Patents

Literature

62 results about "Pressed wood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressed wood is any engineered wood building and furniture construction material made from wood veneers, wood shavings and particles, sawdust or wood fibers bonded together with an adhesive under heat and pressure.

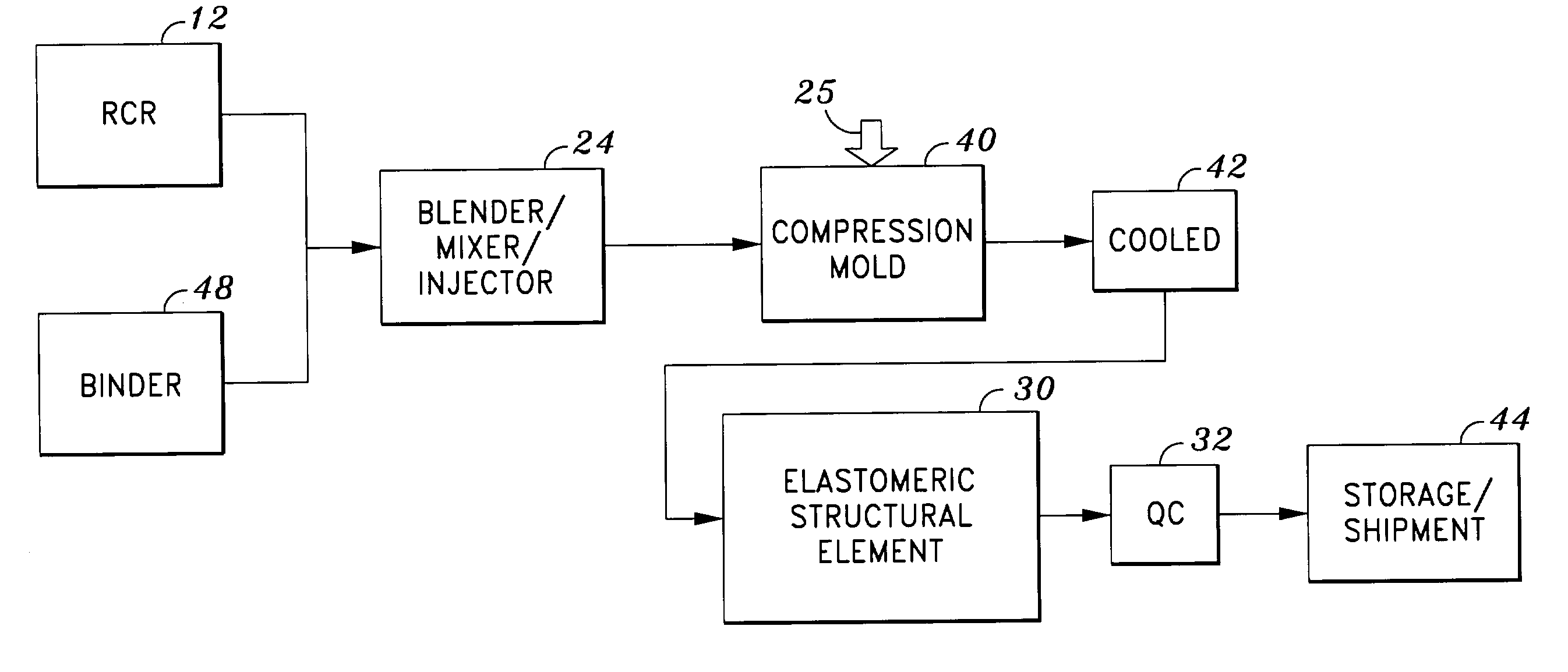

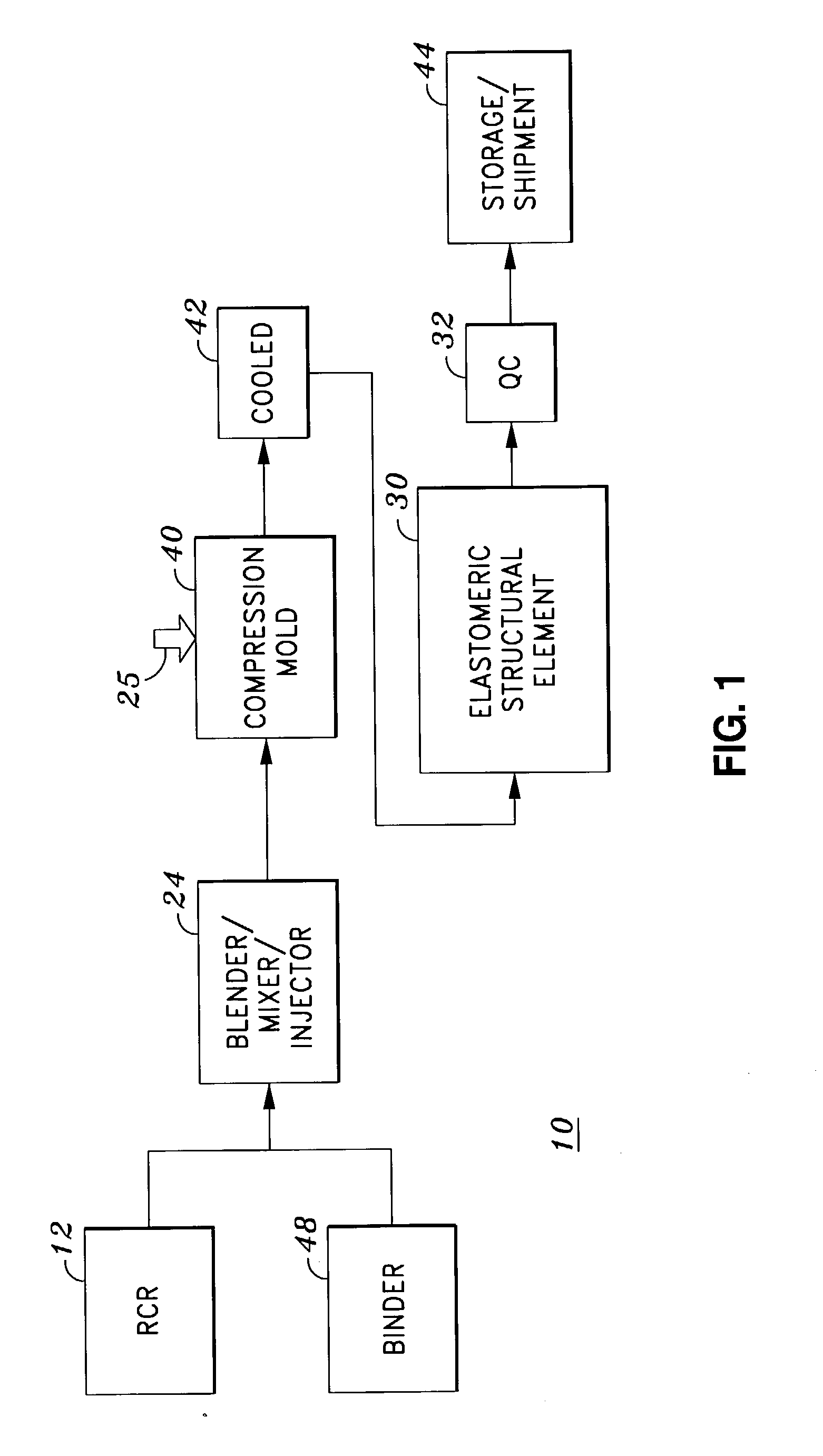

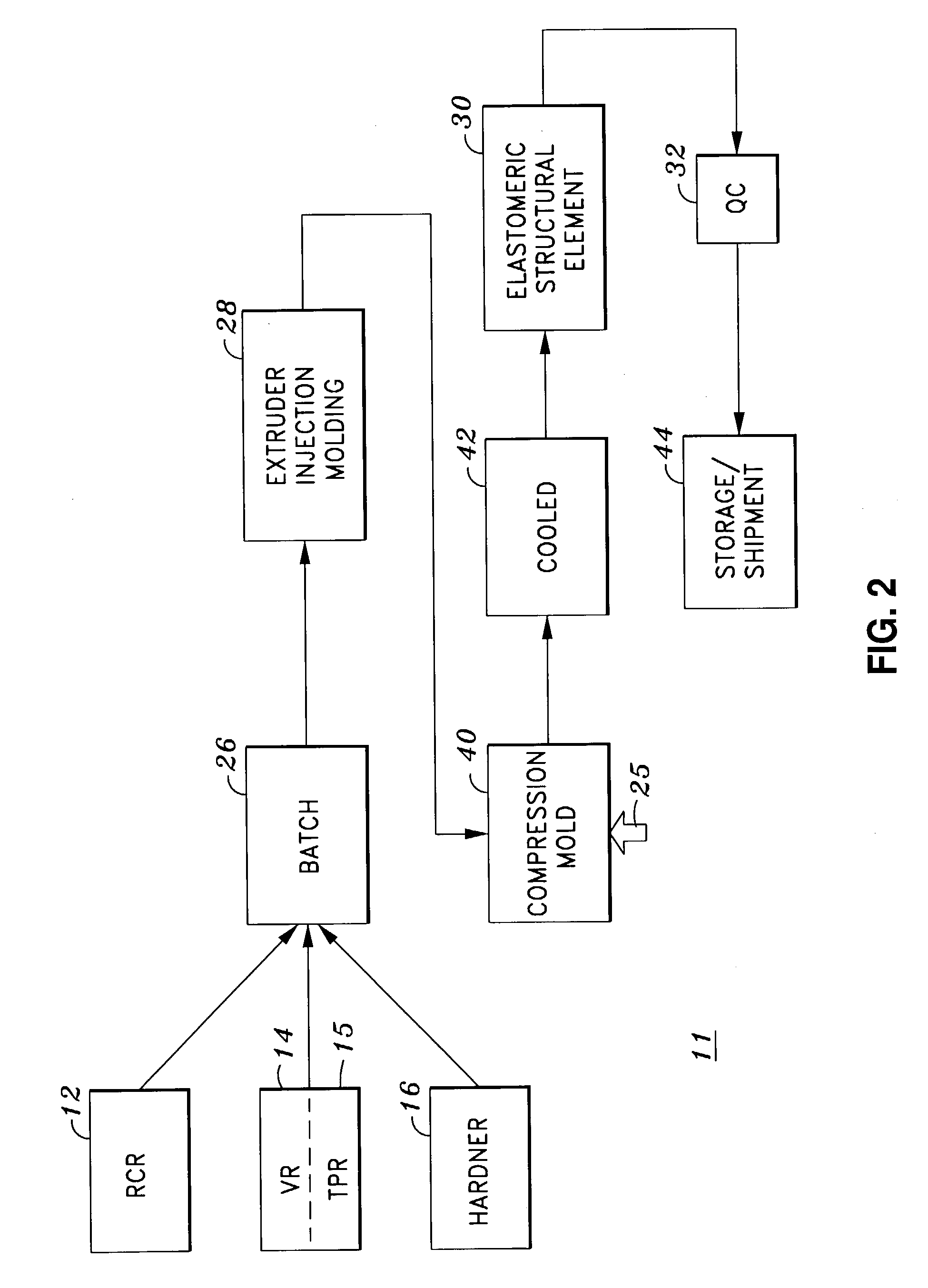

Elastomeric structural elements

Apparatus for and methods to manufacture elastomeric structural elements utilizing significant quantities of discarded rubber as well other materials, such as unvulcanized rubber compounds, commercial rubber binders, and thermoplastic rubber. The inventive elastomeric structural elements are well suited for use on railroads, highways, buildings, and other structural applications as replacement for traditional materials such as wood, steel, aluminum, concrete, plastics, composites, recycled pressed wood products, and combinations of various recycled materials.

Owner:BUY SMART INT

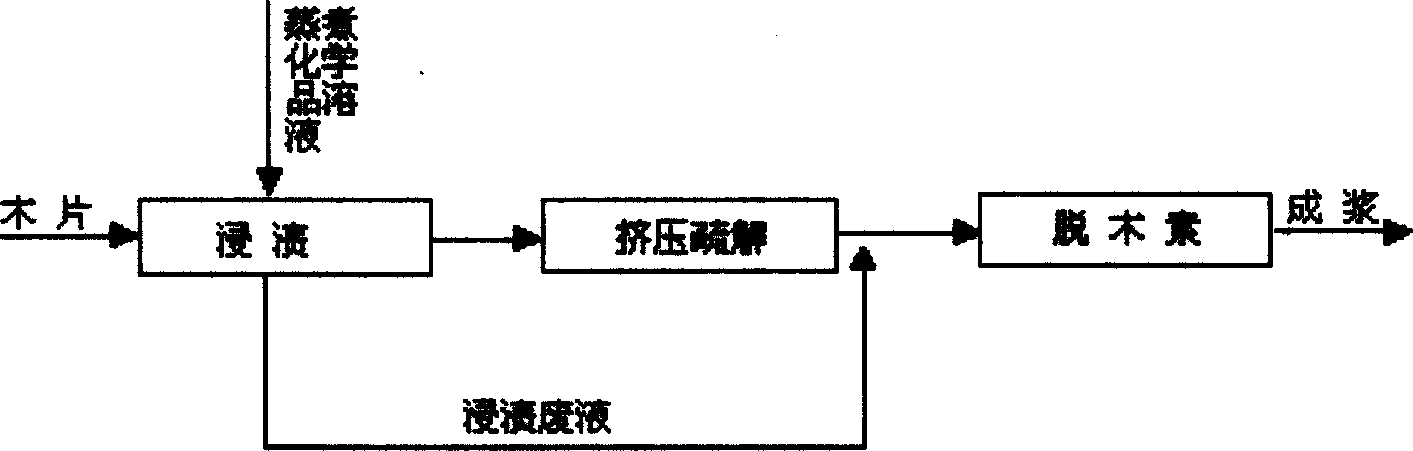

Method for producing chemical wood pulp

InactiveCN1563564AIncrease production capacityTake advantage ofCellulose material pulpingMaterials sciencePressed wood

This invention is a chemical wood pulp productive method. It contains following steps: 1) To soak, Put the thin piece wood plate into the soak liquid container, the soaking temperature is 50-90 deg.C. Soaking time is 15-50 minutes; the soak liquids use part or whole boiling liquid. 2) To relieve squeeze and press; relieve the pressed wood plate, the pressing ratio is 3-6:1. 3) To take-out lignin: put the pressing wood plate and its soak liquid into the boiler, boiling them to do the reaction of take-out lignin.

