Insulation board prepared from biomass energy and preparation method of insulation board

A technology of biomass energy and thermal insulation board, which is applied in the field of building materials to achieve the effects of good wear resistance, improved strength and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

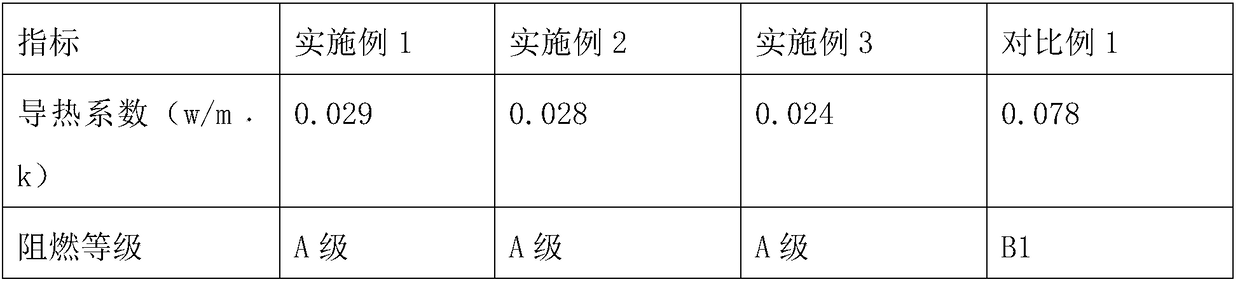

Examples

Embodiment 1

[0034] An insulation board prepared by using biomass energy, including the following raw materials: 15kg of quartz sand, 30kg of gravel, 12kg of cement, 10kg of peanut shells, 8kg of wheat straw, 9kg of rice straw, 11kg of corn straw, 5kg of cotton straw, wood processing Leftovers 4kg, expanded vitrified beads 3kg, rock wool 6kg, ceramic fiber 4kg, boron carbide 6kg, nano-active calcium carbonate 3kg, flame retardant 0.3kg, binder 0.2kg, air-entraining agent 0.1kg, retarder 0.2kg, 0.3kg of water reducing agent and 8kg of water.

[0035] Peanut shells, wheat straw, rice straw, corn straw, cotton straw and wood processing waste are added to the raw materials. These biomass energy can be recycled and reused to achieve the purpose of energy saving and environmental protection.

[0036] Expanded vitrified microbeads are added to the raw materials. The expanded vitrified microbeads are porous inside and vitrified and closed on the surface. They have the characteristics of light weig...

Embodiment 2

[0054]An insulation board prepared by using biomass energy, including the following raw materials: 23kg of quartz sand, 40kg of gravel, 14kg of cement, 14kg of peanut shells, 16kg of wheat straw, 13kg of rice straw, 17kg of corn straw, 13kg of cotton straw, wood processing Leftovers 10kg, expanded vitrified beads 7kg, rock wool 12kg, ceramic fiber 8kg, boron carbide 8kg, nano-active calcium carbonate 7kg, flame retardant 0.5kg, binder 0.4kg, air-entraining agent 0.3kg, retarder 0.6kg, 0.7kg of water reducer and 12kg of water.

[0055] Peanut shells, wheat straw, rice straw, corn straw, cotton straw and wood processing waste are added to the raw materials. These biomass energy can be recycled and reused to achieve the purpose of energy saving and environmental protection.

[0056] Expanded vitrified microbeads are added to the raw materials. The expanded vitrified microbeads are porous inside and vitrified and closed on the surface. They have the characteristics of light weight...

Embodiment 3

[0074] An insulation board prepared by using biomass energy, including the following raw materials: 19kg of quartz sand, 35kg of gravel, 13kg of cement, 12kg of peanut shells, 12kg of wheat straw, 11kg of rice straw, 14kg of corn straw, 9kg of cotton straw, wood processing Leftovers 7kg, expanded vitrified beads 5kg, rock wool 9kg, ceramic fiber 6kg, boron carbide 7kg, nano-active calcium carbonate 5kg, flame retardant 0.4kg, binder 0.3kg, air-entraining agent 0.2kg, retarder 0.4kg, 0.5kg of water reducing agent and 10kg of water.

[0075] Peanut shells, wheat straw, rice straw, corn straw, cotton straw and wood processing waste are added to the raw materials. These biomass energy can be recycled and reused to achieve the purpose of energy saving and environmental protection.

[0076] Expanded vitrified microbeads are added to the raw materials. The expanded vitrified microbeads are porous inside and vitrified and closed on the surface. They have the characteristics of light w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com