Patents

Literature

86results about How to "Control response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for directionally controlling the reaction of LiH and AlCl3 with catalyst to synthesize A1H3

The invention provides a method for directionally controlling the reaction of LiH and AlCl3 with a catalyst to synthesize A1H3, which relates to an AlH3 synthesis method. The technical problems that AlH3 made by the traditional AlH3 making method is unstable and requires high cost are solved. The method comprises the following steps of: 1. uniformly mixing anhydrous AlCl3, tertiary amine and an anhydrous aromatic solvent under anhydrous and anaerobic conditions to obtain a solution A; 2. uniformly mixing LiH and the anhydrous aromatic solvent under anhydrous and anaerobic conditions to obtaina solution B; 3. adding the solution B to the solution A, heating under anhydrous and anaerobic conditions for reaction, then standing and filtering to obtain filtrate; 4. removing the solvent in thefiltrate to obtain powder; and 5. vacuum drying to obtain AlH3. The method has low cost and is suitable for industrial production, and products produced with the method are stable. Made AlH3 can be used for making a high-energy solid propellant.

Owner:HARBIN INST OF TECH

Unsaturated polyester resin with high cohesive force and high wettability and preparation method for unsaturated polyester resin

The invention discloses an unsaturated polyester resin with high cohesive force and high wettability and a preparation method for the unsaturated polyester resin, and belongs to the technical field of unsaturated polyester resins. The unsaturated polyester resin with high cohesive force and high wettability comprises the following components in percentage by weight: 28 to 33 percent of dibasic alcohol, 30 to 40 percent of dibasic acid or acid anhydride, 30 to 35 percent of diluent and 2 to 4 percent of glycerol. The unsaturated polyester resin obtained by the process according to the formula has high wettability and cohesive force, and has a good and quick effect of wetting glass fiber; and the cohesive force is subject to pressure and shear force tests, is increased by over 30 percent compared with an ordinary o-phthalate resin, and is over 20MPa. When quartz stone boards are produced, the average using amount of the resin of each board can be reduced from 25KG to 23KG; and the caking is difficult in the stirring process of the resin and quartz sand, so that the spreading and pressing are easier during production of manufacturers, the phenomena of deformation, cracking and the like which appear in the convention manufacturers can also be further improved, and the thixotropic property of the resin and gaseous silicon can be greatly improved additionally.

Owner:浙江天和树脂有限公司 +1

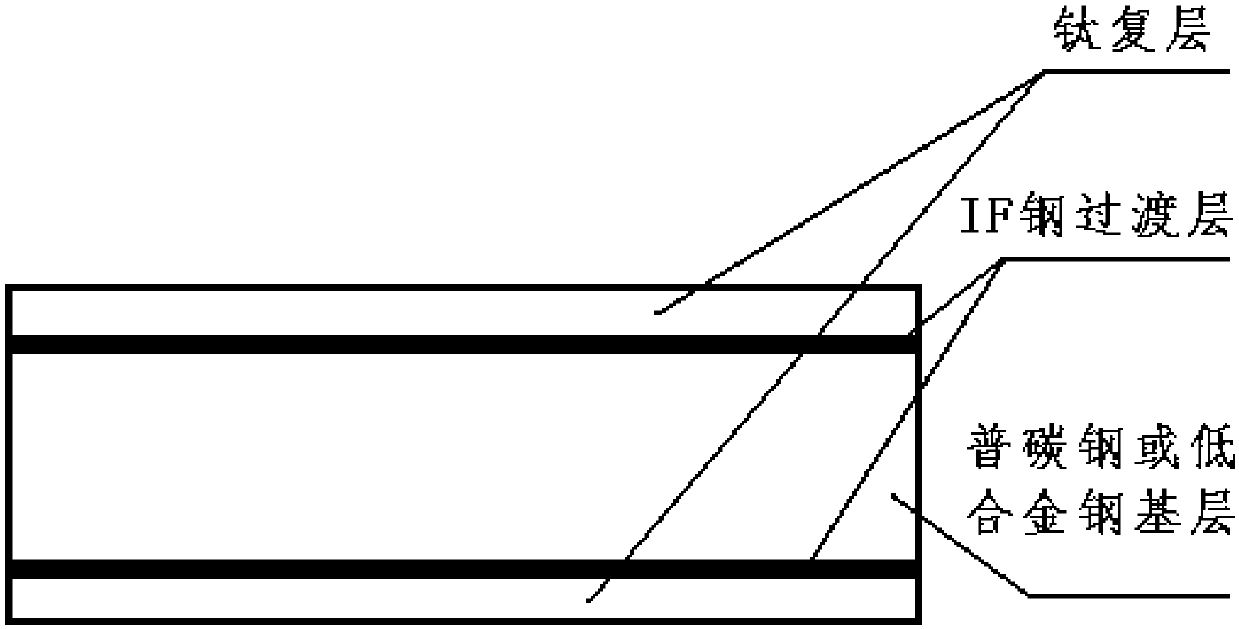

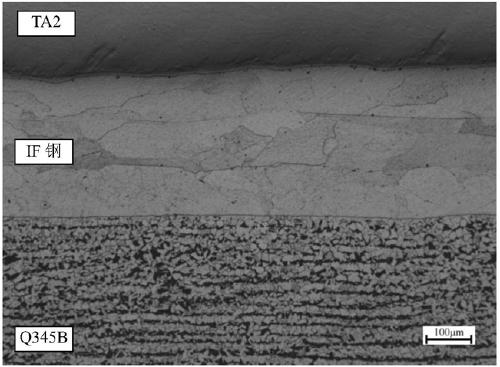

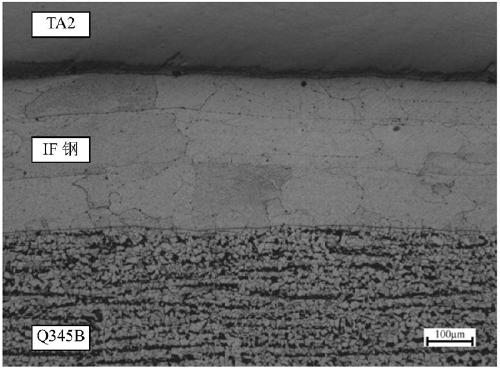

Double-sided titanium steel composite plate taking IF steel as transition layer and high-temperature preparation method thereof

ActiveCN109695000AImprove distributionImprove and enhance bond qualityMetal layered productsComposite plateMechanical property

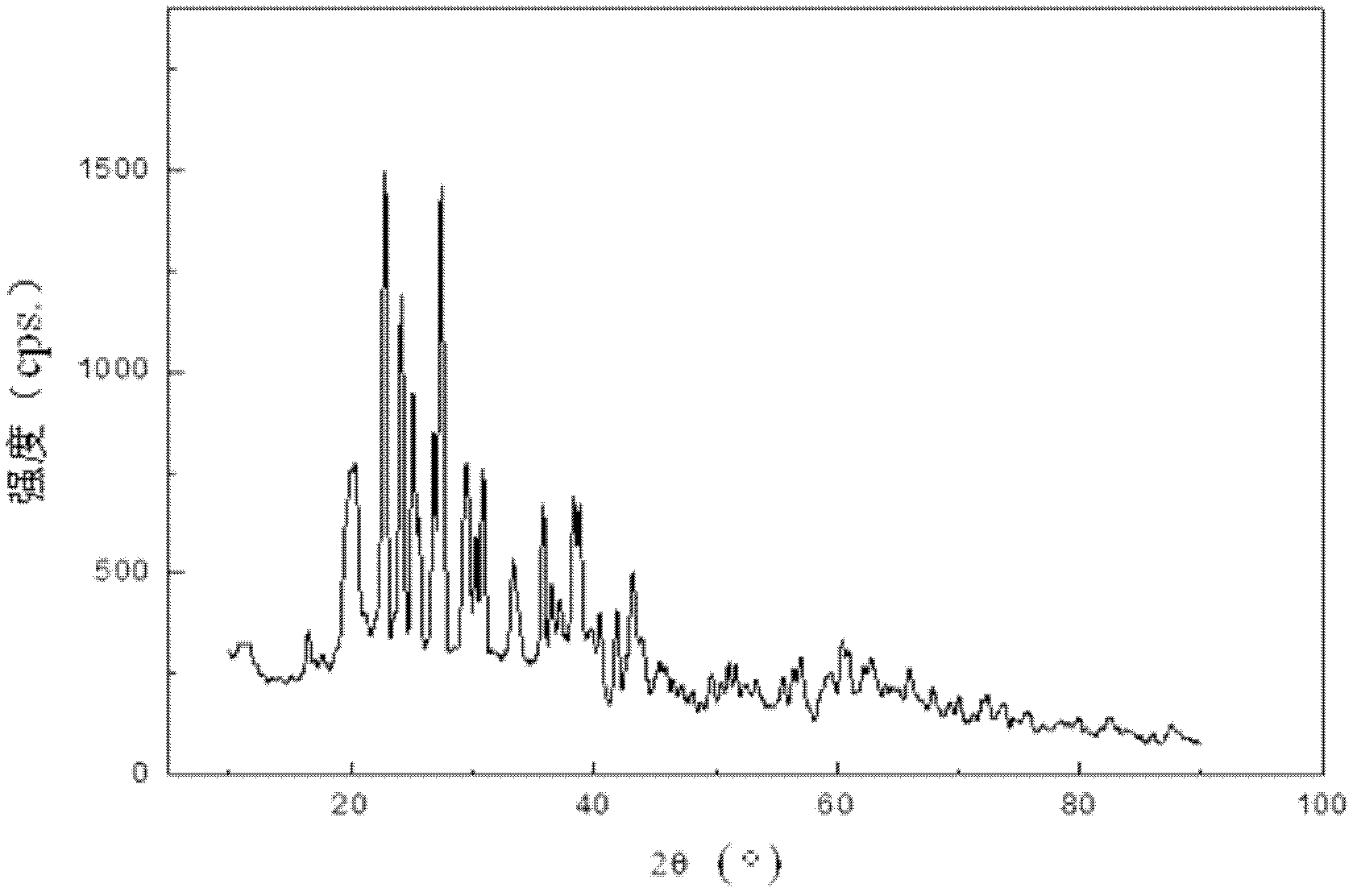

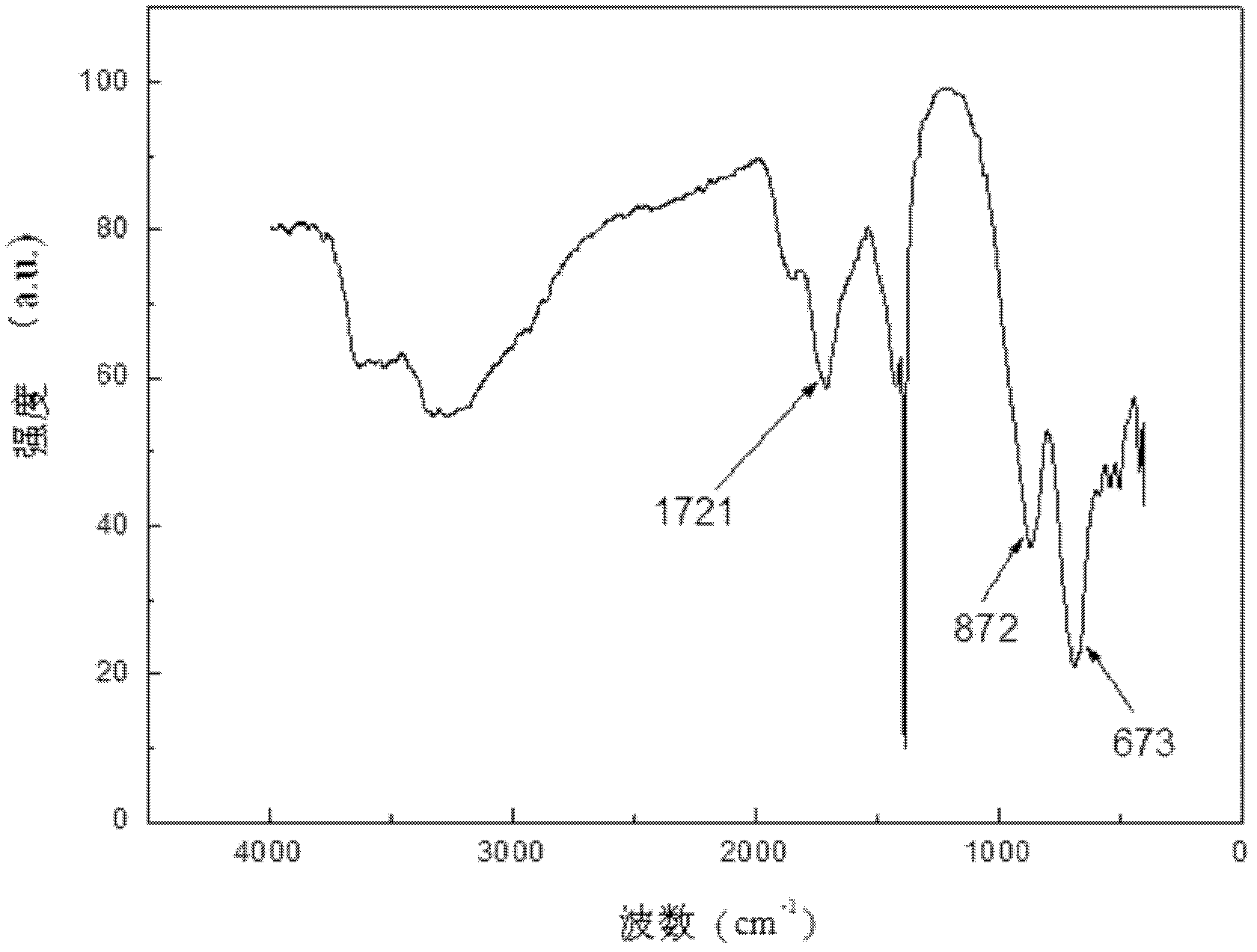

The invention discloses a double-sided titanium steel composite plate taking IF steel as a transition layer and a high-temperature preparation method thereof. A composite blank for preparing the composite plate comprises a base material, the IF steel and a titanium composite material, wherein the base material is plain carbon steel or low alloy steel with C less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, the thickness ratio of the base material to the titanium composite material is 5-10, the length and width of the titanium composite material are smaller than those of the base material, and the margin between the titanium composite material and four sides of the base material is 60-100 mm; and the vacuum welded composite blank is heated to 1040-1060 EDG C for heat preservation, the heat preservation time is 1 min / mm * the total thickness of the composite blank, the initial rolling temperature is 1020-1040 DEG C, the single-pass reduction rate is 15%-25%, the total reduction rate is greater than or equal to 70%, the finish rolling temperature is greater than or equal to 850 DEG C, air cooling is carried out to a room temperature, the thickness of the rolled IF steel transition layer is 280-320 [mu]m, and the double-sided titanium steel composite plate with the thickness of 6-75 mm is obtained after plate splitting, and excellent corrosion resistance and mechanical properties are achieved.

Owner:ANGANG STEEL CO LTD

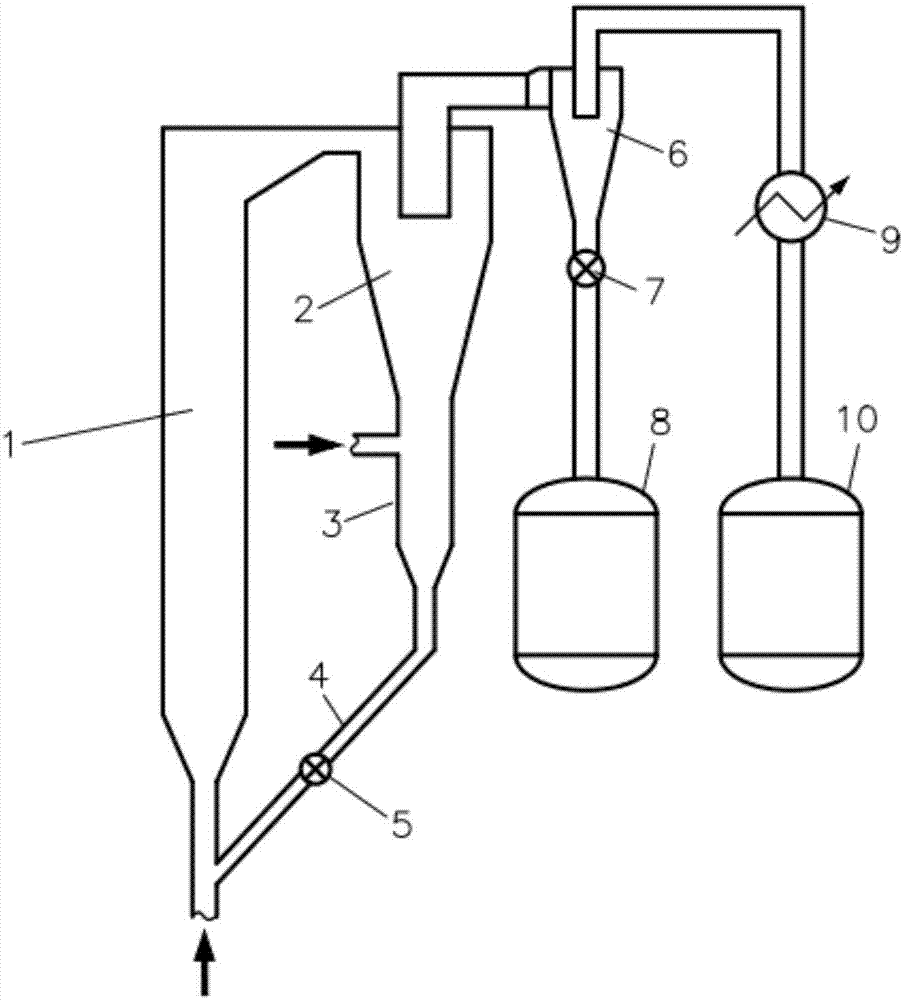

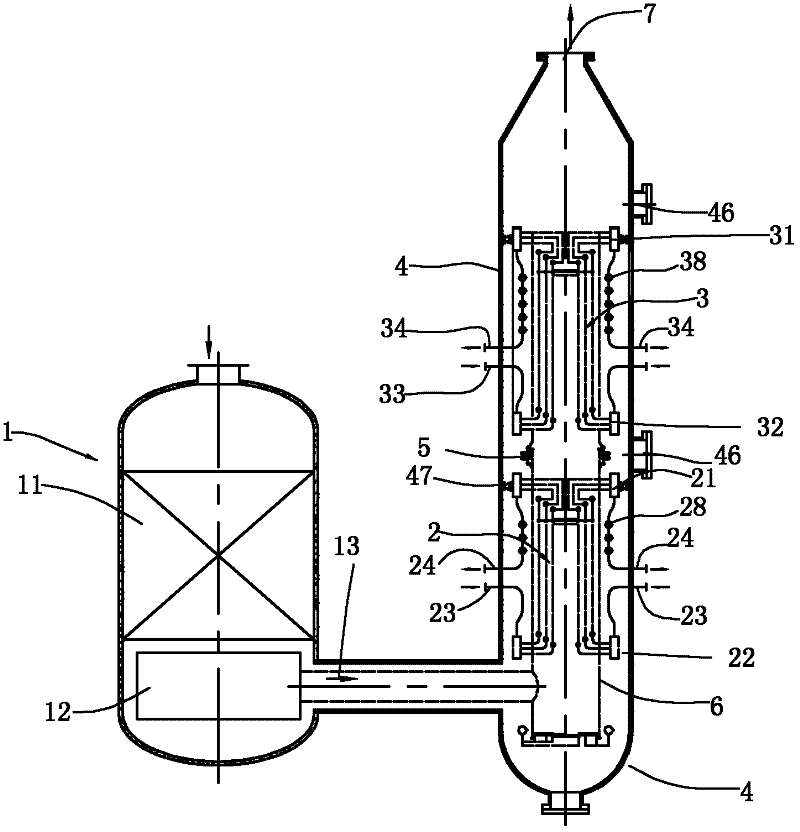

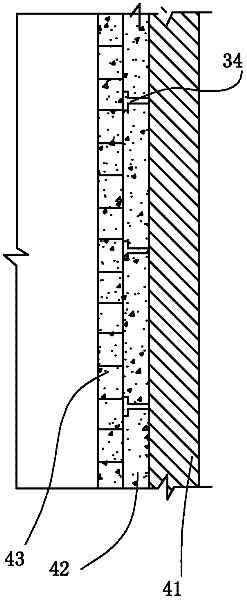

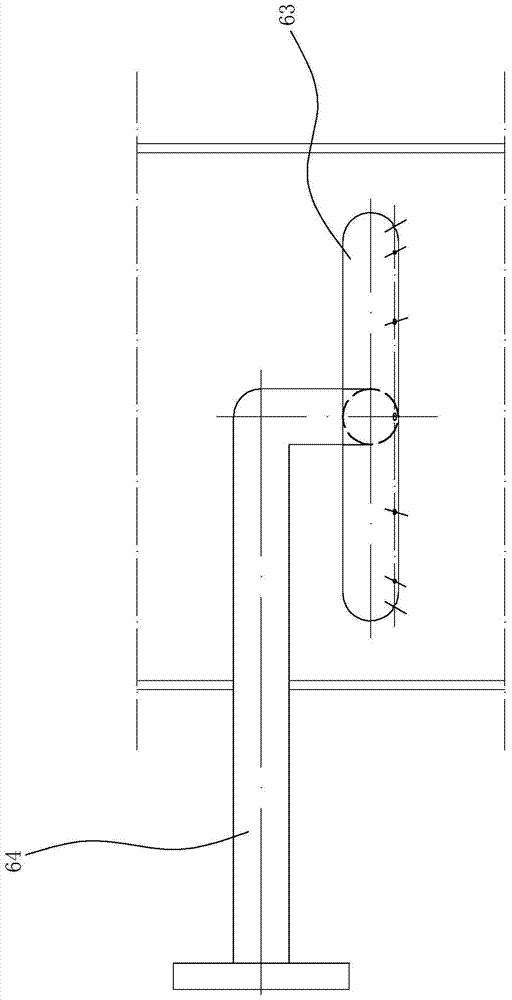

Circulating fluidized bed system and method for production of hydrogen fluoride from fluorite powder

ActiveCN107311109AFlow fastAvoid abnormal phenomena such as agglomeration and sticking to the wallHydrogen fluorideChemical/physical processesGas solidHydrogen fluoride

The invention discloses a circulating fluidized bed system and method for production of hydrogen fluoride from fluorite powder. The system comprises a reactor, a circulating part, a solid separation part and a gas condensation part, wherein the reactor is the place where a reaction takes place; the circulating part separates unreacted solids, allows the unreacted solids to settle and then returns the unreacted solids to the reactor for the reaction again; the solid separation part separates a gas-solid two-phase product and collects totally reacted solids as a solid product; and the gas condensation part liquefies and collects a gas product left after separation in the solid separation part. According to the invention, abnormal phenomena such as agglomeration and adhesion onto walls are avoided; mass transfer and heat transfer efficiency is improved; the circulation rate of a circulating fluidized bed is controlled by controlling the amount of gas and controlling the opening of a valve on an inclined tube, and the ratio of the separated solid product is controlled so as to control the reaction degree of the solids; liquid condensation is controlled via the temperature and amount of a condensate; and when the gas product contains other impurities, multi-stage condensers can be installed so as to control product quality.