Owner:QILU UNIV OF TECH

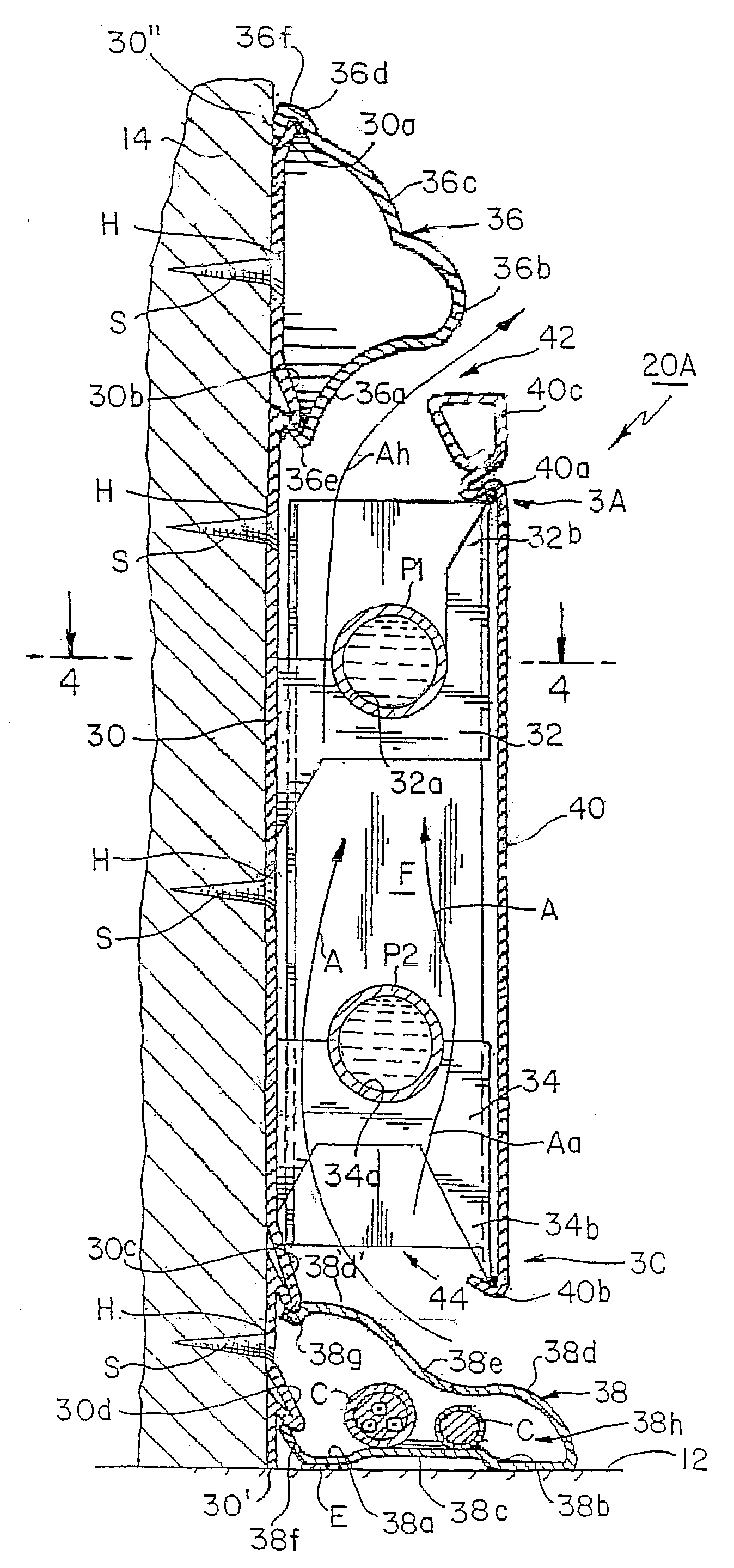

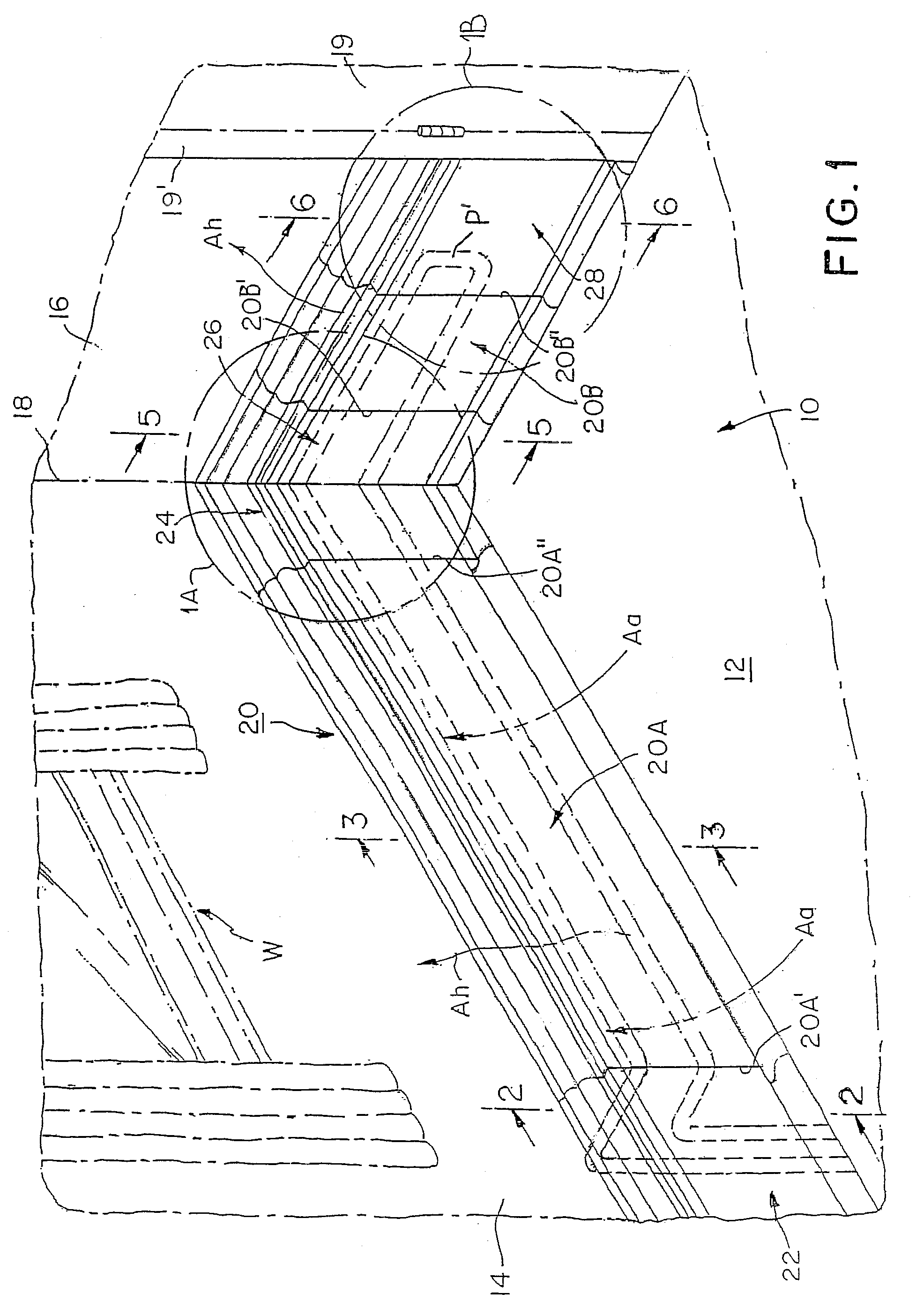

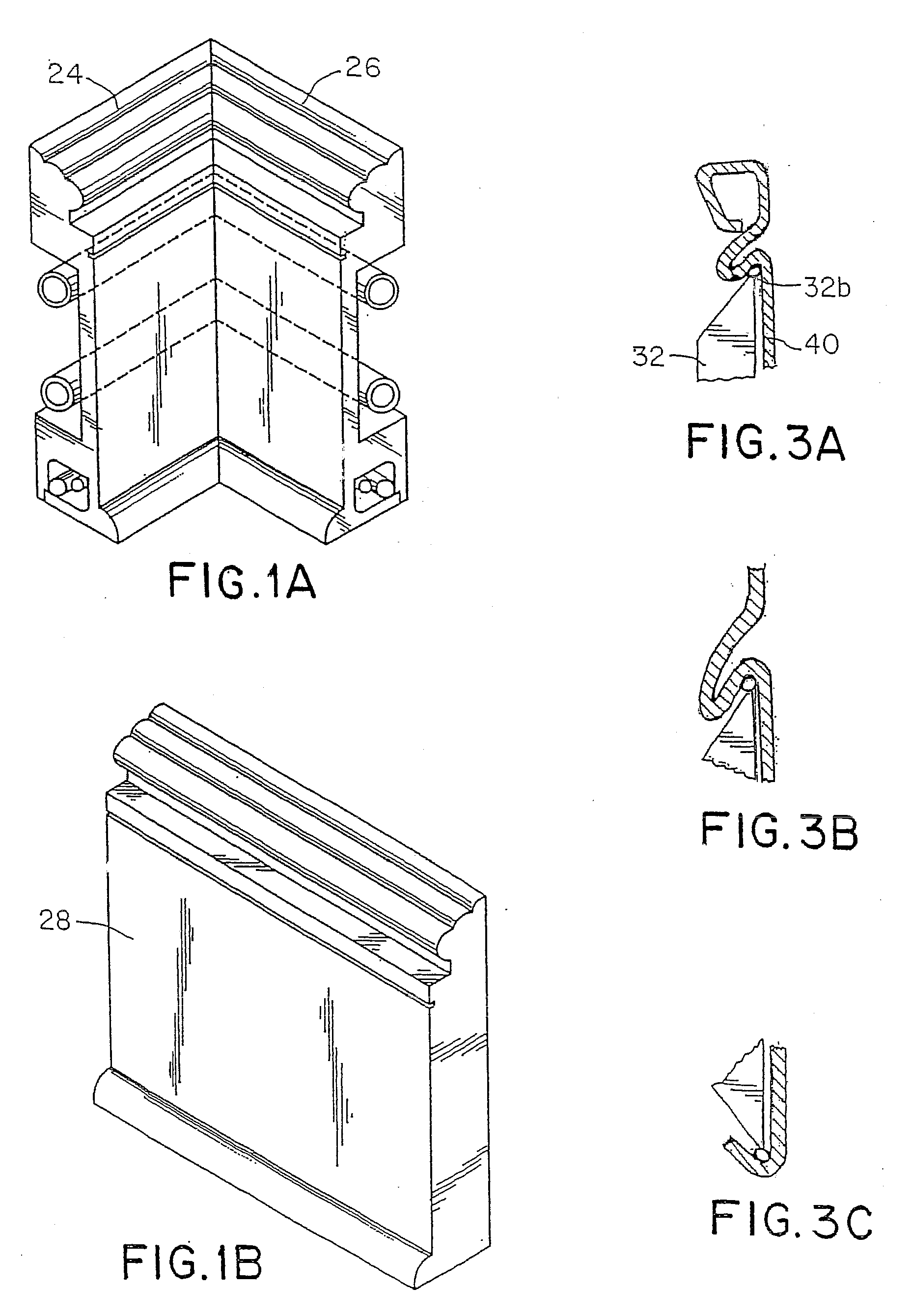

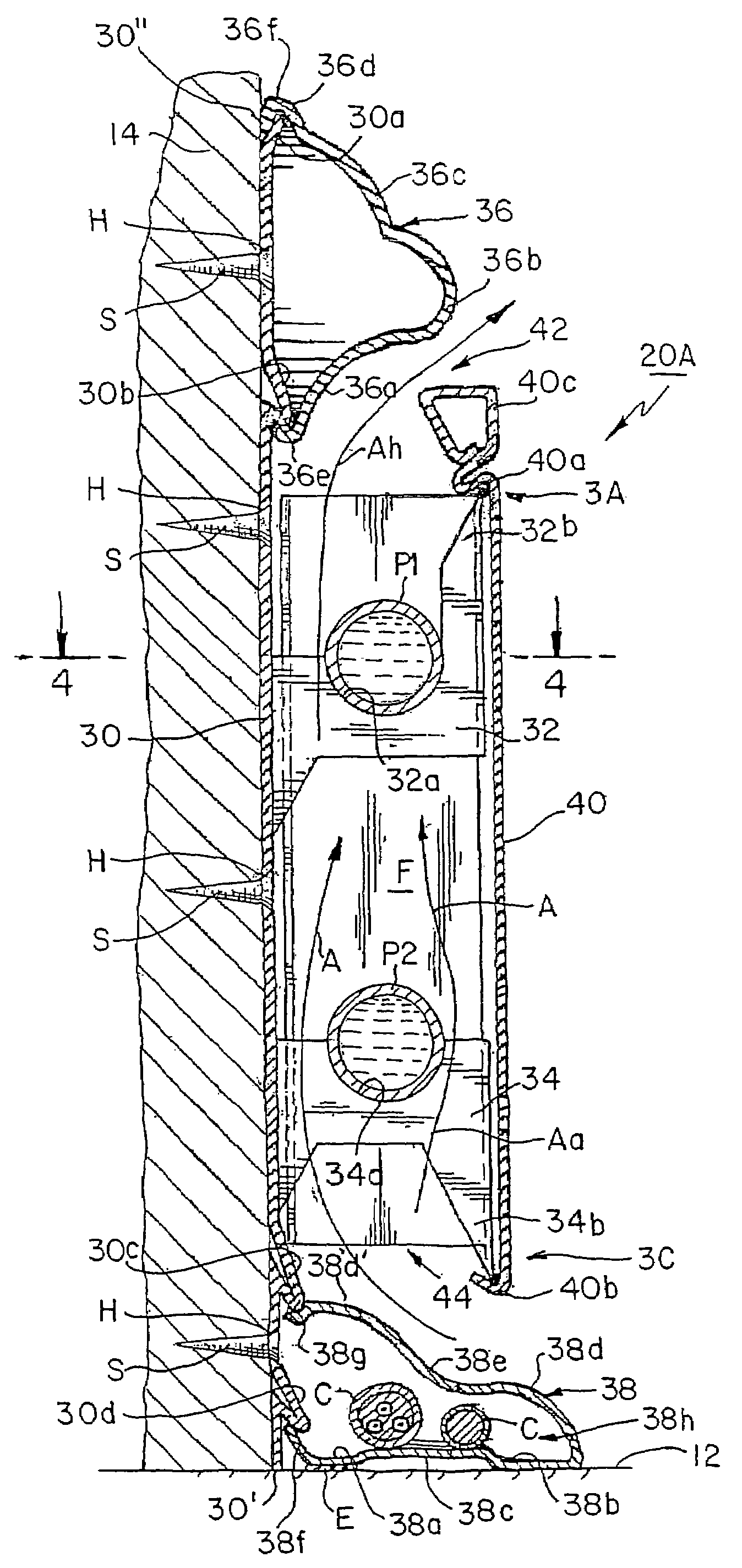

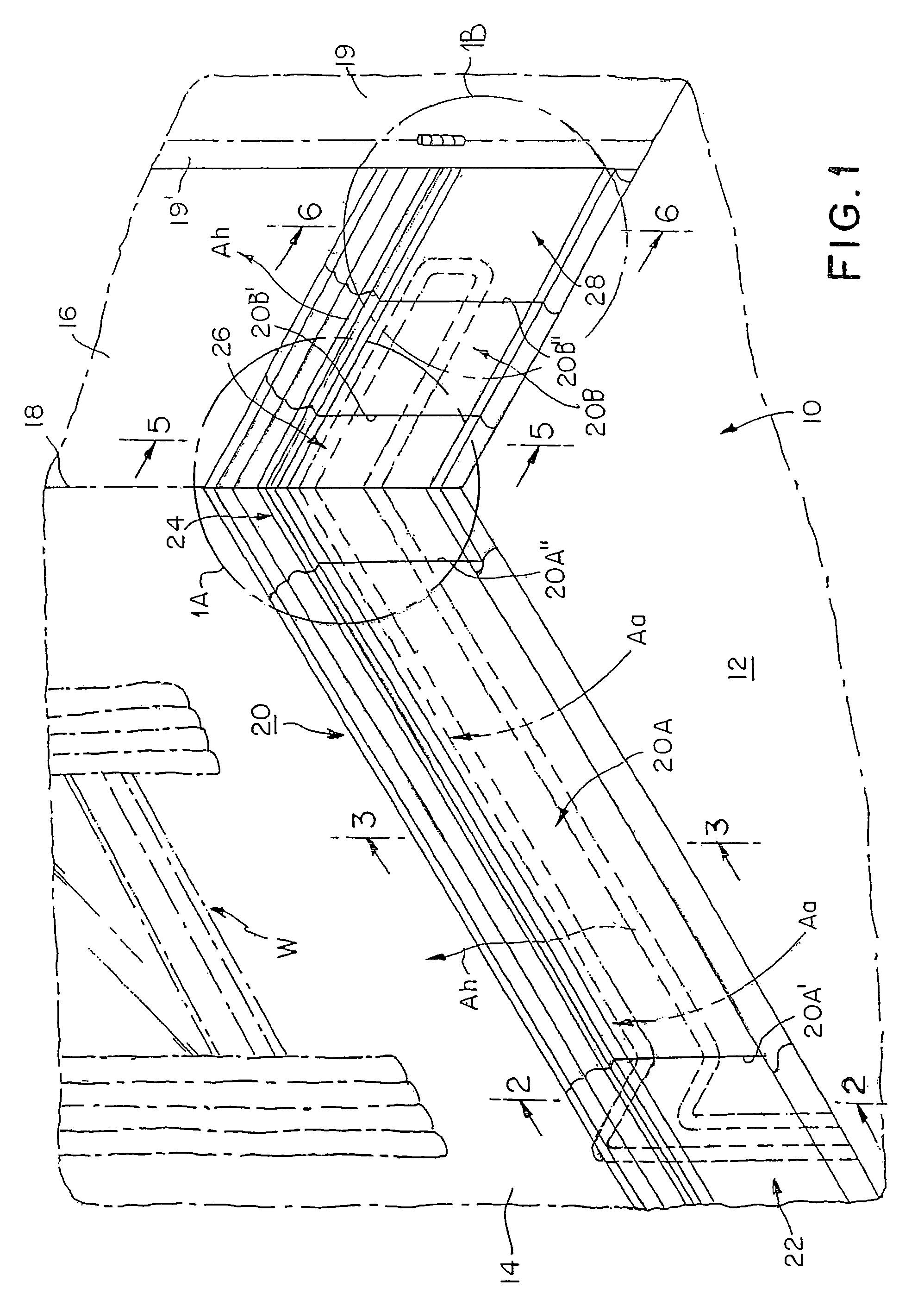

Adjustable baseboard and molding system

InactiveUS20080029613A1Good lookingAvoid damageFluid heatersHot-air central heatingBaseboardEngineering

A baseboard system includes baseboard units through which conduits extend carrying heated fluids, and moldings about the free ends of the baseboards, to provide a generally uniform external surface configuration. The moldings are in the nature of conventional moldings made of wood, pressed wood, plastic or the like. The use of the moldings with the baseboards provides an efficient, cost-effective system that produces a uniform appearance and facilitates cleaning.

Owner:FRIEDLICH WILLIAM

Baseboard and molding system

A baseboard system includes baseboard units through which conduits extend carrying heated fluids, and moldings about the free ends of the baseboards, to provide a generally uniform external surface configuration. The moldings are in the nature of conventional moldings made of wood, pressed wood, plastic or the like. The use of the moldings with the baseboards provides an efficient, cost-effective system that produces a uniform appearance and facilitates cleaning.

Owner:FRIEDLICH WILLIAM

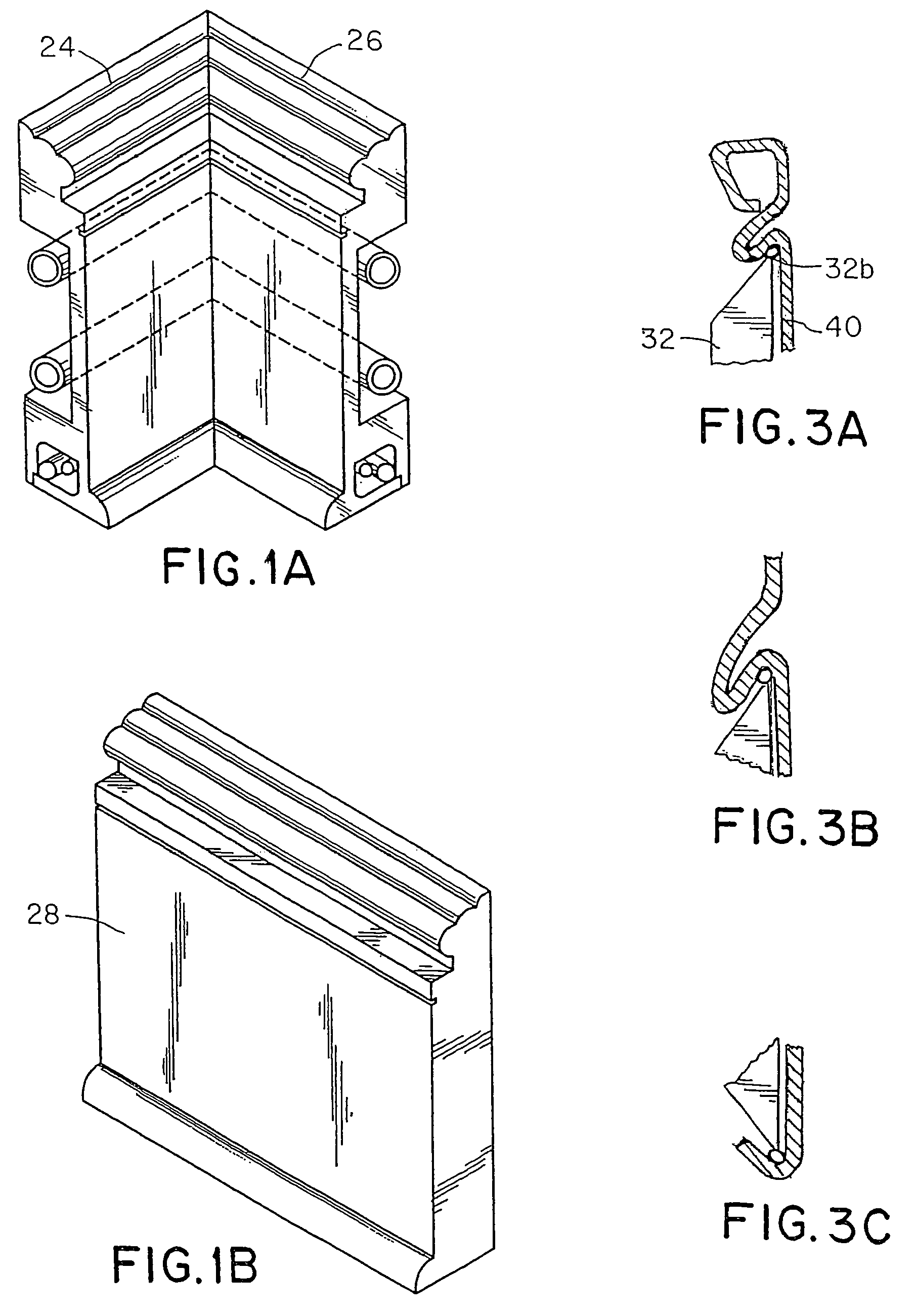

Method for densifying wood/bamboo by combining hot pressing with steam injection and densified wood/bamboo

ActiveCN106881755AGood color consistencyImprove surface propertiesWood treatment detailsReed/straw treatmentHigh pressureSmall hole

The invention discloses a method for densifying wood / bamboo by combining hot pressing with steam injection. The method comprises the following steps: additionally mounting high-pressure-resistant high-temperature-resistant air permeable plates on upper and lower press plates of a hot press machine provided with steam injection holes, wherein the smooth surfaces of the air permeable plates faces out and get in contact with to-be-pressed wood / bamboo; heating the upper and lower press plates to 160-220 DEG C, and keeping the temperature of the upper and lower press plates in the follow-up steps; putting the wood / bamboo of which the water content is 8-30% on the lower press plate of the hot press machine; quickly closing the upper and lower press plates; stopping the closing process when the upper press plate gets in contact with the to-be-pressed wood / bamboo and applying certain pressure to the to-be-pressed wood / bamboo, and enabling the injection of high-pressure steam; slowly closing the above upper and lower press plates, and continuing the steam injection at the same time; stopping the closing process when the to-be-pressed wood / bamboo is pressed to reach the thickness as required, remaining in place, and continuing the steam injection at the same time; and stopping the steam injection and enabling the air sucking function of small holes in the upper and lower press plates, so that extra water and extract gas can be discharged.

Owner:INT CENT FOR BAMBOO & RATTAN

Hot-pressed wood-plastic composite with sandwich structure and manufacturing method thereof

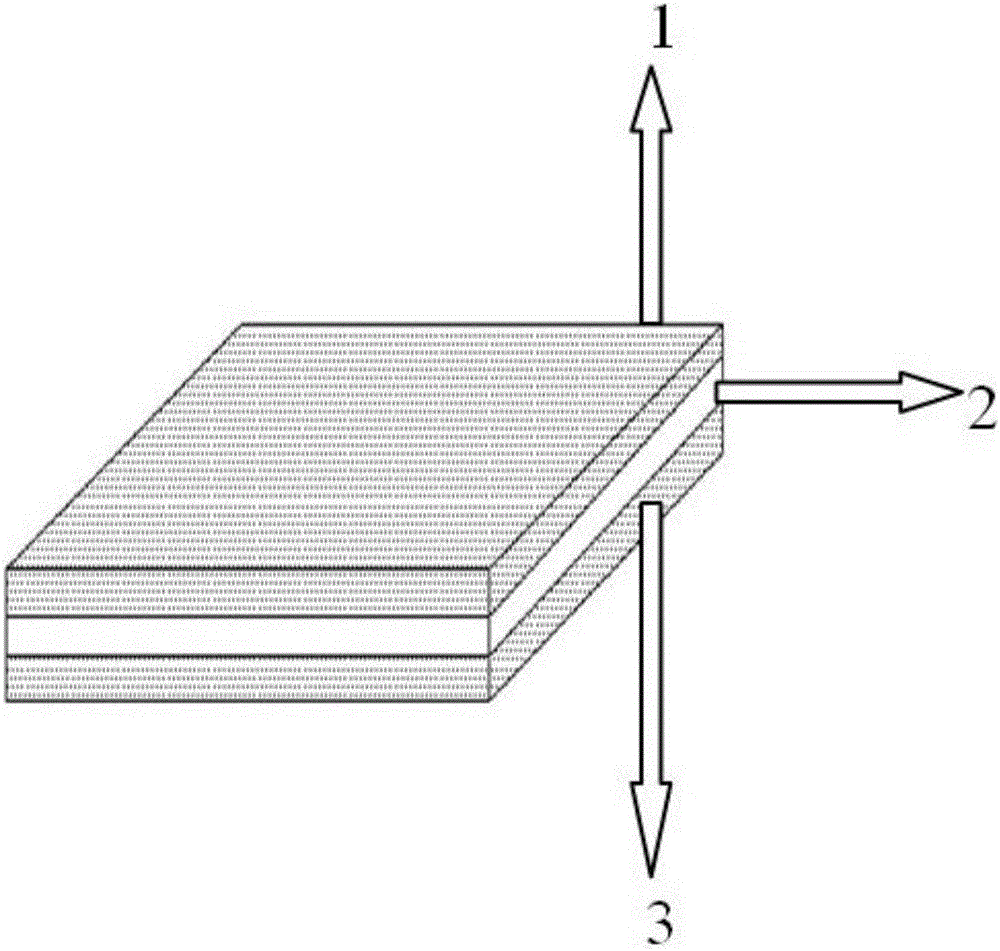

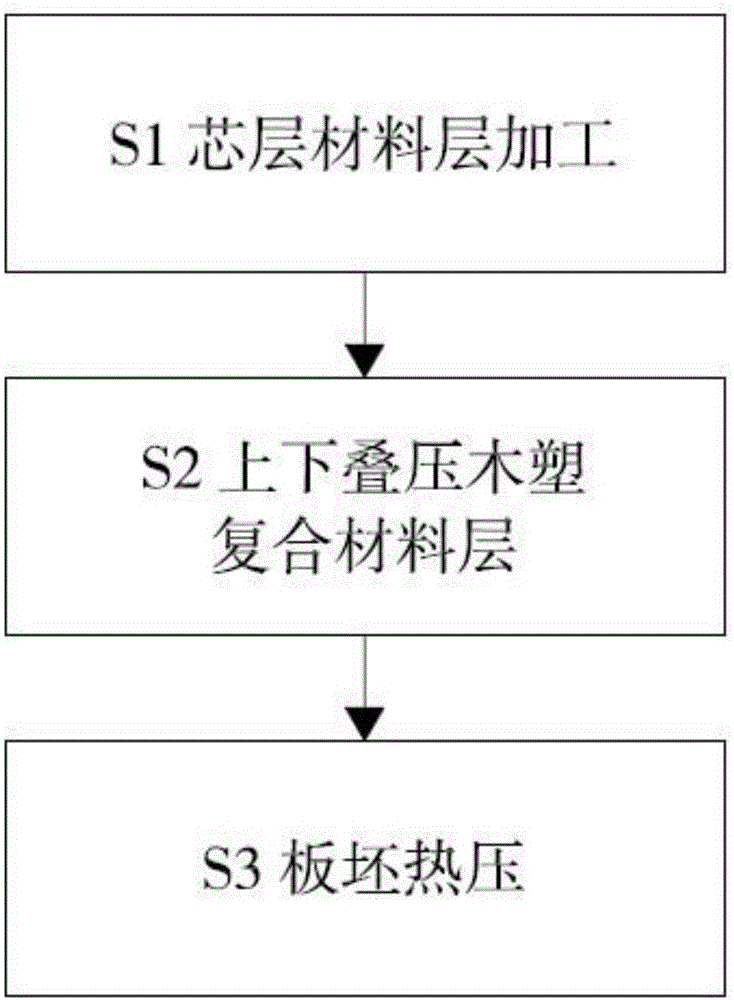

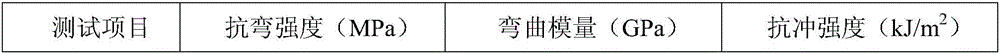

InactiveCN106515150ANo shatteringImprove impact toughnessSynthetic resin layered productsLaminationSurface layerHigh density

The invention provides a hot-pressed wood-plastic composite with a sandwich structure, relates to a wood-plastic composite and specifically relates to the wood-plastic composite with the sandwich structure. The invention aims to solve the problems that the reinforcing and toughening effects cannot be simultaneously achieved, the comprehensive mechanical property is poor, the material density is high, the cost is high and the recycled waste plastic is difficult to be recycled when the wood-plastic composite taking a present thermoplastic polymer as a substrate is used as a panel. The wood-plastic composite comprises a thermoplastic polymer plastic core-layer material, an upper surface layer of wood-plastic material and a lower surface layer of wood-plastic material. The wood-plastic composite with the sandwich structure is obtained by hot-pressing in the manner of layering laminating. According to the invention, the problems of poor comprehensive mechanical property, high density and high cost of the wood-plastic composite based on the thermoplastic polymer can be solved. The invention also provides a preparation method for the wood-plastic composite with the sandwich structure.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing compressed section bar

InactiveCN102941609AEasy to produceReduce manufacturing costWood compressionWood charring/burningFire retardantSuperheated steam

The invention relates to a method for preparing a compressed section bar, which belongs to a wooden product production process technology. The method comprises the following steps of: a, preparing a material: preparing a wooden blank from a raw wood fast-growing lumber; b, dipping a flame retardant of which the thermal decomposition temperature is over 200 DEG C for 1-2 hours at normal temperature and under normal pressure or a low pressure; c, pressing and carbonizing: on a hot press, controlling the temperature of a base plate of the hot press at 150-180 DEG C, feeding wood obtained in the step b into the hot press, rapidly closing the hot press till wood is just contacted, preheating wood for 10-120 seconds, and preserving heat for 1-3 hours; and piling pressed wood, putting onto a tray, feeding into a carbonizing kiln in which overheat steam is taken as a thermal treatment medium, and treating at the temperature of 180-210 DEG C for 2-4 hours; and d, forming for 5-8 hours. Due to the adoption of the production method disclosed by the invention, a rapid-growing solid wood flame-retardant section bar of a large thickness can be molded at one time, and the prepared section bar has high corrosion resistance, high weather resistance, a long service life and a wide application range.

