Carbon steel pickling solution, and applications thereof

A technology of pickling liquid and carbon steel acid, applied in the field of carbon steel pickling liquid, can solve the problems of high operation risk, slow sulfuric acid pickling speed, poor effect, etc., and achieves low acid concentration, low processing difficulty, inhibition The effect of excessive corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

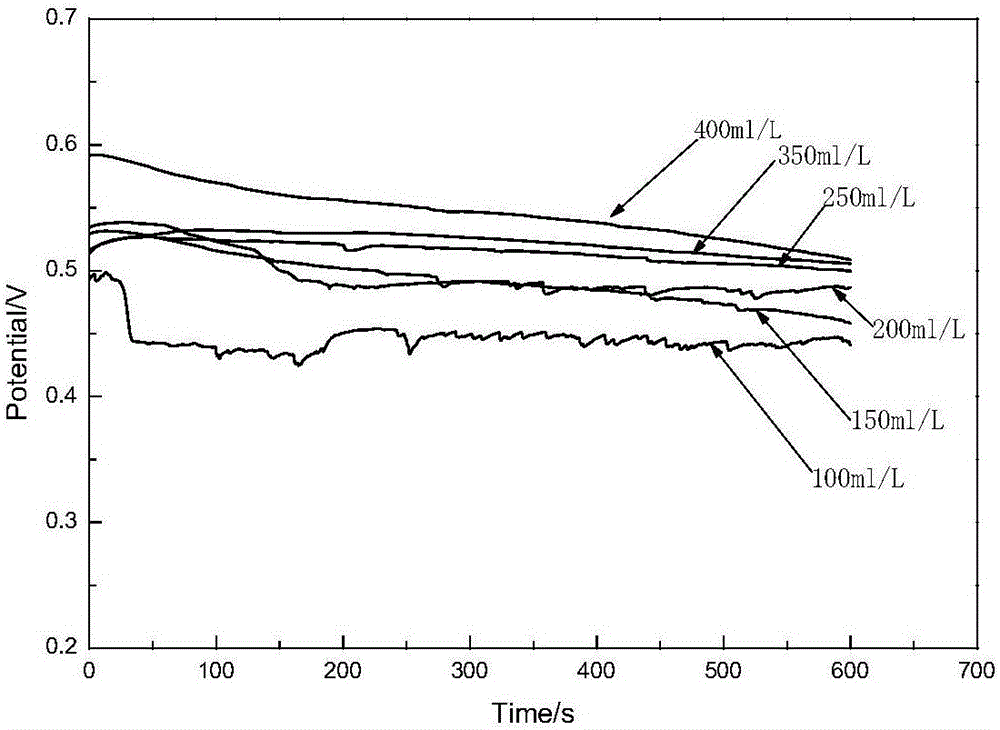

[0037] The current pickling solution formula mostly uses sulfuric acid (H 2 SO 4 ) and phosphoric acid (H 3 PO 4 ) and add other additives on this basis. In the experiment without adding other additives, the H 2 SO 4 Screening was performed by electrochemical experiments at different concentrations. h 2 SO 4 Concentrations are 100-400ml / L respectively.

[0038] Depend on figure 1 It can be seen that the H 2 SO 4 When the concentration is 400ml / L, 350ml / L, and 250ml / L, the open circuit potential value is relatively large. The smaller values are 0.4843V, 0.4610V, 0.4437V. At the same time, it can be seen that with H 2 SO 4 As the concentration increased, the open circuit potential value gradually increased. h 2 SO 4 When the concentration is 400ml / L, the pickling solution has the least corrosion on the steel sheet.

[0039] H 2 SO 4 The optimal content to add is 400ml / L, the use temperature is normal temperature, and the time is 25min.