Owner:ZHEJIANG UNIV

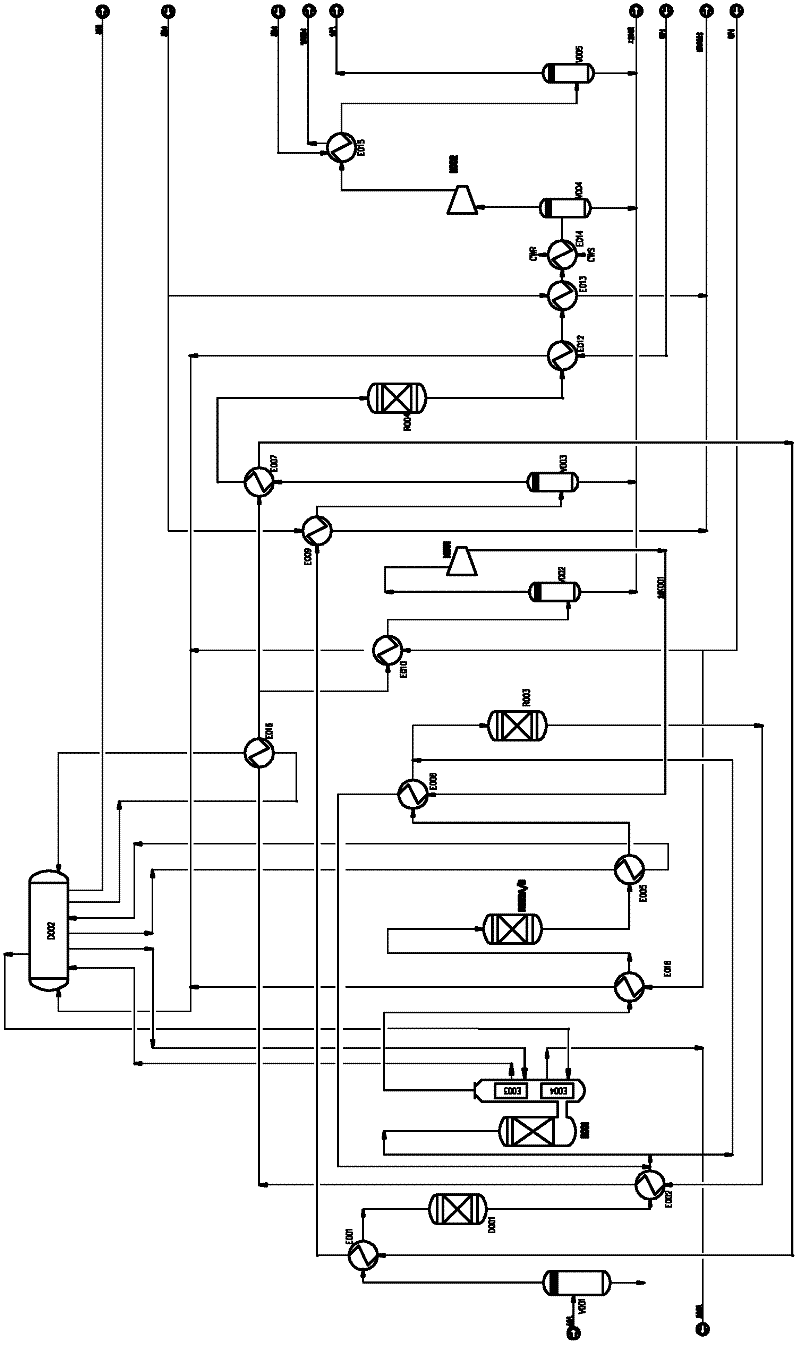

Process for preparing substitute natural gas from synthesis gas

ActiveCN102585949AExtended service lifeReduce manufacturing difficultyGaseous fuelsMethanationReaction temperature

The invention relates to a process for preparing substitute natural gas from synthesis gas, which comprises the following steps that: after being subjected to detoxification and desulfuration, the raw materials are subjected to heat exchange and are mixed with recycle gas from a third methanator and the obtained mixture is divided into two strands, wherein the first strand enters a first methanator to be subjected to the methanation reaction; all high-temperature first synthesis gas obtained after the first strand of raw material gas reacts in the first methanator is sequentially fed into a steam superheater and a first waste heat boiler to be subjected to heat exchange and then is fed into a second methanator to be subjected to the further methanation reaction to obtain second synthesis gas; after being subjected to heat exchange, the second synthesis gas is mixed with the second strand of raw material gas, and then the mixture is fed into the third methanator; and third synthesis gas discharged out of the third methanator is divided into two strands after being subjected to heat exchange compression, one strand of the third synthesis gas serving as the recycle gas is mixed with the raw material gas, the rest of the third synthesis gas enters a fourth methanator to enable the unreacted raw material gas to be synthesized into methane so as to obtain the synthesis gas capable of replacing the natural gas. The process has the characteristics that the reaction temperature rise is easy to control; the utilization of system energy is optimized; and the like.

Owner:CHINA PETROLEUM & CHEM CORP +2

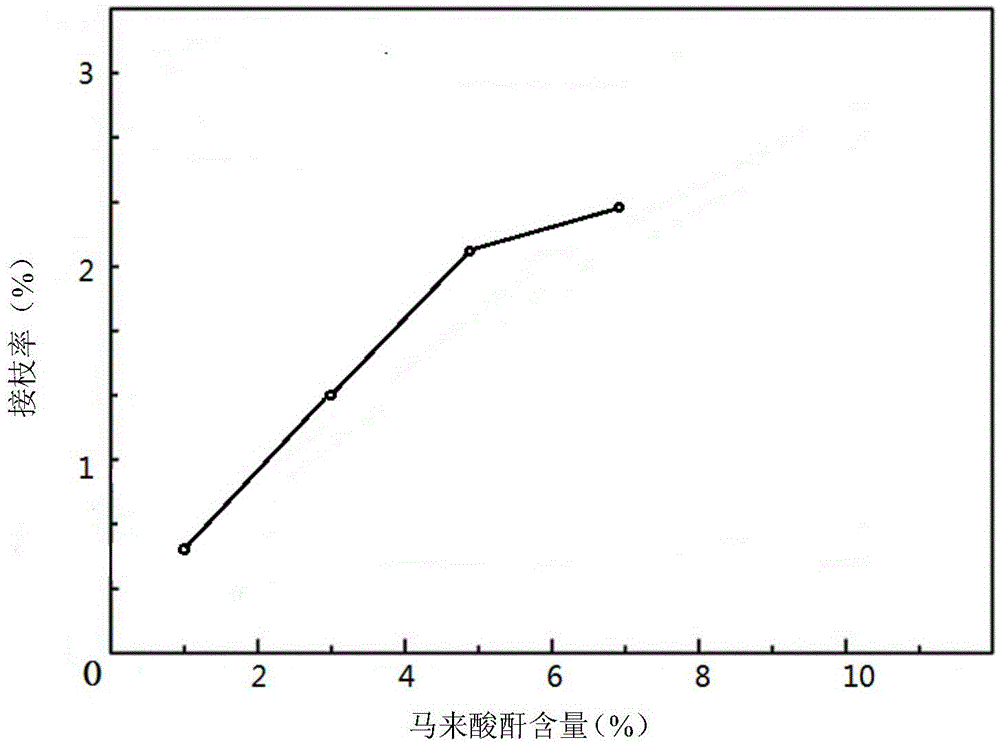

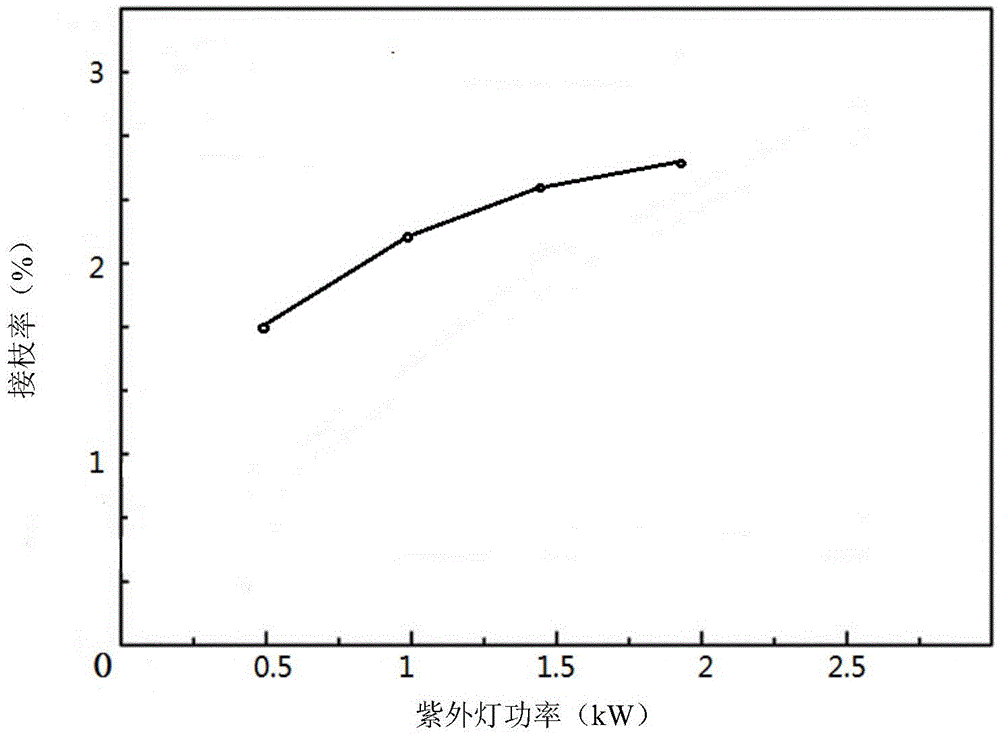

Preparation method of PP-g-MAH (Polypropylene grafting Maleic Anhydride) triggered and melt by ultraviolet irradiation

The invention belongs to the field of polymer materials, and discloses a preparation method of PP-g-MAH (Polypropylene grafting Maleic Anhydride) triggered and melt by ultraviolet irradiation. The preparation method comprises the following steps of (1) uniformly mixing polypropylene resin, MAH, a photosensitizer and a grafting additive; (2) setting the temperature of an extruding machine, and turning on an ultraviolet lamp, wherein a light passing opening is formed in a feed cylinder of the extruding machine, and the ultraviolet lamp is arranged above the light passing opening; (3) adding a mixture obtained in step (1) into the feed cylinder of the extruding machine; (4) turning on the extruding machine to carry out melt blending after the extruding machine reaches a set temperature, and obtaining the PP-g-MAH. According to the preparation method disclosed by the invention, the reaction time is short, and the equipment is simple; the reaction degree can be controlled by controlling the factors of the rotating speed of a main machine, the feeding speed, the temperature and the like; severe degradation of peroxide initiators on polypropylene can be avoided by using ultraviolet trigger.