Owner:HUZHOU TIEFO REFRACTORIES

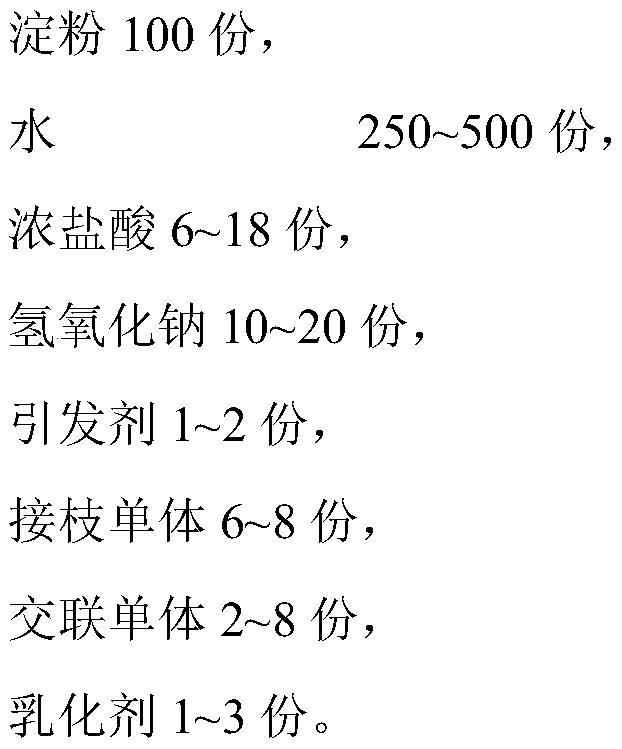

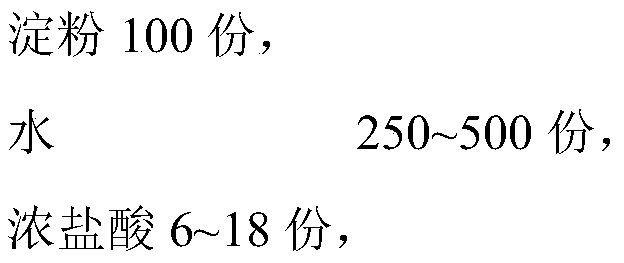

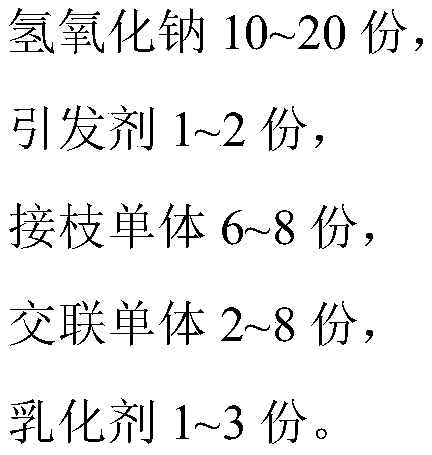

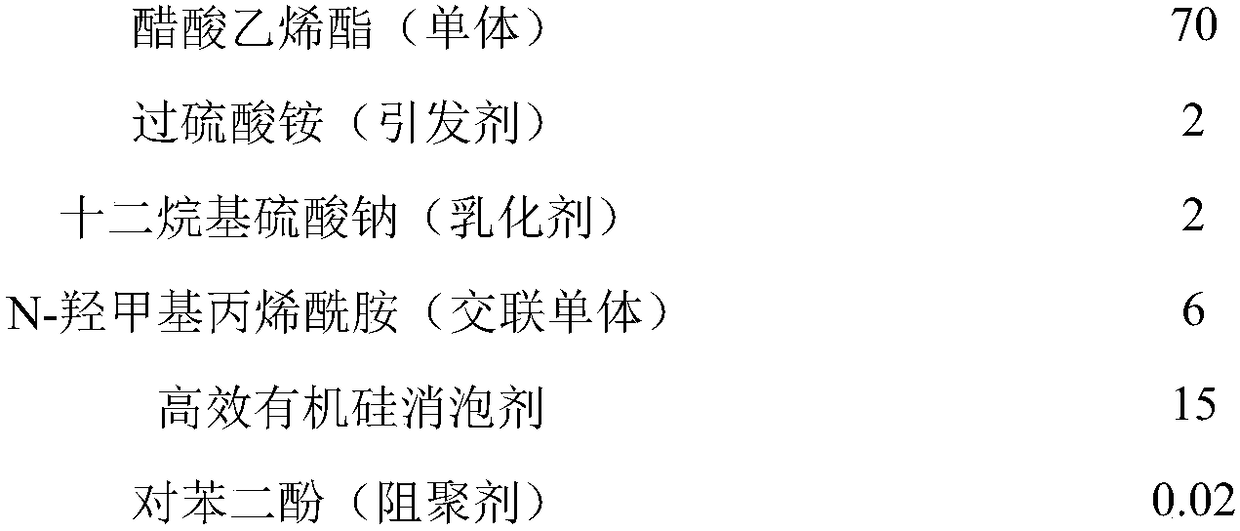

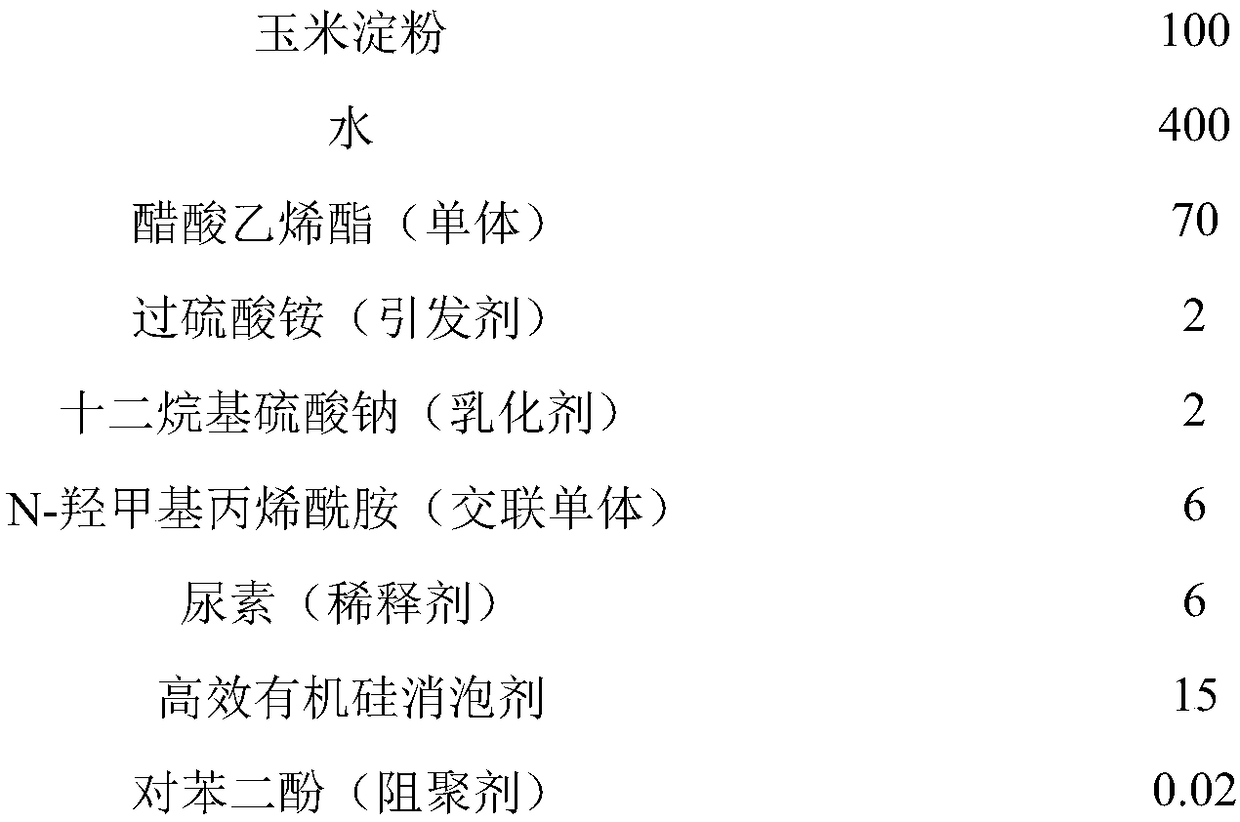

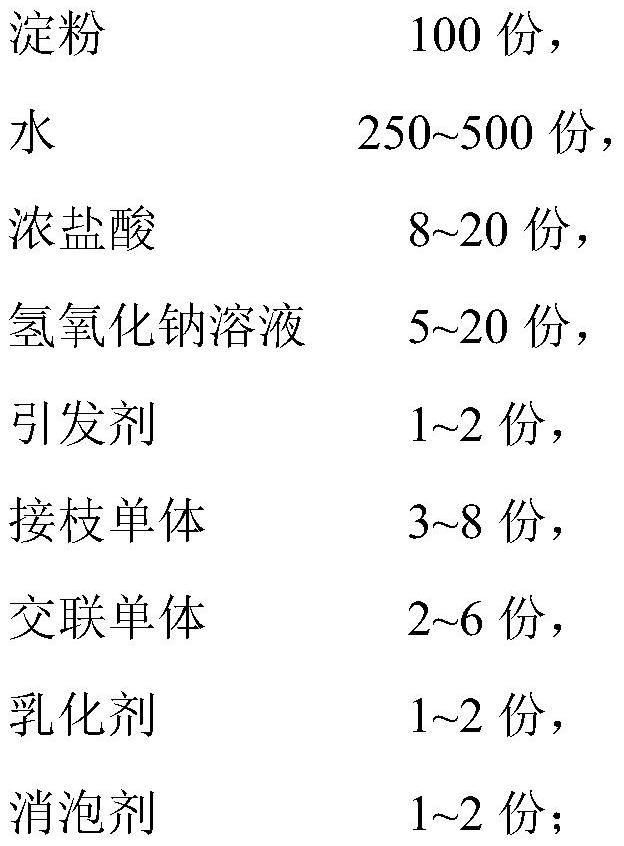

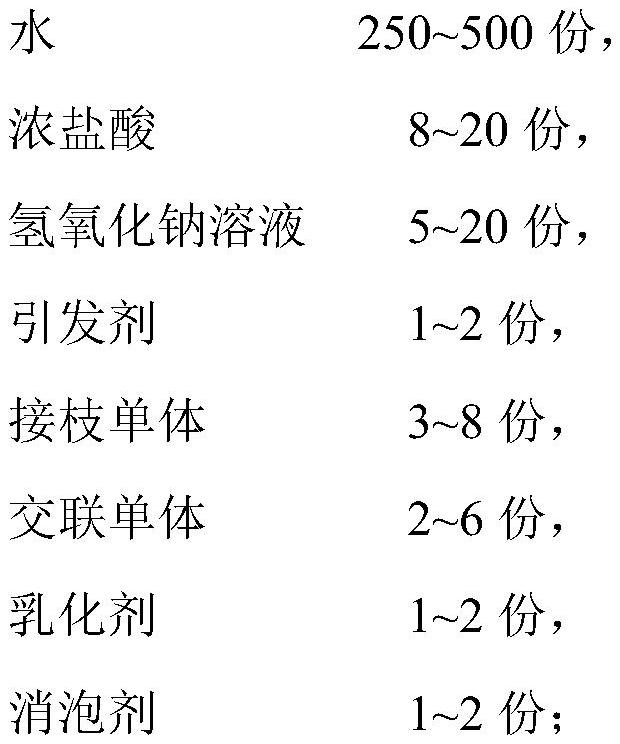

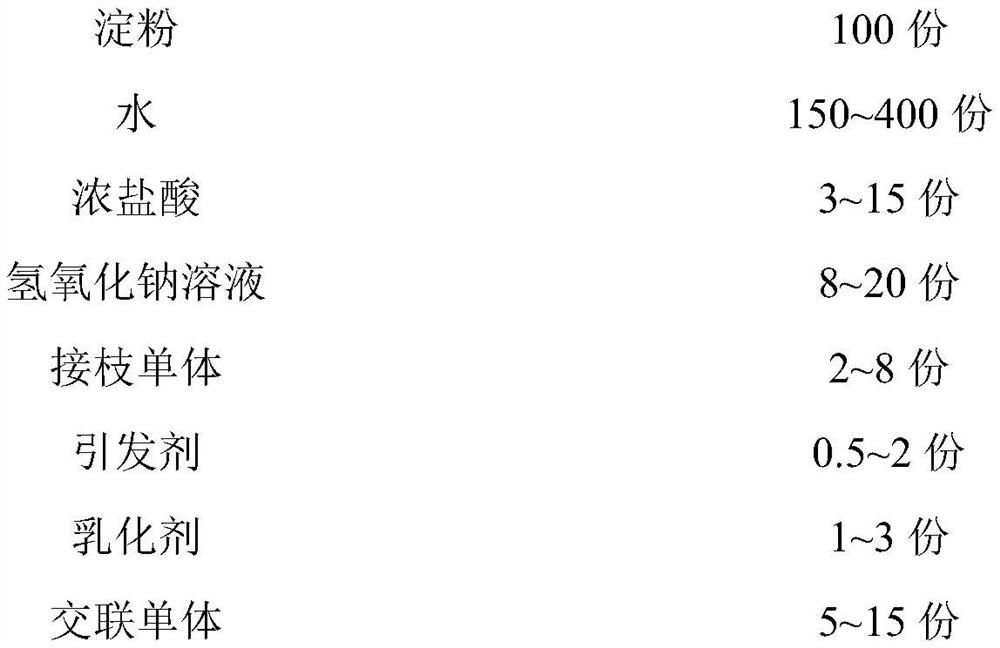

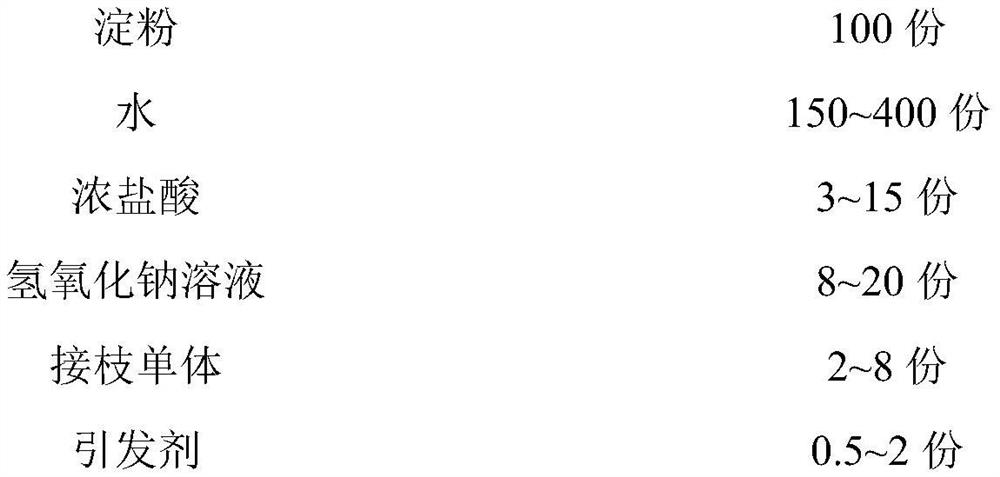

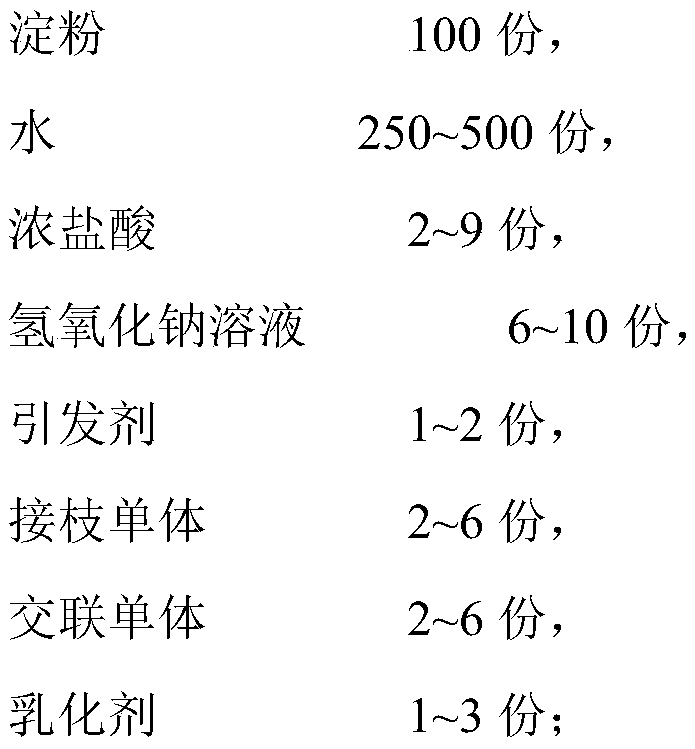

Thermosetting artificial board starch adhesive and preparation method thereof

ActiveCN111205794AFix stability issuesSolve the costGraft polymer adhesivesAdhesive cementPolymer science

The invention discloses a thermosetting artificial board starch adhesive and a preparation method thereof, and belongs to the technical field of adhesive preparation. Starch is used as a main raw material, and after acidolysis, a semi-continuous seeded emulsion polymerization method is adopted for preparation. By accurately controlling the pre-gelatinization temperature, the initiator adding time,the crosslinking monomer adding amount, the crosslinking monomer dripping speed and the crosslinking monomer dispersion liquid concentration, the reaction degree of crosslinking monomers is reasonably controlled, and the step of dripping comonomers is omitted. Meanwhile, the reaction time is greatly shortened, the use amount of petroleum monomers is reduced, complex reaction steps are simplified,the proportion of starch accounting for the total solid content is increased to 75% or above from 40%, and the cost of the starch adhesive is reduced. The adhesive disclosed by the invention is goodin water resistance and strong in cohesion, various properties of the manufactured artificial board exceed the standard of class II artificial boards, and the adhesive is suitable for mass productionand is widely applied to adhesion of hot-pressed wood decorations, artificial boards and plywood.

Owner:JIANGNAN UNIV

Thermoset artificial board starch adhesive and preparation method thereof

ActiveCN109266265ASolve the problem that it cannot be used as type II plywoodEasy to operateAdhesive articlesAdhesive processes with adhesive heatingAdhesive cementPolymer science

The invention discloses a thermoset artificial board starch adhesive and a preparation method thereof, and belongs to the technical field of adhesive preparation. In the invention, starch is adopted as a main raw material; after acidolysis of the starch, the control on monomer polymerization stability is improved by semi-continuous seed emulsion polymerization. The preparation method comprises thefollowing steps: after grafting, adding cross-linked monomers with two functional groups of polymerization type double bond and condensation type hydroxymethyl for polymerization, wherein the cross-linked monomers are added also in a semi-continuous way; after the cross-linking reaction, performing gelatinization and heat preservation to finally obtain a thermoset adhesive for bonding a hot-pressed artificial board. With the properties of two-step crosslinking and high-temperature fast crosslinking and curing, the adhesive disclosed by the invention has the advantages of good film forming property, high heat resistance and strong cohesion; by adopting the developed gluing way, the temperature, the pressure and the matching hot-pressing technology, the produced artificial board exceeds type-II artificial board in all properties and can be widely applied to the bonding of hot-pressed wood decoration, artificial boards and plywood.