Embodiment 2

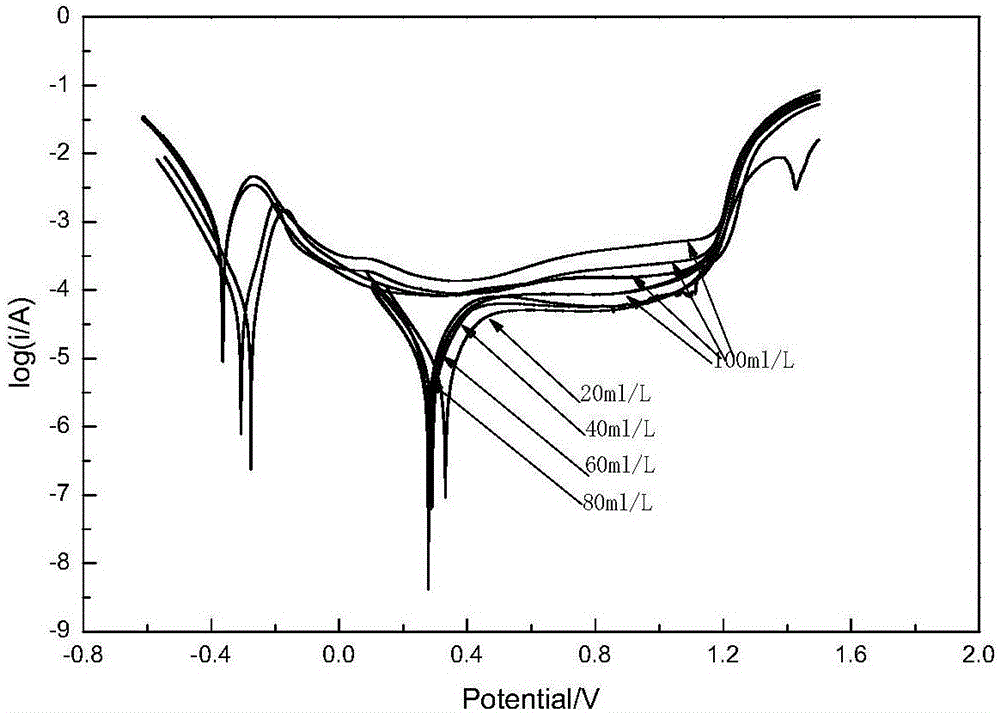

[0041] Add 400ml / L of H to the steel sheet 2 SO 4 After that, different concentrations of phosphoric acid (H 3 PO 4 ) The anodic polarization curve in pickling solution is shown in figure 2 . It can be seen that in the presence of H 2 SO 4 and H 3 PO 4 The stable passivation zone ΔE on the anodic polarization curve in the pickling solution is more than that of pure 400ml / L H 2 SO 4 broaden in solution. h 3 PO 4 When the concentration is 100ml / L, the open circuit potential of the steel sheet is 1.06V, and when the concentration is 20-80ml / L, the stable passivation zone ΔE of the steel sheet is 0.65V, 0.62V, 0.72V, 0.69V, combined with the open circuit potential-time curve Analyzing the best H 3 PO 4 The concentration is 100ml / L.

[0042] H 2 SO 4 with H 3 PO 4 The optimal content to add is 400ml / L and 100ml / L respectively, the use temperature is normal temperature, and the time is 25min.

Embodiment 3

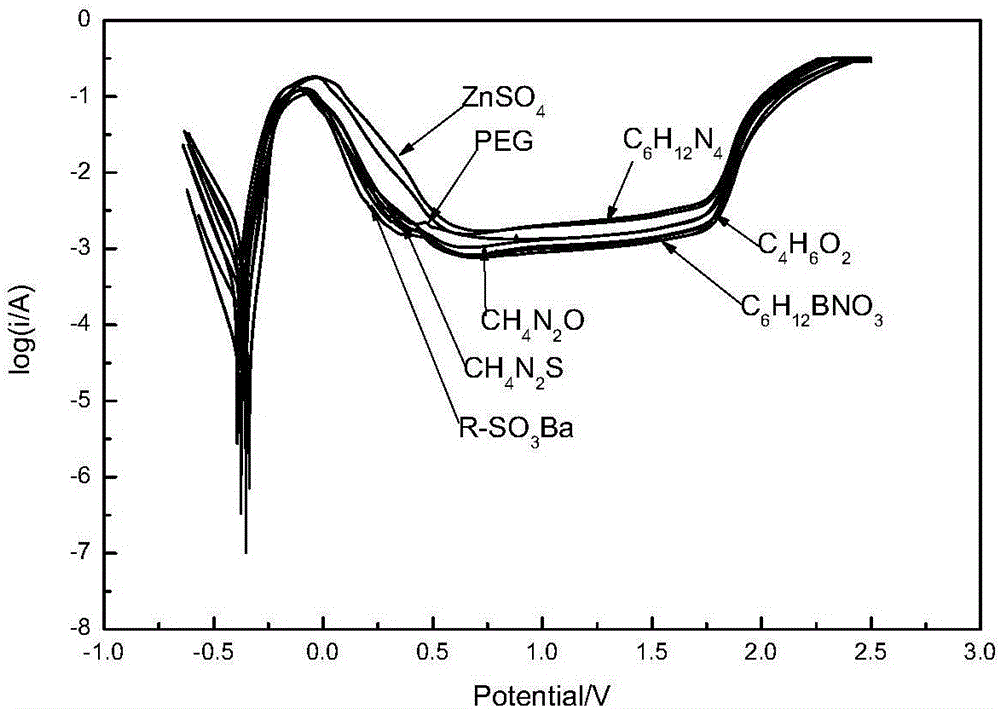

[0044] Anodic polarization curves of steel sheets in pickling solutions with different corrosion inhibitors image 3 . It can be seen from the figure that the coincidence degree of the anodic polarization curves of the steel sheets in this kind of corrosion inhibitor pickling solution is very high, and they all have a wide and stable passivation zone. The corrosion inhibitor is hexamethylenetetramine (C 6 h 12 N 4 ), the stable passivation zone width ΔE of the steel sheet is the largest, which is 1.28V, and the corrosion inhibitor is triethanolamine borate (C 6 h 12 BNO 3 ) when the stable passivation zone width ΔE of the steel sheet is the smallest, which is 1.08V. The corrosion inhibitor is barium petroleum sulfonate (R-SO 3 Ba), urea (CH 4 N 2 O), thiourea (CH 4 N 2 S), the stable passivation region width ΔE is equal, both are 1.11V. Generally speaking, the width ΔE of the stable passivation zone of the steel sheet in the pickling solution of other corrosion inh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com