Owner:SOUTH CHINA UNIV OF TECH

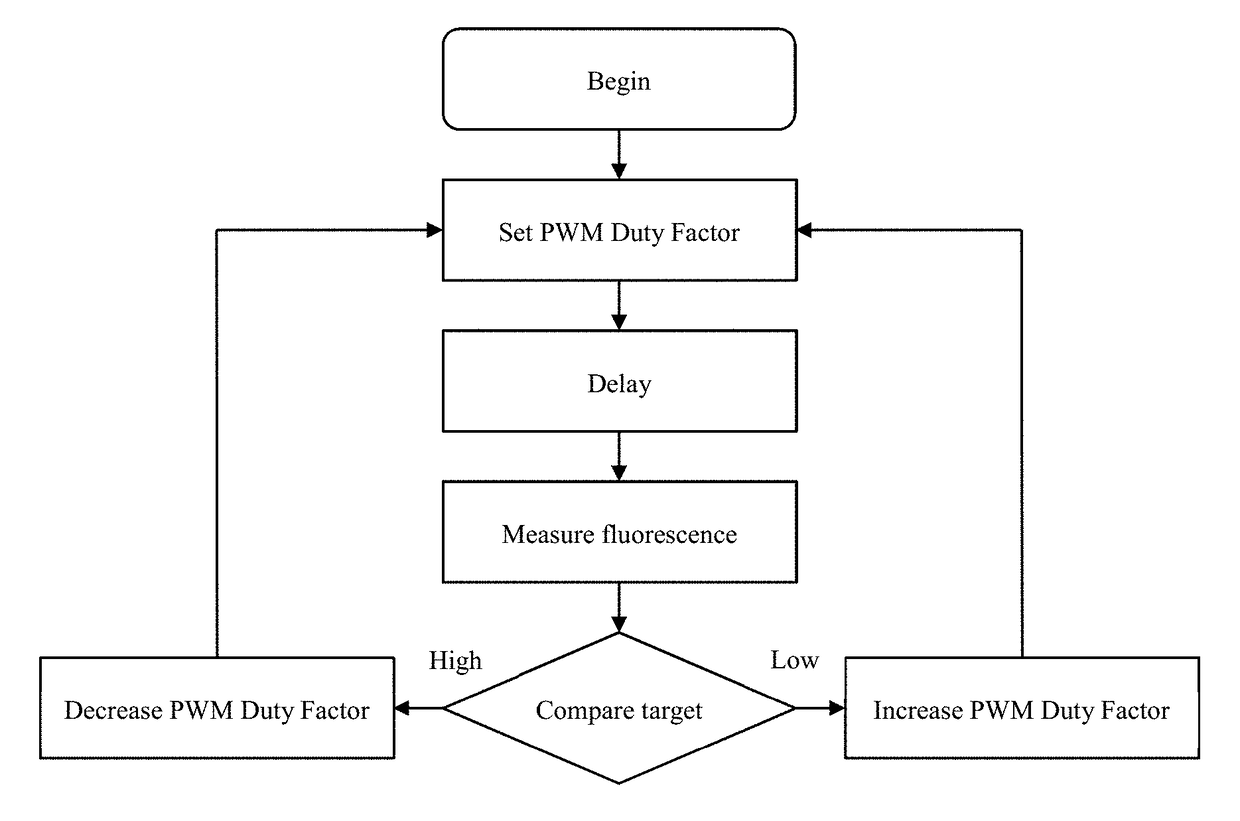

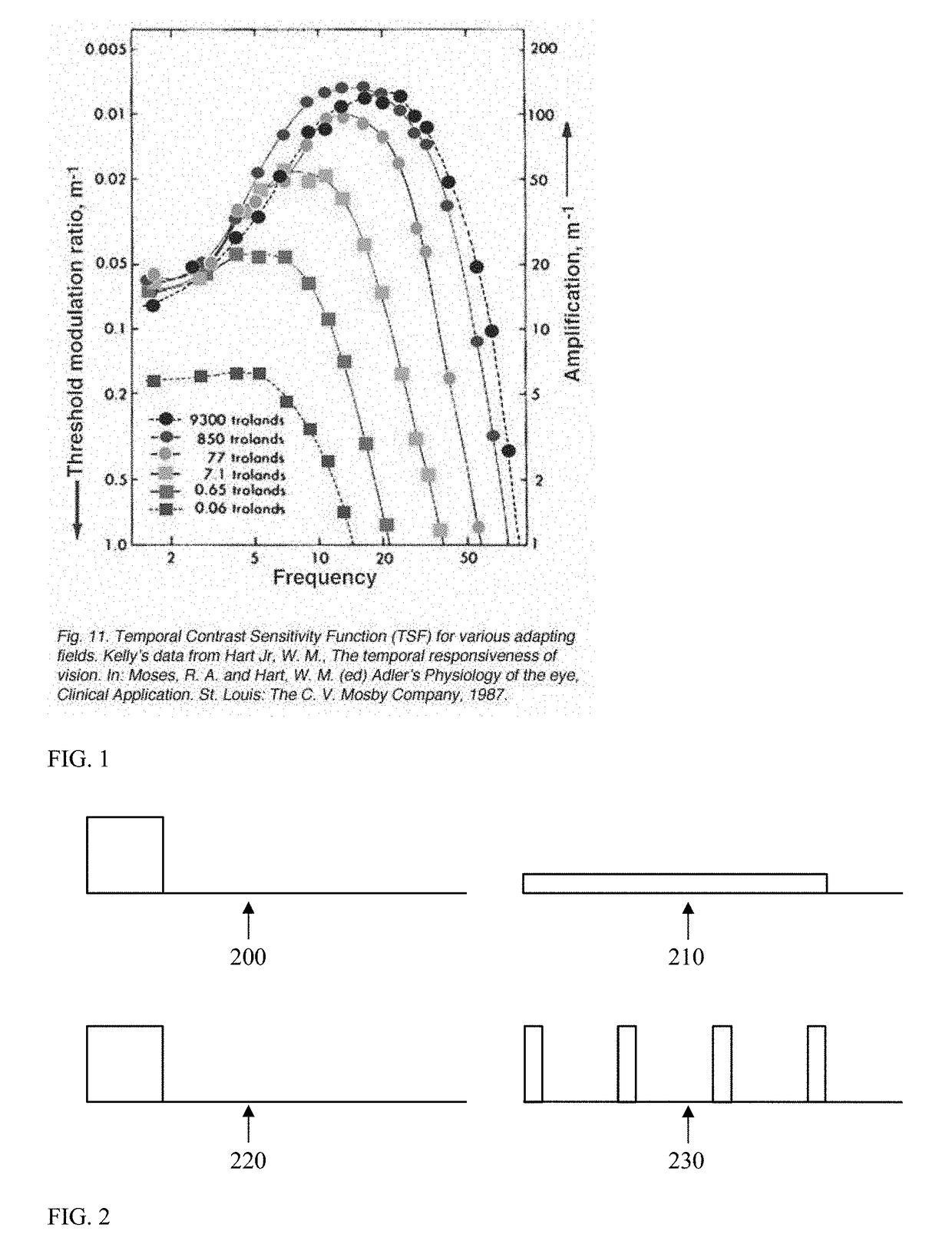

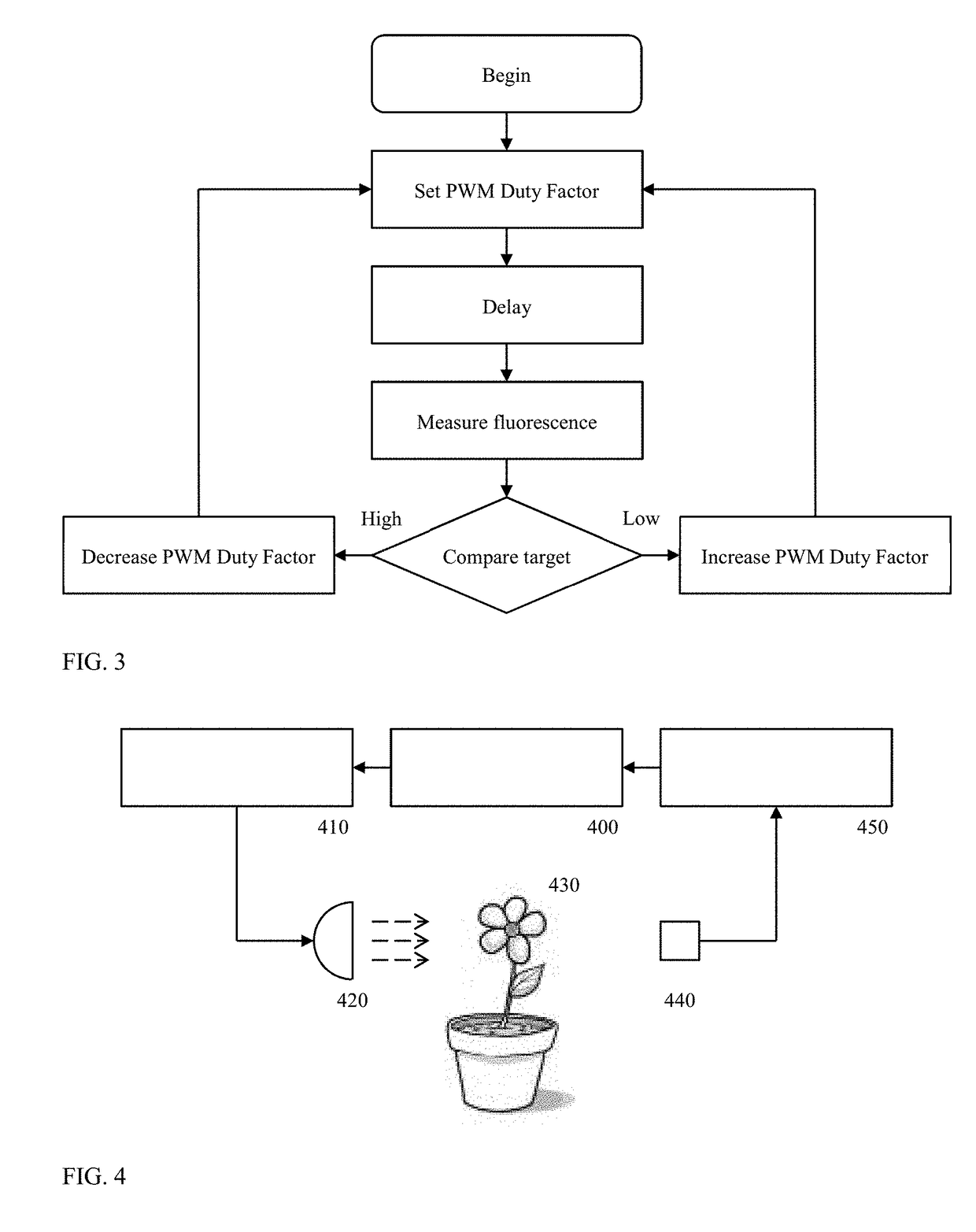

Temporally modulated lighting system and method

InactiveUS20170295727A1Control responseElectrical apparatusElectric light circuit arrangementLighting systemRadiant flux

Electric light sources typically exhibit temporal variations in luminous flux output, commonly referred to as “flicker.” Flicker, or temporal modulation, is known to influence the growth, health and behavior patterns of humans, and is also linked to growth, health and behavior patterns throughout the growth cycle of plants and animals. Control of peak radiant flux emitted by a light source to temporally modulate a light source will allow for the control of plants and animals for sustainable farming including but not limited to horticultural, agricultural, or aquacultural endeavors.

Owner:SUNTRACKER TECH

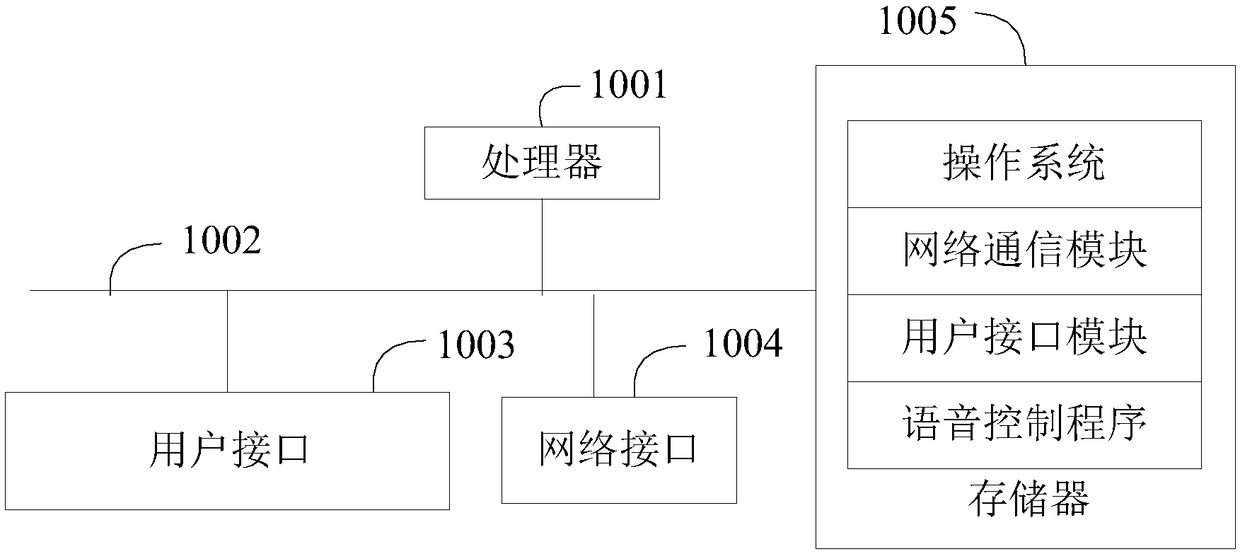

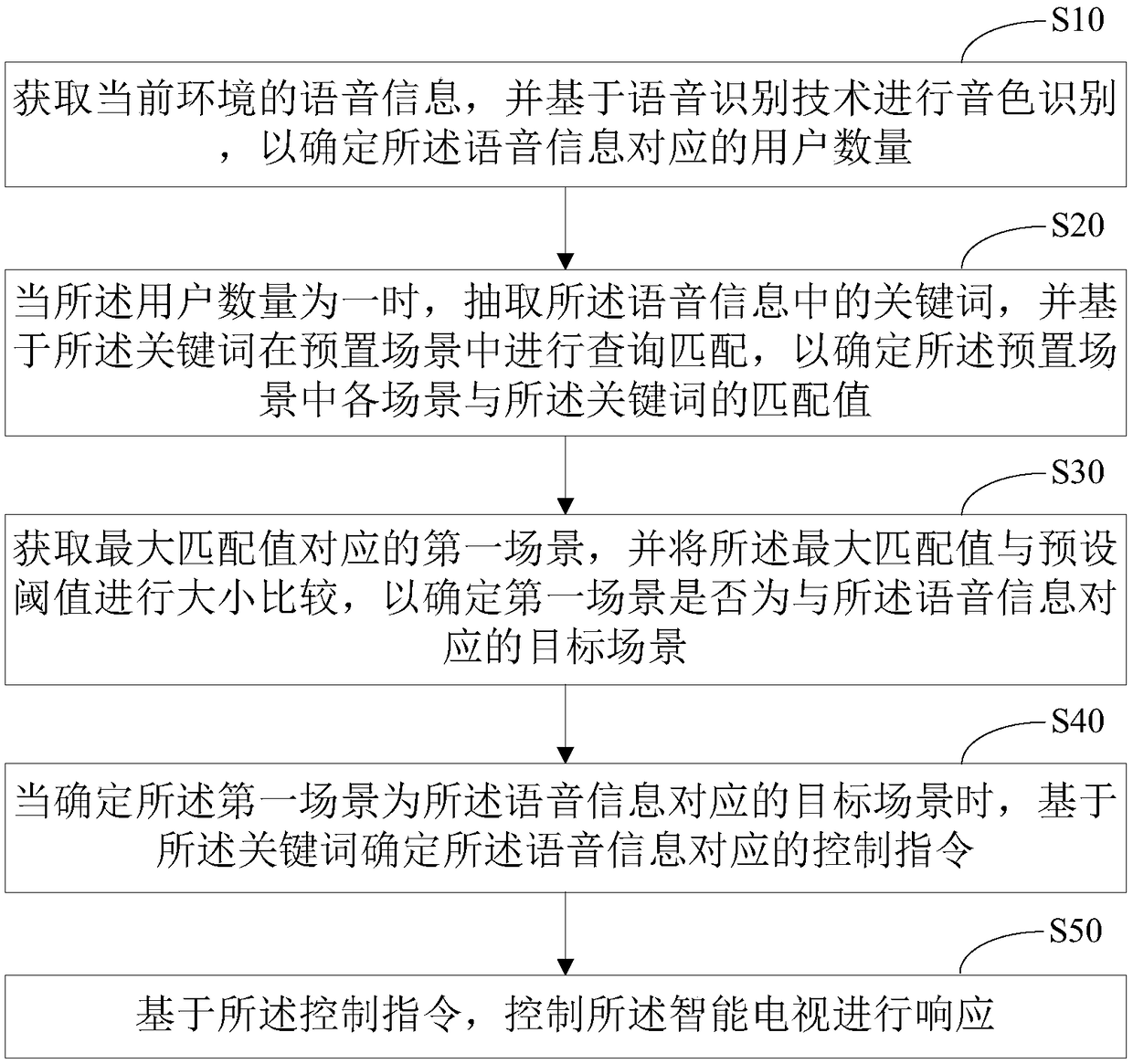

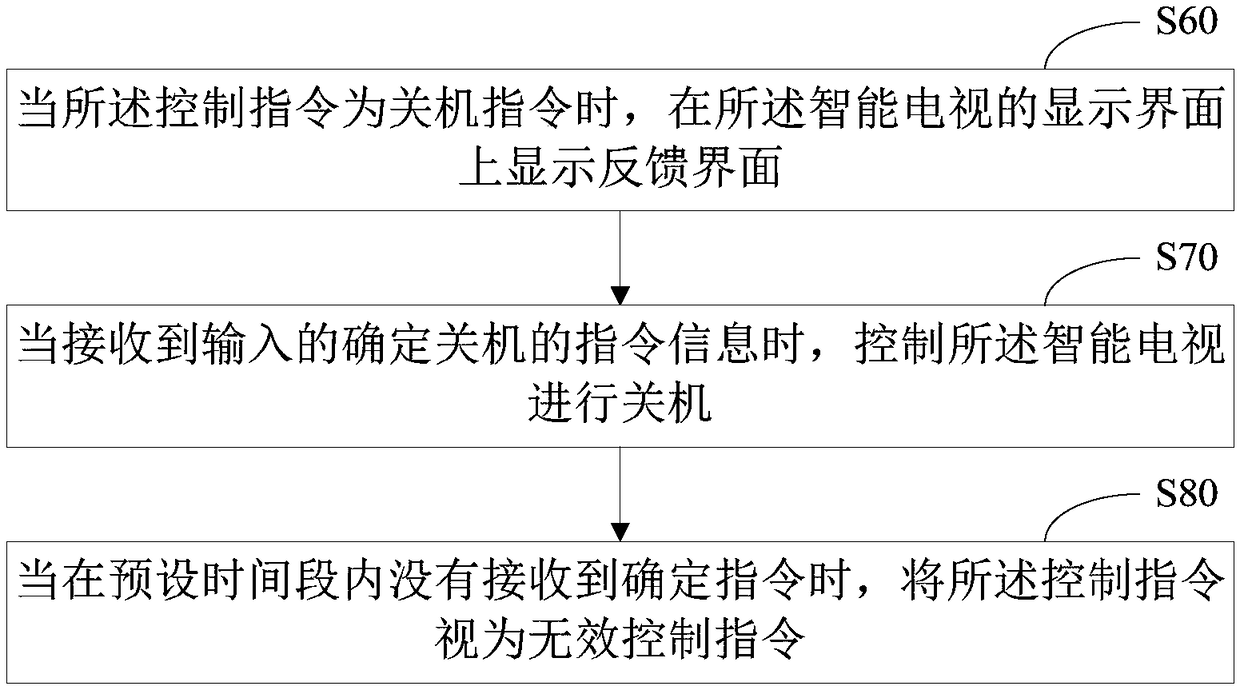

Smart TV voice control method, smart TV and readable storage medium

InactiveCN108712681AControl responseEasy to controlSpeech recognitionSelective content distributionSpeech soundCable television

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

Method for producing carbon felt electrode material for flow battery

The invention discloses a method for producing a carbon felt electrode material for a flow battery and relates to the technical field of production of storage batteries. The method comprises the following steps: pre-treating a polyacrylonitrile (PAN) pre-oxidation felt which serves as a raw material in a carbonized furnace with temperature gradient; placing the carbonized PAN pre-oxidation felt in an activation area, filling O2 or CO2 for reaction, and performing in-situ growth on a COOH group on the surface of the PAN pre-oxidation felt. By the adoption of the method, a carbon felt electrode can be prepared and modified in one step, the type of oxygen-containing functional groups formed on the surface of a carbon felt is changed, and the in-situ growth of the oxygen-containing functional groups is realized. A PAN carbon felt electrode containing different types and numbers of oxygen-containing functional groups can be correspondingly applied to different types and scales of flow battery systems. By comprehensively evaluating the battery performance, an optimal matching relationship between the type and number of the oxygen-containing functional groups and the performance of the flow battery can be constructed, so that the carbon felt electrode material can be optimally applied to the flow battery.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

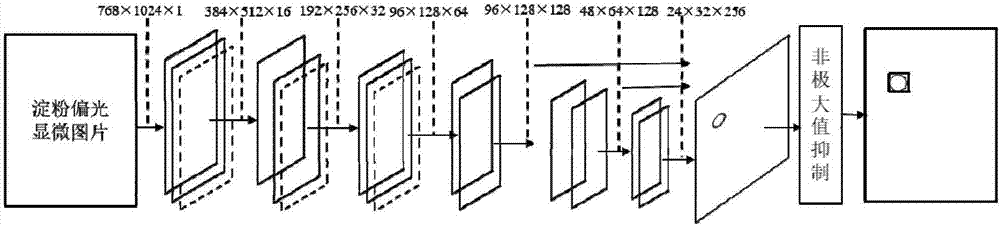

Method for on-line detection of starch gelatinization degree and gelatinization temperature

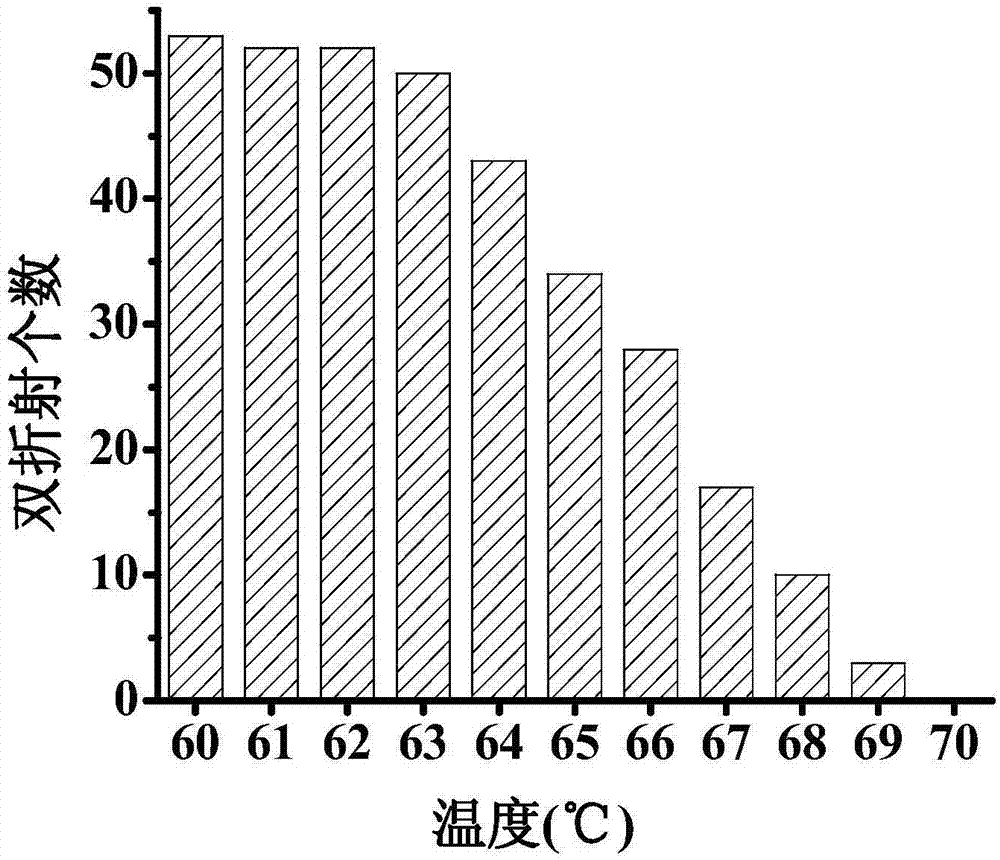

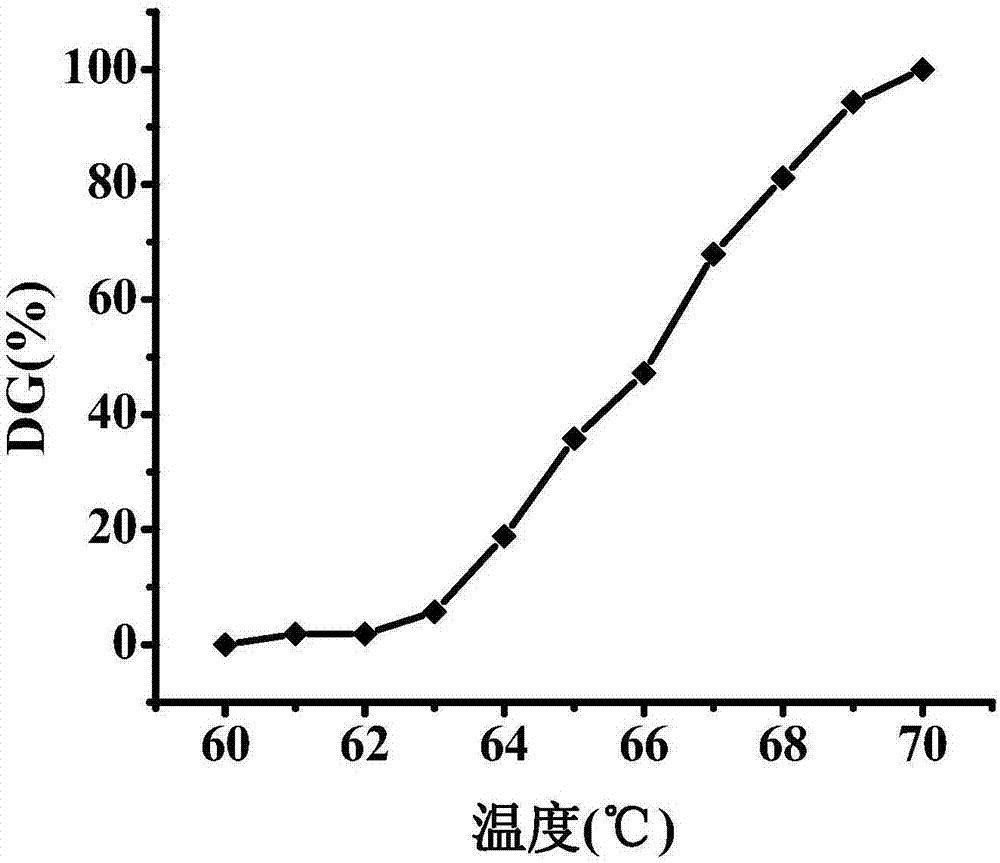

InactiveCN107515198AImprove parallelismOvercome manual observationPreparing sample for investigationMaterial analysis by optical meansStarch gelatinizationMicroscopic observation

The invention discloses a method for on-line detection of a starch gelatinization degree and a gelatinization temperature. According to the method, microscope observation and artificial intelligence image recognition technology are combined, and with utilization of a principle that starch granules have unique birefringence characteristics under polarized light, a Starch-SSD method based on deep learning is proposed and is used for monitoring morphological changes of a starch gelatinization process. Experimental results of the method have good parallelism, and the error of the measurement results is within 1%. Compared with artificial vision observation, the method not only eliminates the influence of subjective errors but also makes the whole detection process have less time consuming, the operation is faster and more convenient, and the experimental results are more accurate. The method is based on target tracking of the starch birefringence characteristics in the gelatinization process, and a new method for on-line observation and design control of the extent of starch reaction is provided.