Owner:JIANGNAN UNIV

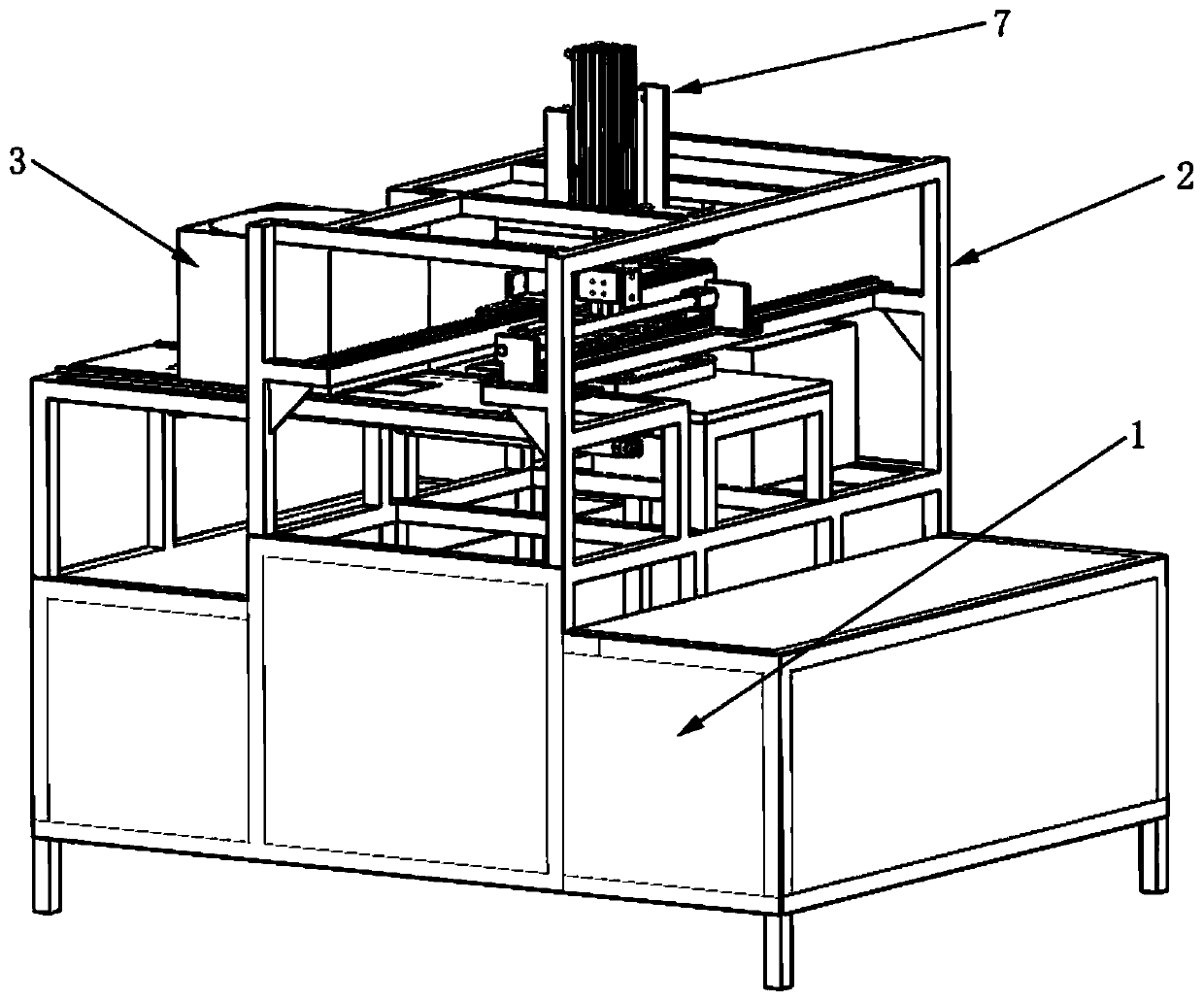

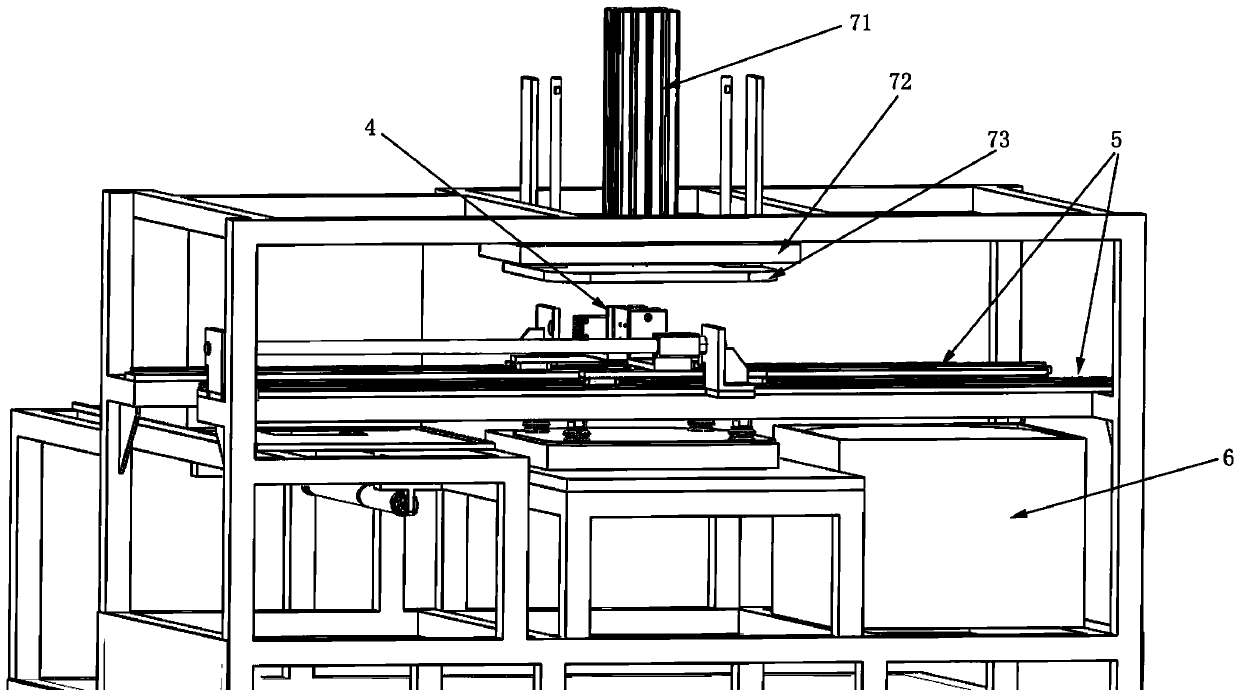

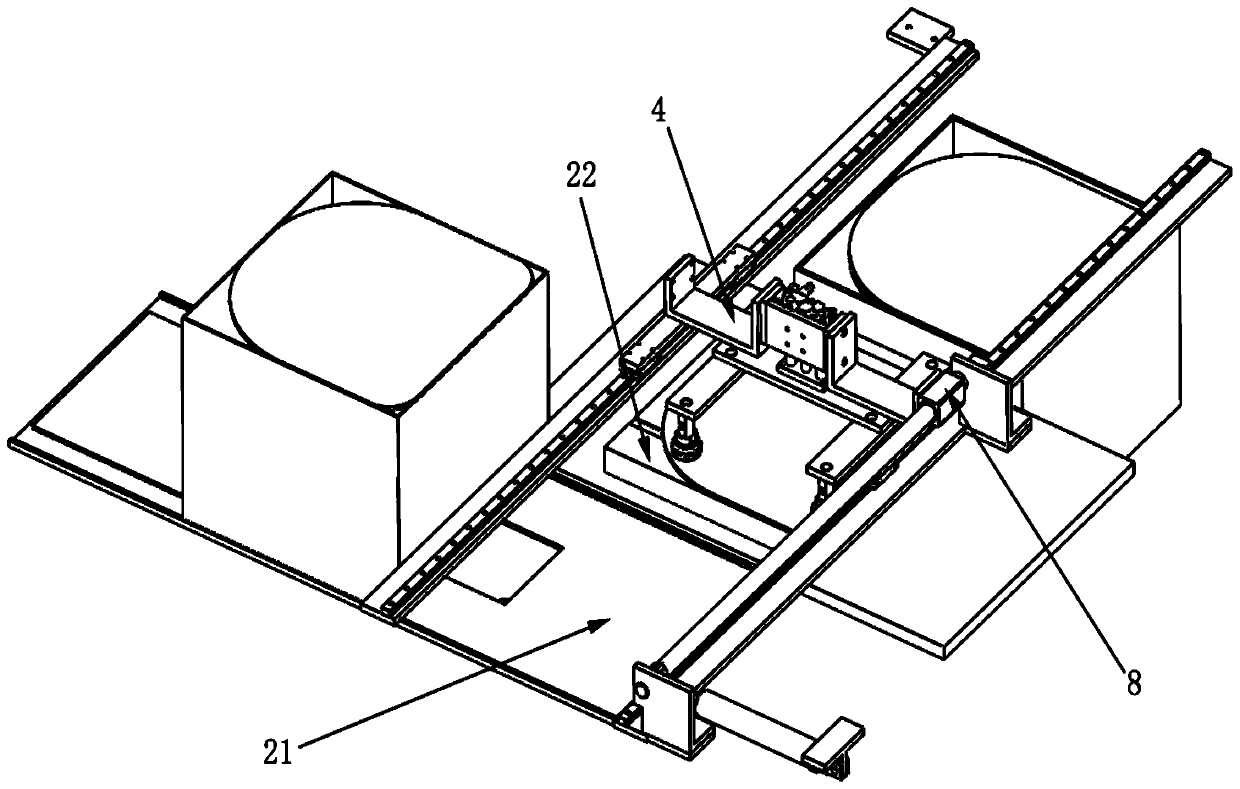

Wood board glue smearing and pressing device

The invention discloses a wood board glue smearing and pressing device, and relates to the technical field of wood board pressing. The wood board glue smearing and pressing device comprises a base, aframe body, a material supply part, a grabbing part and a pressing part; the frame body is arranged on the base; the middle of the frame body is provided with slide rails, the grabbing part is arranged on the slide rails, a driving device is arranged at the joints between the grabbing part and the slide rails, and the driving device is used for driving the grabbing part to move on the slide rails;the grabbing part is provided with a glue smearing device; one ends of the slide rails are provided with the material supply part, and a collecting part is arranged below the other ends of the sliderails; a pressing platform is arranged below the middles of the slide rails; the grabbing part is used for transferring wood boards on the material supply part to the pressing platform; the pressing platform is used for allowing the two to-be-pressed wood boards to be placed; the glue smearing device is used for smearing glue onto the upper surface of the first wood board placed on the pressing platform; and the pressing part is arranged at the top of the frame body and used for pressing the two wood boards located on the pressing platform.

Owner:郑军锋

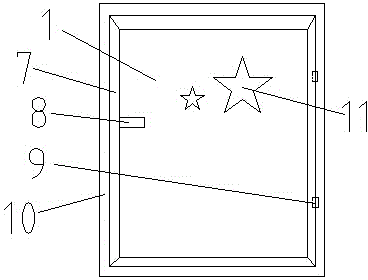

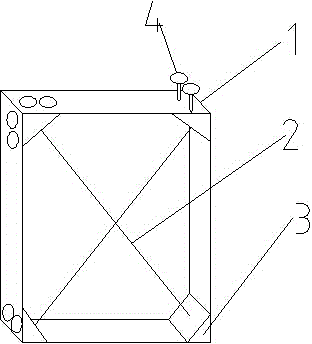

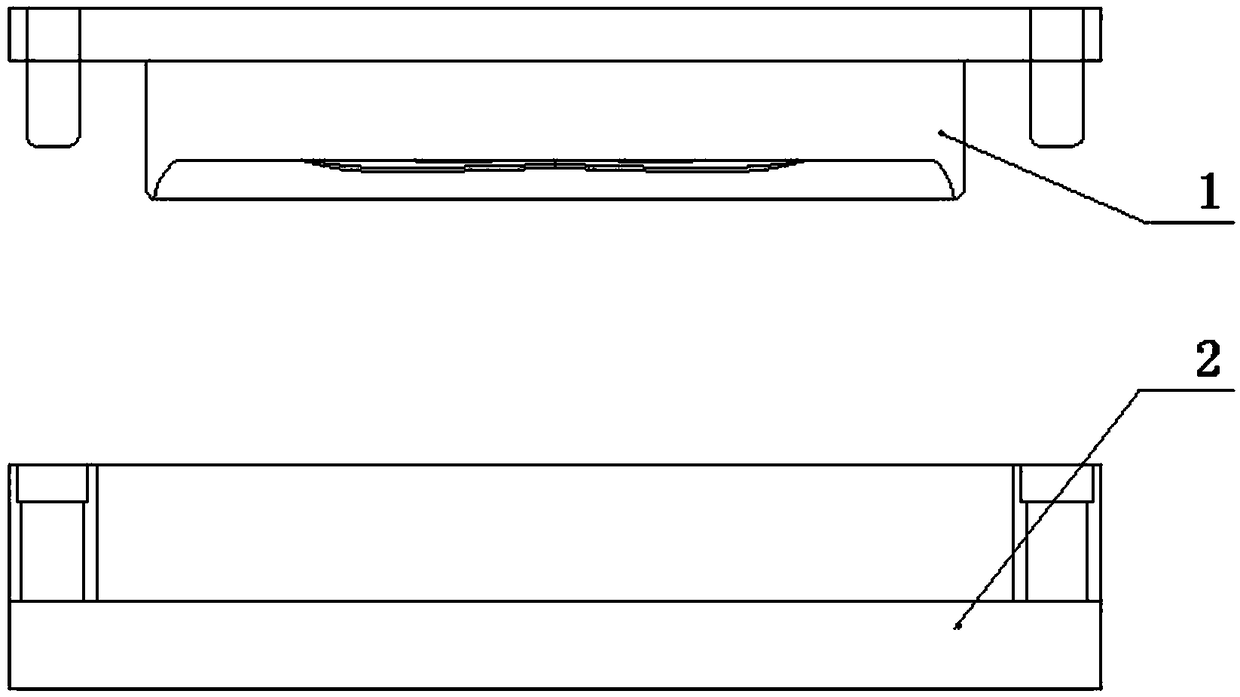

Anti-deformation suit door

The invention relates to a suit door, in particular to an anti-deformation suit door. The anti-deformation suit door comprises a doorframe, a door plate and a door lock, wherein a square frame in clearance fit with the doorframe is arranged in the doorframe; a triangular reinforcing rib is arranged at each of the four corners in the square frame; elastic pull rods which are diagonally connected are arranged on the reinforcing ribs; pressed wood chips are arranged in the square frame and are fully filled in the whole square frame; the door plate with the same size as the square frame is respectively arranged on the side surface of the square frame; a wood skin decorating surface is arranged on each door plate; wood lacquer is sprayed to each decorating surface; relief patterns are arranged on each decorating surface; solid wood covered edges are arranged on the sides of the door plate; the thickness of the covered edges is equal to a clearance between the doorframe and the square frame; the door lock is arranged on the door plate; hinges connected with the door plate are arranged on the doorframe; a lock hole used for accommodating the lock cylinder of the door lock is formed in the doorframe. The anti-deformation suit door has the beneficial effects that the suit door can be prevented from being deformed, and meanwhile, the manufacturing cost is saved.

Owner:CHONGQING YISHI TIANRUN SUIT DOOR

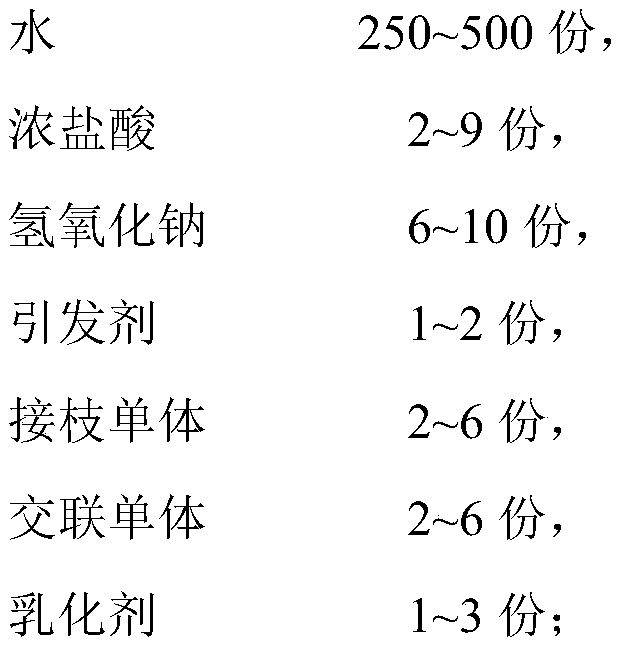

Viscosity-adjustable thermosetting artificial board starch adhesive and preparation method thereof

InactiveCN111647112AImprove fault toleranceExpand the field of market applicationWood veneer joiningGraft polymer adhesivesAdhesive cementPolymer science

The invention discloses a viscosity-adjustable thermosetting artificial board starch adhesive and a preparation method thereof, and belongs to the technical field of adhesive preparation. In the mehtod, starch, as a main raw material, is subjected to acidolysis; then the viscosity of the adhesive is reasonably controlled by precisely controlling the pre-gelatinization temperature, the pre-gelatinization duration and the dripping speed of the cross-linking monomer and dropwise adding the cross-linking monomer and the initiator in sections; the control requirement of industrial production on thereaction precision is reduced, and the method can be widely applied to application fields with different requirements on the viscosity of the adhesive. The adhesive product prepared by the inventiondoes not release formaldehyde and has the advantage of environmental protection. Meanwhile, the adhesive disclosed by the invention is good in water resistance and strong in cohesion, various properties of the manufactured artificial board exceed the standard of class II artificial boards, and the adhesive is suitable for mass production and is widely applied to adhesion of hot-pressed wood decorations, artificial boards and plywood.

