure 1 , the present invention provides following technical scheme: a kind of fly ash board, is made up of the material of following ratio weight: 80 parts of fly ash; 15 parts of PVC; 5 parts of coupling agent; 50 parts of polyvinyl chloride; 5 parts of triethanolamine; 10 parts of calcium-zinc composite stabilizer; 5 parts of foam regulator; NC0.5-10 parts; 2 parts of PE wax; 3-5 parts of NNO; 1 part of JY-01;

[0026] In the present invention, the thickness of the fly ash plate is between 5 and 25 mm, which is beneficial to reduce the quality of the main body of the plate, save materials and reduce production costs.

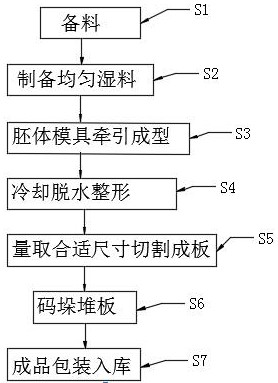

[0027] A preparation method of fly ash plate, comprising the following steps:

[0028] Step S1, material preparation: Measure 80 parts of fly ash; 15 parts of PVC; 5 parts of coupling agent; 50 parts of polyvinyl chloride; 5 parts of triethanolamine; 10 parts of calcium-zinc composite stabilizer; 5 parts of foam regulator; N0. 5-10 parts; 2 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com