Owner:SOUTH CHINA UNIV OF TECH

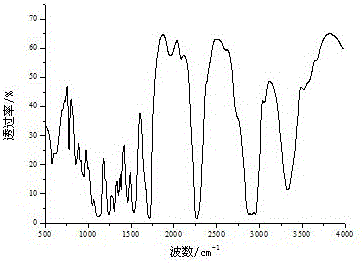

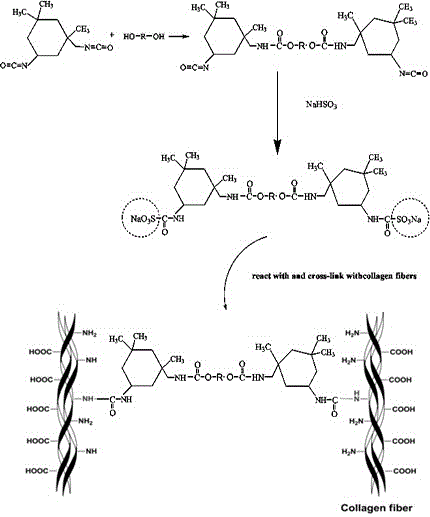

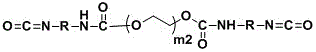

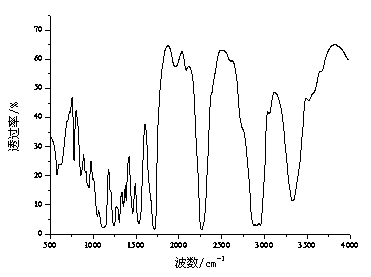

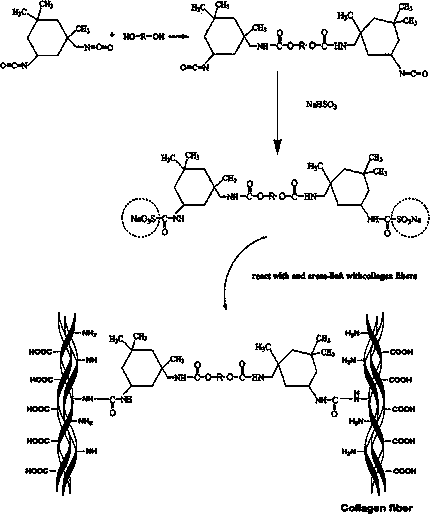

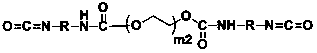

Isocyanate-based fur tanning agent and preparation method thereof

The invention discloses an isocyanate-based fur tanning agent and a preparation method thereof. The process is to use diisocyanate molecules to cap the fatty diol or polyether diol at both ends under catalytic conditions and in a mixed solution to obtain a prepolymer with high selectivity and high conversion rate; The isocyanate groups at both ends of the prepolymer are protected to improve the water solubility of the compound and finally obtain the tanning agent. The tanning agent has a controllable molecular weight and is suitable for tanning fur with different fiber structures. During the tanning process, it can effectively penetrate into the skin collagen, and the bisulfite decomposes under the condition of rising temperature and alkali, and the tanning agent molecule re-exposes the isocyanate group to react with the amino group on the collagen molecule, and cross-links the skin collagen to To achieve the purpose of tanning. The whole process only releases neutral salts, does not produce heavy metal ions and free aldehyde groups, simplifies the purification procedure, is environmentally friendly, and low in price, and is very suitable for tanning fur, especially light-colored rabbit skin.

Owner:SICHUAN UNIV

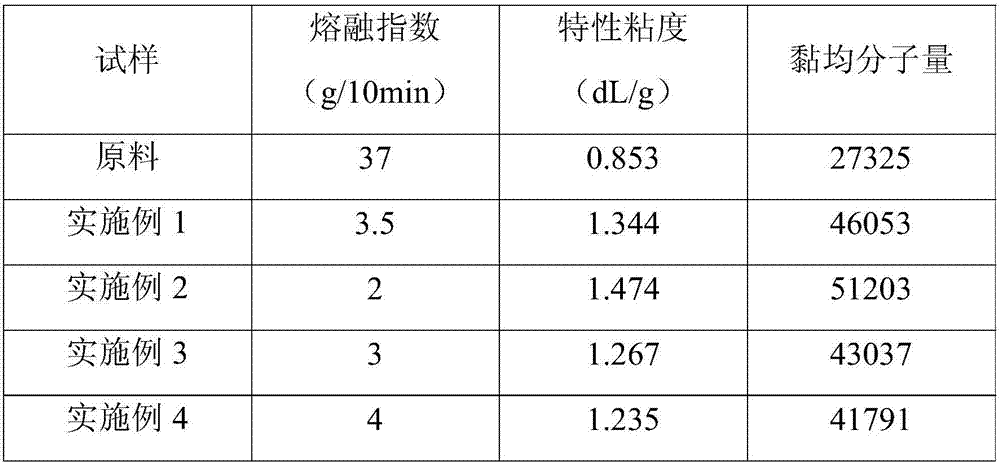

Preparation method of high-viscosity hydrolysis resistant polybutylene terephthalate

The invention belongs to the technical filed of preparation of polymer materials, and discloses a preparation method of high-viscosity hydrolysis resistant polybutylene terephthalate. The method comprises the following steps: uniformly mixing 100 parts of a polybutylene telephthalate raw material, 0.01-5 parts of a functional group monomer chain extender A containing C=C and 0.01-5 parts of a functional group monomer chain extender B containing C=C and an epoxy group, adding the obtained mixture into an extruder, reacting and extruding the mixture at an extruder feeding segment temperature of 160-210 DEG C, a melting segment temperature of 220-250 DEG C and a homogenizing segment temperature of 250 DEG C, and irradiating the material in the melting segment or the homogenizing segment of the extruder with ultraviolet lights in order to obtain an extrusion product that is the high-viscosity hydrolysis resistant polybutylene terephthalate. The method for preparing the high-viscosity hydrolysis resistant polybutylene terephthalate through a two-step technology by using the extruder, the composite chain extender and ultraviolet light irradiation conditions has the advantages of short reaction time, fast reaction speed and simple device.

Owner:SOUTH CHINA UNIV OF TECH

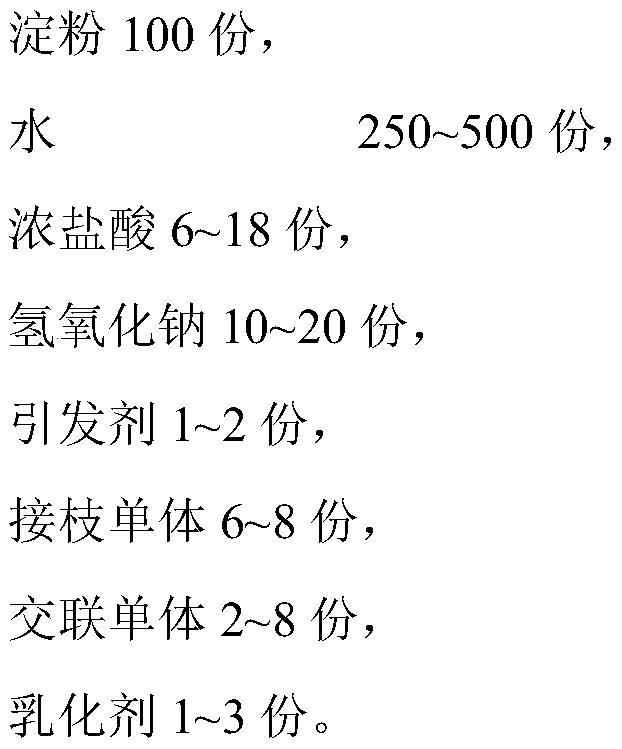

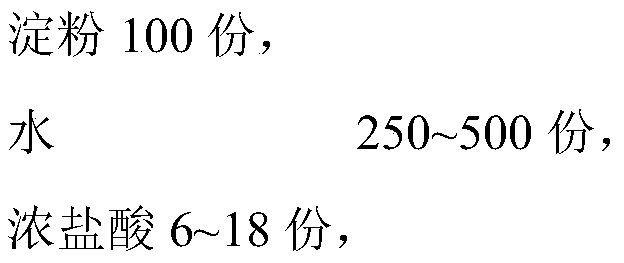

Thermosetting artificial board starch adhesive and preparation method thereof

ActiveCN111205794AFix stability issuesSolve the costGraft polymer adhesivesAdhesive cementPolymer science

The invention discloses a thermosetting artificial board starch adhesive and a preparation method thereof, and belongs to the technical field of adhesive preparation. Starch is used as a main raw material, and after acidolysis, a semi-continuous seeded emulsion polymerization method is adopted for preparation. By accurately controlling the pre-gelatinization temperature, the initiator adding time,the crosslinking monomer adding amount, the crosslinking monomer dripping speed and the crosslinking monomer dispersion liquid concentration, the reaction degree of crosslinking monomers is reasonably controlled, and the step of dripping comonomers is omitted. Meanwhile, the reaction time is greatly shortened, the use amount of petroleum monomers is reduced, complex reaction steps are simplified,the proportion of starch accounting for the total solid content is increased to 75% or above from 40%, and the cost of the starch adhesive is reduced. The adhesive disclosed by the invention is goodin water resistance and strong in cohesion, various properties of the manufactured artificial board exceed the standard of class II artificial boards, and the adhesive is suitable for mass productionand is widely applied to adhesion of hot-pressed wood decorations, artificial boards and plywood.

Owner:JIANGNAN UNIV

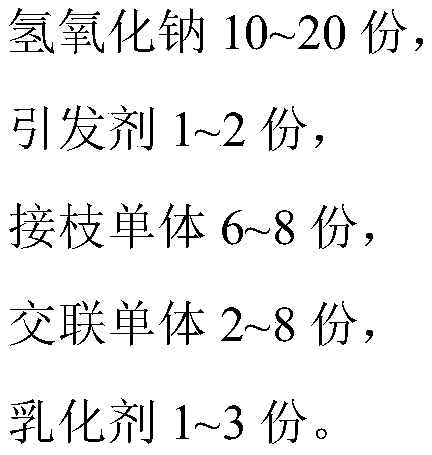

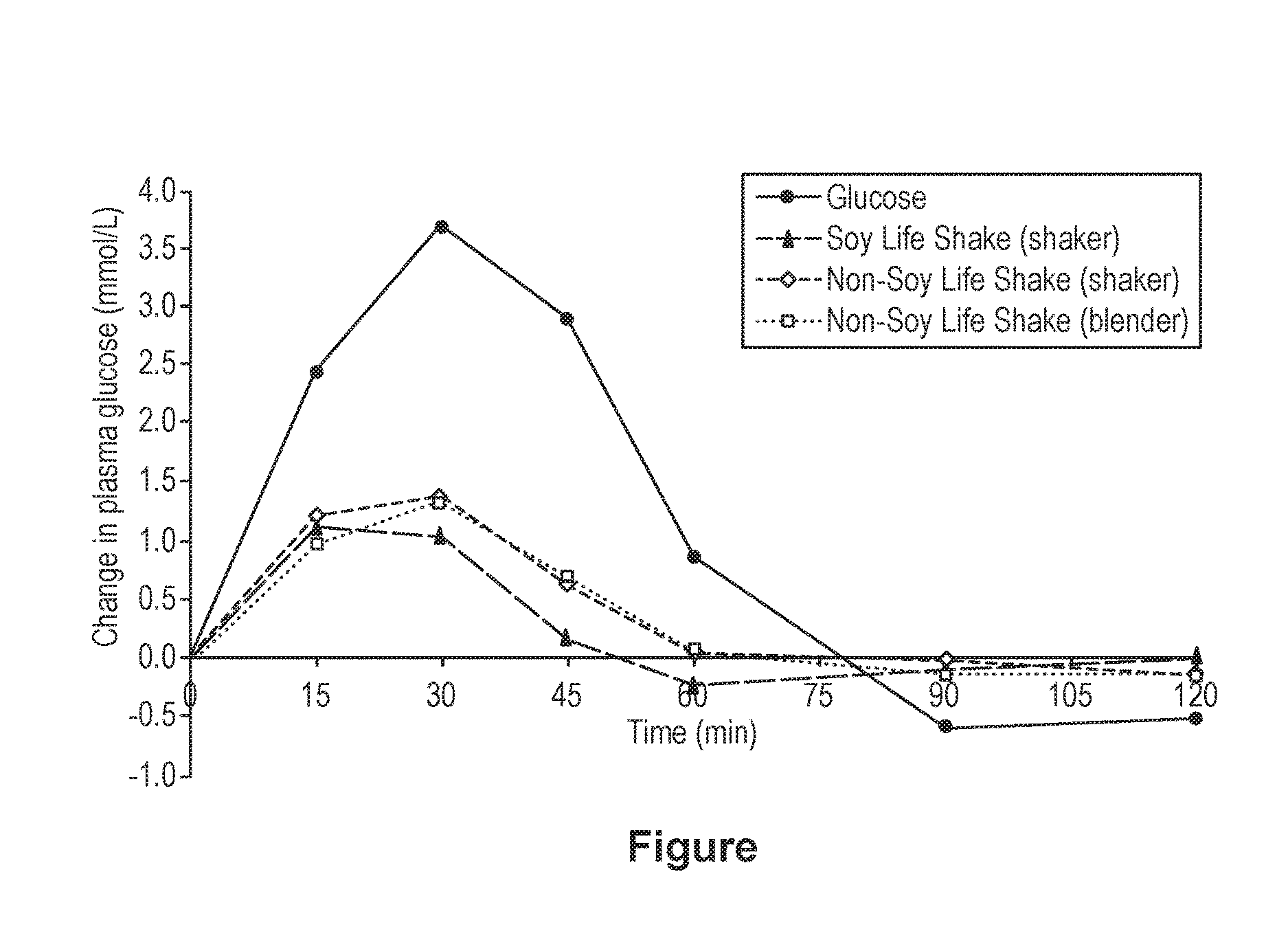

Materials and methods for improving gastrointestinal health

InactiveUS20170042950A1Maintain and improve gastrointestinal healthControl responseOrganic active ingredientsMetabolism disorderPlant basedBacillus coagulans

Described herein is a composition comprising a mixture of a probiotic composition and a prebiotic composition, wherein the probiotic composition comprises the bacterium Bacillus coagulans and wherein the prebiotic composition comprises a plant-based fiber, a resistant starch and a short-chain oligosaccharide. Uses of the compositions described herein for maintaining or improving gastrointestinal health is also contemplated.

Owner:SHAKLEE CORP

Fur tanning agent based on isocyanate and preparation method of fur tanning agent

The invention discloses a fur tanning agent based on isocyanate and a preparation method of the fur tanning agent. According to the process, diisocyanate molecules are adopted to perform end-capping on two ends of fat-diol or polyether glycols in a mixed solution under the condition of catalysis, and prepolymer with high selectivity and high conversion rate is obtained; then, hydrosulphite is adopted to protect isocyanate groups on two ends of the prepolymer, the water solubility of the compound is increased, and the tanning agent is obtained finally. The molecular weight of the tanning agent can be controlled, thereby being applicable to tanning of furs with different fibrous textures; during the tanning process, the fur tanning agent can effectively permeate to the position among the fur collagen; hydrosulphite decomposes under the condition of raised temperature and raised alkali, the tanning agent molecule expose the isocyanate group to cause the isocyanate group to react with the amino group on the collagen molecule, crosslinking of the fur collagen is realized, and the purpose of tanning is achieved; only neutral salt is released during the entire process, heavy metal ions or free aldehyde groups are not generated, the process is simplified, the fur tanning agent is environment friendly, the price is low, the fur tanning agent is very suitable for fur, especially tanning of rabbit fur with light color.