Owner:JIANGNAN UNIV

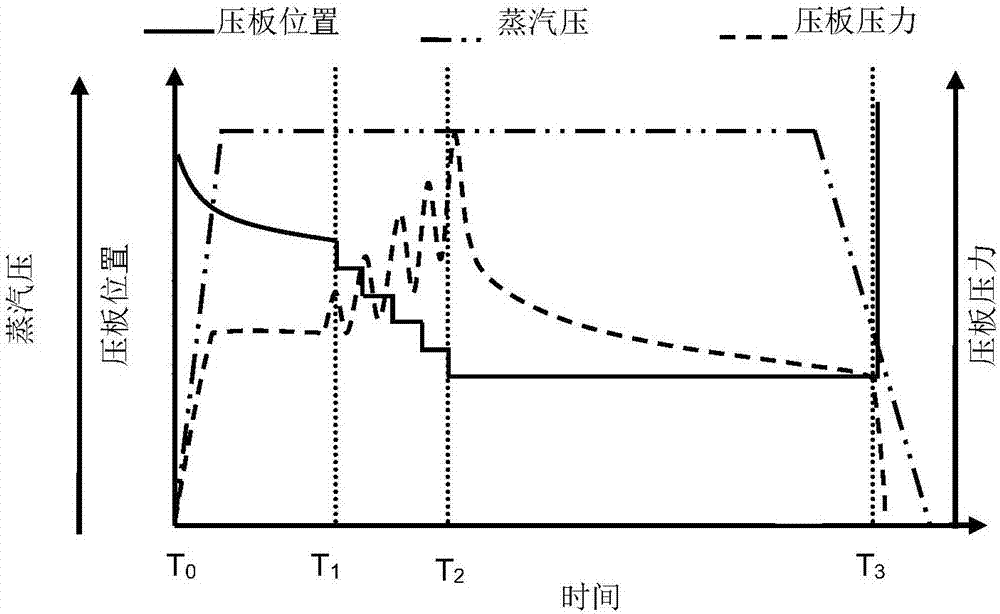

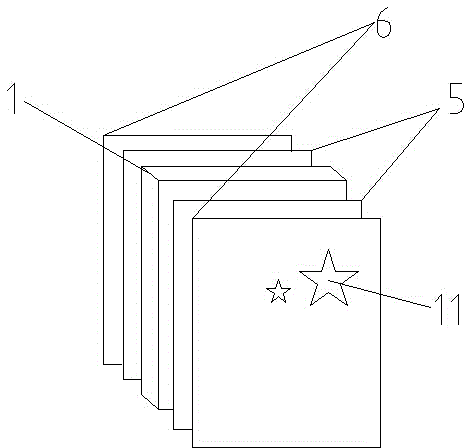

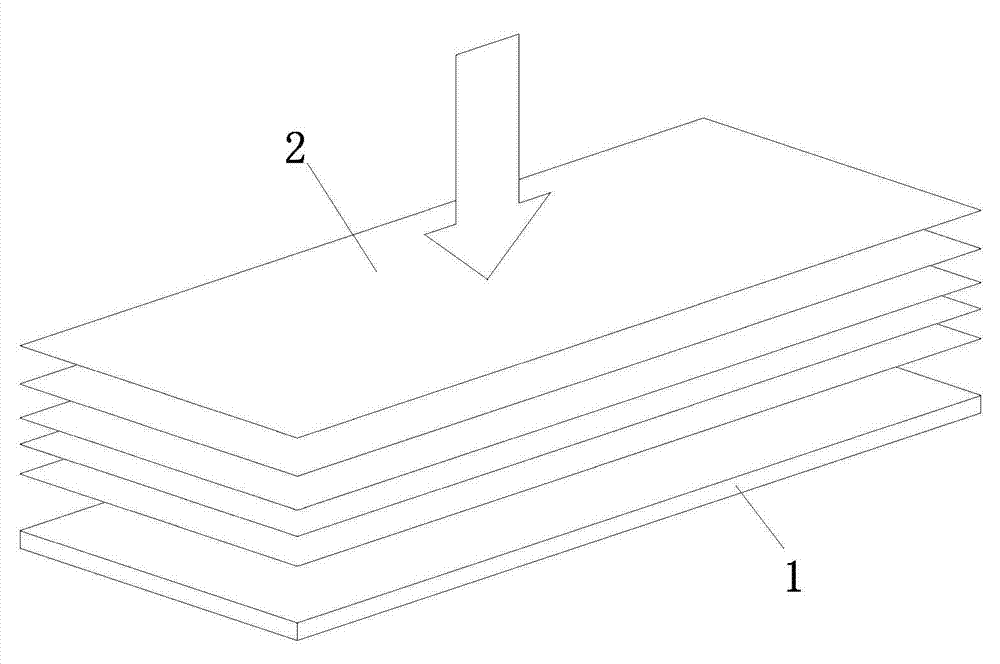

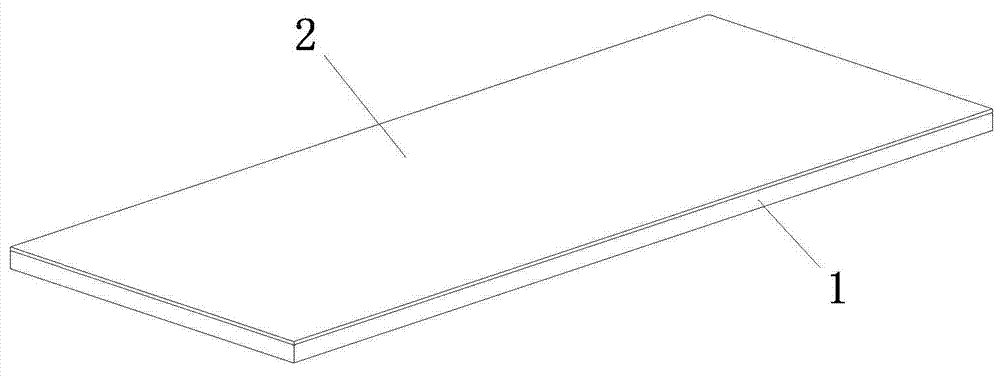

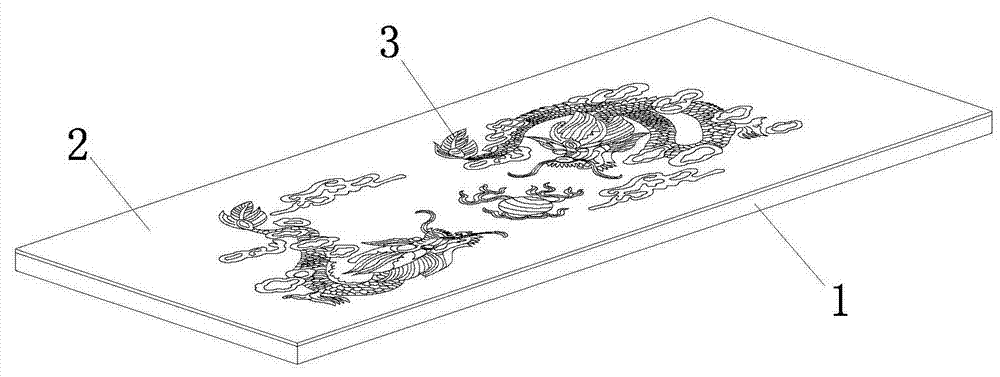

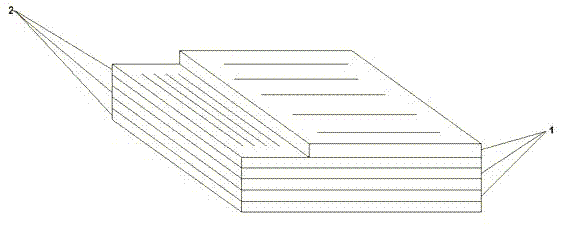

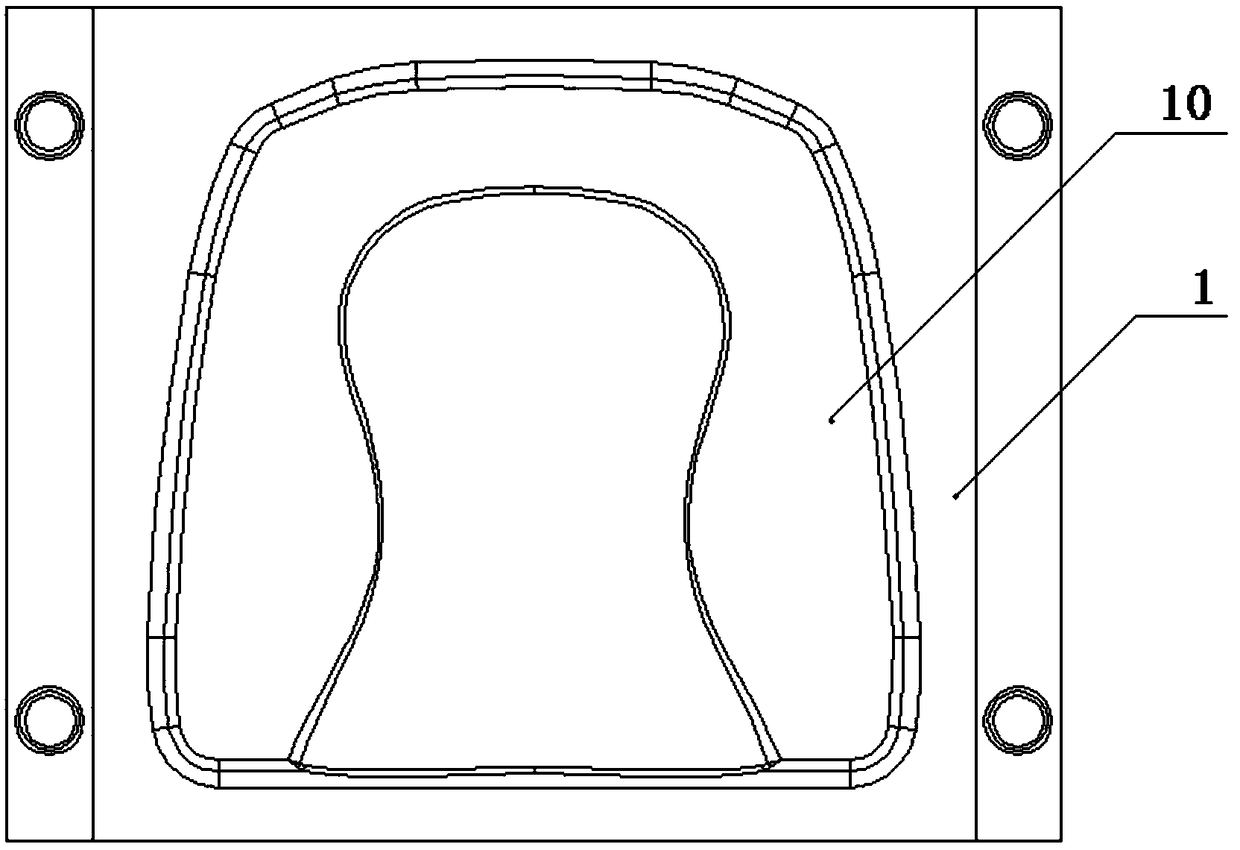

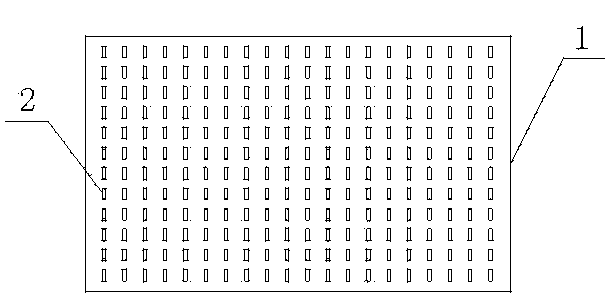

Wooden relief structure and manufacturing method

InactiveCN103029500ASave resourcesProcessing time savingSpecial ornamental structuresEmbossing decorationsWood veneerSolid wood

The invention discloses a wooden relief structure. The wooden relief structure comprises a base plate (1) and a relief body fixed on the surface of the base plate, wherein the relief body is formed by laminating multiple layers of wood veneers (2). The invention further discloses a manufacturing method of the wooden relief. The manufacturing method of the wooden relief comprises the following steps: 1, selecting the multiple layers of wood veneers according to the size of the relief body, brushing bonding adhesive on the surfaces of the wood veneers, and laminating all the wood veneers on the base plate; 2, putting the base plate and the wood veneers adhered to the base plate into a hot press, and pressing to bond the base plate and the wood veneers; 3, putting aside and cooling the hot-pressed base plate and the hot-pressed wood veneers for use; 4, blanking, sleeking and polishing a billet to form a relief; and 5, painting or waxing the relief. The artistic effect and the using performance of the wooden relief structure can match those of a solid wood relief; by the manufacturing method, a large-area relief product can be manufactured; the manufacturing method is time-saving in processing; the manufactured relief product is difficult to crack and low in cost; limited solid wood resources are saved; and the wooden relief structure has a wide market prospect.

Owner:深圳市森源蒙玛家具有限公司

Low-viscosity thermosetting shaving board starch adhesive and preparation method thereof

ActiveCN114106749ASolve the problem of sharp rise in viscosityLow viscosityGraft polymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a low-viscosity thermosetting shaving board starch adhesive and a preparation method thereof, and belongs to the technical field of adhesive preparation. A crosslinking monomer, namely N-hydroxyethyl acrylamide or acetoxyethyl methacrylate, which is low in crosslinking degree in an adhesive preparation process and can be quickly crosslinked in a plate hot pressing process is selected, so that the problem that the viscosity is increased in an adhesive reaction process is avoided; and the crosslinking monomer is subjected to a self-crosslinking reaction in the hot pressing process to form a three-dimensional network structure, so that the water resistance of the adhesive is improved, and meanwhile, the itaconic acid is added to promote the self-crosslinking reaction of the crosslinking monomer in the hot pressing process, so that the water resistance of the adhesive is further improved. Various properties of the manufactured shaving board reach the standard of P2 type shaving boards, and meanwhile, various properties of the manufactured plywood exceed the standard of II type plywood, so that the adhesive can be suitable for mass production and can be widely applied to bonding of hot-pressed wood decoration, shaving boards, plywood and fiberboards.

Owner:JIANGNAN UNIV

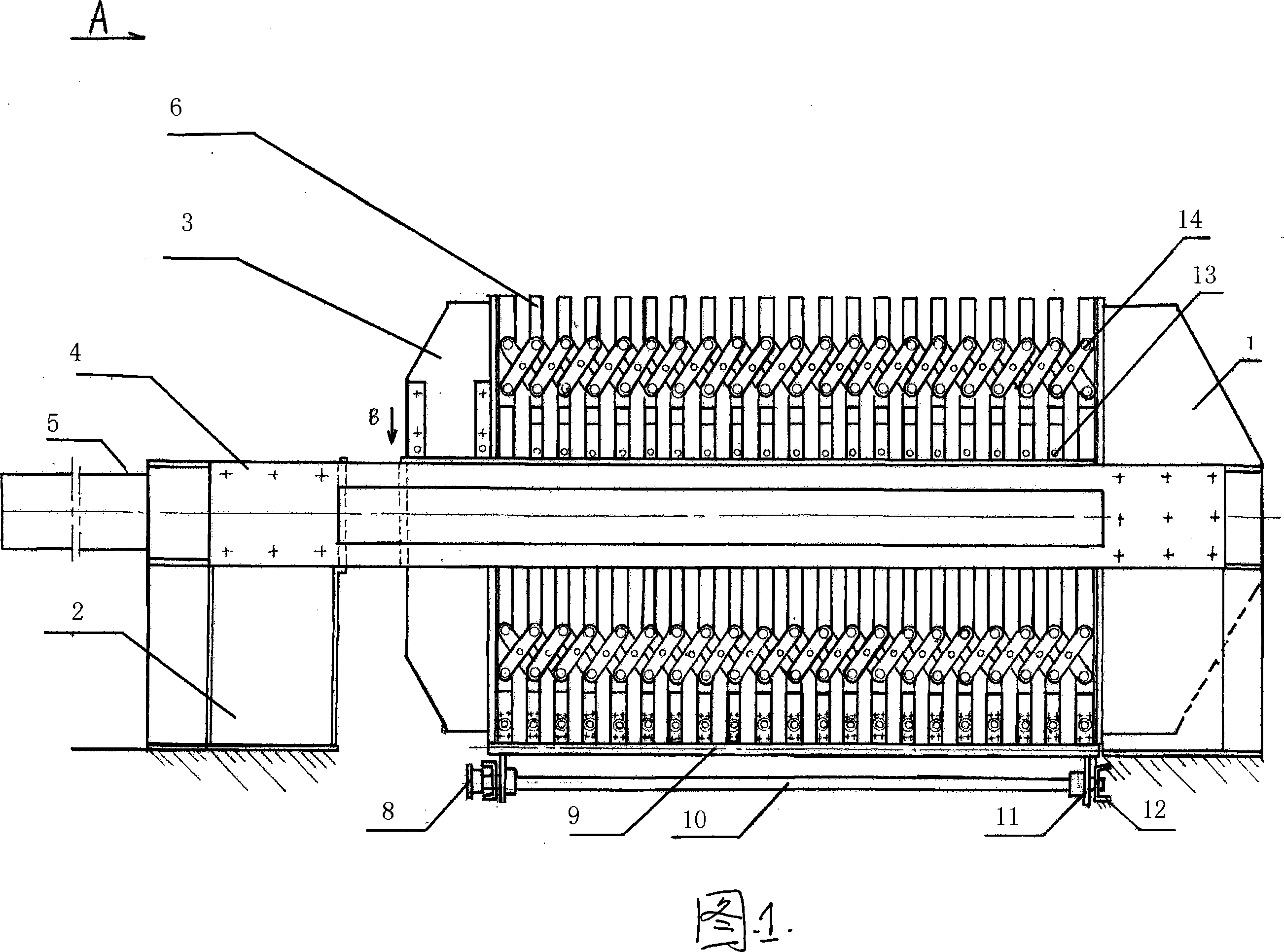

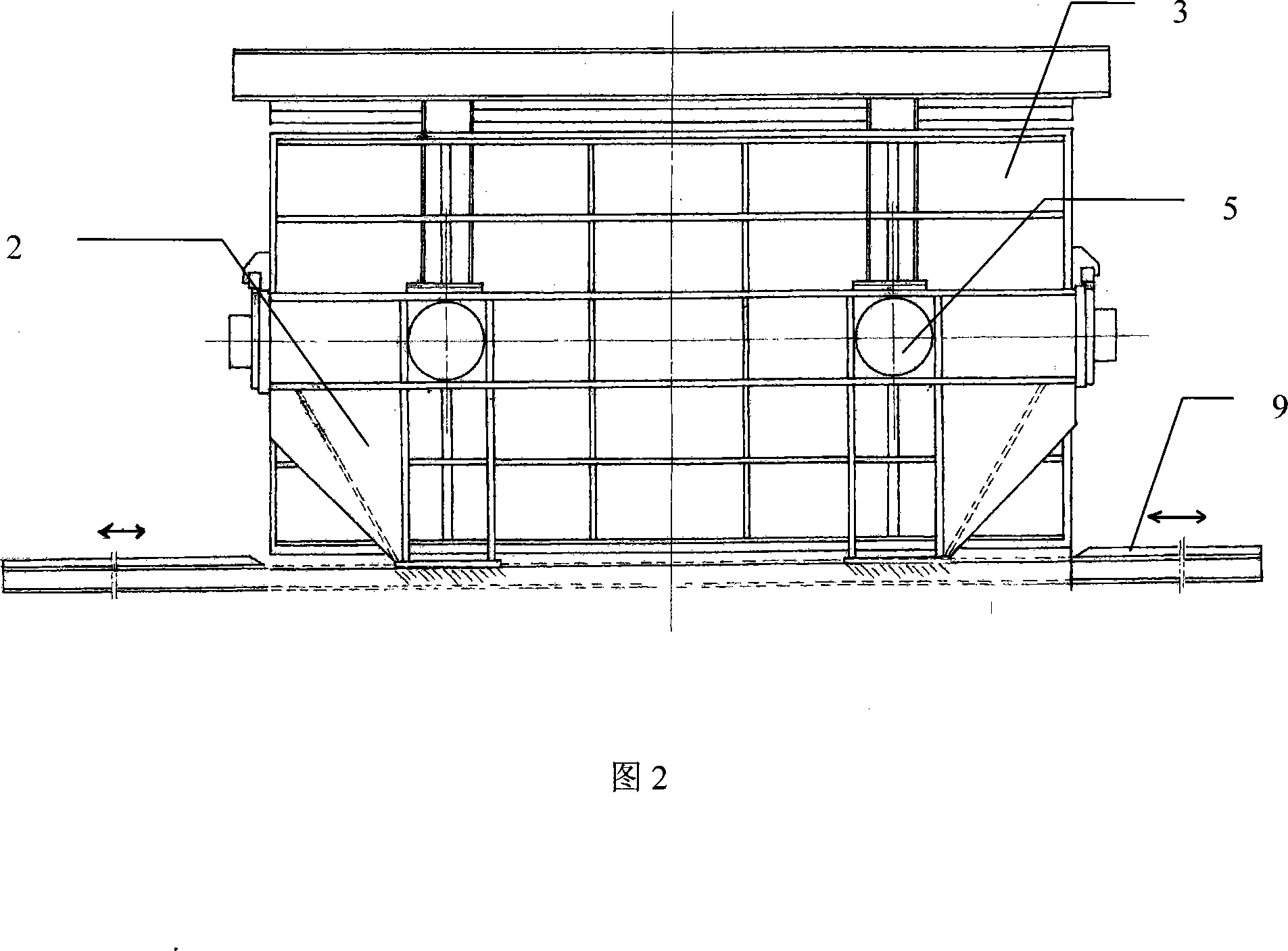

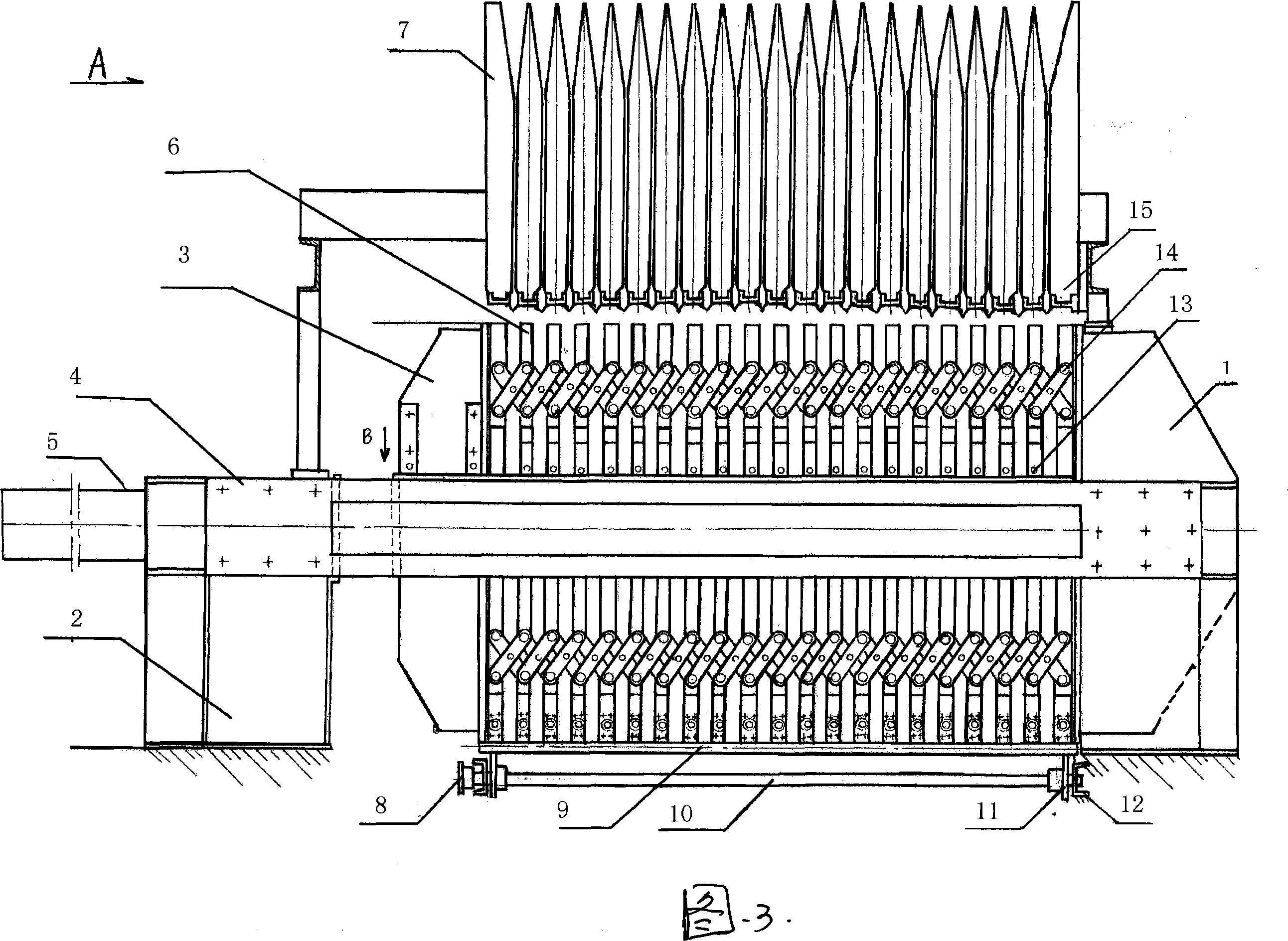

Horizontal hot pressing veneer drier

ActiveCN101130252ASimple structureRealization of automatic board feedingPlywood pressesVeneer pressesHydraulic cylinderAgricultural engineering

Owner:JINMEN HYDRAULIC PRESS MFG DATIAN COUNTY FUJIAN PROV

Recombination wooden furniture board with natural wood grain and manufacturing method thereof

Provided are a recombination wooden furniture board with natural wood grain and a manufacturing method thereof. Fast growing wood veneers which are low in manufacturing price and environment-friendly are adopted as raw materials, the wood veneers are dried into to-be-pressed wood chips after drying and gum dipping, and phenolic resin or polyamine ester adhesive is used as glue. The wood veneers are laminated to form an assembly, two adjacent layers of horizontally-arranged wood veneers and vertically-arranged wood veneers are perpendicular to each other and bonded through the glue, and pressed and solidified through a hot press or a cold press. After solidification, furniture board coarse finished products are supposed to be balance health maintenance and then polished and cut into the finial size. The recombination wooden furniture board with the natural wood grain has the grain of natural solid wood, the environment-friendly fast growing wood is used as the raw materials, and therefore the recombination wooden furniture board with the natural wood grain has the advantages of being attractive, large in strength, high in rigidity and low in manufacturing cost.

