Thermosetting artificial board starch adhesive and preparation method thereof

A starch adhesive and wood-based panel technology, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems of long reaction time and high requirements for reaction control, so as to save time in the process, shorten the reaction time, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

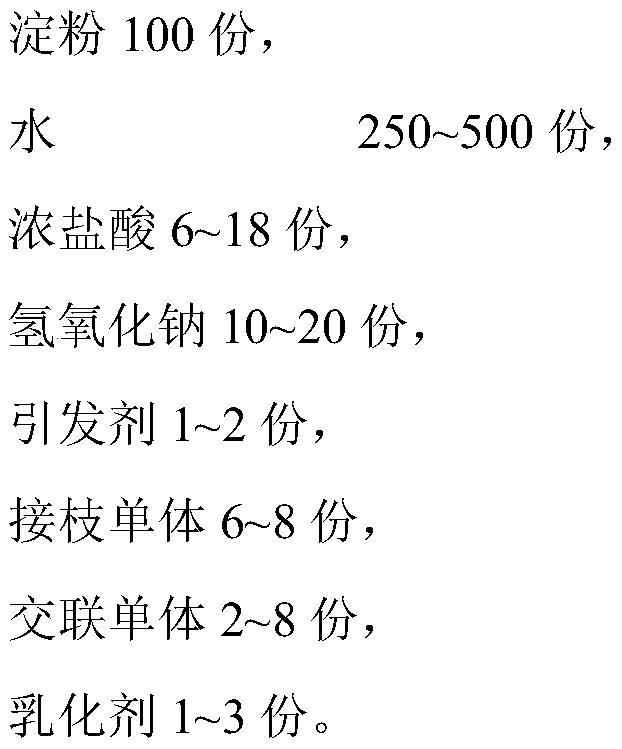

[0040] Formula (mass / g):

[0041]

[0042]

[0043] Process flow:

[0044] (1) Starch and water are made into starch milk with a mass ratio of 20% concentration based on starch dry basis, and stirred evenly;

[0045] (2) Adjust the temperature of the starch milk to 50°C, add 0.5mol / L hydrochloric acid, acidify for 1.5h, and then adjust the pH to 4;

[0046] (3) Adjust the temperature of the starch milk after acid hydrolysis to 80°C, and pregelatinize for 20 minutes;

[0047] (4) Take the initiator, grafting monomer and emulsifier accounting for 10% of the total addition amount to make a seed emulsion, add it to the reaction system after pre-gelatinization in step (3); cool down to 70 ° C, and the initial grafting is completed in 5 minutes After that, immediately add the remaining initiator for further grafting. After 20 minutes, add the cross-linking monomer solution with a mass concentration of 5% dropwise at a constant speed within 3 hours, and add 20 g of an initiat...

Embodiment 2

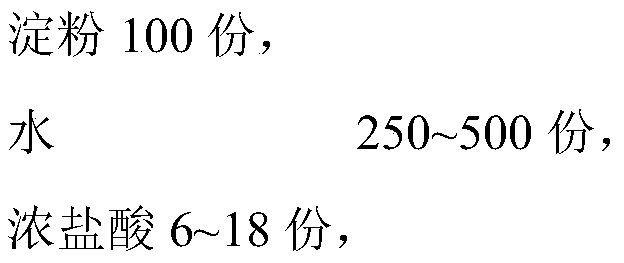

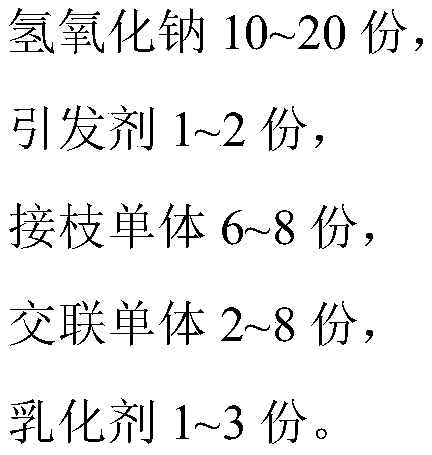

[0051] Formula (mass / g):

[0052]

[0053] Process flow:

[0054] (1) Starch and water are made into starch milk with a mass ratio of 20% concentration on a starch dry basis, and stirred evenly;

[0055] (2) Adjust the temperature to 50°C, add 0.5mol / L hydrochloric acid, acidify for 1.5h, and then adjust the pH to 4;

[0056] (3) Adjust the temperature of the acid-hydrolyzed starch milk to 90° C., and pregelatinize it for 20 minutes;

[0057] (4) Take the initiator, grafting monomer and emulsifier accounting for 10% of the total addition amount to make a seed emulsion, add it to the reaction system after pre-gelatinization in step (3); cool down to 70 ° C, and the initial grafting is completed in 5 minutes Afterwards, the remaining initiator was added immediately for further grafting, and after 20 minutes, a cross-linking monomer solution with a mass concentration of 5% was added dropwise at a constant speed within 3 hours. As a result, it was found during the experiment ...

Embodiment 3

[0061] Formula (mass / g):

[0062]

[0063] Process flow:

[0064] (1) Starch and water are made into starch milk with a mass ratio of 20% concentration based on starch dry basis, and stirred evenly;

[0065] (2) Adjust the temperature of the starch milk to 50°C, add 0.5mol / L hydrochloric acid, acidify for 1.5h, and then adjust the pH to 4;

[0066] (3) Adjust the temperature of the starch milk after acid hydrolysis to 80°C, and pregelatinize for 20 minutes;

[0067] (4) Take the initiator, grafting monomer and emulsifier accounting for 10% of the total addition amount to make a seed emulsion, add it to the reaction system after pre-gelatinization in step (3); cool down to 70 ° C, and the initial grafting is completed in 5 minutes After that, immediately add the remaining initiator for further grafting. After 20 minutes, add the cross-linking monomer solution with a mass concentration of 5% dropwise at a constant speed within 3 hours, and add 20 g of an initiator with a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com