Owner:SICHUAN UNIV

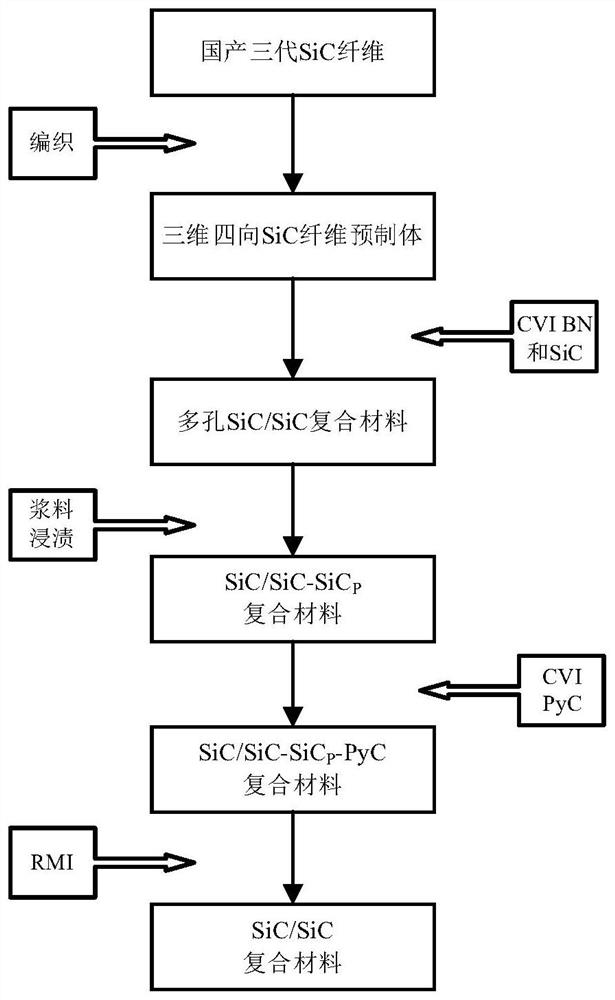

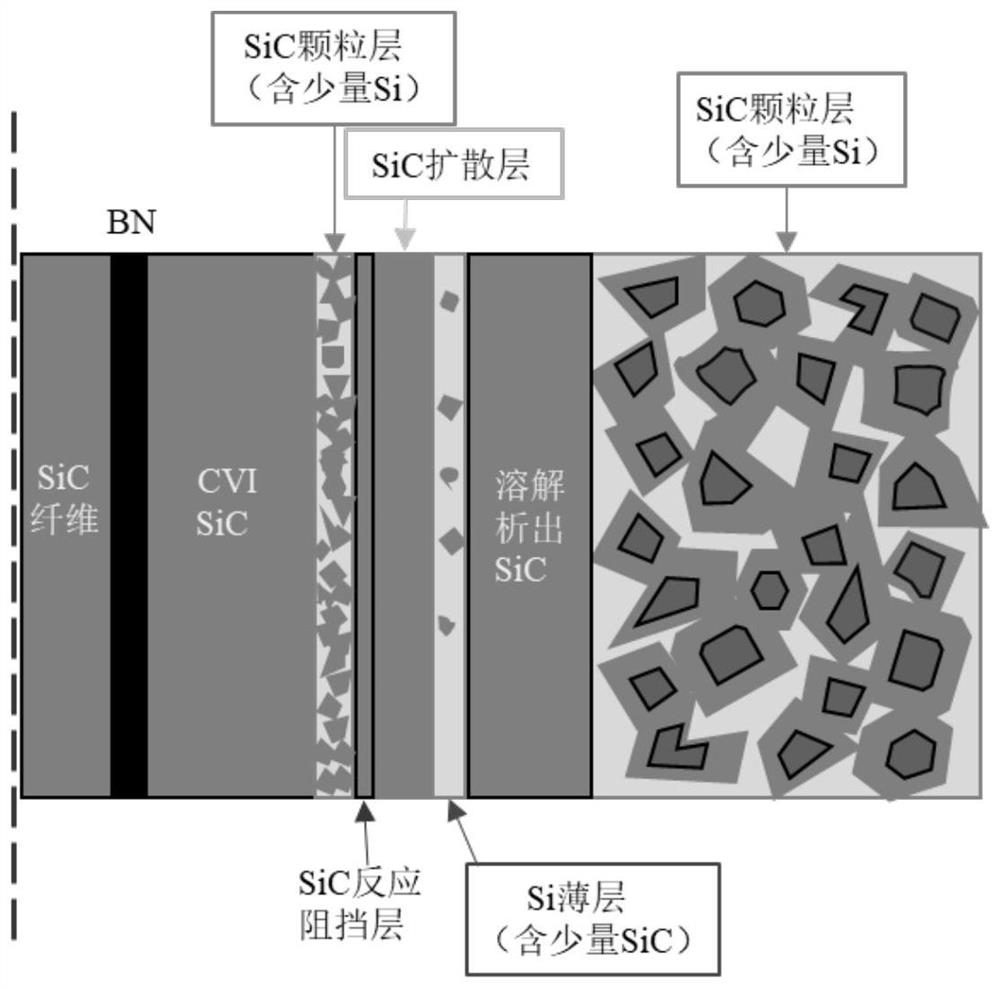

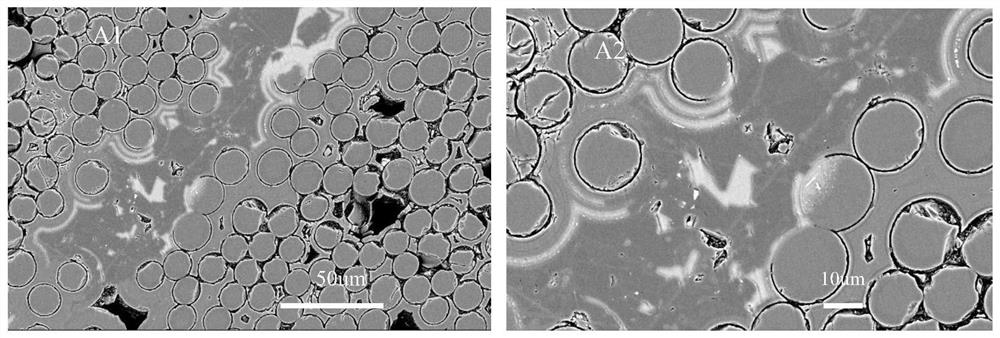

SiC/SiC composite material high-density multilayer matrix and preparation method thereof

The invention relates to a SiC / SiC composite material high-density multilayer matrix and a preparation method thereof. Prepared SiC particle (SiCp) slurry is introduced into a porous SiC / SiC composite material through vacuum impregnation and pressure impregnation methods, then a certain content of pyrolytic carbon is prepared in the porous SiC / SiC composite material by adopting a CVI method, the SiC particles are uniformly wrapped by the pyrolytic carbon, and finally, densification of the SiC / SiC composite material is completed through reaction of pyrolytic carbon and molten silicon by adopting an RMI method. SiC particles with different particle sizes are sequentially introduced to form a layered structure, so that a genetic effect is generated on subsequently prepared PyC and SiC matrixes, a uniform SiC matrix phase with a high volume fraction is obtained, the density of the composite material is increased, the energy of crack propagation is increased, and the mechanical property of the composite material is effectively improved. The composite material prepared by the method has a SiC matrix phase with high volume fraction and uniform distribution, high mechanical property and low open porosity, and solves the problems of low SiC phase content, non-uniform distribution and insufficient toughness in the SiC / SiC matrix prepared by the existing RMI process method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

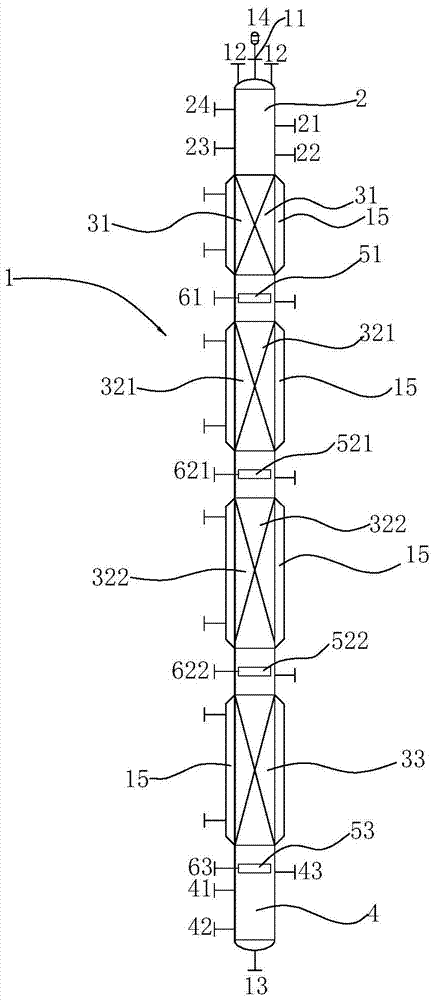

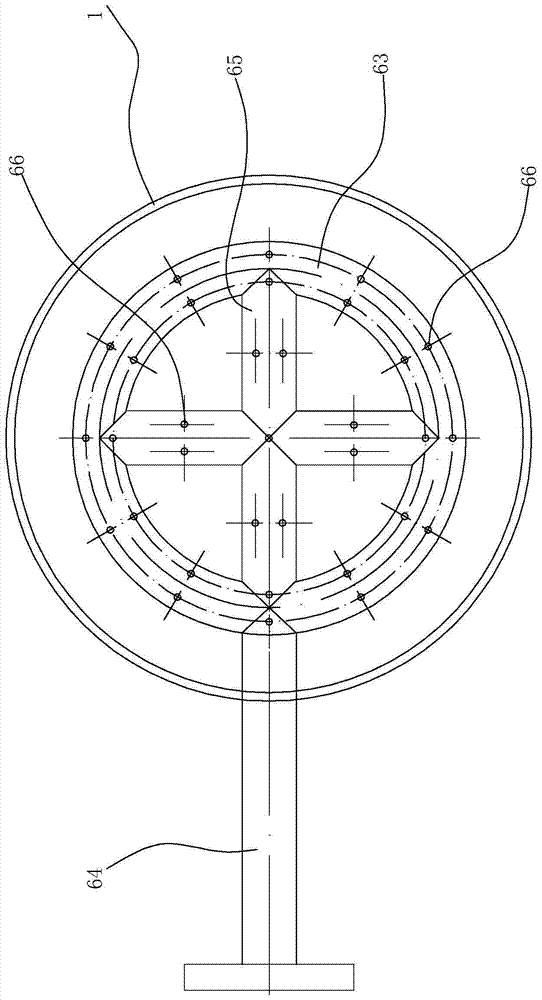

A kind of synthetic method of 4,4-dimethyl-1,3-dioxane

The invention relates to a 4,4-dimethyl-1,3-dioxane synthesis method. According to the 4,4-dimethyl-1,3-dioxane synthesis method, reaction monomers enter into a reactor respectively from different inlets, wherein an organic phase isobutene or isobutene-containing C4 fraction enters into the reactor from the lower part of the reactor and flows upward and a water phase phosphoric acid solution enters into the reactor from the upper part of the reactor and flows downward, the water phase material and the oil phase material contact in a counter current contact way in a multistage filling material zone and are fully dispersed so that a reaction is promoted, the reacted water phase is discharged from the bottom and the oil phase is discharged from the upper part. The 4,4-dimethyl-1,3-dioxane synthesis method has the advantages that a reaction conversion rate is high, reaction is thorough, formaldehyde-caused side reaction in the downstream process is greatly reduced, the reaction can be controlled easily, according to yield requirements, technical process conditions can be adjusted in the same reactor by adjustment of tertiary butanol and formaldehyde inlets so that the optimal reaction effects are obtained, and when the reaction occurs fluctuation, the reaction case can be improved and controlled by adjustment of the tertiary butanol and formaldehyde inlet positions.

Owner:NINGBO JINHAI CHENGUANG CHEM

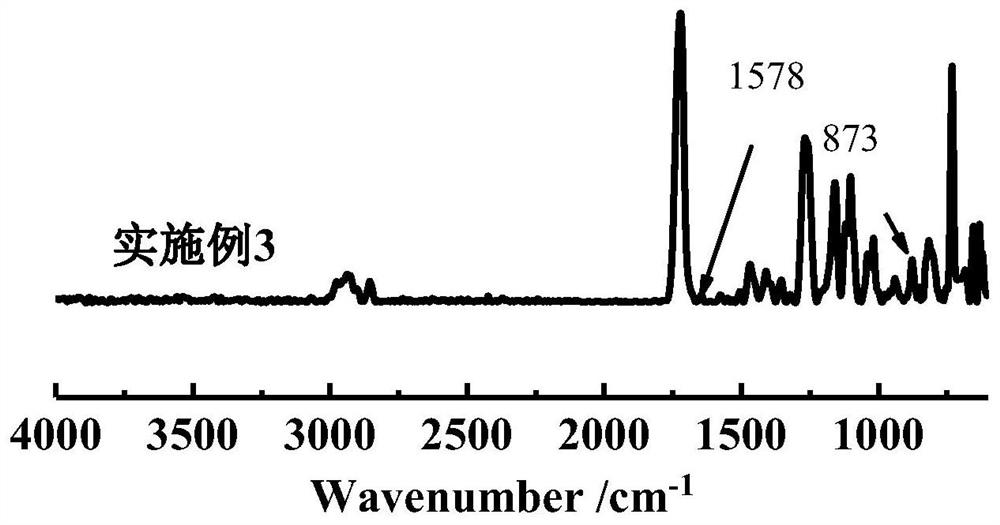

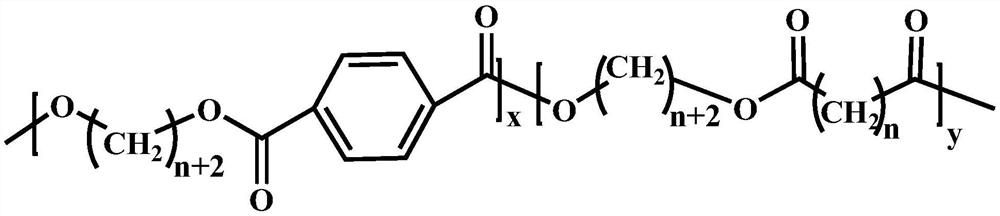

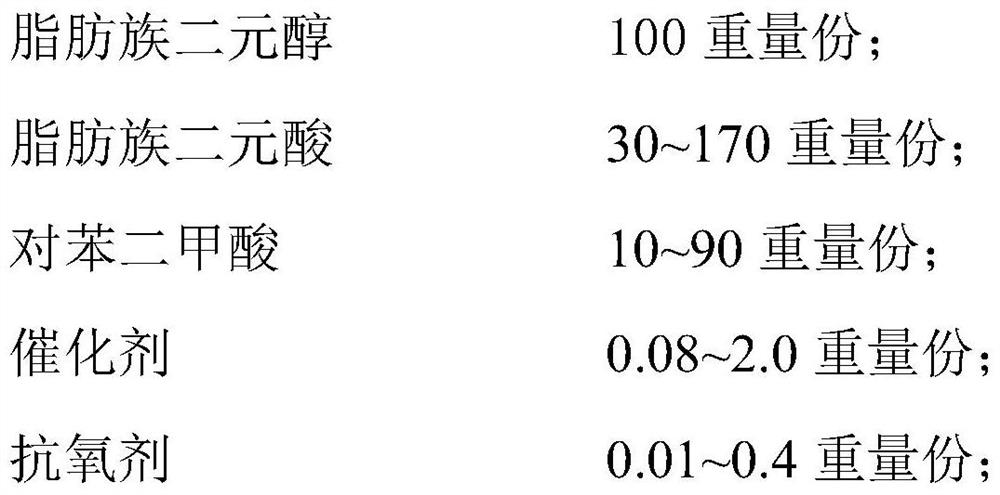

High-fluidity degradable polyester melt-blown material, and preparation method and application thereof

The invention discloses a high-fluidity degradable polyester melt-blown material, and a preparation method and application thereof. The molecular structure of the high-fluidity degradable polyester melt-blown material is as shown in the specification. In the structure, n is equal to 0, 2, 4 or 8, x is greater than or equal to 12 and smaller than or equal to 65, y is greater than or equal to 31 and smaller than or equal to 120, and a ratio of x: y is smaller than or equal to 2: 5. The melt-blown material disclosed by the invention is high in melt index, can be used for preparing melt-blown cloth materials applied to masks, is finally made into degradable masks, and provides an effective way for solving the pollution problem of waste masks.

Owner:RED AVENUE NEW MATERIALS GRP CO LTD +1

Recycling method and device of waste industrial oil

InactiveCN101974363AControl flow ratePlay the role of heat exchangeThermal non-catalytic crackingLubricant compositionCollection systemWarming process

The invention discloses a recycling method and device of waste industrial oil. The method comprises the following steps: fresh waste oil performs heat exchange with the heated waste oil mixture and the vapor of the volatile component in turn for temperature rising, wherein in the temperature rising process, the volatile component in the fresh waste oil is evaporated into vapor; after passing through a pressure balance adjustment device, the fresh waste oil performs thermal cracking reaction at 360-420 DEG C under atmospheric pressure, wherein in the reaction process, the vapor of the volatilecomponent is buffered firstly and performs heat exchange with the fresh waste oil secondly; the vapor of the volatile component performs stepped cooling to obtain finished oil products, the finished oil products are collected respectively; the residual non-volatile oil in the waste oil mixture is discharged; and the discharged waste gas in the cooling process is collected to provide heat for the cracking reaction. The device of the invention comprises a heat exchanger, a pressure balance assembly, a reaction furnace, a buffer, a cooler and a waste gas collection system. The method of the invention has low investment cost and operation cost and high safety factor.

Owner:潘校良

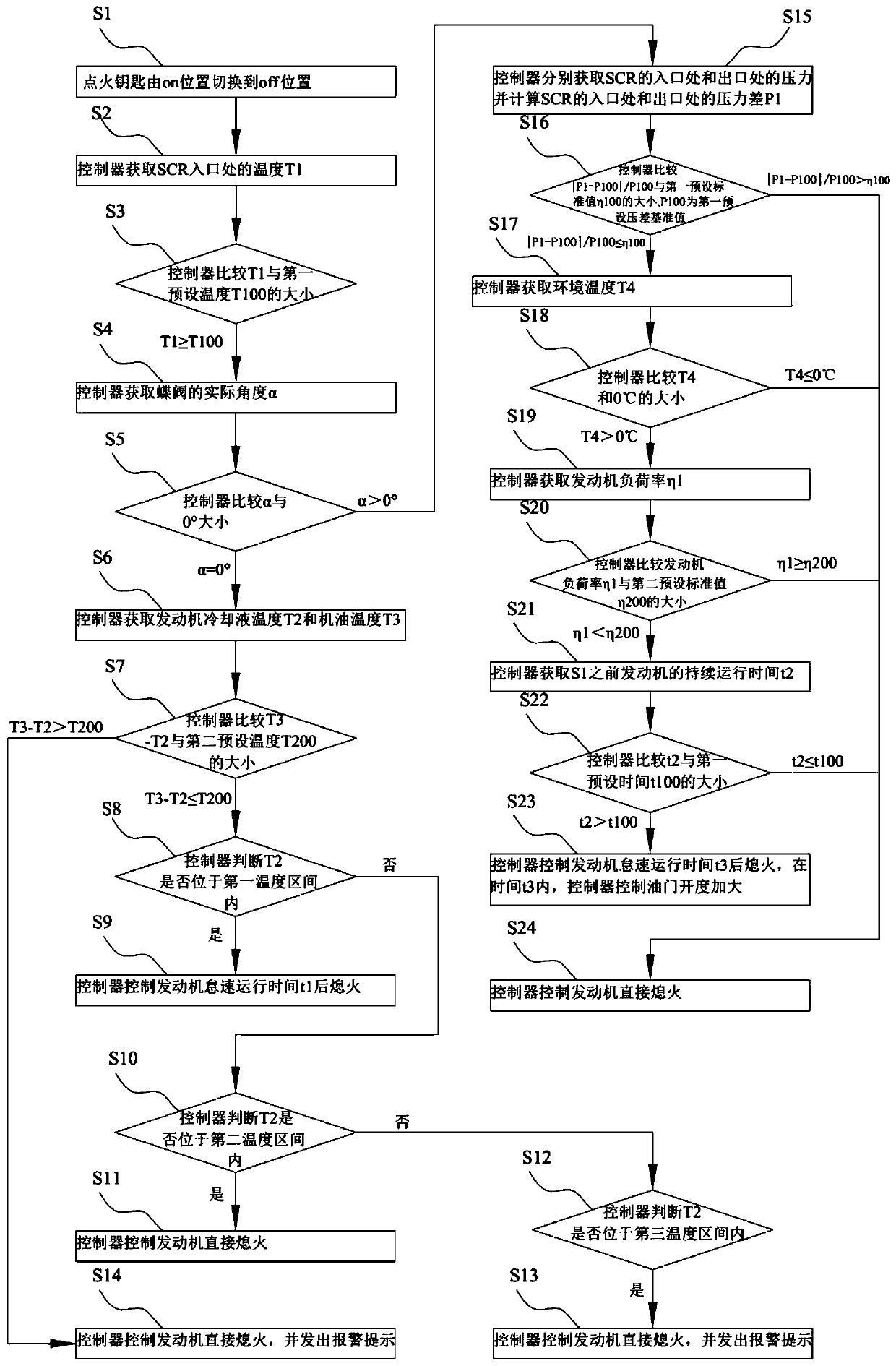

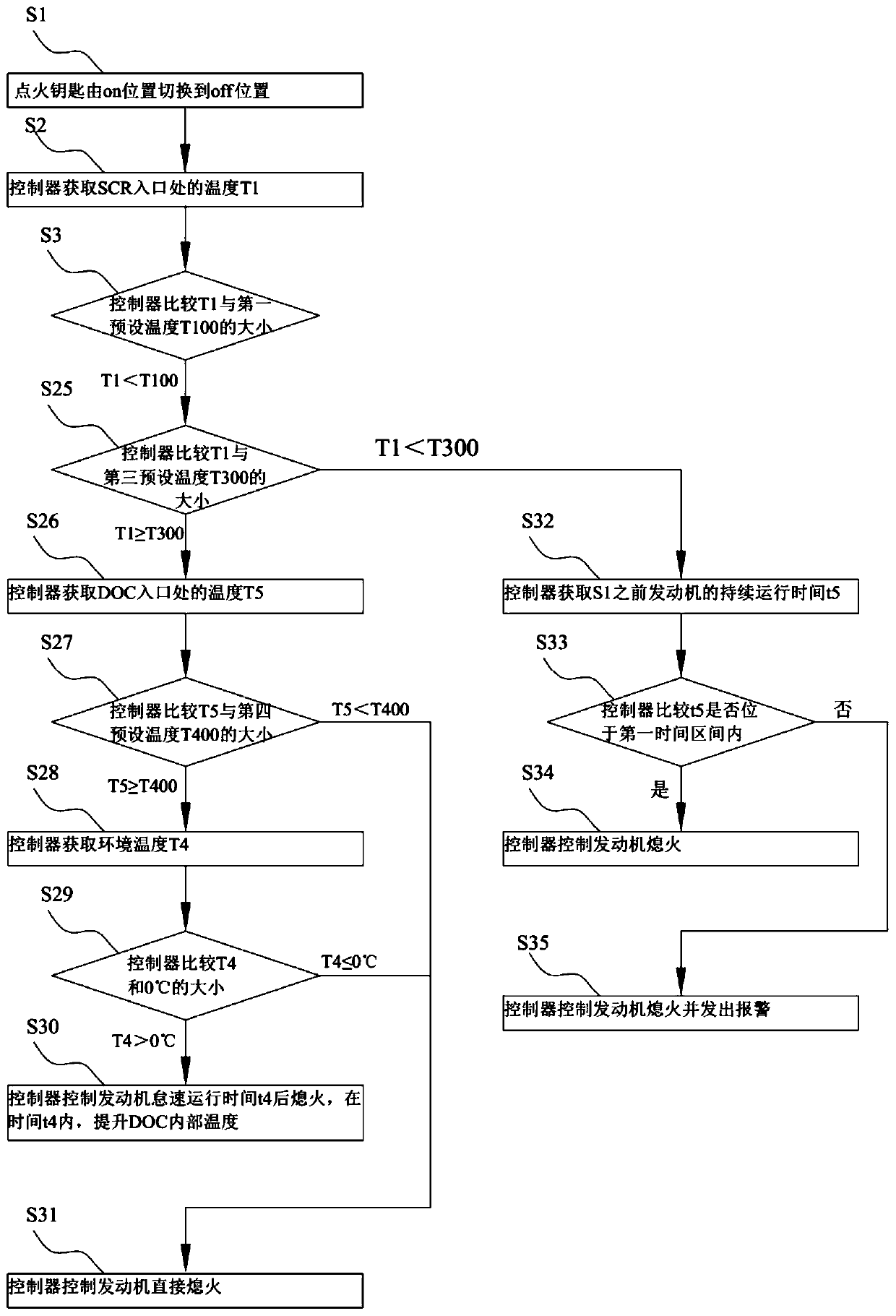

Engine delay stalling control method and engineering vehicle

ActiveCN110067688AControl responseElectrical controlSpeed sensing governorsAutomotive engineeringOperation time

The invention relates to the technical field of engine assemblies and particularly discloses an engine delay stalling control method. The engine delay stalling control method comprises the steps thatan ignition key is switched from the on position to the off position; a controller obtains the temperature T1 at an SCR inlet, and compares T1 with the first presetting temperature T100; if T1 is greater than or equal to T100, the actual angle alpha of a butterfly valve is obtained, and if alpha is equal to 0 degree, the difference value between the oil coolant temperature T2 and the oil temperature T3 is taken and is compared with the second presetting temperature T200; if the difference value is not greater than T200, the controller compares T2 and the third presetting temperature T300; andif the difference value is greater than T200, an engine is controlled to be stalled after being idled by the operation time t1. In the method, the temperature at the SCR inlet and the angle of the butterfly valve can reflect whether the post-processing state of a complete machine is normal, the difference value between the oil coolant temperature and the oil temperature can reflect whether a cooling system of the engine is normal, the oil coolant temperature reflects the working condition before the stalling movement of the engine, and the method is fitter for the actual working condition of the engine.