Owner:安徽郝好建材有限公司

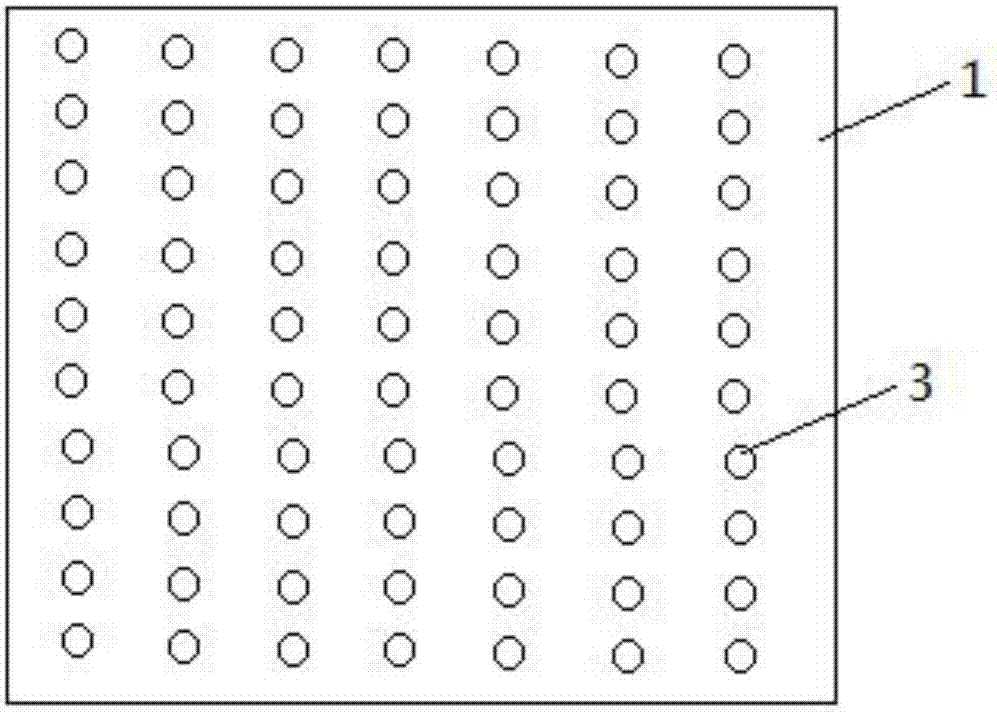

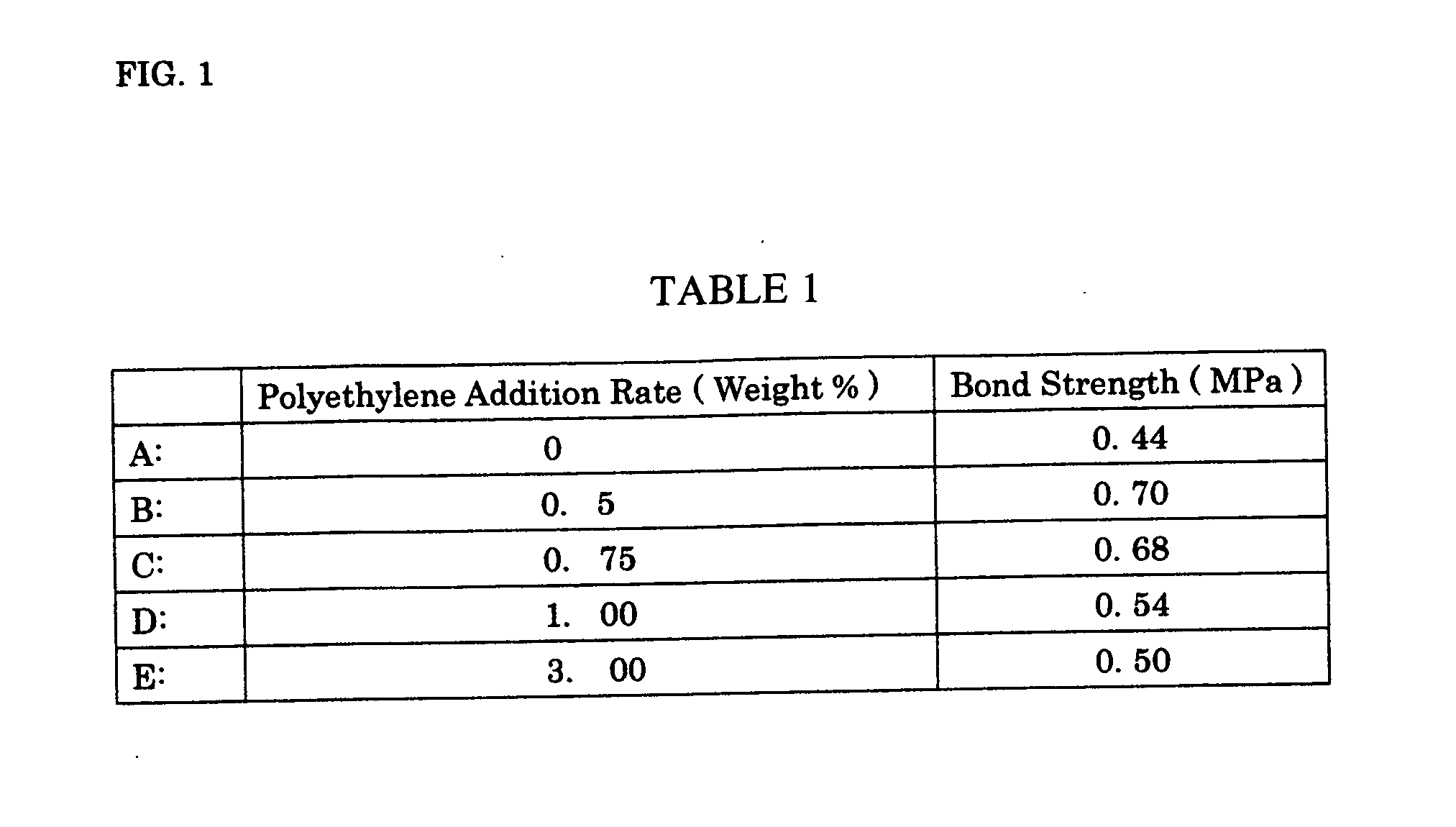

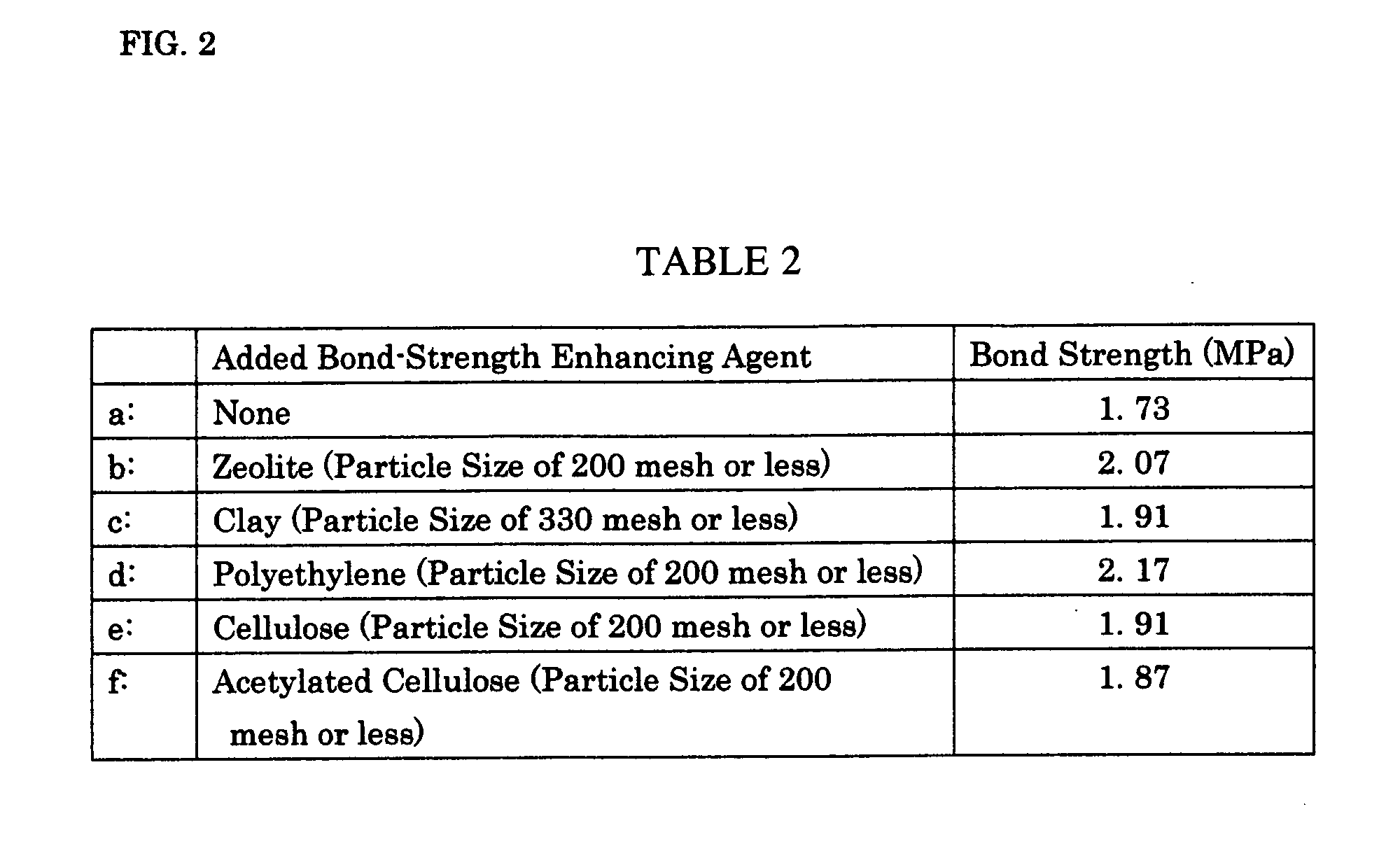

Adhesive compositions containing bond-strength enhancing agent and methods for producing woody board using adhesive compositions

InactiveUS20100326583A1Adhesive processes with adhesive heatingWood working apparatusUltimate tensile strengthBond strength

Improved adhesives with significantly-enhanced bond strength is provided in accordance with the present invention, in particular by adding a bond-strength enhancing agent comprising particles to a binder. Such adhesives can be used in a process of producing a woody board, which results in a substantial reduction in amount of the adhesive used, thus leading to a reduction in overall woody board production costs. Methods for producing a woody board are also provided. The method includes the steps of: coating or spraying an adhesive composition on a wood raw material that is an aggregate composed of wood chips; forming the wood raw material coated or sprayed with the adhesive composition into a specified shape; and heat-pressing the wood raw material formed into the specified shape and again forming the heat-pressed wood raw material into the specified shape. The adhesive composition is obtained by adding a bond-strength enhancing agent composed of particles to an adhesive.

Owner:FORESTRY & FOREST PRODS RES INST

METHOD FOR REMOVING VOLATILE ORGANIC COMPOUNDS (VOCs) FROM AN AIR STREAM

InactiveUS20080014433A1High solubility compoundReduce solubilityGas treatmentTreatment using aerobic processesBiological oxidationPressed wood

A composite wood product is manufactured by heating and pressing wood materials in contact with a mixture of resin and urea. Gases that evolve from the heating and pressing of the wood materials, resin and urea are collected and are passed through a biological oxidation system to remove volatile organic compounds.

Owner:MPC INC

High-starch-content thermosetting artificial board starch adhesive and preparation method thereof

PendingCN111592842ASolve agglomerationLow costWood veneer joiningDomestic articlesAdhesive cementPolymer science

The invention discloses a high-starch-content thermosetting artificial board starch adhesive and a preparation method thereof, and belongs to the technical field of adhesive preparation. Under a gradient heating mode, the phenomena of non-uniform reaction and the like caused by agglomeration with overlarge viscosity formed by a high-starch-proportion mixing system in the heating process are avoided, so that the proportion of starch is remarkably increased. According to the process, the reaction time is greatly shortened, the use amount of petroleum monomers is reduced, complex reaction steps are simplified, most importantly, the proportion of starch accounting for the total solid content is increased to 85% or above, the cost of the starch adhesive is greatly reduced, and green manufacturing of the formaldehyde-free artificial board adhesive is achieved. The adhesive disclosed by the invention is good in water resistance and strong in cohesion, various properties of the manufactured artificial board exceed the standard of class II artificial boards, and the adhesive is suitable for mass production and is widely applied to adhesion of hot-pressed wood decorations, artificial boardsand plywood.

Owner:JIANGNAN UNIV

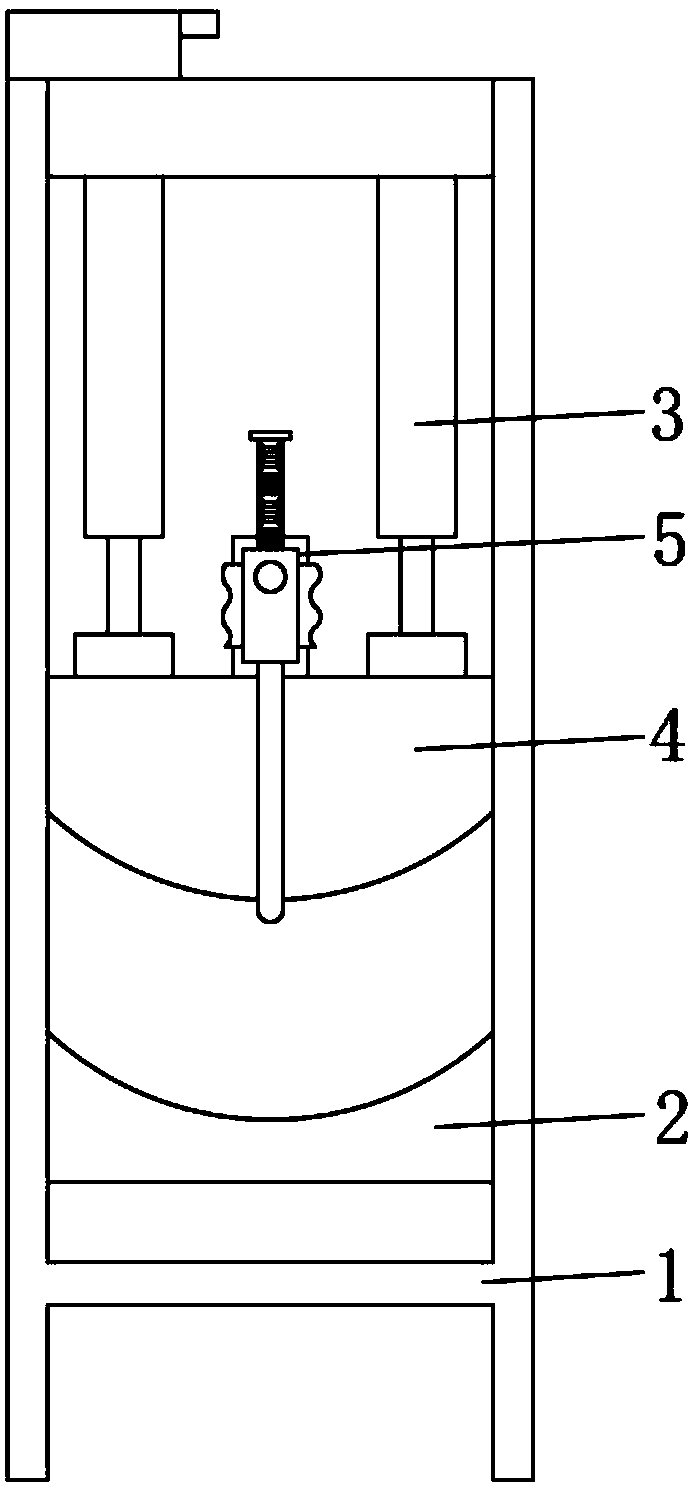

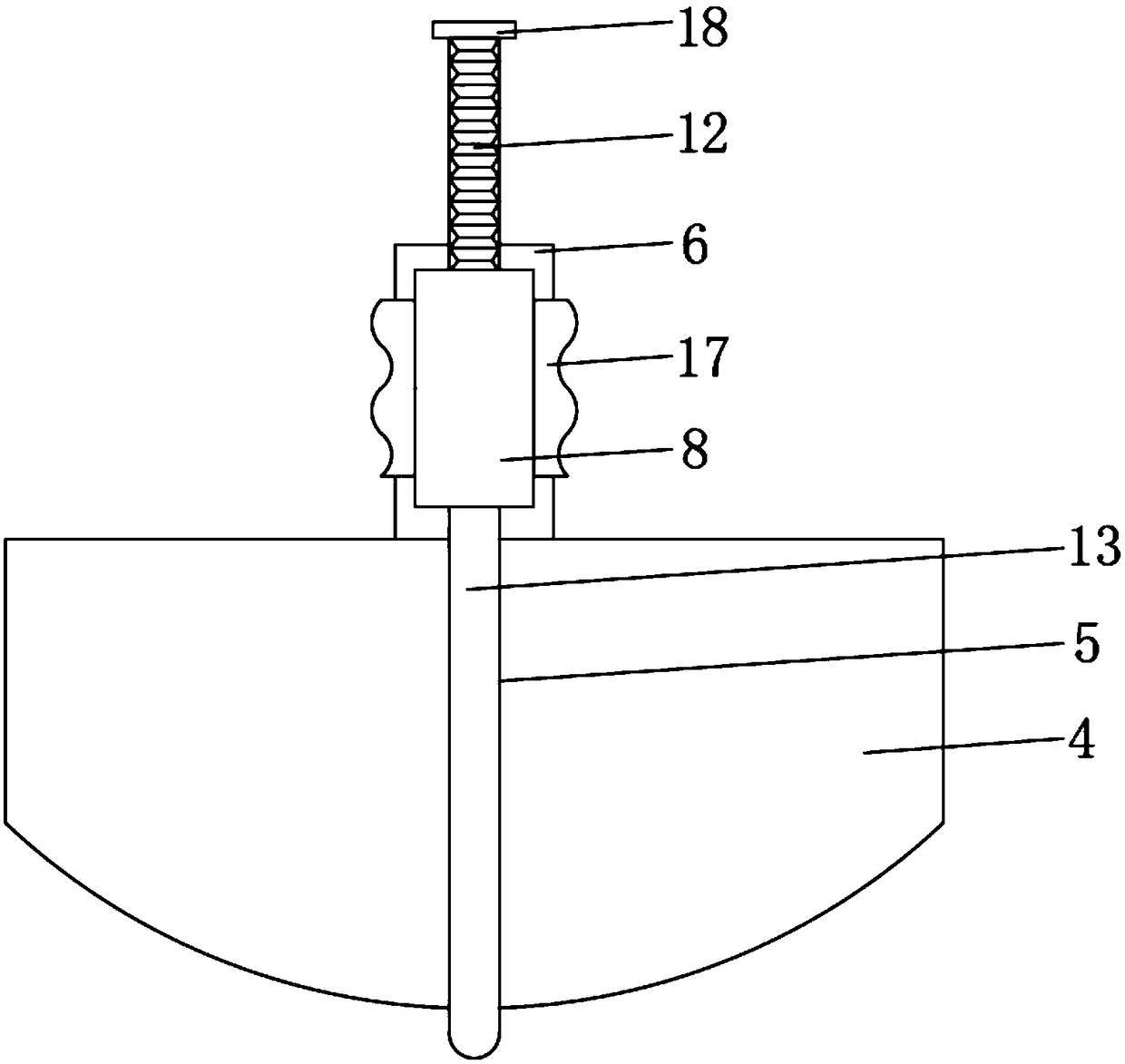

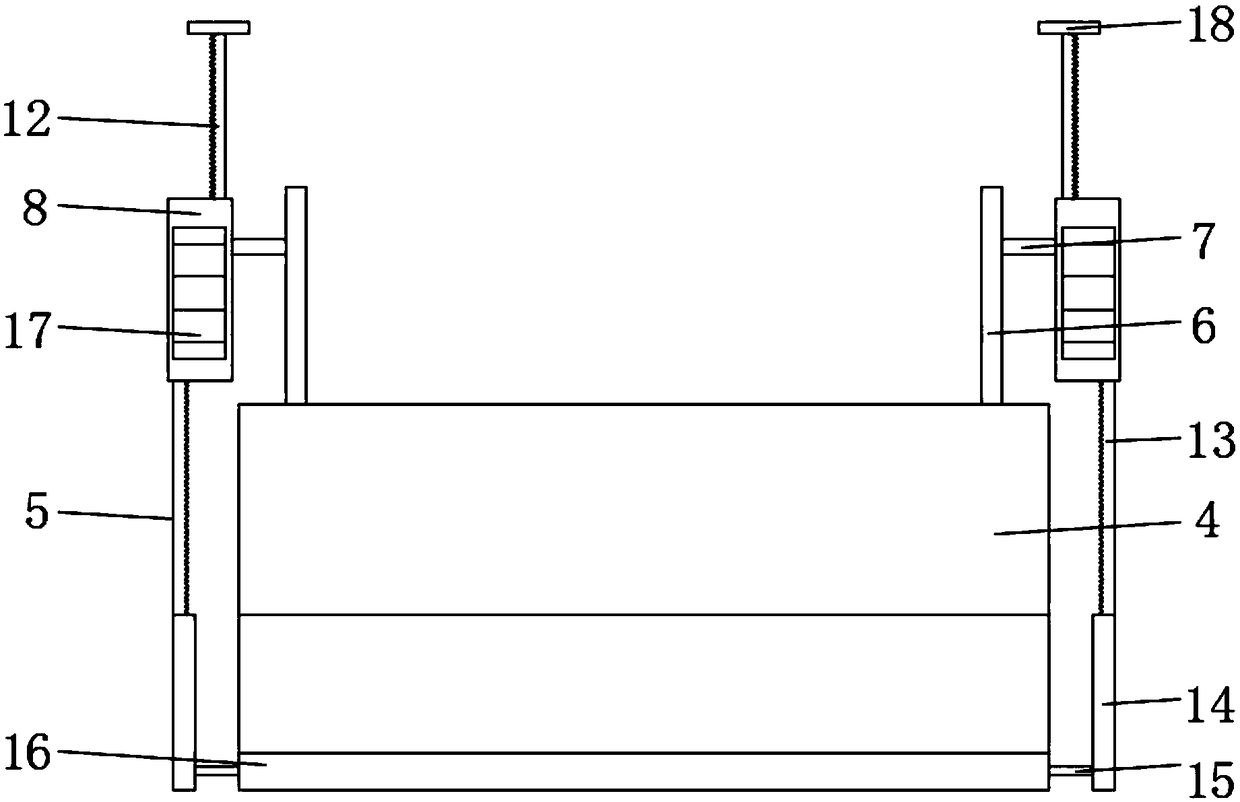

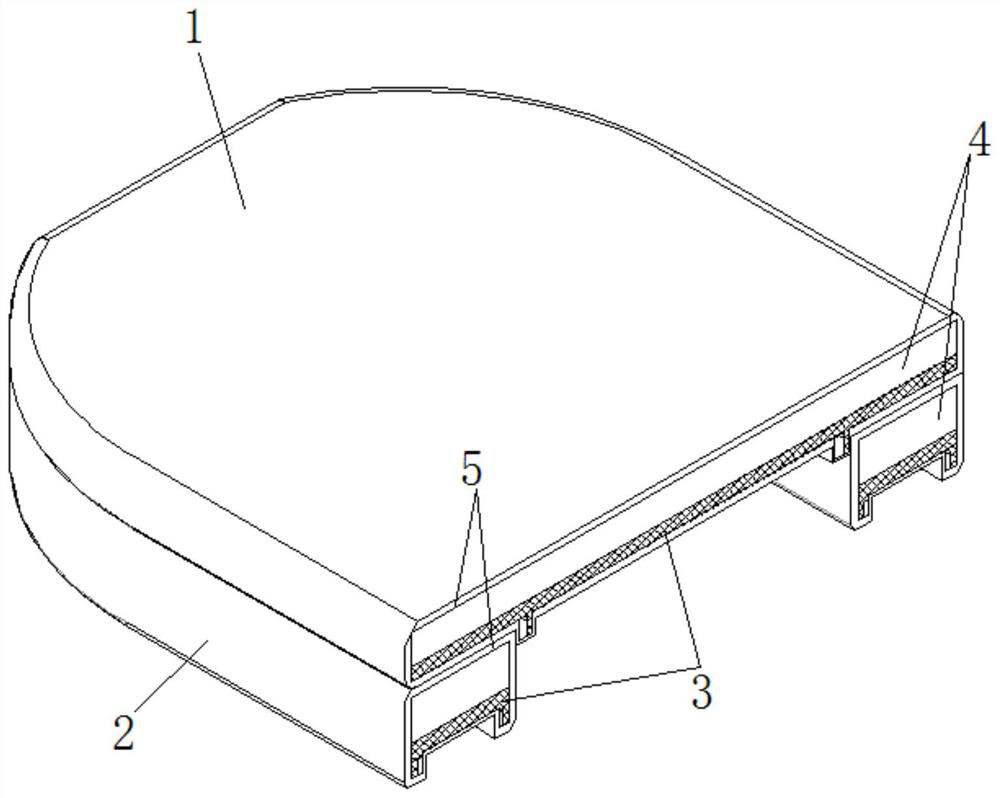

Arc-shaped hot press

InactiveCN109016029AFast and full removalQuality assuranceWood compressionBark-zones/chip/dust/waste removalHydraulic cylinderEngineering

The invention discloses an arc-shaped hot press. The arc-shaped hot press comprises a rack; the inner wall, close to the bottom, on the rack is fixedly connected with a base; the top of the inner wallon the rack is fixedly connected with a hydraulic cylinder; the bottom of the hydraulic cylinder is fixedly connected with a hot pressing head which is an arc-shaped hot pressing head; the lower surface of the hot pressing head is movably connected with the upper surface of the base; the upper surface, close to the two sides, on the hot pressing head is fixedly connected with cleaning devices; and the cleaning devices comprise fixing plates, and the opposite sides, close to the top, on the two fixing plates are fixedly connected with first shafts correspondingly. According to the arc-shaped hot press, through matched using of the structures, the problems that in the actual using process, wood chips are prone to being left on the arc face of the bottom of the hot pressing head after hot pressing is completed, if the wood chips are not removed in time, subsequent hot pressing is prone to being affected, consequently, the surface of a subsequent pressed wood plate is not smooth enough, and the hot pressing quality is lowered are solved.

