Wooden relief structure and manufacturing method

A manufacturing method and a relief technology, applied in the field of wood relief, can solve the problems of easy cracking of the wood relief, high cost of wood relief, waste of solid wood resources, etc., and achieve the effects of saving resources, low cost, and processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

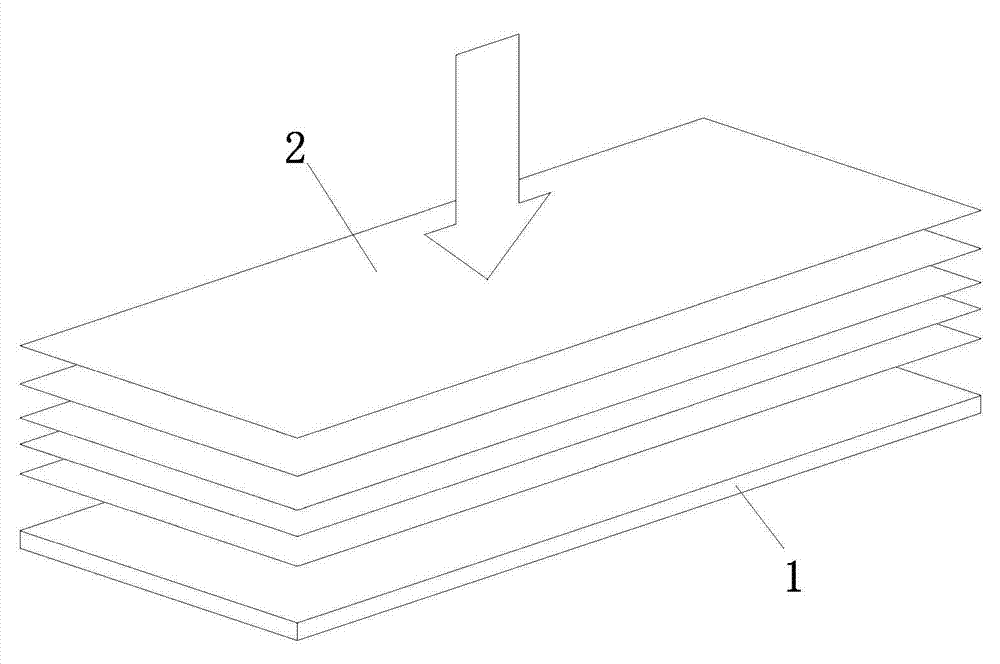

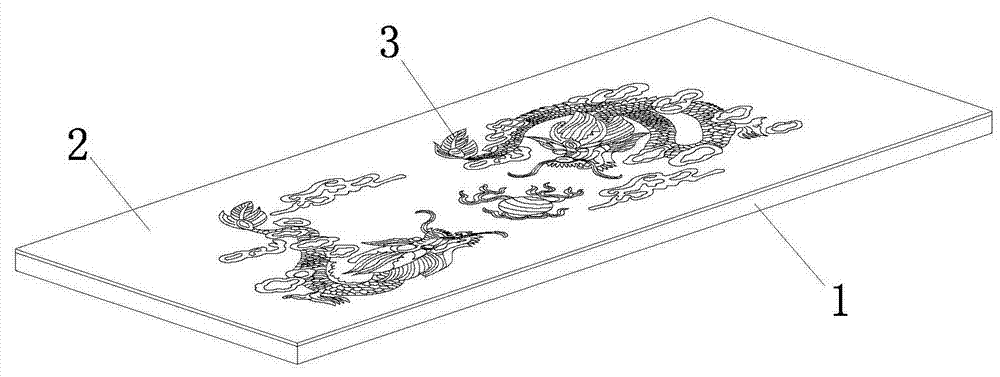

[0017] The invention discloses a wooden relief structure, and the problem to be solved is that the manufacturing cost of the whole wood relief is high, and the spliced wood is easy to crack. The solution is to replace the whole solid wood with stacked veneers to reduce the finished product and improve the product quality. see image 3 , which includes: a base plate 1, a relief body 3 fixed on the surface of the base plate; the relief body is composed of multiple layers of veneer 2 stacked.

[0018] The multiple layers of veneer 2 are veneers with similar color and luster, and the textures of all the veneers are arranged in a uniform direction. The effect of relief color and texture produced in this way is comparable to that of solid wood. The selection of veneer is relatively extensive, and mahogany, boxwood, rosewood, sandalwood, walnut, cypress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com