Owner:SHANTUI CONSTR MASCH CO LTD

Seafood seasoning and preparation method thereof

The invention discloses a seafood seasoning and a preparation method thereof. The seafood seasoning provided by the invention comprises 7-10% of sodium glutamate, 0.5-1% of sodium inosinate, 0.5-1% ofsodium guanylate, 1-3% of lentinus edodes powder, 1-3% of yolk powder, 60-80% of freshening seafood powder, 0.1-0.2% of yeast extract, 1-3% of white granulated sugar, 0.05-0.15% of edible spice and the balance of corn starch. Shellfish processing by-products and rich flavoring substances of low-value shellfishes are fully utilized, the flavoring substances in the raw materials are fully releasedand play a synergistic refreshing role, the flavoring substances of natural seafood are greatly reserved, and meanwhile the peculiar earthy smell, which is extremely easy to perceive, of the shellfishes is effectively removed, so that the palatability is improved.

Owner:JIANGSU QUANYING BIOLOGICAL TECH CO LTD

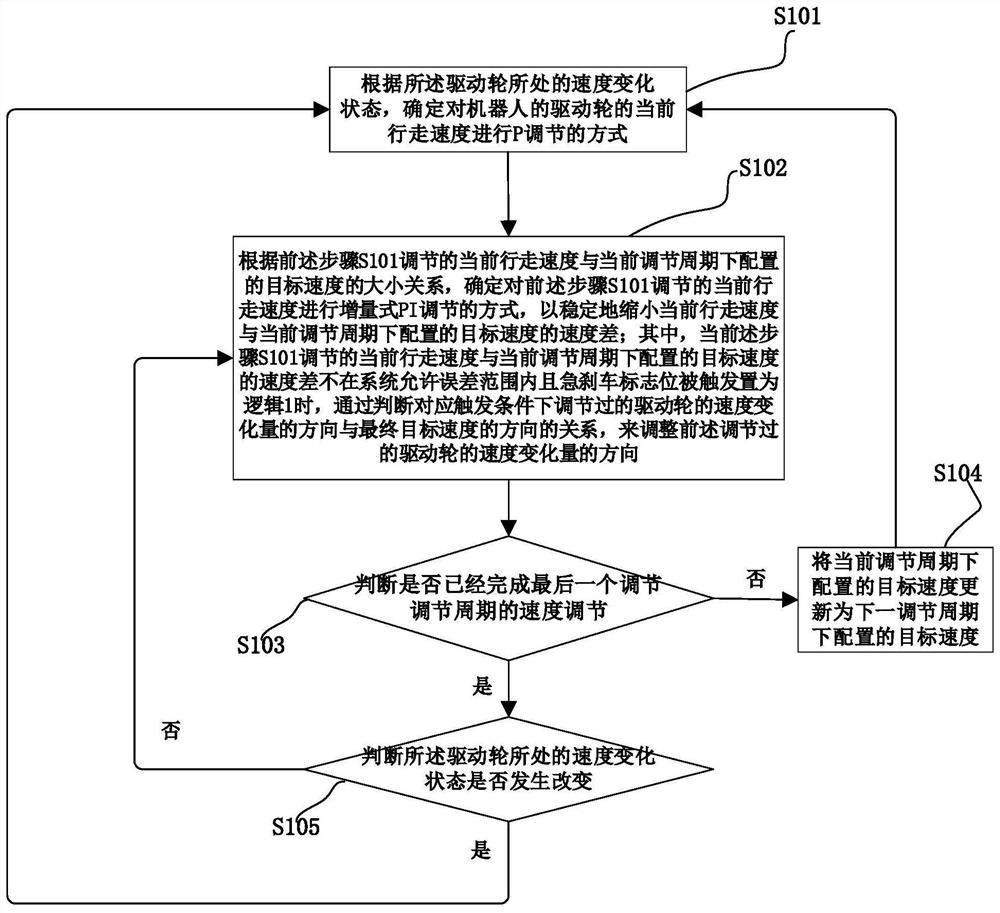

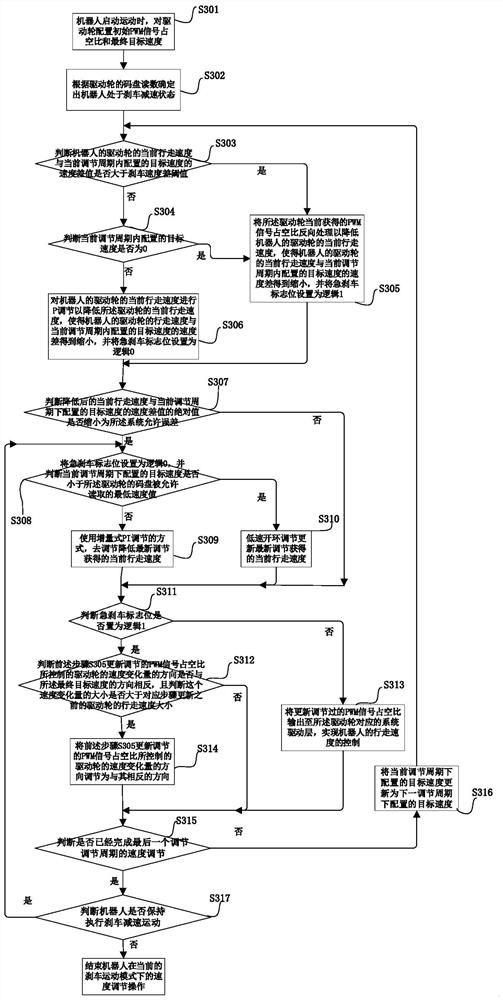

PID adjusting method for robot in decelerating and braking state

ActiveCN112641384AIncrease smoothnessHigh precisionCarpet cleanersFloor cleanersDrive wheelSimulation

The invention discloses a PID adjusting method for a robot in a decelerating and braking state. According to the PID method, based on the change conditions of the decelerating and walking speed of driving wheels of the robot, including the change conditions of the speed and the speed direction, the deceleration walking speed of the driving wheels of the robot is controlled to stably change to the target speed in the corresponding adjustment period through incremental PI adjustment, and the wrong walking speed direction is corrected in time, so that the walking speed of the robot can be controllably reduced to the pre-configured target speed in a brake deceleration change scene, the situation that the guide speed is increased towards the wrong direction due to the wrong direction of the speed change amount is avoided, the robot does not brake but does accelerated motion towards the opposite direction, and the smooth degree of braking walking and the precision of decelerated walking of the robot are improved.

Owner:AMICRO SEMICON CORP

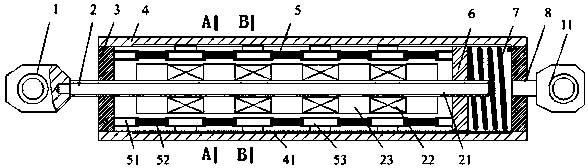

A tension-compression magnetic shape memory alloy multi-mode smart damper

ActiveCN105735507BControl responseProtect the main structureShock proofingSemi activeTension compression

The invention relates to a tension-compression type magnetic shape memory alloy multi-mode intelligent damper. The damper is mainly composed of connecting flanges, a core rod, a guide nut, a cylinder barrel, magnetic shape memory units, a guide piston, a spring and a closing nut. The core rod is arranged in the cylinder barrel. The multiple magnetic shape memory units are distributed along the periphery of the core rod. The two ends of the magnetic shape memory units are connected with the guide nut and the guide piston correspondingly. The spring is installed between the guide piston and the closing nut. The connecting flanges arranged at the two ends of the damper are connected with a main body structure. The damper has multiple working states such as passive control, semi-active control and active control, is high in intelligence degree and has the advantages of high response frequency, high damping capacity, automatic resetting, stable performance and the like.

Owner:SUZHOU UNIV OF SCI & TECH

Diffusion-welding connecting method taking Ti foil and titanium-based solder foil as interlayer

ActiveCN108480838AOptimize welding parametersHigh hardnessNon-electric welding apparatusTitaniumBase metal

The invention discloses a diffusion-welding connecting method taking Ti foil and titanium-based solder foil as an interlayer. The method is characterized by comprising the following steps of: processing a TiAl alloy and a Ti2AlNb alloy or a Ti3Al based alloy into needed dimensions; grinding and polishing welded base metal; putting the welded base metal, the Ti foil and the titanium based solder foil into acetone to ultrasonically clean; enabling the Ti foil to be in contact with the TiAl alloy and enabling the titanium based solder foil to be in contact with the Ti2AlNb alloy or the Ti3Al based alloy, thereby forming a welded workpiece of the Ti2AlNb alloy or the Ti3Al based alloy / titanium based solder foil / Ti foil / TiAl alloy; and putting the welded workpiece into a vacuum heating furnace,applying pressure, and completing welding after heating, preserving the heat, cooling and thermally circulating. The diffusion-welding connecting method can control solder residues in a joint, and inhibits forming trend of a continuous brittle reaction layer in the joint, so that the performances of the joint are improved. The obtained joint has room-temperature tensile strength being 510-600 MPa, and has tensile strength being 480 MPa-510 MPa at a high temperature being 650 DEG C.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

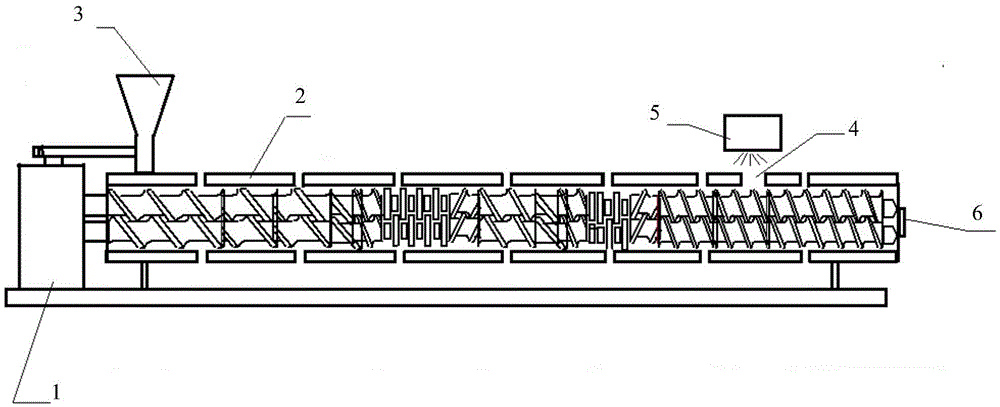

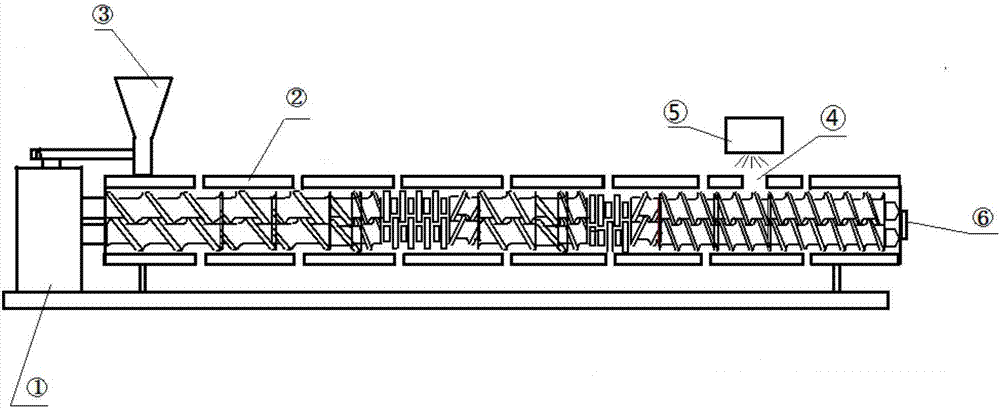

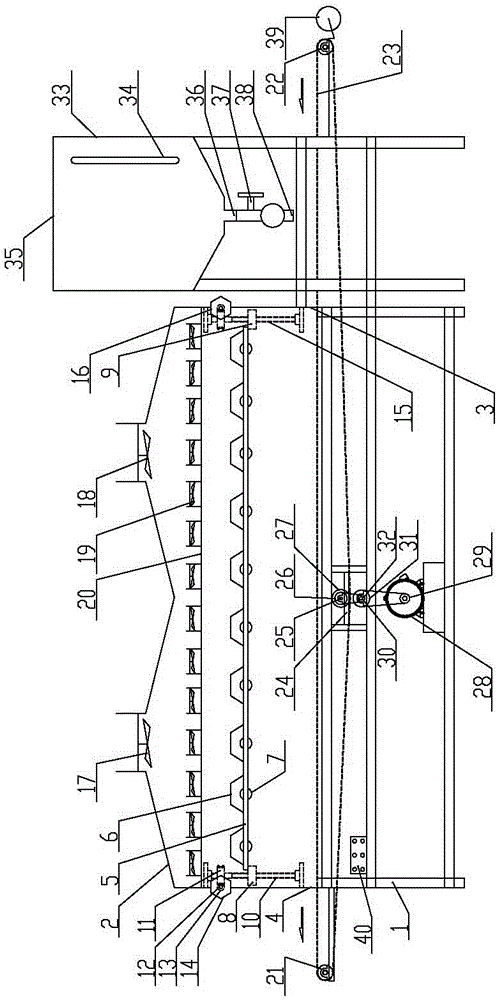

Ultraviolet (UV) polymerization device

The invention relates to the technical field of photopolymer production devices and relates to an ultraviolet (UV) polymerization device. The device comprises a rack, a polymerization cabin shell, a belt conveyor, a UV emission device and a fan temperature regulator, wherein the polymerization cabin shell is fixedly installed at the upper part of the rack; an input port is formed at the right end of the polymerization cabin shell; an output port is formed at the left end of the polymerization cabin shell; and the belt conveyor capable of conveying materials from right to left and regulating the conveying speed is installed on the rack. The device has a reasonable and compact structure, is convenient to use, achieves continuous automatic production of photopolymers by irradiating the raw materials on the belt conveyor with the UV emission device, controlling the product irradiation time by regulating the conveying speed of the belt conveyor and regulating the air temperature in the polymerization cabin shell with the fan temperature regulator, can better control the reaction degree, and has the characteristics of good product quality, low byproduct content, compact layout, small floor area, low energy consumption, simplicity and convenience in operation and high efficiency.