Owner:洛阳七狼房车装备有限公司

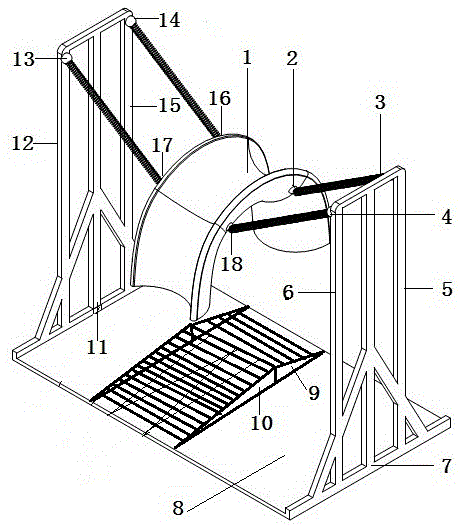

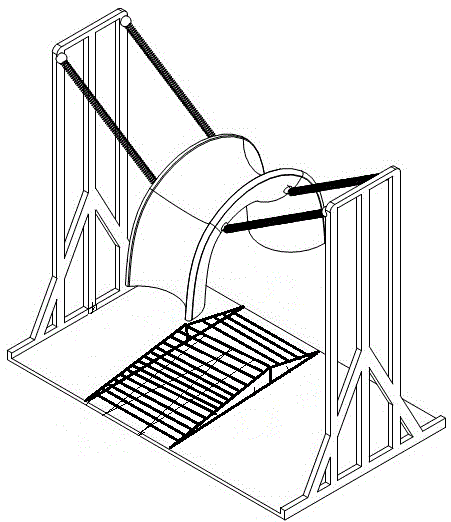

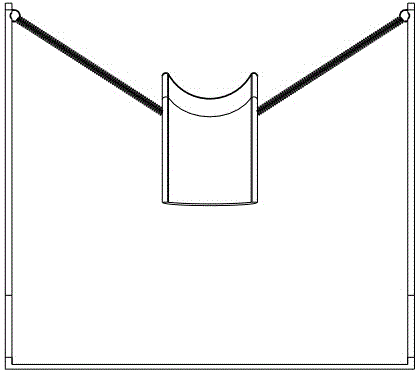

Suspended-type front and back handspring auxiliary training device

InactiveCN105617617AImproving and raising the level of technologyConsolidate and improve the cultivation of empty space meaningStiltsEngineeringMechanical engineering

The invention relates to an auxiliary exercise instrument, in particular to a suspended-type front and back handspring auxiliary training device. The suspended-type front and back handspring auxiliary training device is characterized in that a concave sponge dragging plate (1) is shaped like an n-shaped groove, the internal radius of the groove is 40 centimeters, the distance between the two ends of the lower portion of the groove is 60 centimeters, an internal material of the concave sponge dragging plate (1) is made of pressed wood boards for one time, the thickness of the internal material is 1 centimeter, and a layer of a sponge mat with the thickness of 10 centimeters is manufactured outside the concave sponge dragging plate (1); a steel plate with the length of 130 centimeters, the width of 1 meter and the thickness of 5 millimeters is adopted as a bottom face steel plate (8), a first hand pushing spring board (9) and a second hand pushing spring board (10) are arranged on the bottom face steel plate (8), 20-degree slope-type S-shaped double-bevel hand pushing spring boards are adopted as the first hand pushing spring board (9) and the second hand pushing spring board (10), and front and back handspring auxiliary exercises can be done in front of and at the back of the suspended-type front and back handspring auxiliary training device.

Owner:苟小平

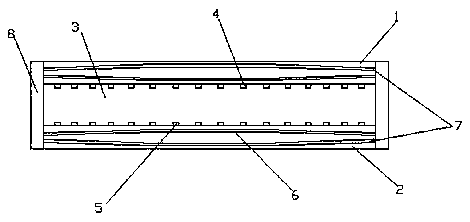

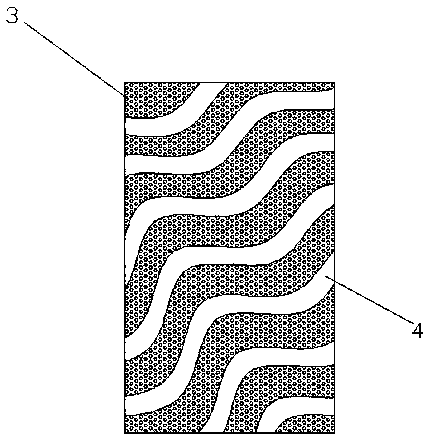

Bamboo-wood combined chopping board

The invention discloses a bamboo-wood combined chopping board. The bamboo-wood combined chopping board includes a chopping board body. The chopping board body includes an upper bamboo board layer anda lower bamboo board layer. A pressed wood board layer is arranged between the upper bamboo board layer and the lower bamboo board layer. The structural points of the bamboo-wood combined chopping board are that the upper surface and the lower surface of the pressed wood board layer are respectively provided with upper stripe grooves and lower stripe grooves, the upper stripe grooves and the lowerstripe grooves are arranged to be wavy and inclined, inclination directions of the upper stripe grooves and the lower stripe grooves are opposite, the lower surface of the upper bamboo board layer and the upper surface of the lower bamboo board layer are provided with frosted layers, and the pressed wood board layer is bonded and compacted with the upper bamboo board layer and the lower bamboo board layer by high-strength waterproof glue. Compared with the prior art, the beneficial effects of the bamboo-wood combined chopping board are that the bamboo-wood combined chopping board is reasonable in design and simple in structure, reduces the production cost without reducing the strength of force, reduces the weight to facilitate transportation, and can make use of discarded wood chips.

Owner:江苏金茂木业有限公司

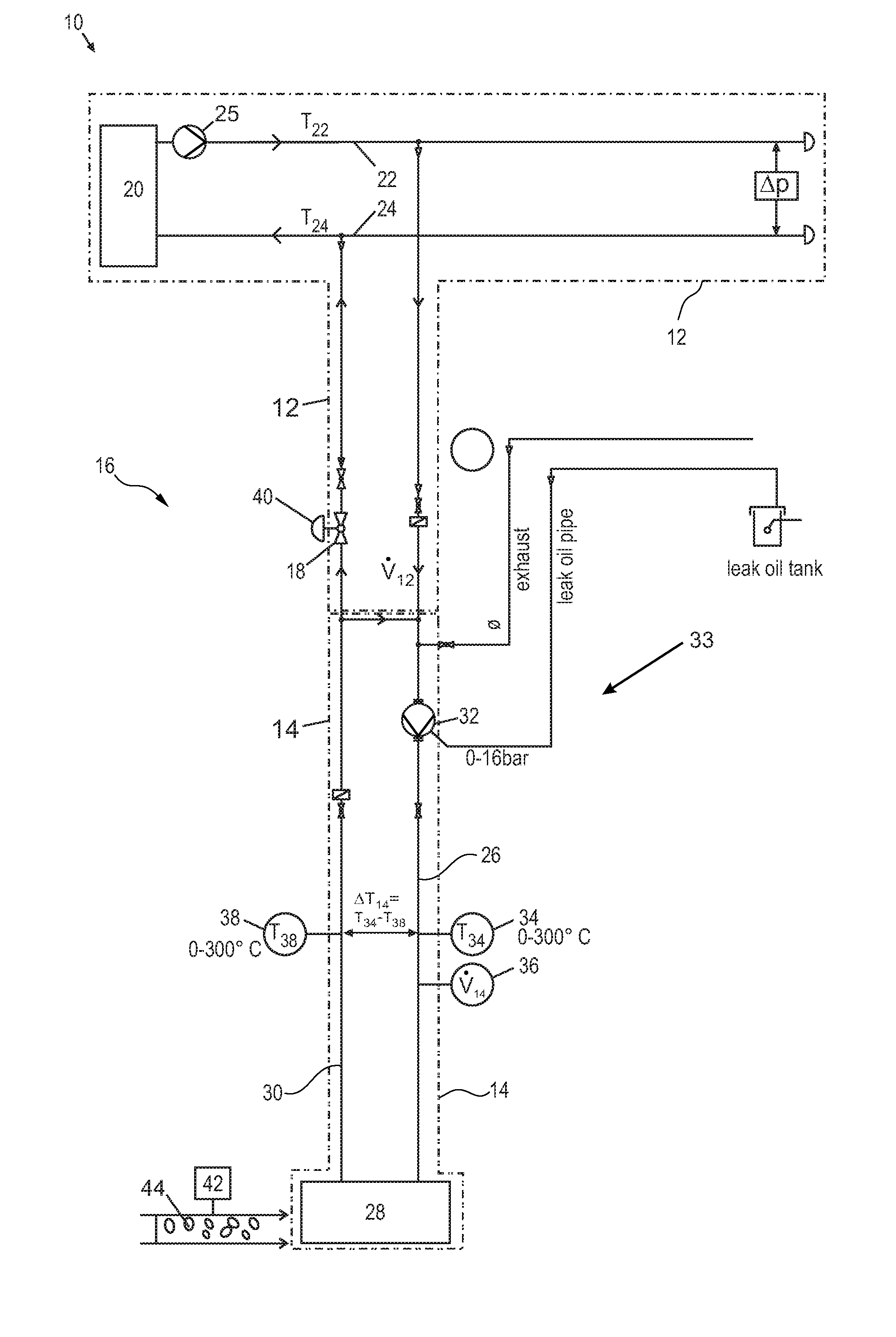

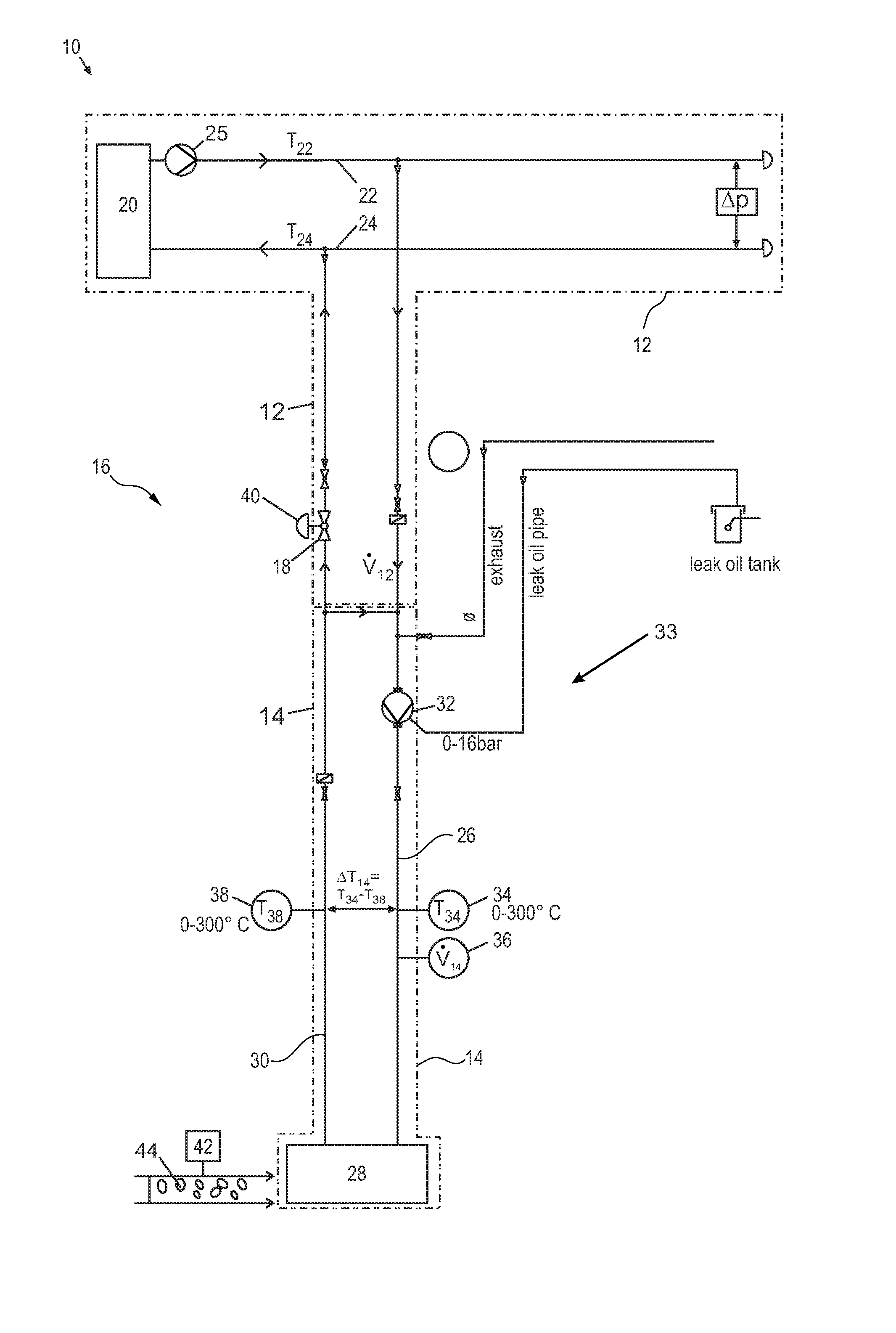

Wood material board hot-pressing device and operation process for such a device

ActiveUS9539738B2Improve productivityWood working apparatusFlat articlesAutomatic controlEngineering

A wood material board hot-pressing system with a primary circuit includes a supply pipe for discharging of hot heat transfer fluid from a heat generator and a return pipe for supplying cooled heat transfer fluid to the heat generator. A secondary circuit features a pressing device for pressing wood material boards. A supply channel supplies heat transfer fluid to the pressing device and a return channel returns cooled heat transfer fluid to the primary circuit. A controlling device contains a control valve and is configured to control a flow of heat transfer fluid from the primary circuit to the secondary circuit. A secondary circulation pump with variable output is set up to circulate the heat transfer fluid in the secondary circuit. The controlling device features a heat output recording device and is configured to automatically control a level of heat output (P) supplied to the pressing device.

Owner:KRONOTEC

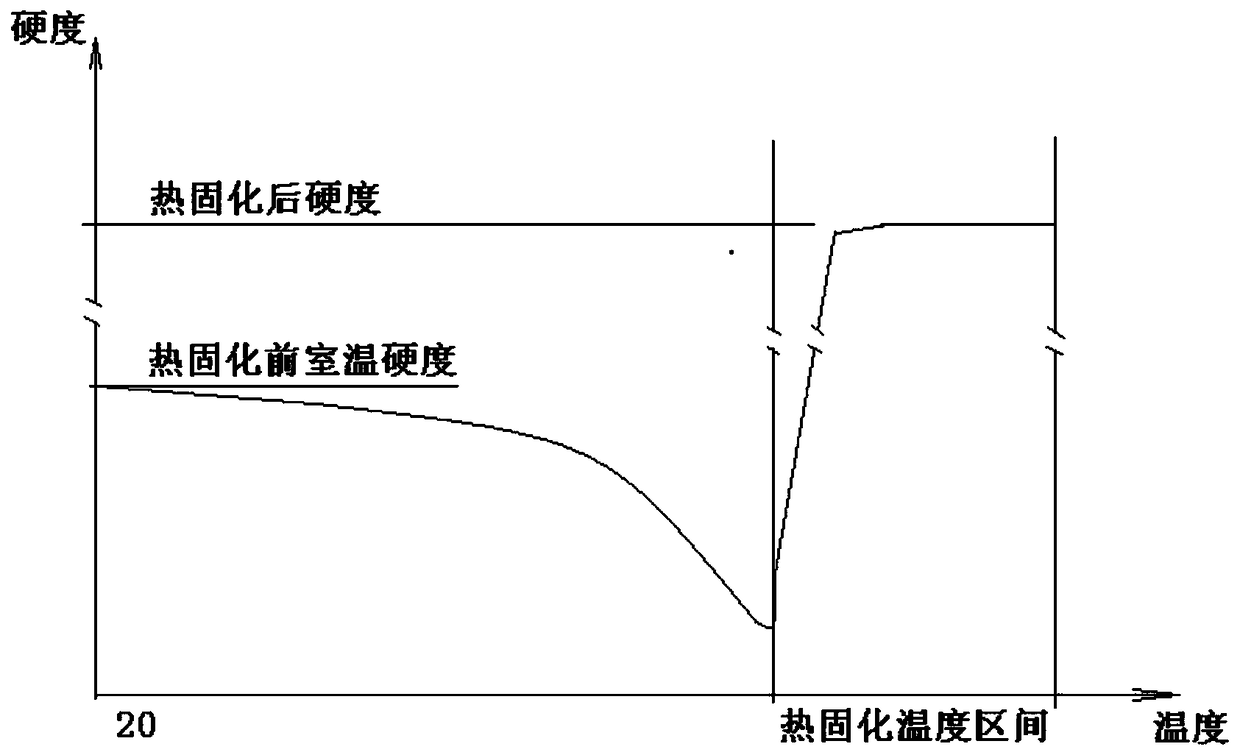

Improved production technology for mold-pressed wood part coated with melamine impregnated abrasion-resistant paper

An improved production technology for a mold-pressed wood part coated with melamine impregnated abrasion-resistant paper is invented in order to optimize product performance. The improved production technology comprises the process that the surface of a to-be-coated layer of a mold-pressed wood part blank is clad with the melamine impregnated abrasion-resistant paper in a mold, and mold-closing, pressurizing and heating are conducted, so that the melamine impregnated abrasion-resistant paper is attached to the surface of the mold-pressed wood part blank and cured. The improved production technology is characterized in that the melamine impregnated abrasion-resistant paper which is gradually soft during low heat and is cured during high heat is adopted, in a mold press with the mold arranged in the mode of up-down mold opening and closing, the mold-pressed wood part blank is arranged in a lower mold cavity, the mold-pressed wood part blank is covered with the melamine impregnated abrasion-resistant paper which is gradually soft during the low heat and is cured during the high heat, the melamine impregnated abrasion-resistant paper which is gradually soft during the low heat and is cured during the high heat is baked and heated firstly till the melamine impregnated abrasion-resistant paper is softened, and then mold-closing, pressurizing and heating are conducted, so that the melamine impregnated abrasion-resistant paper which is gradually soft during the low heat and is cured during the high heat is attached to the upper surface of the mold-pressed wood part blank and cured.

Owner:陈敏芬

Musical instrument fingerboard wooden material and preparation method and acoustic functional body impregnation solution thereof

ActiveCN107283566AControllable moisture contentControllable densityRadiation/waves wood treatmentWood compressionPhosphoric acidSound quality

The invention relates to a preparation method of a musical instrument fingerboard wooden material. The method comprises the following steps that a furan compound with alcoholic hydroxyl groups, boric acid, phosphoric acid and carbon tetrachloride are mixed, triethylamine is dropwise added into the mixture, all the substances react sufficiently, and a solution is obtained; 1,2,3,4-butanetetracarboxylic acid and a carbon nanomaterial are added into the solution, and a needed acoustic functional body impregnation solution is obtained; needed wood is introduced through impregnation, pretreatment is conducted through microwaves with certain power or heating to enable oligomers to be formed in an acoustic functional body, and then hot-pressing treatment is conducted; and finally, the hot-pressed wood is dried in vacuum and then sliced and polished after being cooled, and the musical instrument fingerboard wooden material is obtained. The invention further relates to the musical instrument fingerboard wooden material prepared through the method. According to the musical instrument fingerboard wooden material prepared through the method, the moisture content and density can be controlled, the color difference is uniform, the solid wood texture is strong, the acoustic vibration performance is comparable with that of natural wood, the sound quality is good, and the musical instrument fingerboard wooden material can be used for replacing endangered precious natural wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Hot pressing plate for pressing wood panel

InactiveCN103448111AImprove the effect of hot pressingPlywood pressesVeneer pressesEngineeringMechanical engineering

The invention relates to a hot pressing plate for pressing a wood panel. The hot pressing plate comprises a plate body, wherein a plurality of cavities through which heat conduction oil flows are formed in the plate body; a plurality of grooves are formed in the pressing surface of the plate body and are narrow grooves; water absorption cotton is arranged in each groove. Water on the contact surface between the hot pressing plate and the wood panel is timely drained, the hot-pressing effect is enhanced, and the surface of the hot-pressed wood panel is smoothened.

Owner:KUNSHAN SHUOHUA MOLD PLATE

Preparation process of environment-friendly soft seat toilet lid

InactiveCN113305972AConvenient healthy home choiceComfortable seatingWood working apparatusBathroom coversEngineeringMechanical engineering

The invention relates to the technical field of environment-friendly soft seat toilet lids, in particular to a preparation process of an environment-friendly soft seat toilet lid. The preparation process comprises the following steps that S1, a plate core is selected for a toilet seat and a toilet lid plate to be pressed into the shapes of the toilet seat and the toilet lid plate through a wood flour molding press, or a PP plate core is selected; S2, the pressed wood plate core is polished and ground; S3, coating materials with the shapes of the toilet seat and the toilet lid plate are selected, the coating materials are horizontally cut open, and the plate core is arranged between the upper-layer coating material and the lower-layer coating material; and S4, the wrapping material is wrapped and pressed on the outer side of the wrapping material through a high-frequency machine, the plate core is used as a base plate, the plate core is wrapped by the soft wrapping materials which are sponge or sponge and pearl wool, the plate core is very comfortable, TPU is wrapped on the outer layer, therefore the toilet lid plate and the toilet seat are very environmentally friendly and safe and do not have pungent smell, and healthy home selection of a user is facilitated.

Owner:DONGGUAN YIJIA TOILET & BATHROOM TECH CO LTD

Process for producing dark polar wood imitating precious wood

ActiveCN105108858AProcess environmental protectionDeep colorWood compressionPressure impregnationShielding gasSuperheated steam

The invention discloses a process for producing dark polar wood imitating precious wood. The method comprises the following steps: stacking wood beams; transferring the wood beams into a vacuum processing cylinder; impregnating with boric acid and acetic acid solutions as processing solutions by pressurizing in vacuum; drying the wood beams subjected to vacuum-based impregnating until the moisture content is 15-22%, and then thermally pressing; thermally modifying the thermally-pressed wood beams with 0.1-0.2% of trehalose solution as a superheated steam heat-transfer medium and protective gas by the three-step method; then stopping heating; cooling; spraying steam to condition the humidity until the moisture content of the wood beams is 8 to 12%; moving out the wood beams. The polar wood produced by the process is high in transparence and saturation, and colorful, nice and high end in sense experience, and the hardness is high. The dark polar wood imitating precious wood is a new variety of modified fast-growing wood with potential market.