Owner:XINJIANG UNIVERSITY

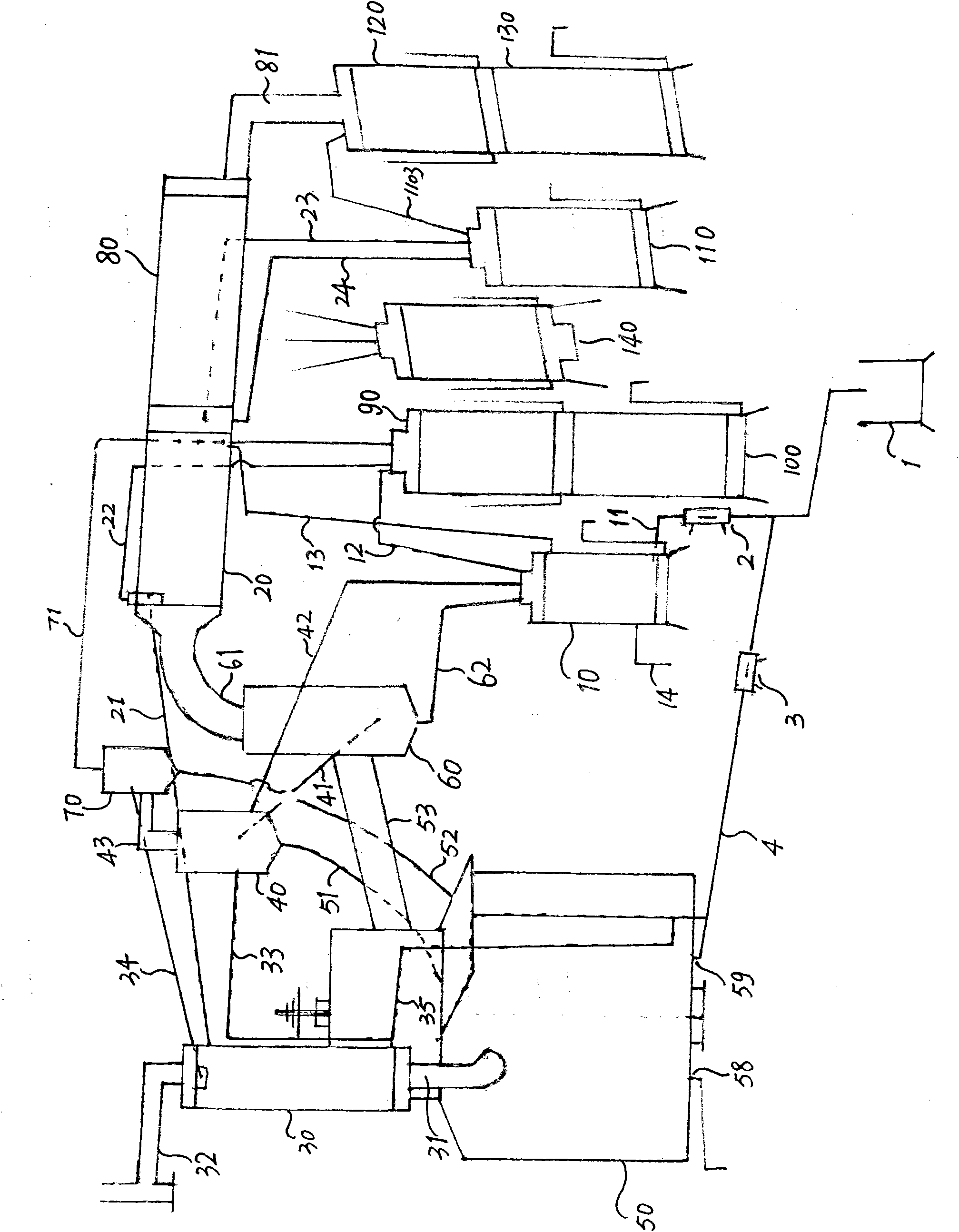

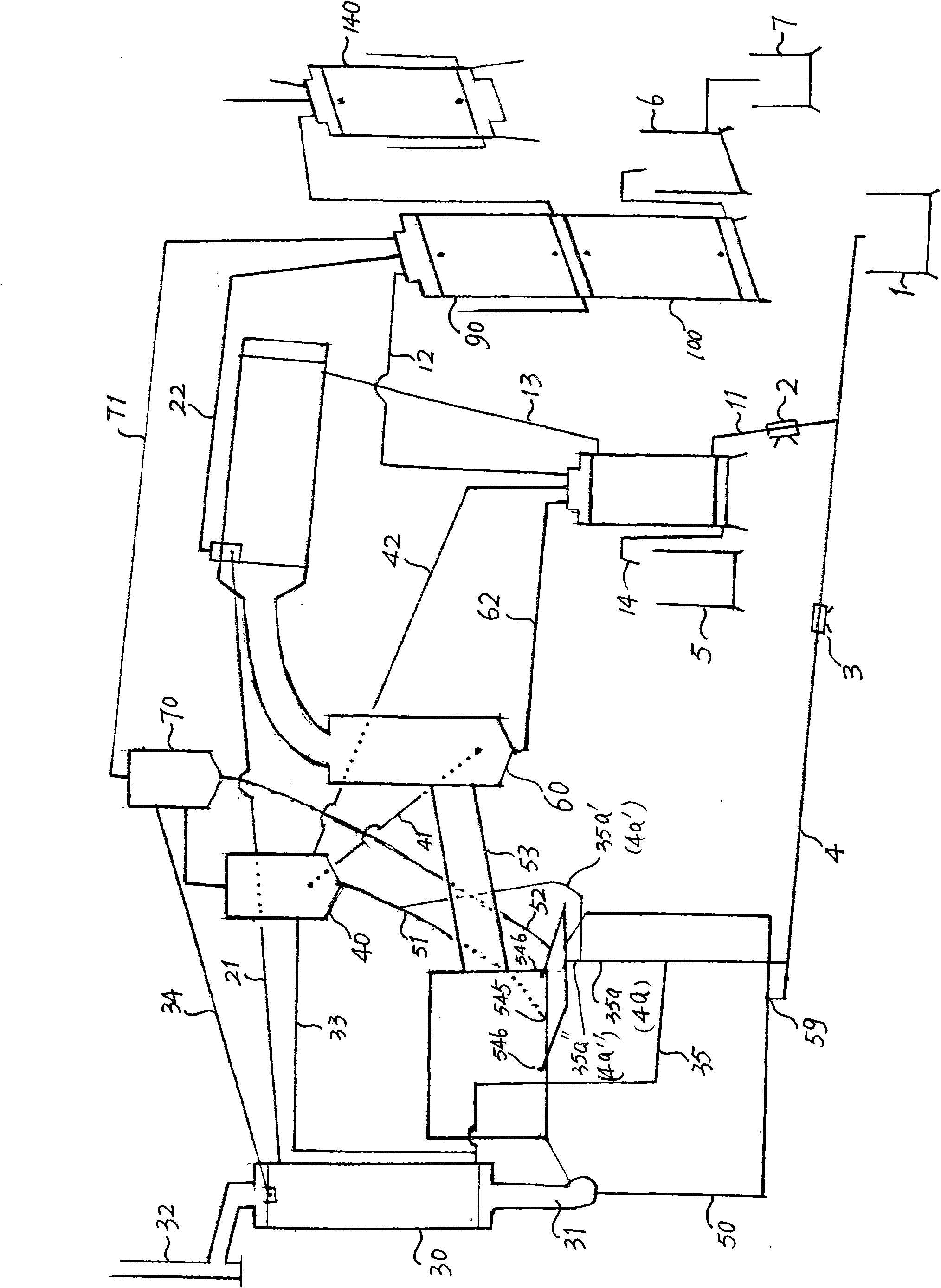

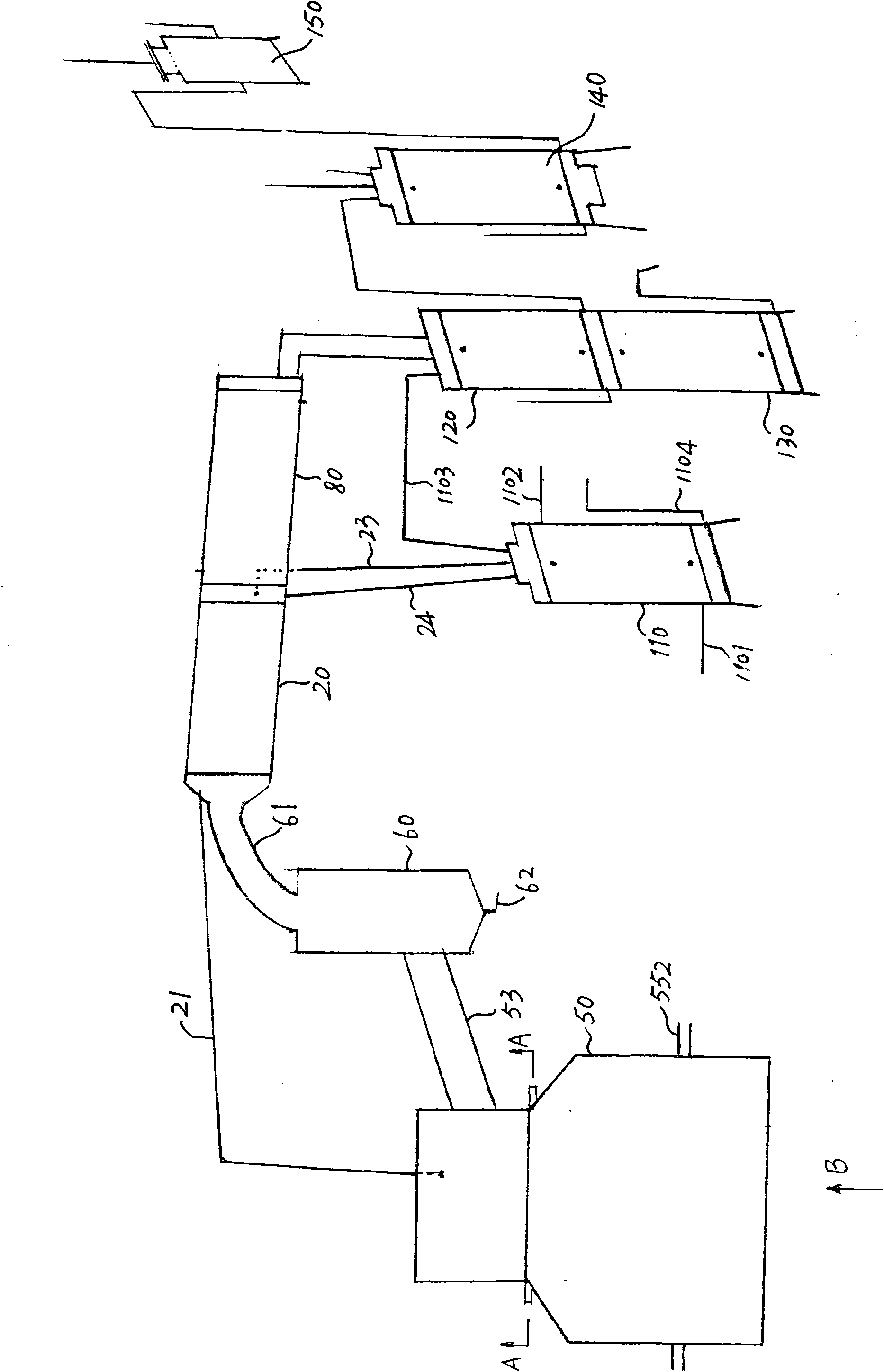

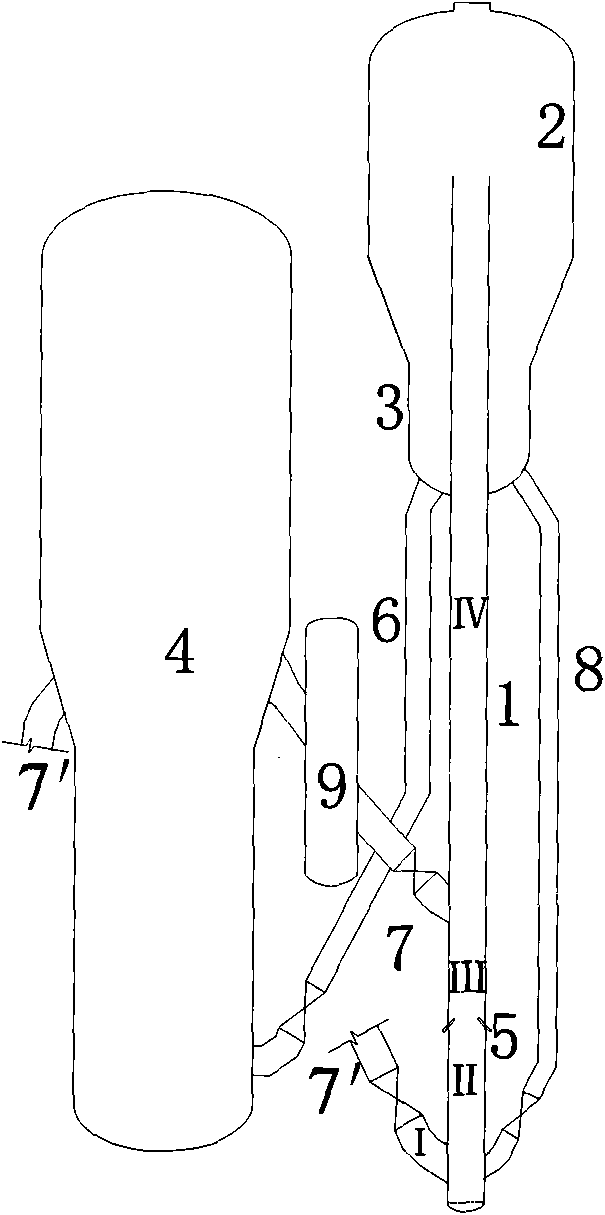

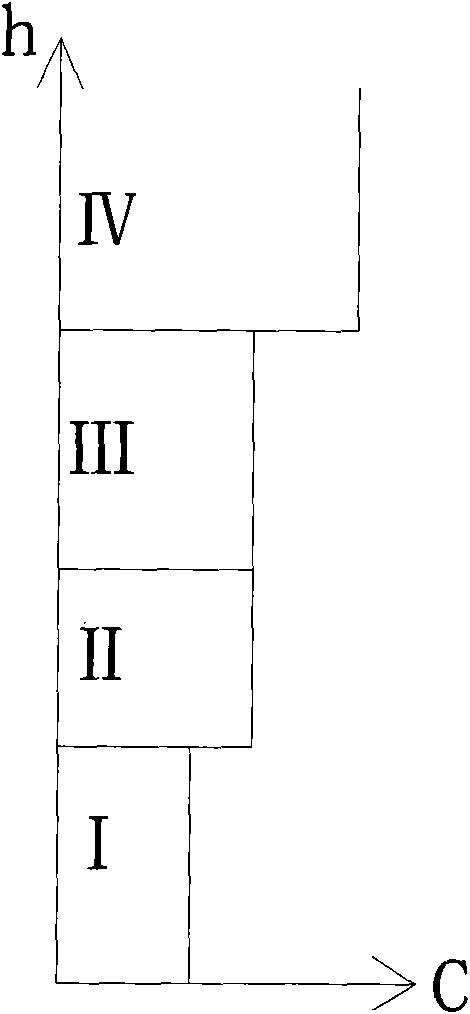

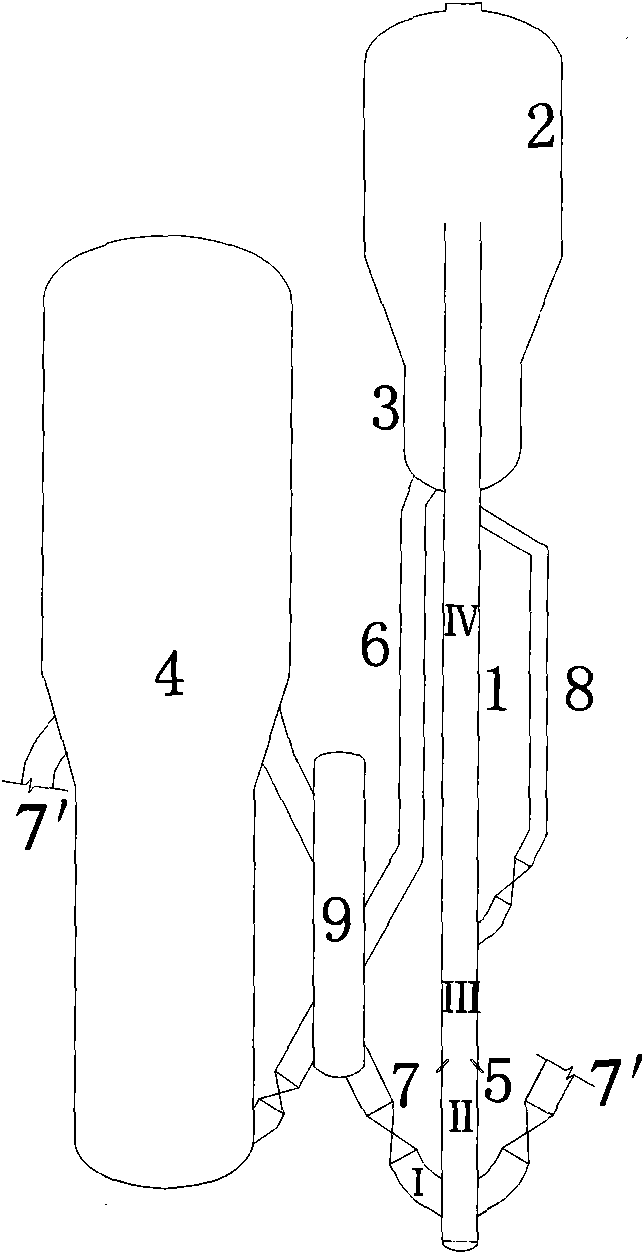

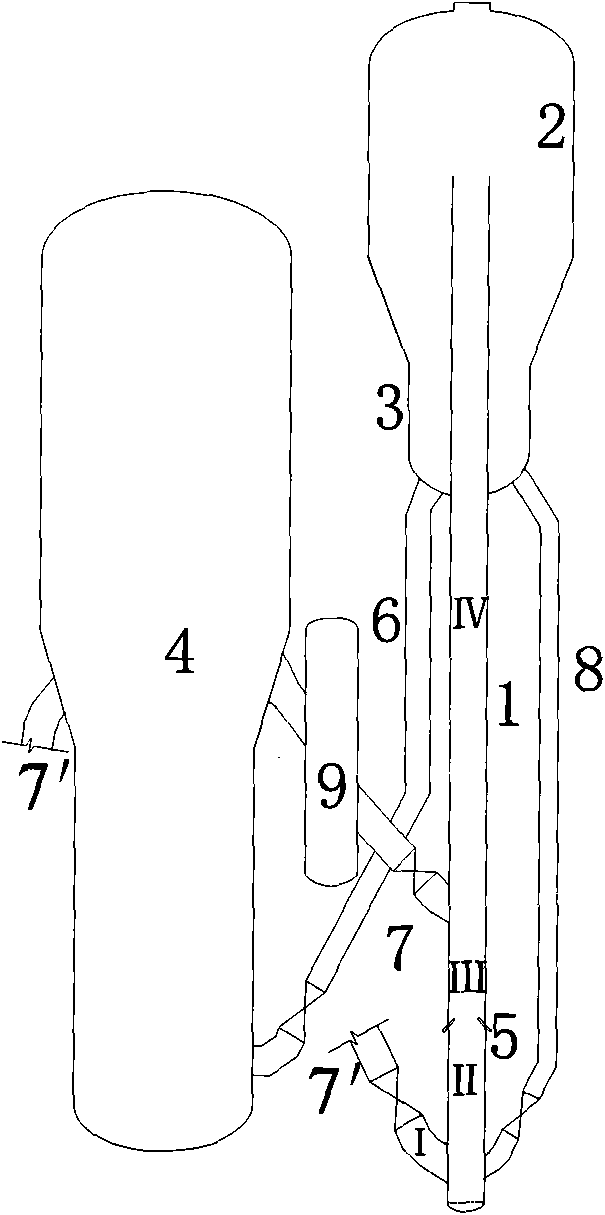

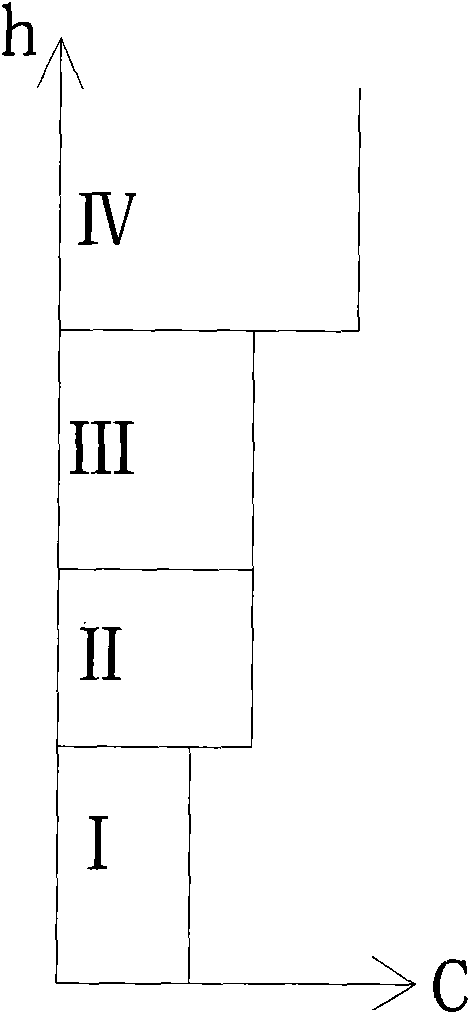

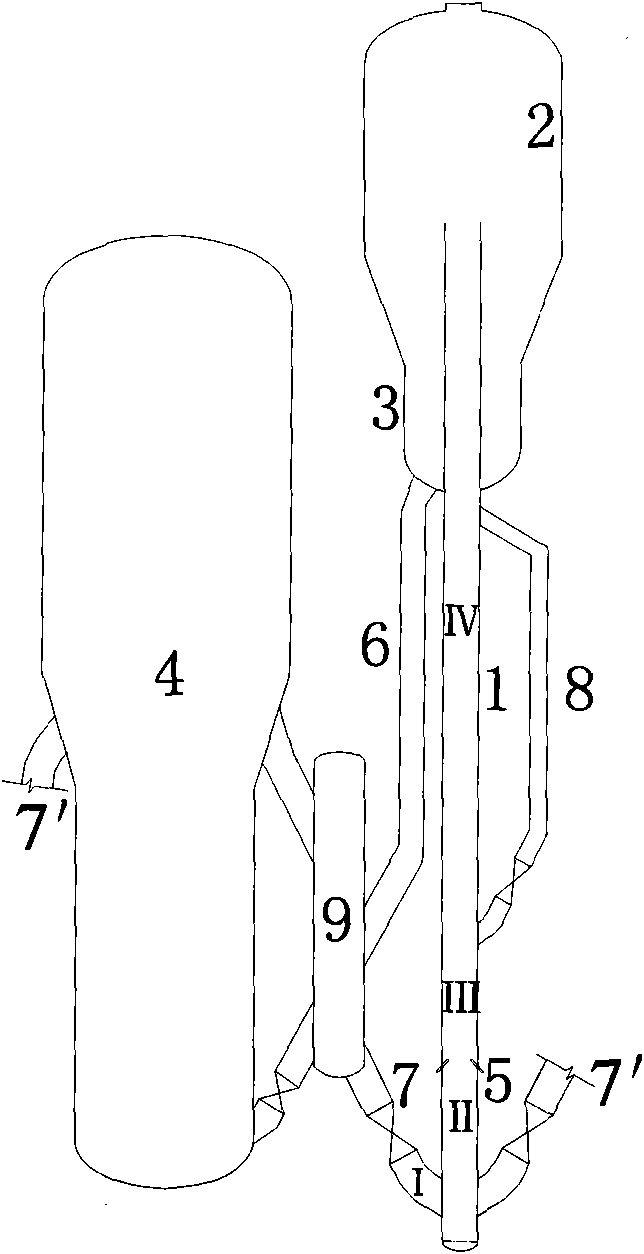

Catalytic conversion method and device for single-riser petroleum hydrocarbon type raw material