Owner:邳州市瑜哲木业有限公司

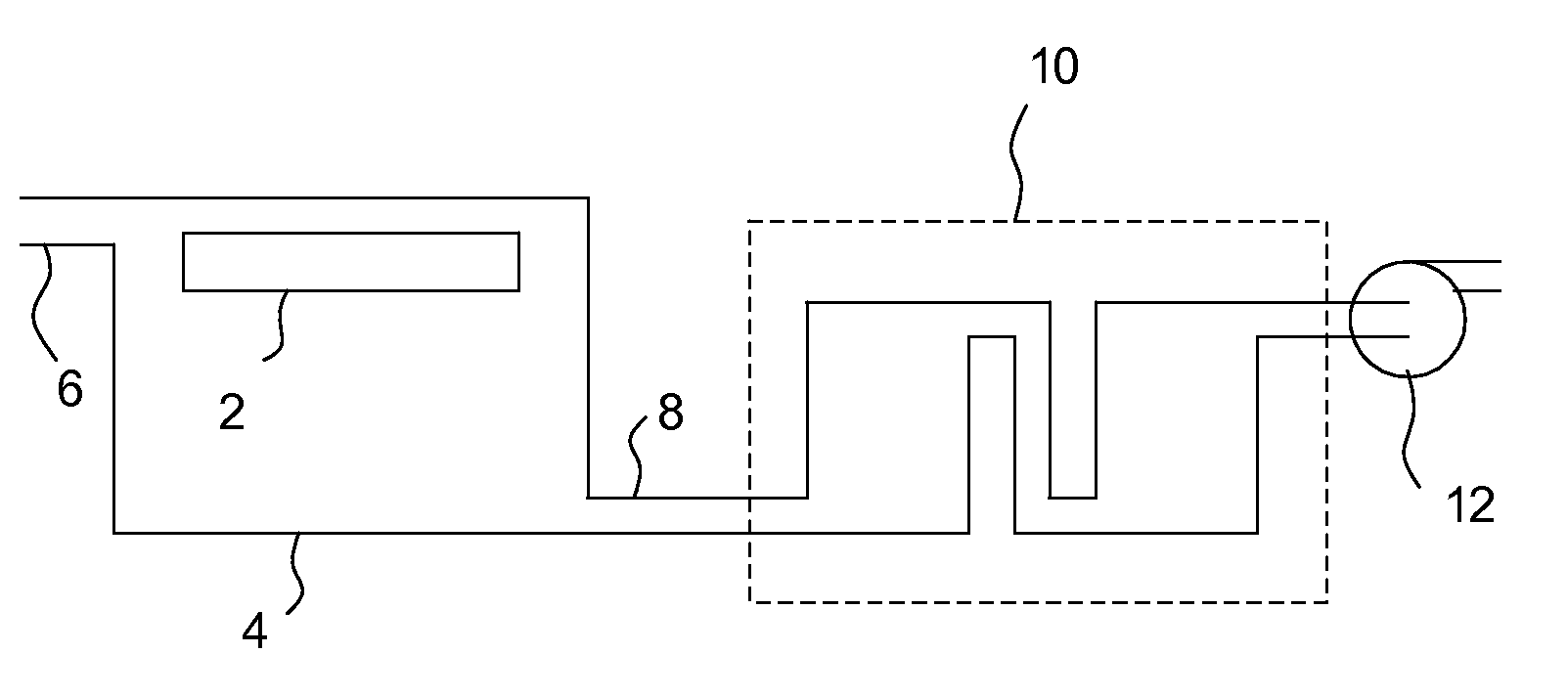

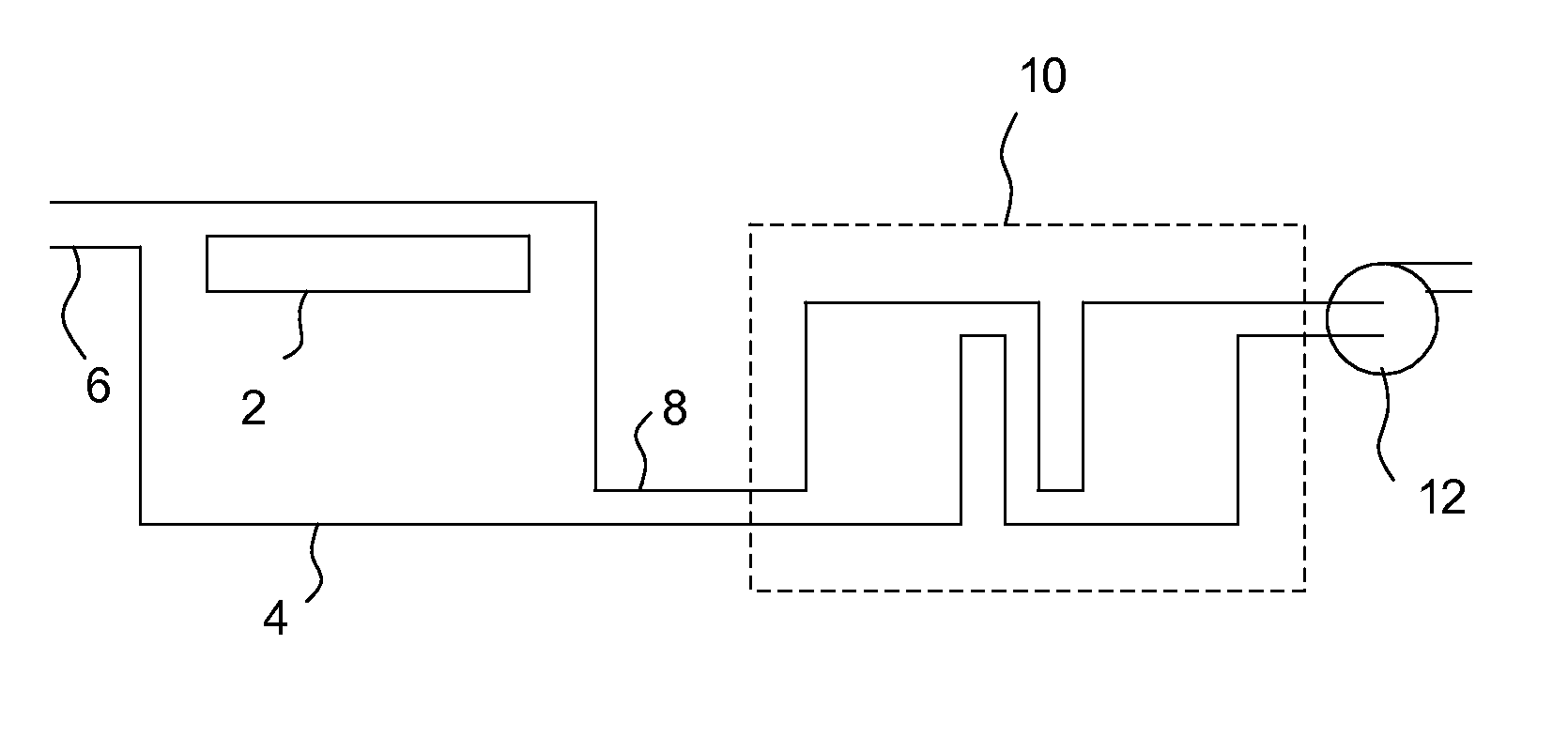

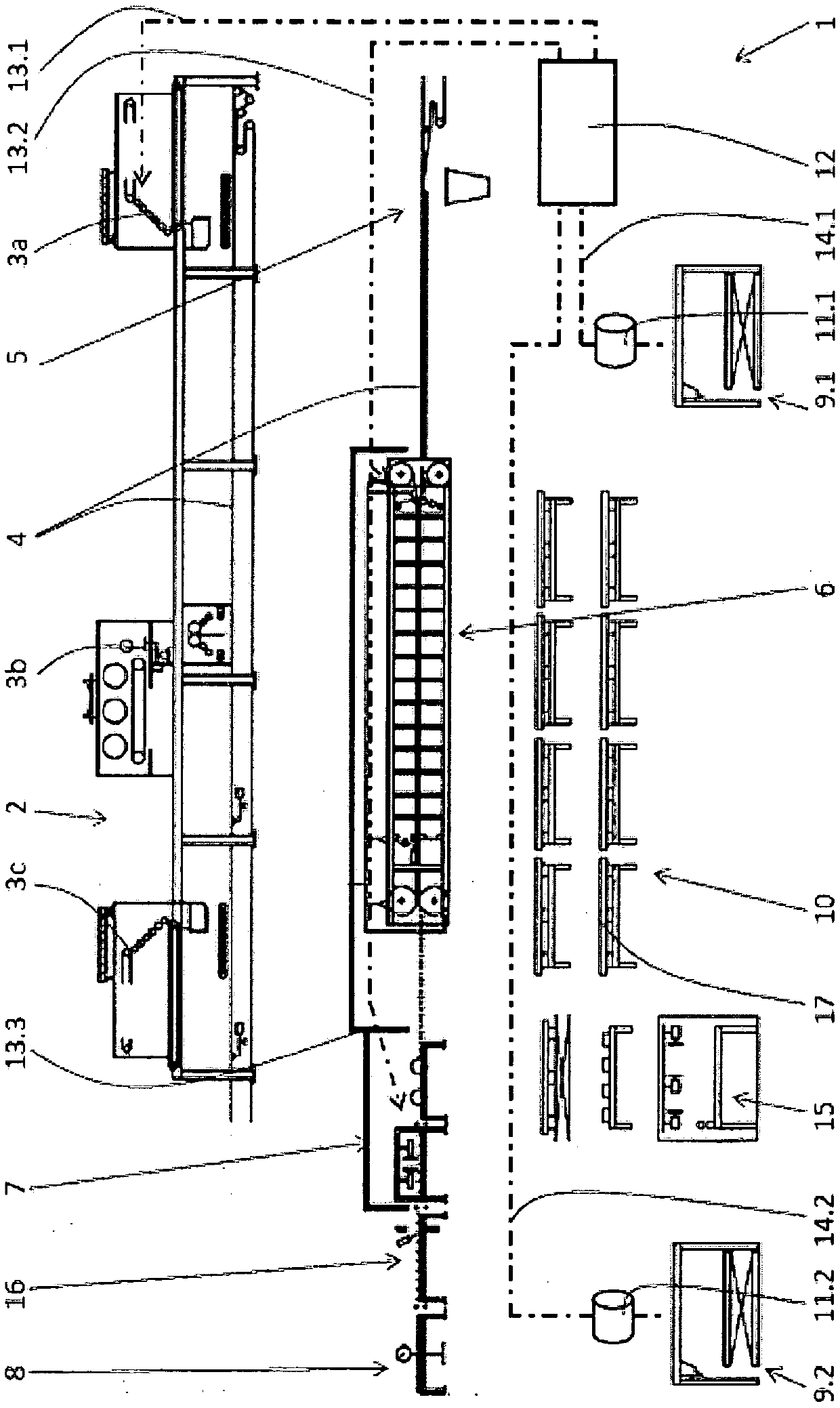

Method for manufacturing wood panels

ActiveCN107618090AIncrease investmentImprove regulation potentialWood working apparatusFlat articlesEngineeringConveyor belt

The invention relates to a method for manufacturing wood panels, in which the following stations are passed through: a metering-adjustable spreading device (2) for placing a wood material on a conveyor belt (4) to form a wood mat; at least one continuous or discontinuous press (6) to press the wood mat with pressurization; at least one separating device (7) for separating the pressed wood mat intoindividual, successive panels; a measuring station (9.1) for determining geometric data of the panels; and a cooling or curing warehouse (10) in which the panels are stored in predetermined atmospheric conditions before being transported to a finishing station (15) or a delivery place. In order to reduce the effort in the finishing of the production of wood panels and to maintain the production accuracy in format changes, it is provided that at least one further measurement of geometric dimensions of the panels is performed after the curing process in the cooling or curing warehouse (10) andthat by means of the difference of the measured values, an adjustment value for the metering-adjustable spreading device (2) and / or a setting of the press (6) and / or a setting of the separating device(7) is determined and set.

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

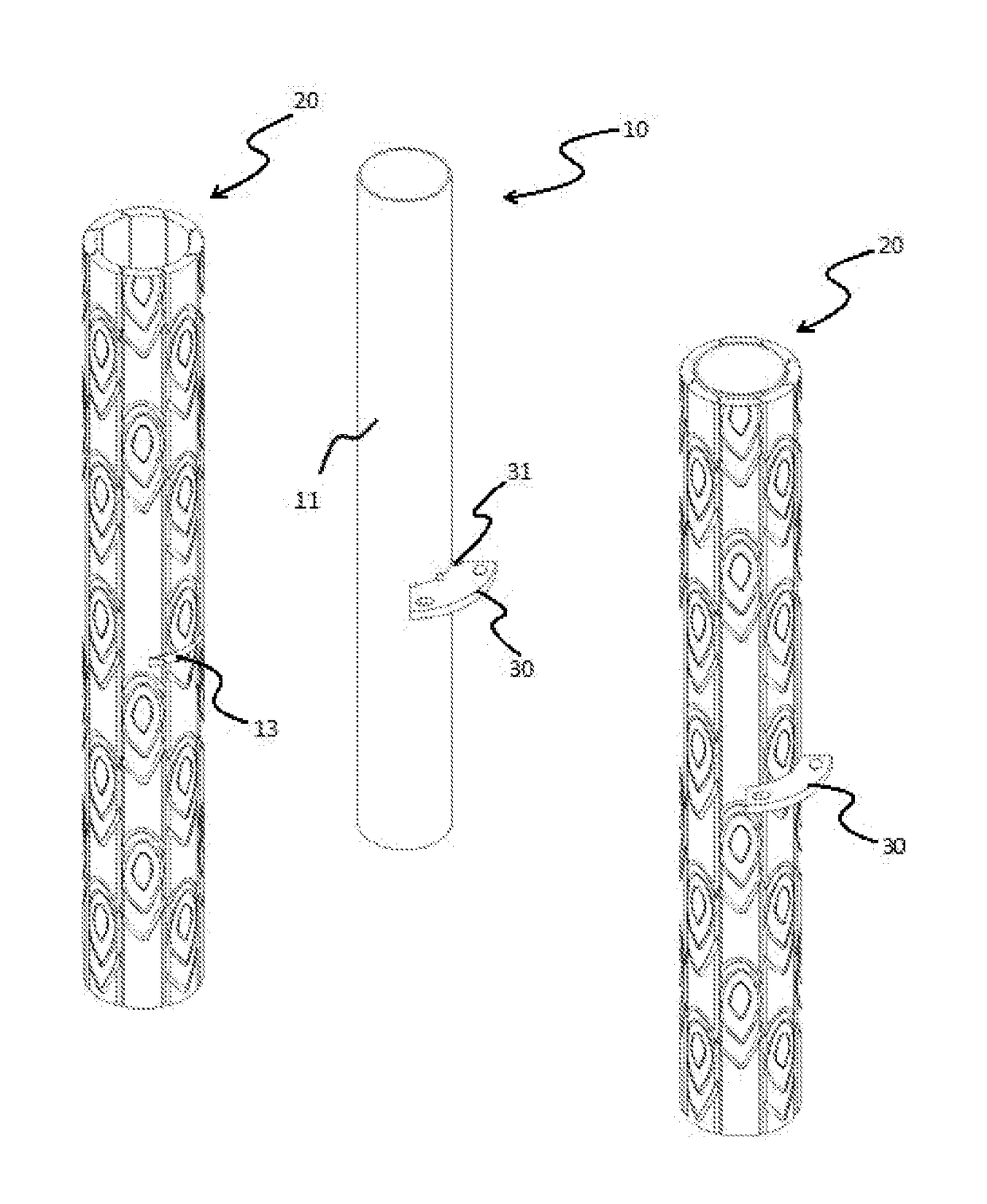

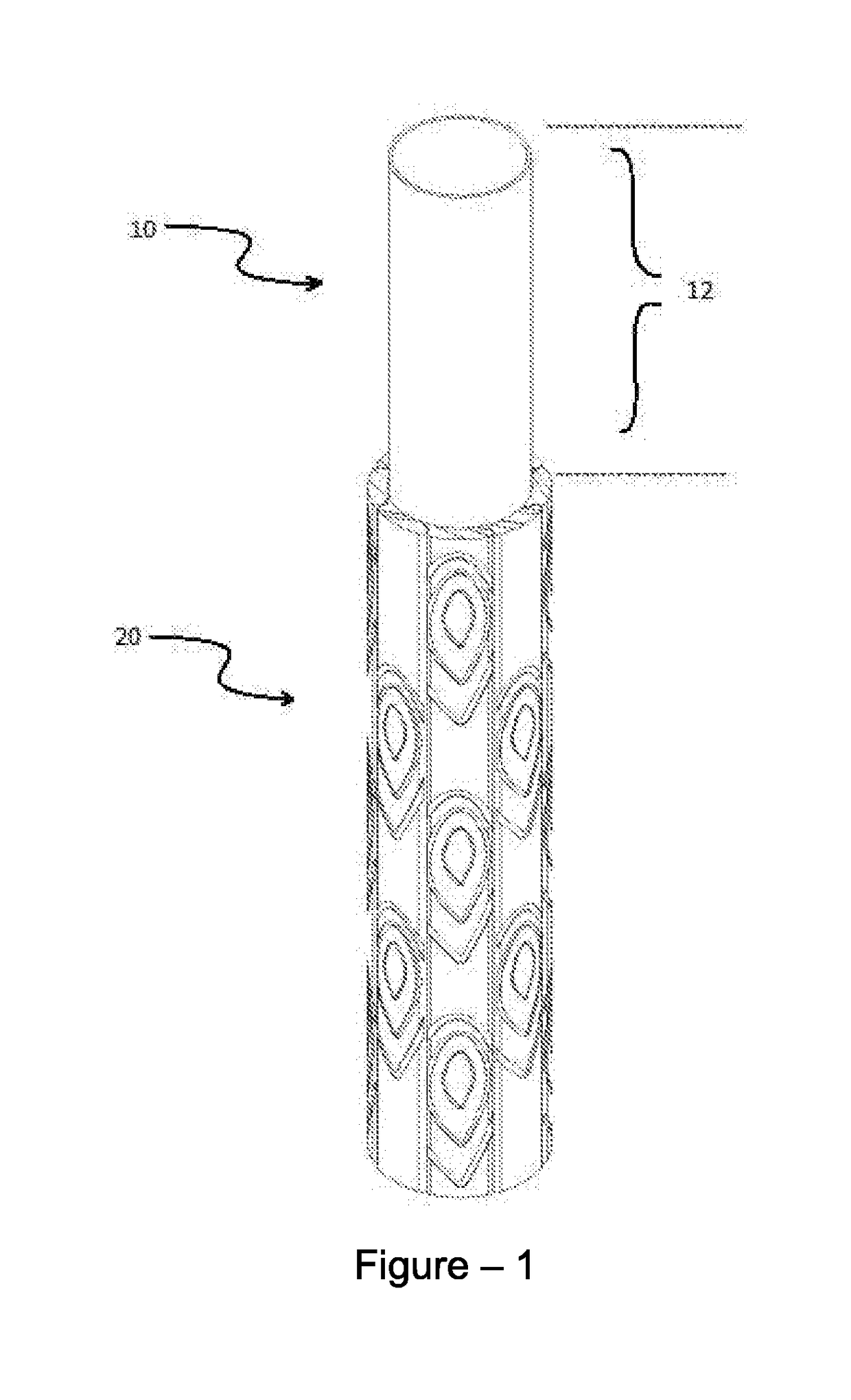

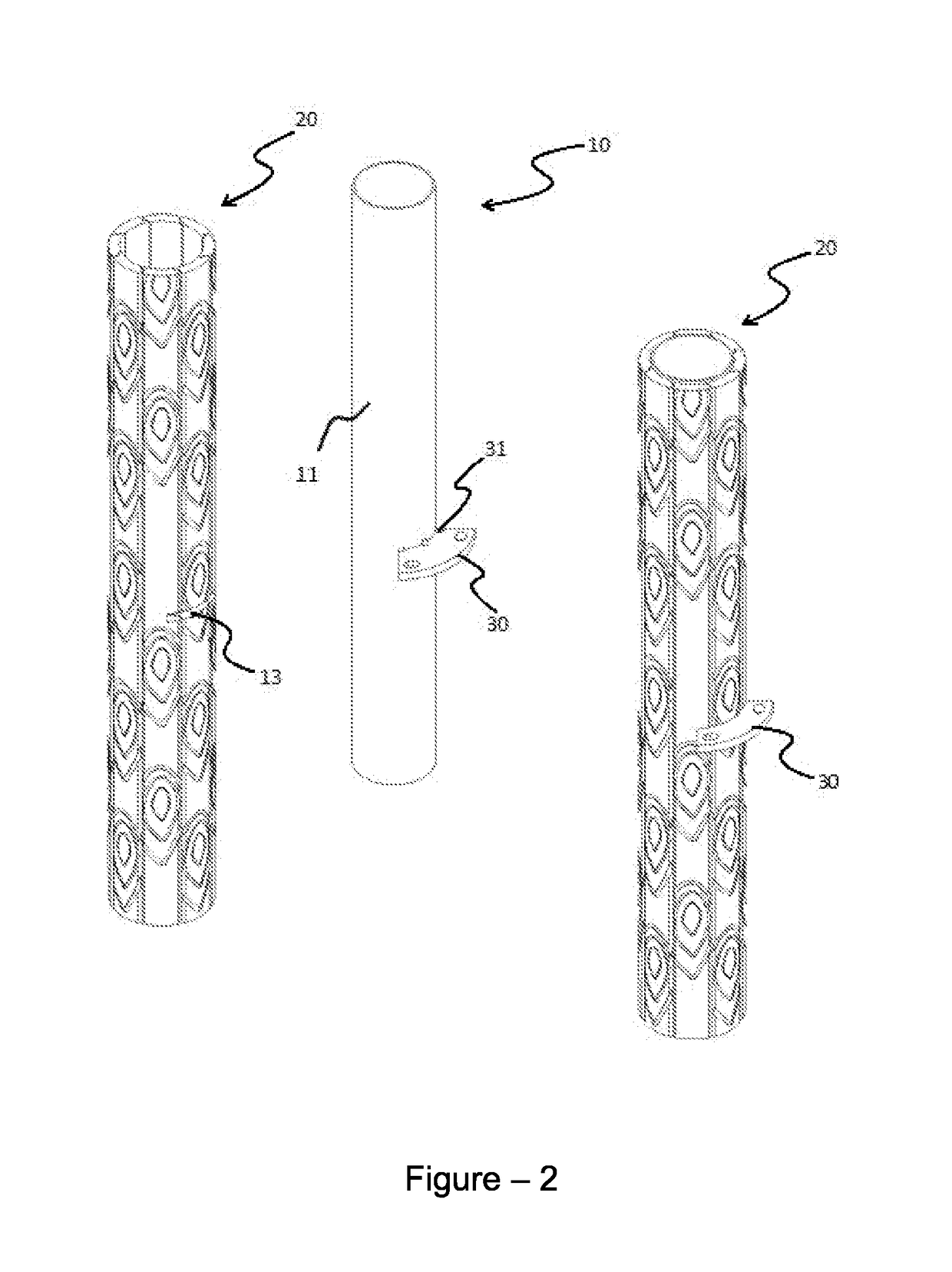

Reinforced covering material for bearing members of play structures

The present invention relates to siding / covering materials (20) which are made of composite materials to be covered over metal posts (10) or horizontal bearing members (50) with angular or circular cross-section and which comprise reinforcing cells (25). Said composite material is composed of materials such as wood, plastics or a derivative thereof, pressed wood and paper, pressed plastics etc.

Owner:CEMER KENT EKIPMANLARI SANAYI VE TICARET ANONIM SIRKETI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com