InactiveCN102051198AEasy to controlControl responseCatalytic crackingChemical/physical processesPetroleumContact reaction

The invention discloses a catalytic conversion method and a catalytic conversion device for a single-riser petroleum hydrocarbon type raw material. A catalyst which has a temperature lower than that of a regenerated catalyst is fed into a pre-rising section of a riser reactor and is conveyed into an oil-catalyst contact reaction section by pre-risen gas to be contacted with the raw material for catalytic conversion reaction; and a cooled regenerated catalyst or a reflowed spent catalyst is fed into the riser reactor from the space above a raw material nozzle to participate in the catalytic conversion reaction. By the method and the device, reaction dry gas can be reduced, product distribution can be improved, and the temperature or the catalyst-oil ratio of the riser oil-catalyst contact reaction section and a post-reaction section can be adjusted and controlled, so catalytic conversion has sufficient flexibility to adapt to change of quality of raw material oil or the requirement of a market on products.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

System for monitoring quality evaluation of ecological environment

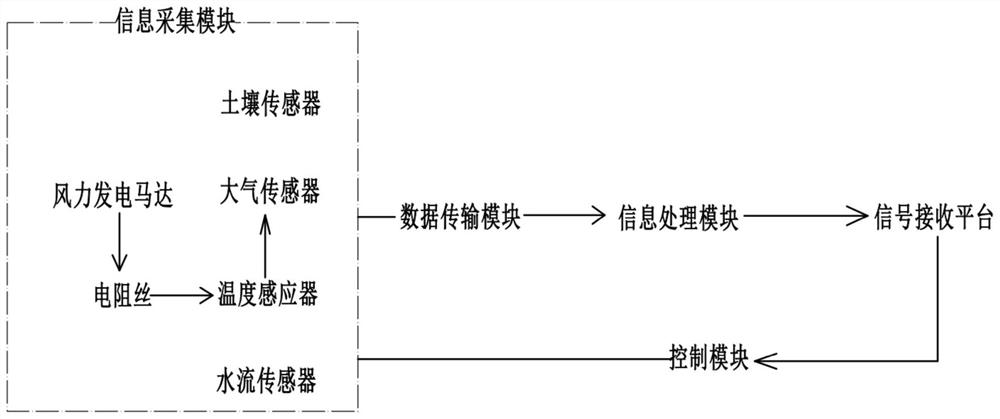

PendingCN113032971AReduce the impact of errorsAchieve captureGeneral water supply conservationForecastingParticulatesInformation processing

The invention discloses a system for monitoring quality evaluation of an ecological environment in the field of environment monitoring. The system comprises an information acquisition module, a data transmission module, an information processing module, a control module and a signal receiving platform, The information acquisition module comprises a soil sensor for acquiring soil information, an atmosphere sensor for acquiring atmosphere information and a water flow sensor for acquiring water quality, the atmosphere sensor comprises a particulate matter sensor and a wind power generation motor, the wind power generation motor is connected with a resistance wire, a temperature sensor is mounted on one side of the resistance wire, and a temperature sensor is mounted on the other side of the resistance wire; And the temperature sensor is connected in parallel with the particulate matter sensor, so that data of the temperature sensor and the particulate matter sensor are synchronously transmitted to the information processing module. According to the technical scheme, heat generated by the resistance wire is captured and then is synchronously transmitted with a signal of the particulate matter sensor, so that the wind power is captured and sensed by the heating temperature of the resistance wire, and wind power data is provided to assist correction and particulate matter content measurement.

Owner:广西壮族自治区生态环境监测中心 +1

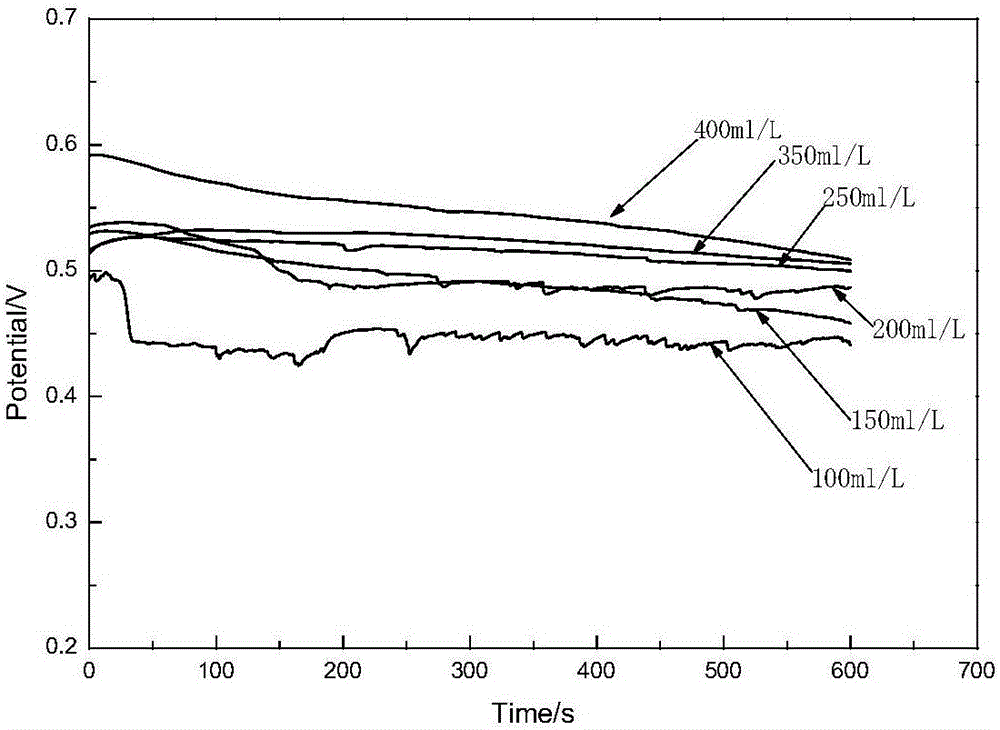

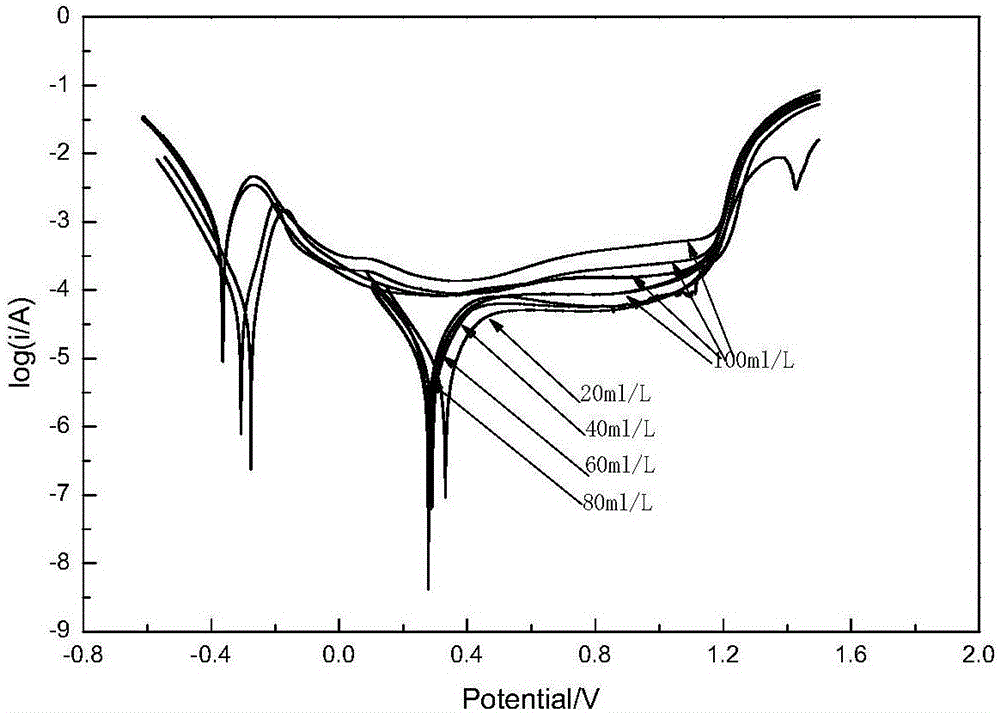

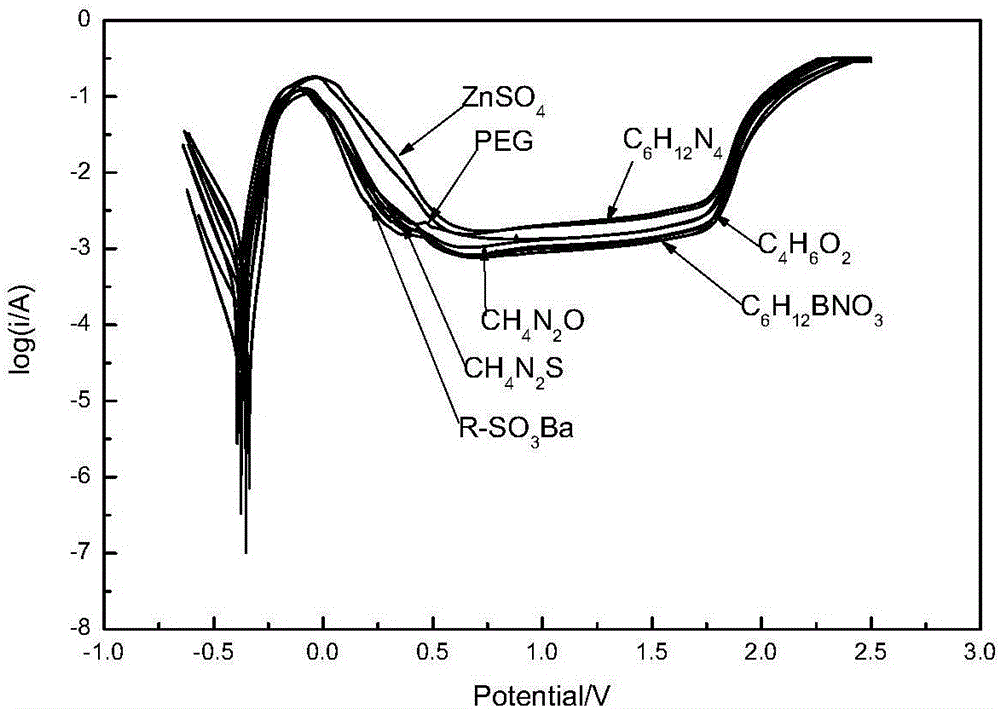

Carbon steel pickling solution, and applications thereof

The invention relates to a carbon steel pickling solution, and applications thereof, and more specifically relates to a carbon steel pickling corrosion inhibitor used for avoiding corrosion of acid on carbon steel materials and excessive consumption of a pickling solution in pickling process of carbon steel and products of carbon steel, and applications of the carbon steel pickling corrosion inhibitor, and belongs to the technical field of carbon steel pickling solution. The carbon steel pickling solution can be widely used at normal temperature; sulfuric acid and phosphoric acid are taken as the main inorganic acids; corrosion inhibitor polyethylene glycol, thiourea, hexamethylenetetramine, and urea are added at the same time; surfactant fatty alcohol ether sodium sulfate and nonylphenol polyoxyethylene ether are combined with oleic acid and oxalic acid. The carbon steel pickling solution is capable of inhibiting excess corrosion of pickling solution, increasing the cleanliness and washing efficiency of carbon steel part surfaces greatly, reducing acid concentration of pickling waste solution, and reducing processing difficulty greatly.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Catalytic conversion method and device for single-riser petroleum hydrocarbon type raw material

InactiveCN102051198BEasy to controlControl responseCatalytic crackingChemical/physical processesContact reactionsProduct gas

The invention discloses a catalytic conversion method and a catalytic conversion device for a single-riser petroleum hydrocarbon type raw material. A catalyst which has a temperature lower than that of a regenerated catalyst is fed into a pre-rising section of a riser reactor and is conveyed into an oil-catalyst contact reaction section by pre-risen gas to be contacted with the raw material for catalytic conversion reaction; and a cooled regenerated catalyst or a reflowed spent catalyst is fed into the riser reactor from the space above a raw material nozzle to participate in the catalytic conversion reaction. By the method and the device, reaction dry gas can be reduced, product distribution can be improved, and the temperature or the catalyst-oil ratio of the riser oil-catalyst contact reaction section and a post-reaction section can be adjusted and controlled, so catalytic conversion has sufficient flexibility to adapt to change of quality of raw material oil or the requirement of a market on products.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

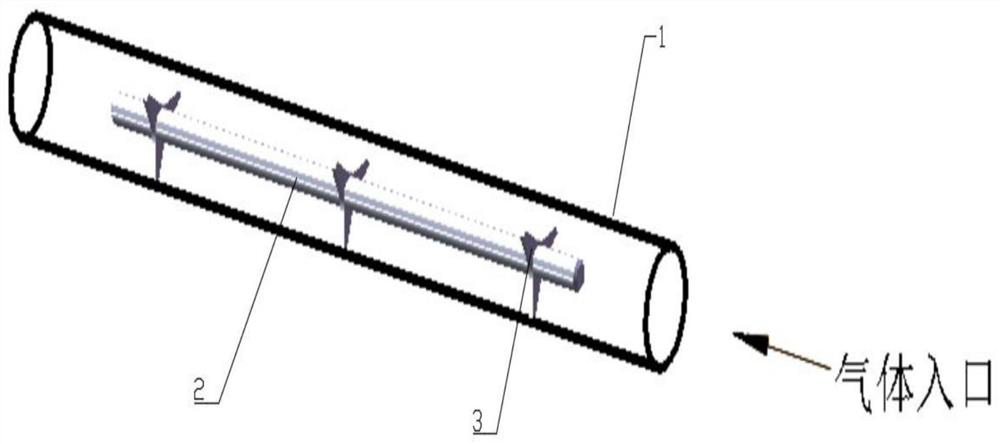

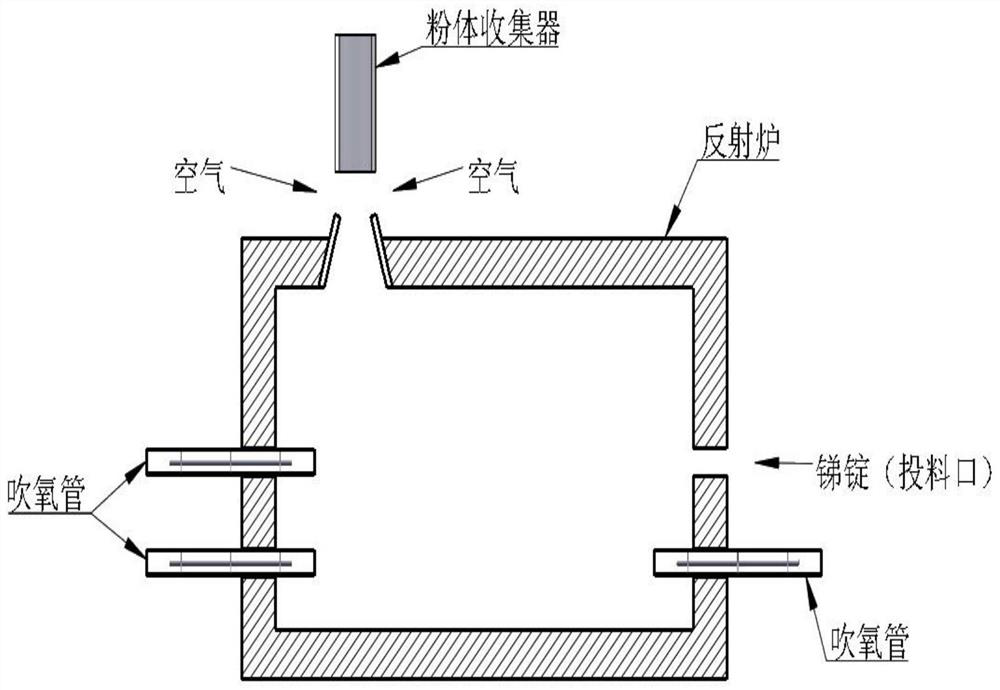

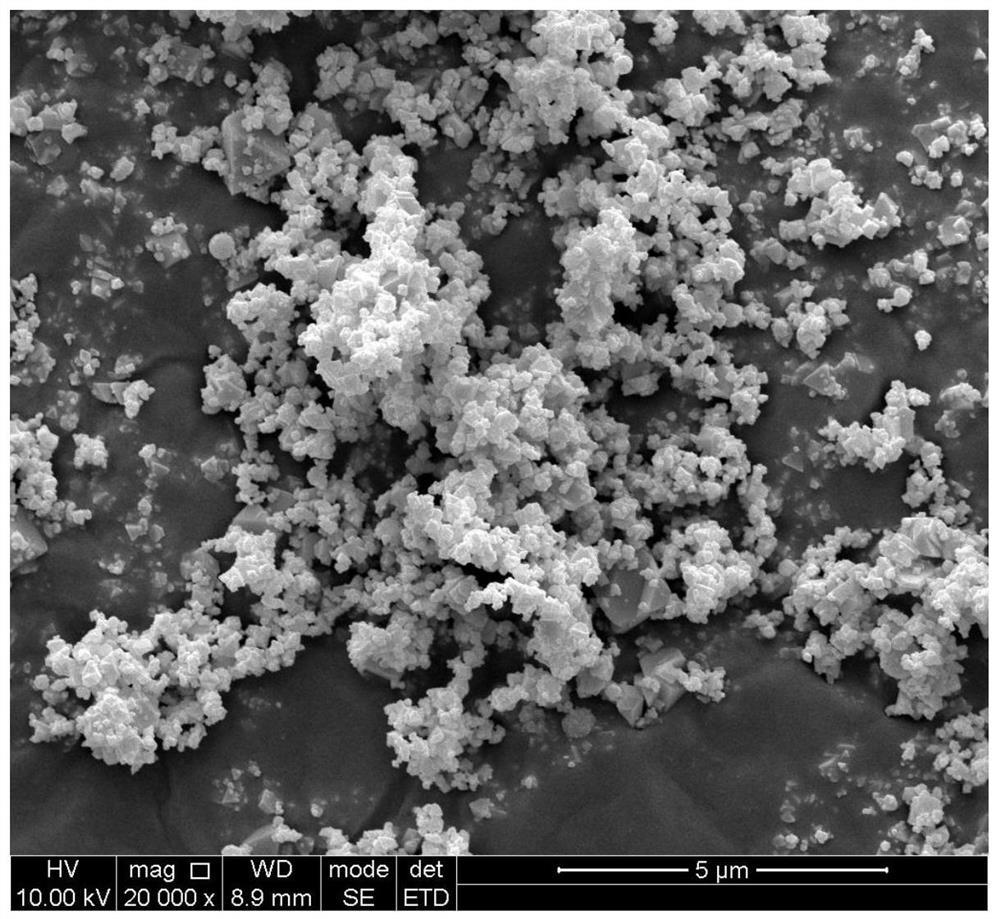

Preparation method of spherical antimonous oxide

ActiveCN112678869ASmall viscosity effectGood compatibilityAntimony compoundsPlastic materialsPhysical chemistry

The invention discloses a preparation method of spherical antimonous oxide, wherein the preparation method comprises the steps: carrying out spheroidization treatment and refinement treatment on traditional cubic crystal form or orthorhombic crystal form antimonous oxide serving as a raw material by using a sand mill, taking as a seed crystal, and introducing the seed crystal into an antimonous oxide preparation system by using a specially designed oxygen blowing pipe to obtain the spherical antimonous oxide. The prepared spherical antimonous oxide is spherical in crystal form and smaller in oil absorption value, the compatibility of a flame retardant in a plastic material is remarkably improved, and the influence on the viscosity of coatings, oil paint and the like is quite small.

Owner:广东宇星阻燃新材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com